High-efficiency environment-friendly coal synergistic agent

A synergist and environmental protection technology, applied in the field of coal synergist, high-efficiency and environmentally friendly coal synergist, can solve the problem of unusable catalyst products, improve safety and stability, add less amount, and reduce activation energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 12

[0019] Embodiment 1 to Embodiment 12: The following embodiments disclose a high-efficiency and environment-friendly coal synergist, which is prepared from raw materials in different parts by mass. The solutes are sequentially added into the deionized water according to the dose, and the mixture is uniformly stirred to obtain a high-efficiency and environment-friendly coal synergist.

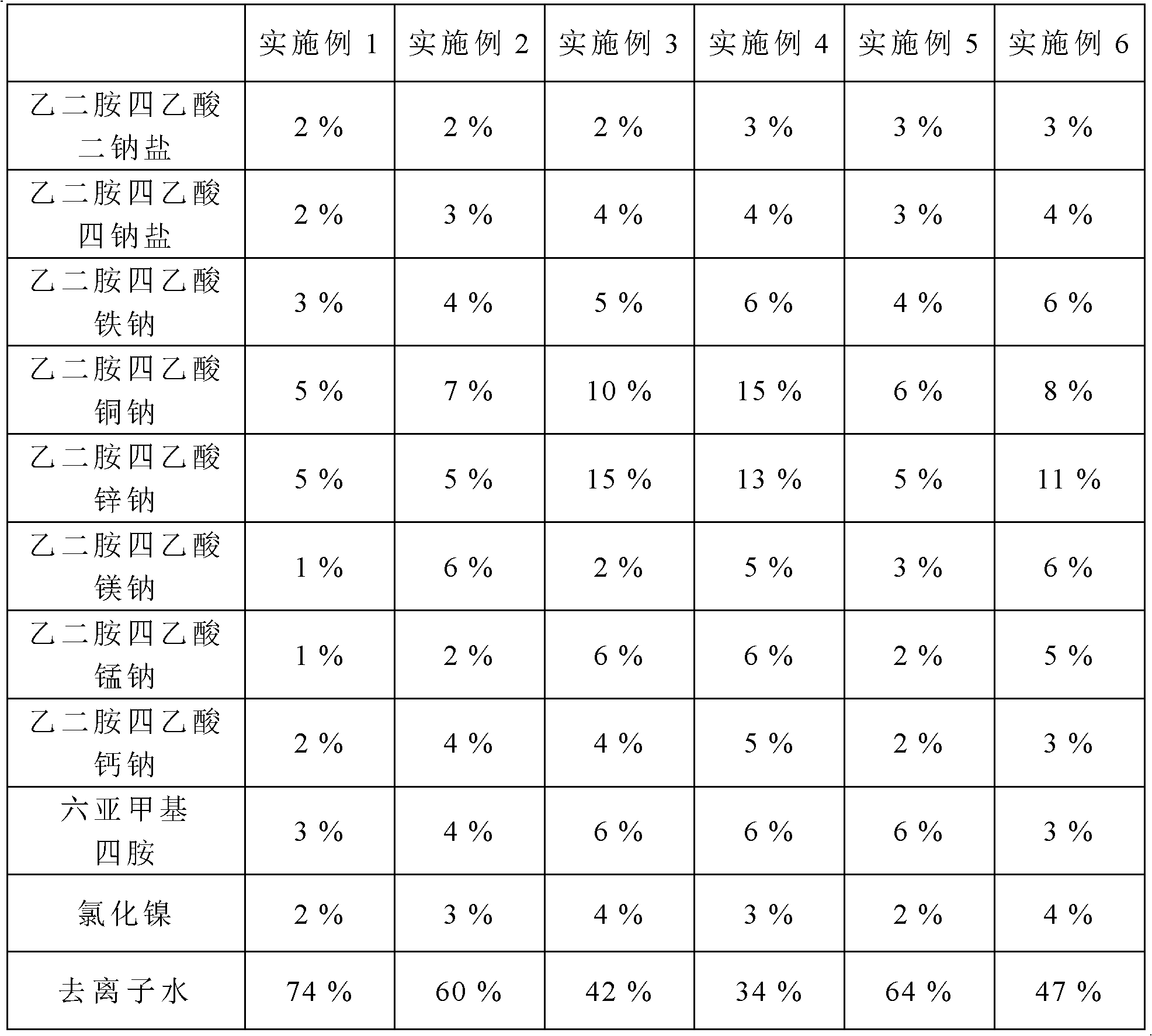

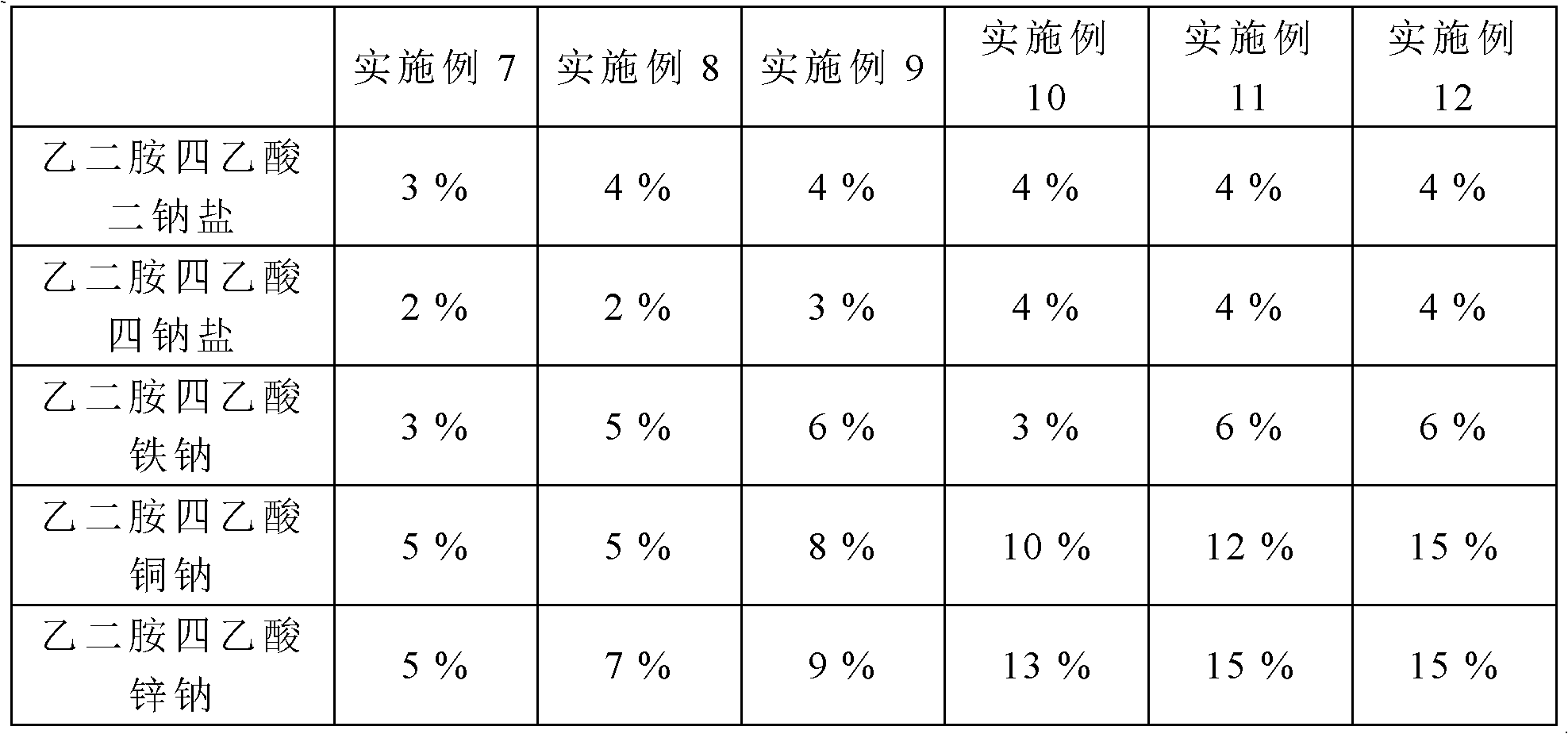

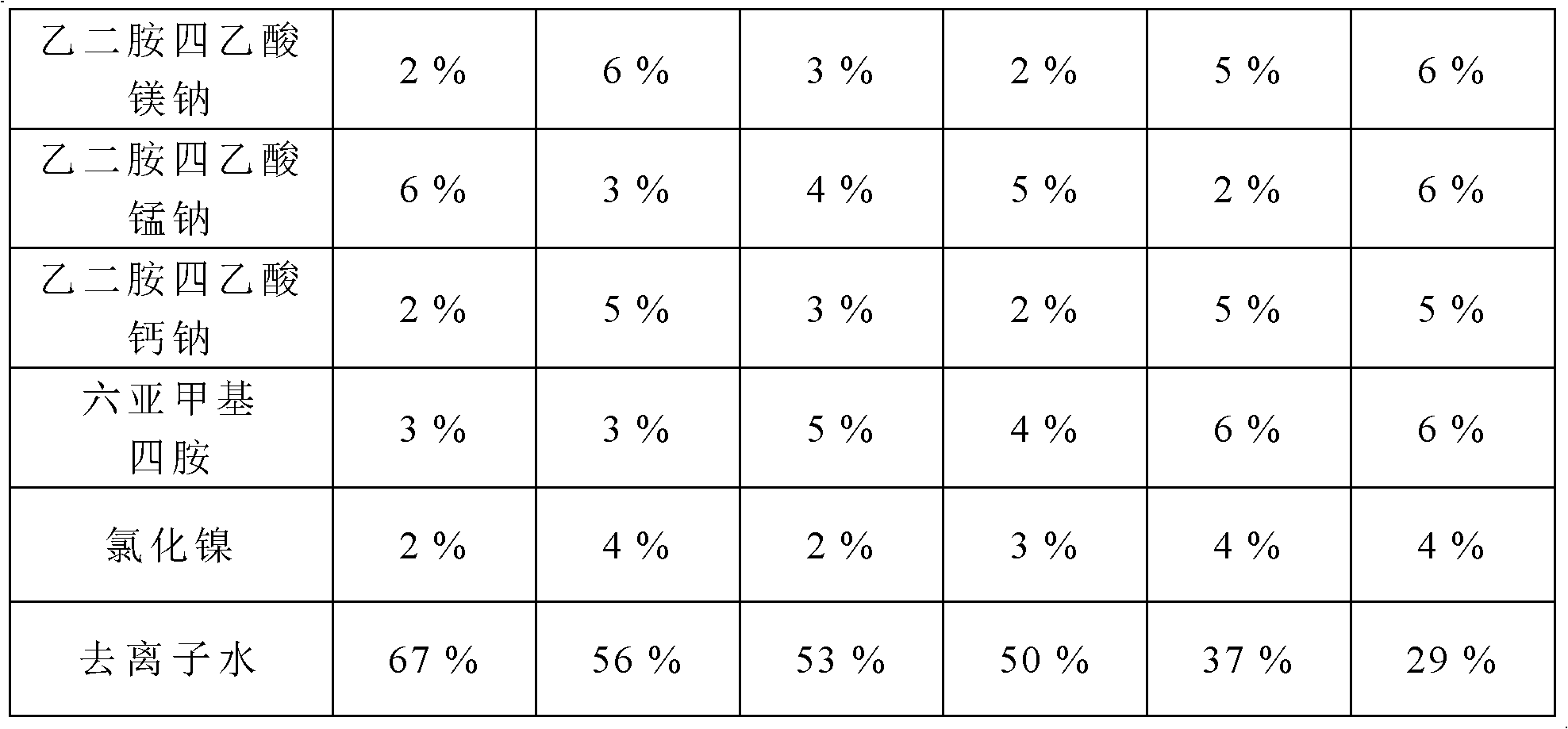

[0020] See Table 1 and Table 2 for specific raw material preparation weight percentages.

[0021]

[0022] Table 1 Raw material preparation weight percentage of embodiment 1~embodiment 6

[0023]

[0024]

[0025] Table 2 Raw material preparation weight percentage of embodiment 7~embodiment 12

Embodiment 13

[0026] Example 13: This example discloses a high-efficiency and environmentally friendly coal synergist, which is prepared from the following raw materials in parts by mass: EDTA disodium salt 2-4%, EDTA tetrasodium salt 2 ~4%, sodium iron EDTA 3~6%, sodium copper EDTA 5~15%, sodium zinc EDTA 5~15%, sodium magnesium EDTA 1~6 %, sodium manganese edetate 1-6%, calcium sodium edetate 2-5%, hexamethylenetetramine 3-6%, nickel chloride 2-4%, the balance is deionized mixed with water. Add each solute into deionized water according to the dosage, stir and mix evenly, and then the high-efficiency and environment-friendly coal synergist can be prepared.

[0027] Use NETZSCH STA 409PC comprehensive thermal analyzer C20 to conduct comparative tests on raw coal and raw coal after adding this high-efficiency and environmentally friendly coal synergist. The test results are: after adding this high-efficiency and environment-friendly coal synergist, the coal combustion intensity is reduced...

Embodiment 14

[0028] Embodiment 14: Trial burning is carried out on a 20T (ton, the same below) steam furnace of a certain power plant. Calculate the steam production per ton of coal by using the coal consumption and the corresponding steam production, and calculate the coal saving rate of the high-efficiency and environmental protection coal synergist according to the steam production per ton of coal before and after adding the high-efficiency and environmental protection coal synergist.

[0029] Wherein, the high-efficiency and environment-friendly coal synergist is prepared by dissolving various solutes in deionized water according to the following mass percentages, and stirring evenly. The specific proportions are as follows: EDTA disodium salt 4%, EDTA tetrasodium salt 4%, EDTA iron sodium 3%, EDTA copper sodium 10%, EDTA Zinc Sodium EDTA 13%, Magnesium Sodium EDTA 2%, Manganese Sodium EDTA 5%, Calcium Sodium EDTA 2%, Hexamethylenetetramine 4%, Nickel Chloride 3%, 50% deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com