Fuel gas decoupling combustor and using method thereof

A burner, gas technology, applied in the combustion method, gas fuel burner, burner and other directions, can solve the problems of reducing the local air volume, reducing the combustion temperature, unfavorable combustion efficiency, etc., to expand the mixing position area, reduce the temperature peak , the effect of expanding the stable combustion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

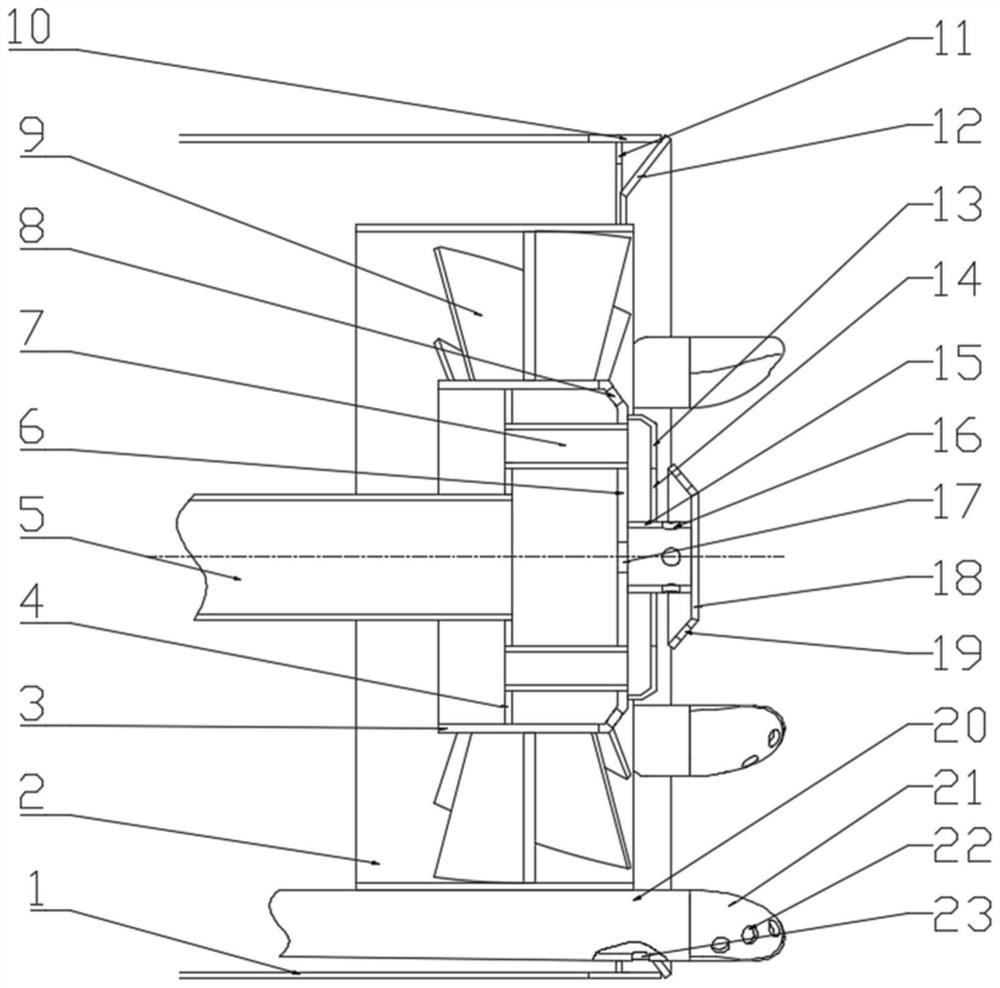

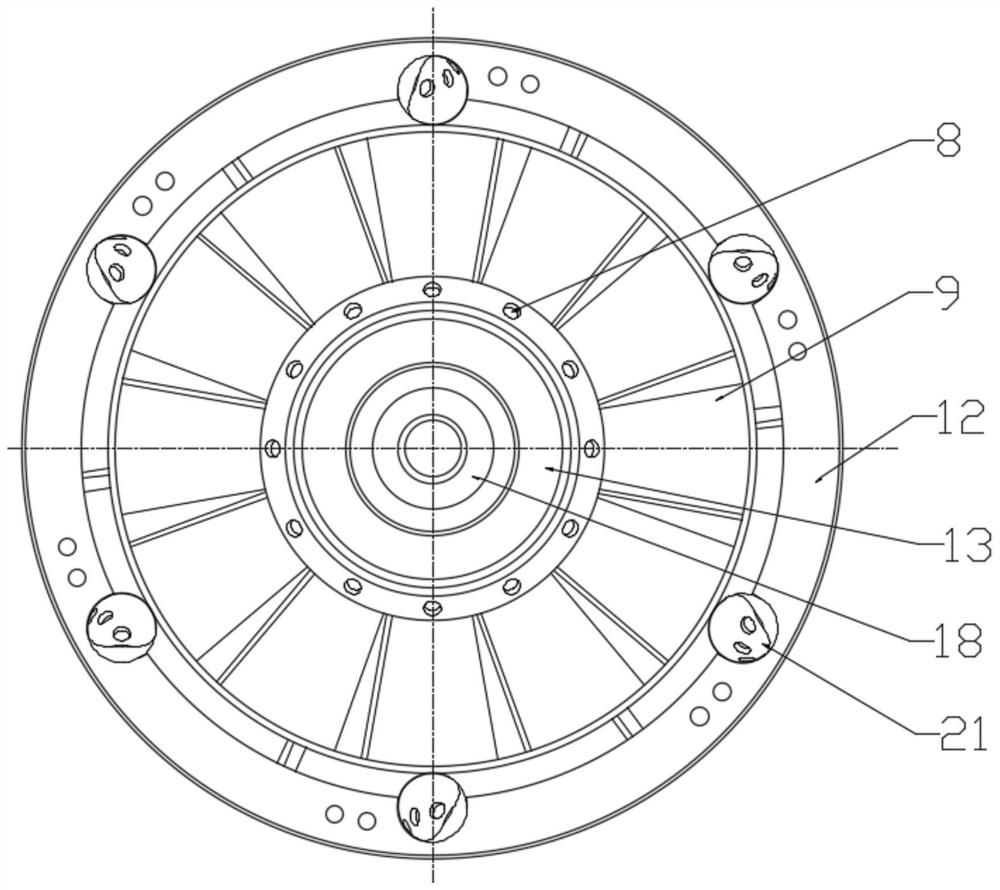

[0108] This embodiment provides a gas decoupling burner. The gas decoupling burner includes a central gas assembly, a cylinder body 2 and an outer cylinder body 1 arranged coaxially from the inside to the outside; the central gas assembly and An annular main air passage is formed between the cylinders 2 ; an annular outer air passage is formed between the cylinders 2 and the outer cylinder 1 .

[0109] The central gas assembly includes a central cylinder 3, a central gas chamber rear cover 4 and a central gas chamber front panel 6; the central cylinder 3, the central gas chamber rear cover 4 and the central gas chamber front panel 6 form a central In the gas chamber, the central axis of the cylinder body 3 coincides with that of the cylinder body 2, the front panel 6 of the central gas chamber is on the side close to the combustion chamber, and the rear cover plate 4 of the central gas chamber is on the side away from the combustion chamber.

[0110] The rear cover plate 4 of ...

Embodiment 2

[0119] This embodiment provides a gas decoupling burner. The gas decoupling burner includes a central gas assembly, a cylinder body 2 and an outer cylinder body 1 arranged coaxially from the inside to the outside; the central gas assembly and An annular main air passage is formed between the cylinders 2 ; an annular outer air passage is formed between the cylinders 2 and the outer cylinder 1 .

[0120]The central gas assembly includes a central cylinder 3, a central gas chamber rear cover 4 and a central gas chamber front panel 6; the central cylinder 3, the central gas chamber rear cover 4 and the central gas chamber front panel 6 form a central In the gas chamber, the central axis of the cylinder body 3 coincides with that of the cylinder body 2, the front panel 6 of the central gas chamber is on the side close to the combustion chamber, and the rear cover plate 4 of the central gas chamber is on the side away from the combustion chamber.

[0121] The rear cover plate 4 of t...

Embodiment 3

[0131] This embodiment provides a gas decoupling burner. The gas decoupling burner includes a central gas assembly, a cylinder body 2 and an outer cylinder body 1 arranged coaxially from the inside to the outside; the central gas assembly and An annular main air passage is formed between the cylinders 2 ; an annular outer air passage is formed between the cylinders 2 and the outer cylinder 1 .

[0132] The central gas assembly includes a central cylinder 3, a central gas chamber rear cover 4 and a central gas chamber front panel 6; the central cylinder 3, the central gas chamber rear cover 4 and the central gas chamber front panel 6 form a central In the gas chamber, the central axis of the cylinder body 3 coincides with that of the cylinder body 2, the front panel 6 of the central gas chamber is on the side close to the combustion chamber, and the rear cover plate 4 of the central gas chamber is on the side away from the combustion chamber.

[0133] The rear cover plate 4 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com