Superheated steam drying power-making coal-fired power generation system

A technology for superheated steam and power generation systems, which is applied in steam applications, steam engine installations, drying gas arrangements, etc., can solve the problems of large flue gas cooling heat exchangers, low water dew point, etc., to improve the poor uniformity of particle size, improve The effect of improving combustion performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

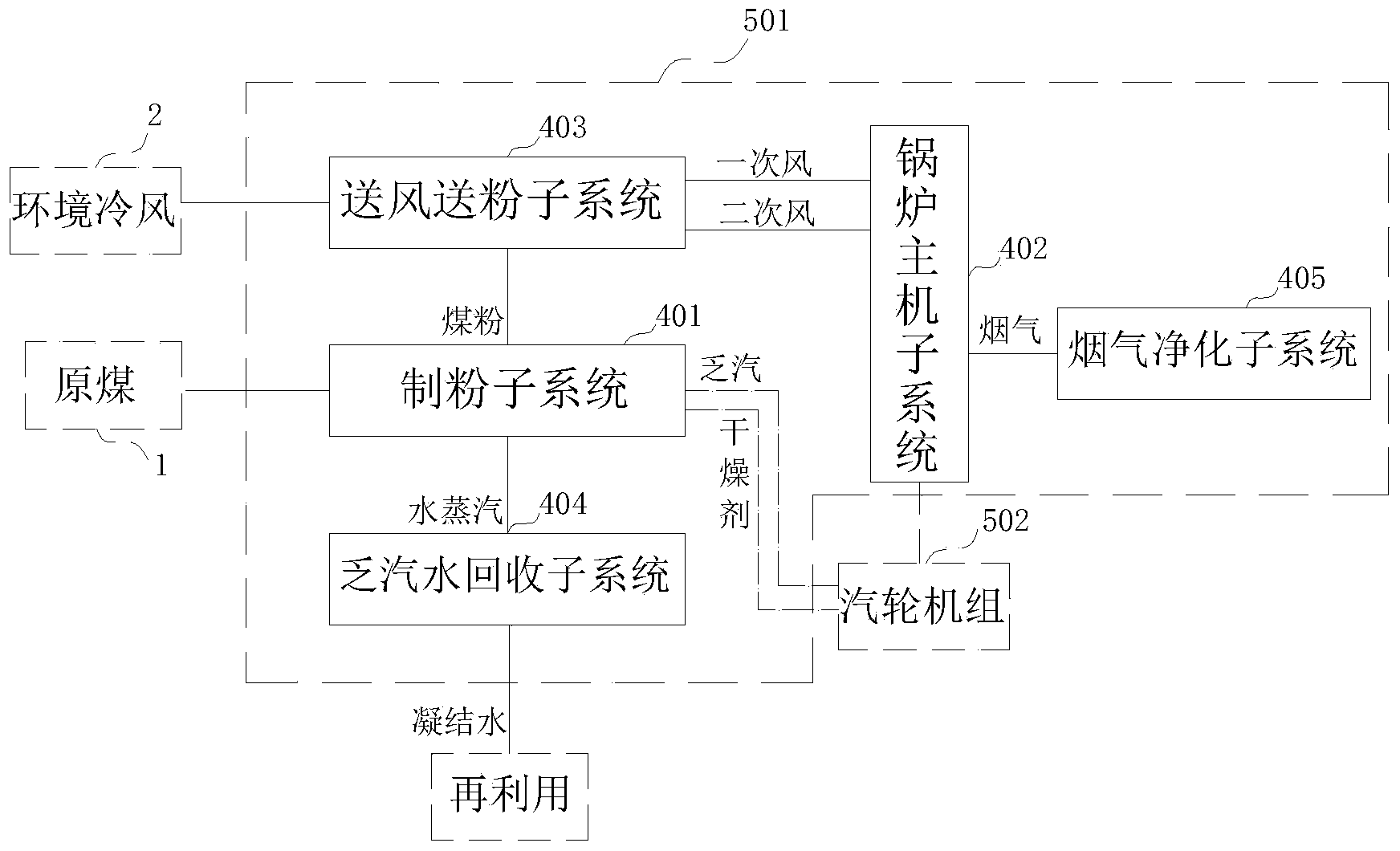

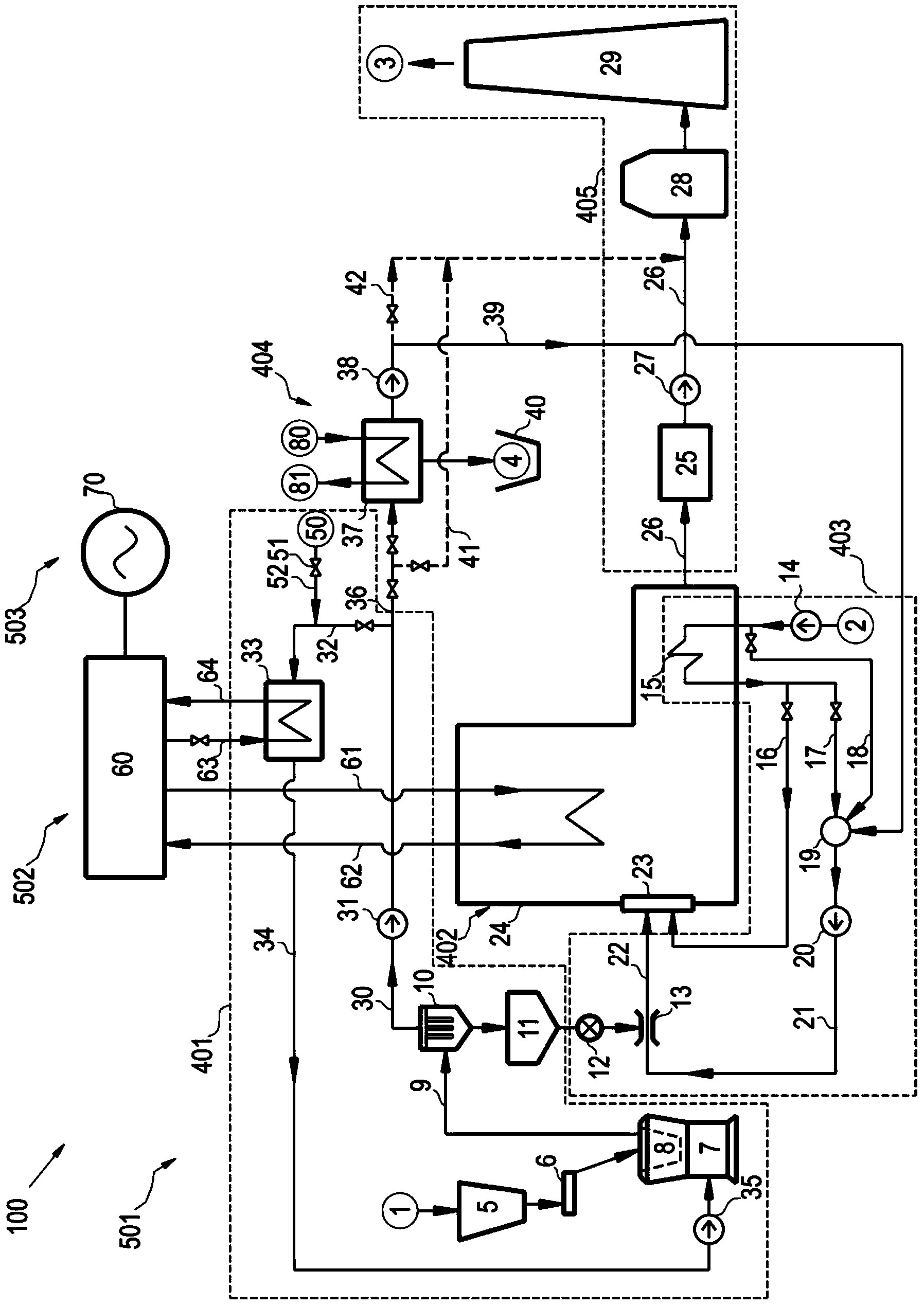

[0031] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following examples will describe in detail the superheated steam drying pulverization coal-fired power generation system related to the present invention in conjunction with the accompanying drawings and examples.

[0032] figure 1 It is a structural block diagram of a superheated steam drying pulverization type coal-fired power generation system in an embodiment of the present invention.

[0033] Such as figure 1 As shown, the superheated steam drying pulverizing coal-fired power generation system 100 includes: a boiler unit 501 , a steam turbine unit 502 , and a generator unit 503 .

[0034] The heat generated by the combustion of raw coal in the boiler unit 501 heats the water to form high-temperature and high-pressure steam that enters the steam turbine unit 502 to do work, and then drives the generator unit 503 to generate electricity.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com