Energy-saving combustor

The technology of a combustion device and a throttle valve, which is applied in the field of combustion devices, can solve problems such as complex structures, and achieve the effect of firm installation, simple structure, and guaranteed combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

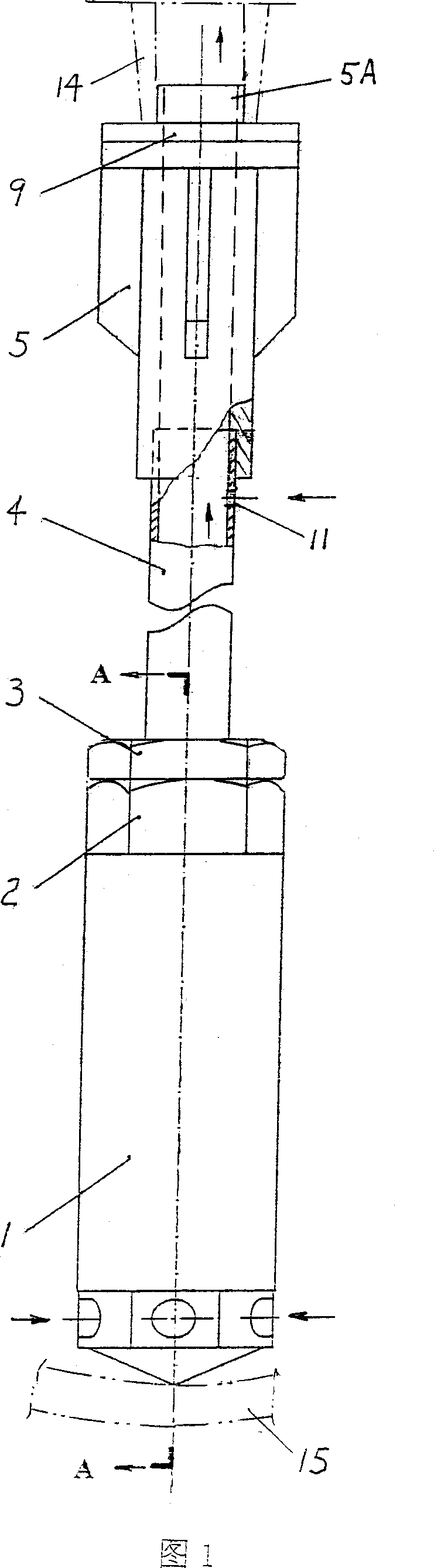

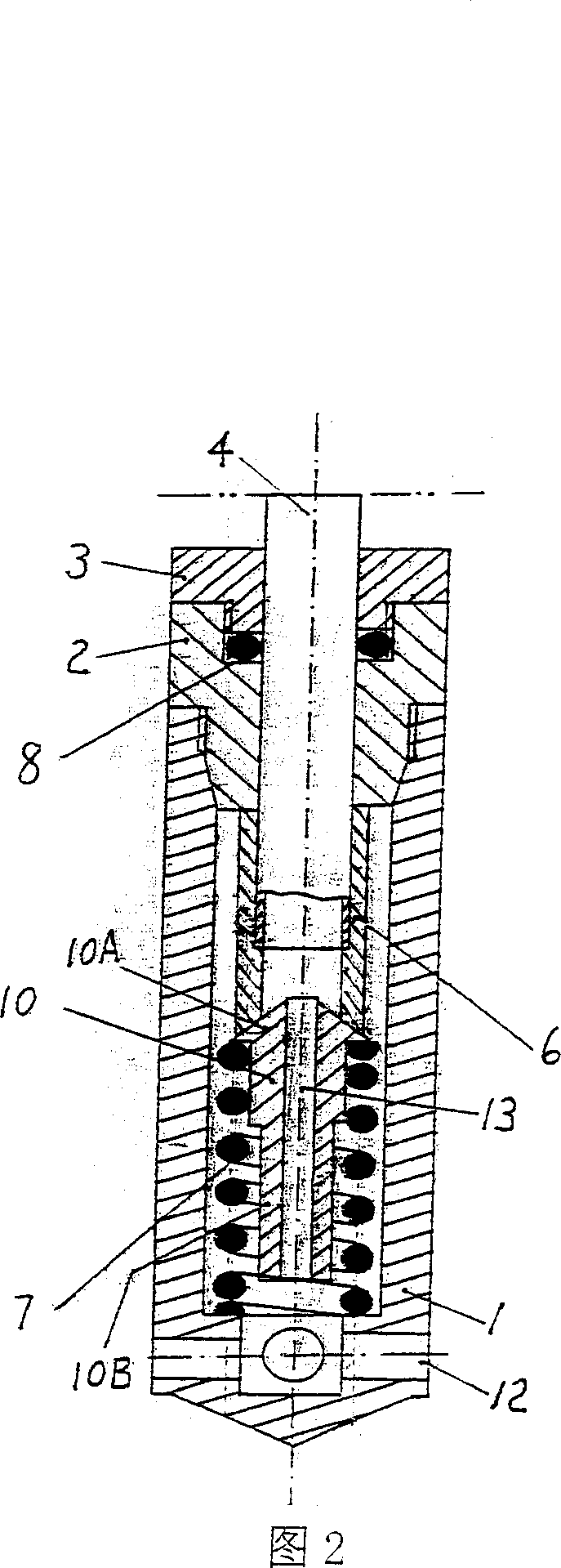

[0024] Fig. 1, 2 show the structure schematic diagram that energy-saving combustion device of the present invention is contained in container 15, and container 15 among the present embodiment is liquefied petroleum gas steel cylinder, and the top of steel cylinder is equipped with angle valve 14, is used for drawing the gas that is burned .

[0025] The energy-saving combustion device of the present invention comprises an upper joint 5, a lower joint 1 and a mixing tube 4 whose two ends are respectively connected to the upper and lower joints,

[0026] The lower end of the mixing tube 4 extends into the inner cavity of the lower joint 1;

[0027] In the inner cavity of the lower joint 1, a throttle valve 10 and a spring 7 are installed. One end of the spring 7 presses against the bottom of the inner cavity of the lower joint 1, and the other end acts on the inner cavity of the lower joint 1. On the throttle valve 10, the throttle valve 10 is pressed against the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com