Horizontal dense-dilute concentration type direct flow pulverized coal burner

A pulverized coal burner and enrichment technology, which is applied to burners, burners for burning powder fuel, combustion methods, etc., can solve problems such as large nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

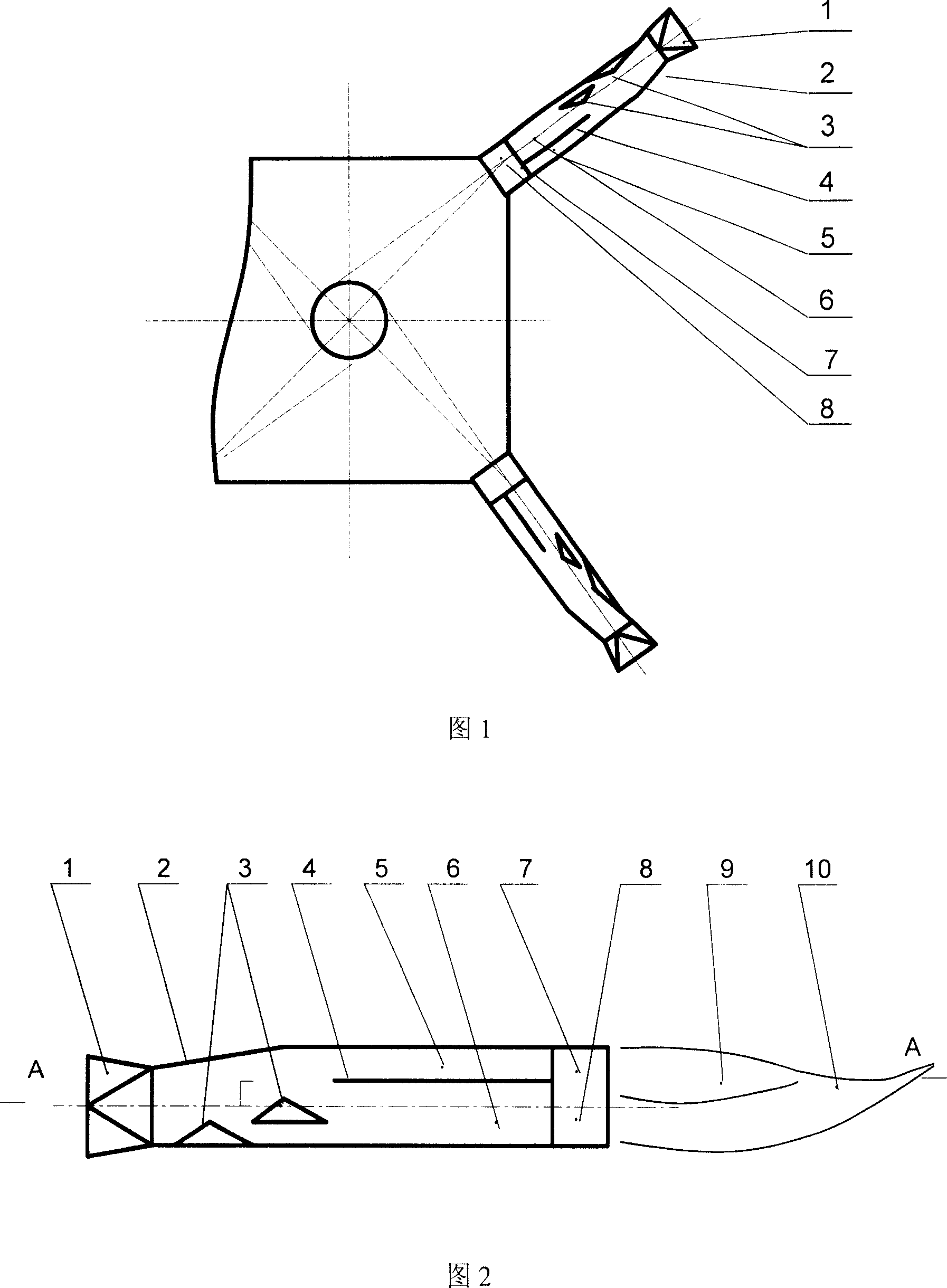

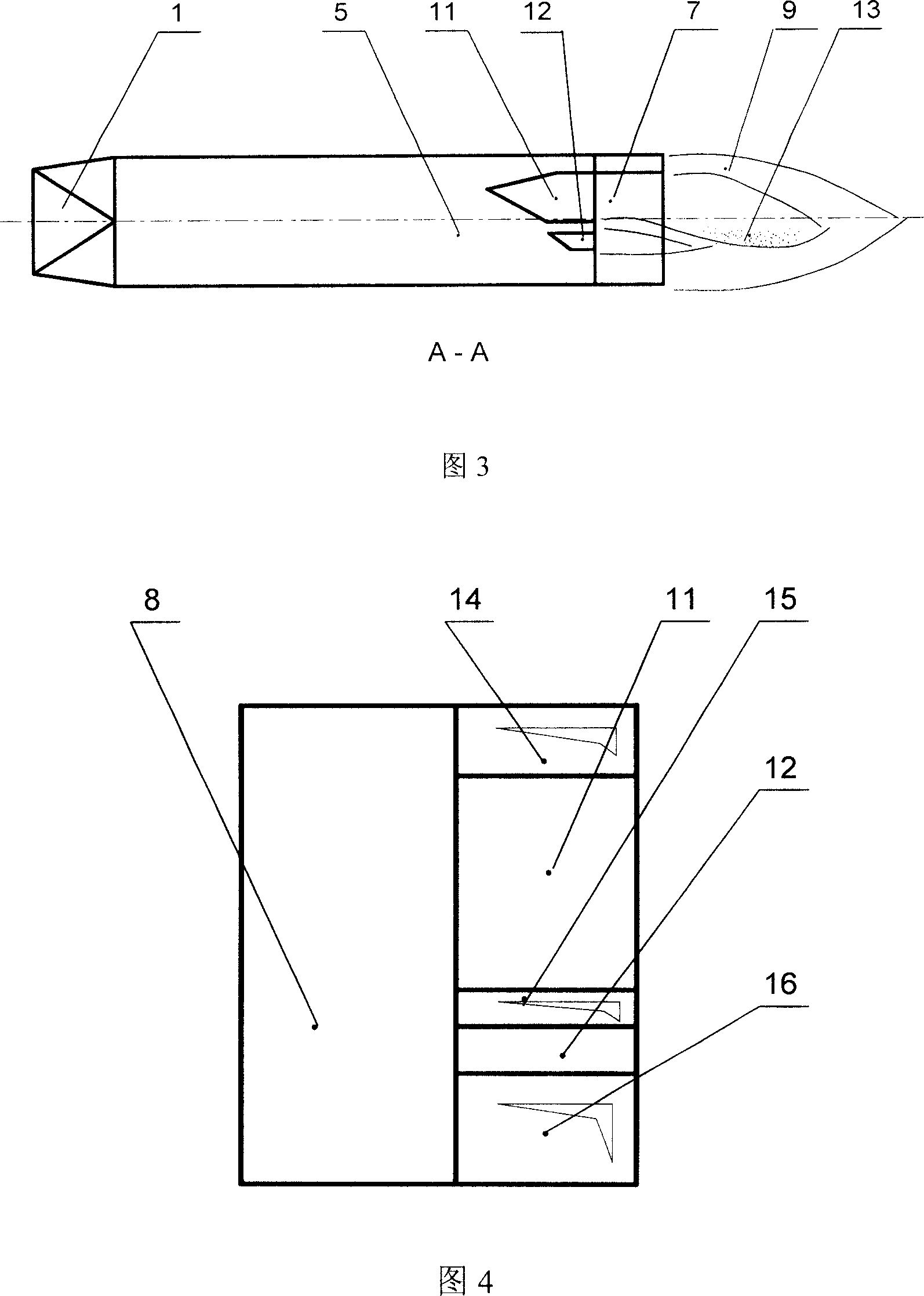

[0017] The principle and specific structure of the present invention will be further described below in conjunction with the accompanying drawings. The horizontal thick-lean enrichment type DC pulverized coal burner provided by the present invention mainly includes a square-circle joint 1, a primary air channel 2 connected with the square-circle joint, a separation block 3 and a separation partition 4 arranged in the primary air channel, separated by The dense air flow passage 5, the light air flow passage 6, the dense air flow nozzle 7 and the light air flow nozzle 8 (as shown in Figure 2) formed by the dividing plate; The primary separation block 11 and the concentrated stock secondary separation block 12 (as shown in Figure 3); the concentrated stock primary separation block 11 separates the concentrated stock airflow into two airflows of up and down in the vertical direction, the upper airflow is a small strand, and the lower part The air flow is large; the dense strand se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com