Thick-thin burner

A technology of thick-thin combustion and thick-thin separation, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of corroded air preheater, shutdown and renovation, ammonia escape, etc., to reduce pipeline wear, expand cross-sectional area, flow even line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

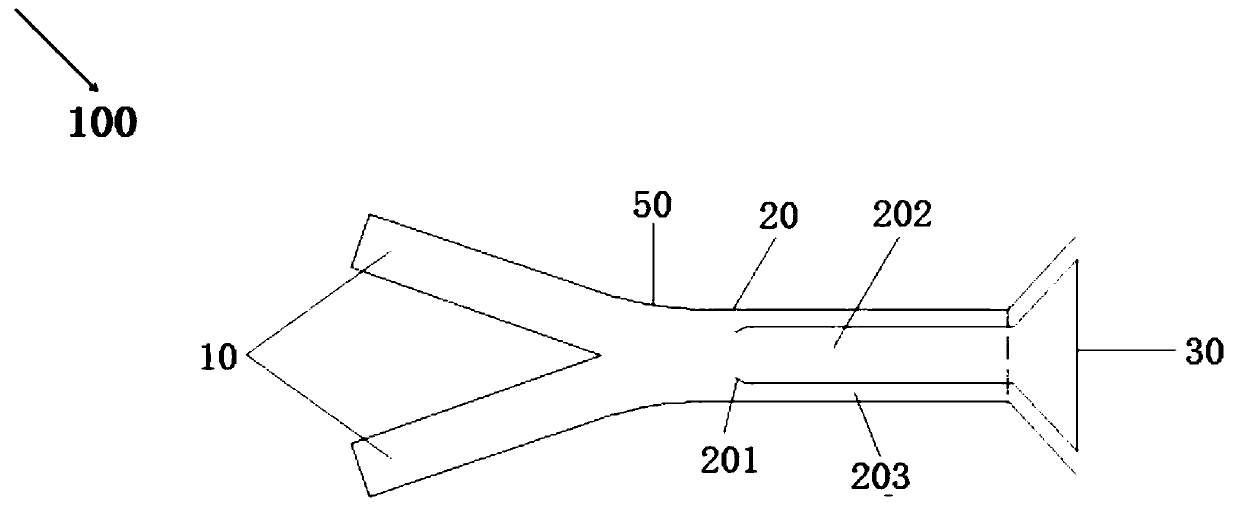

[0016] figure 1 It is a structural schematic diagram of the rich-lean burner in the embodiment of the present invention.

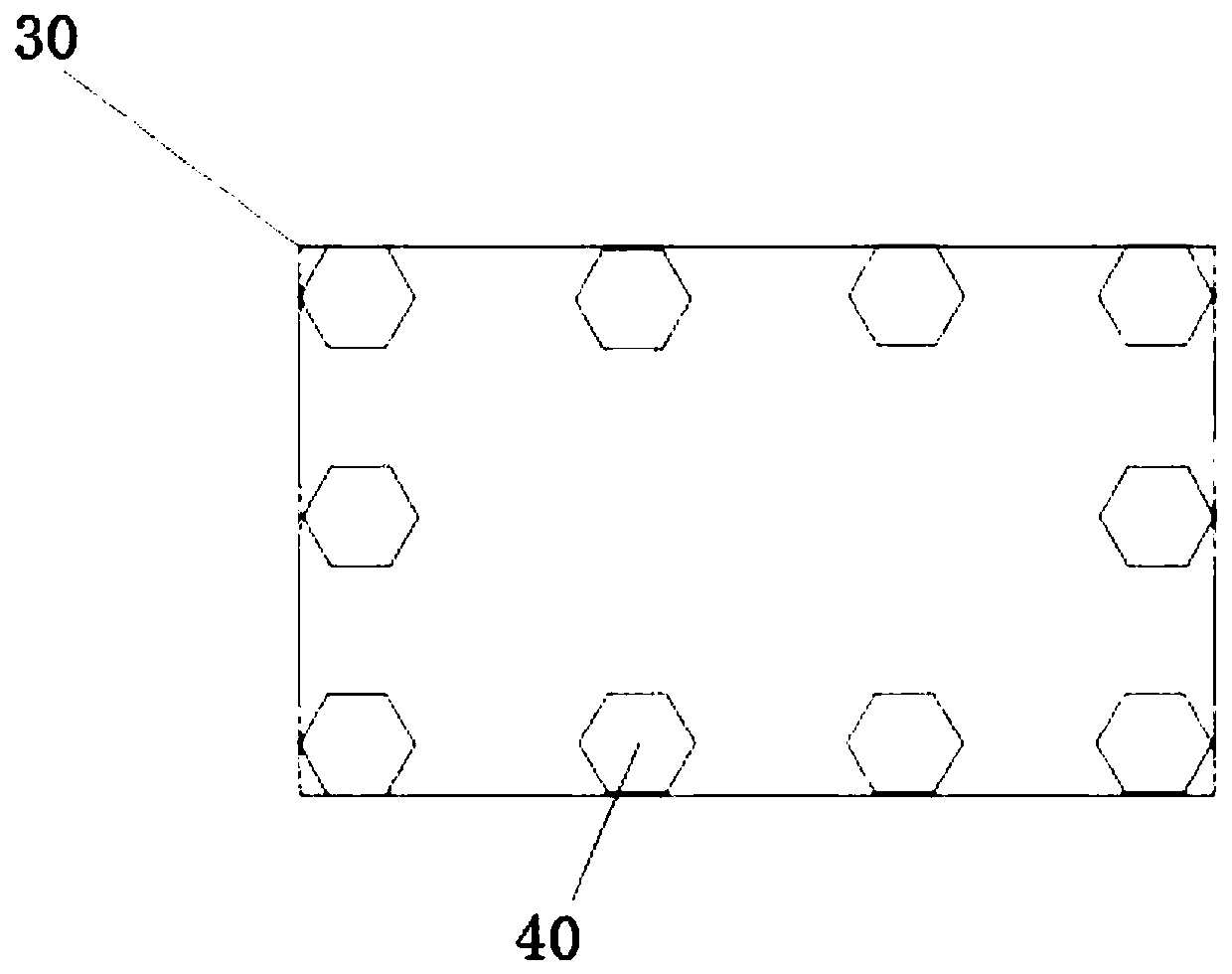

[0017] Such as figure 1 As shown, the rich-lean burner 100 of the present embodiment is connected with the primary air duct to separate the primary air pulverized coal flow for thick-lean separation. The rich-lean burner 100 includes: pulverized coal inlet pipe 10, horizontal main pipe 20, spout 30 and blunt body Member 40.

[0018] One end of the two pulverized coal inlet pipes 10 is a pulverized coal inlet, and the other end intersects each other so that the space between the two pulverized coal inlet pipes is V-shaped.

[0019] The horizontal main pipe 20 is connected to the intersection of two pulverized coal inlet pipes 10, and deflectors 201 are arranged on the upper and lower sides of the interior, and the part between the deflectors 201 on both sides is the main pulverized coal pipe 202, and the pulverized coal pipe is outside. Auxiliary pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com