Patents

Literature

52results about How to "Improve fire stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

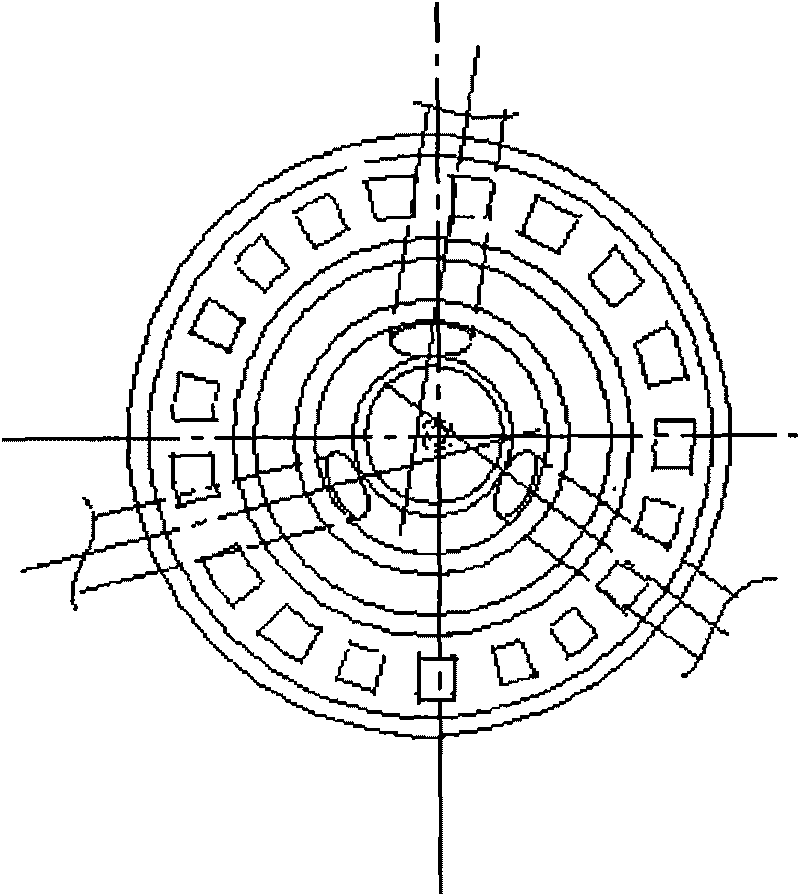

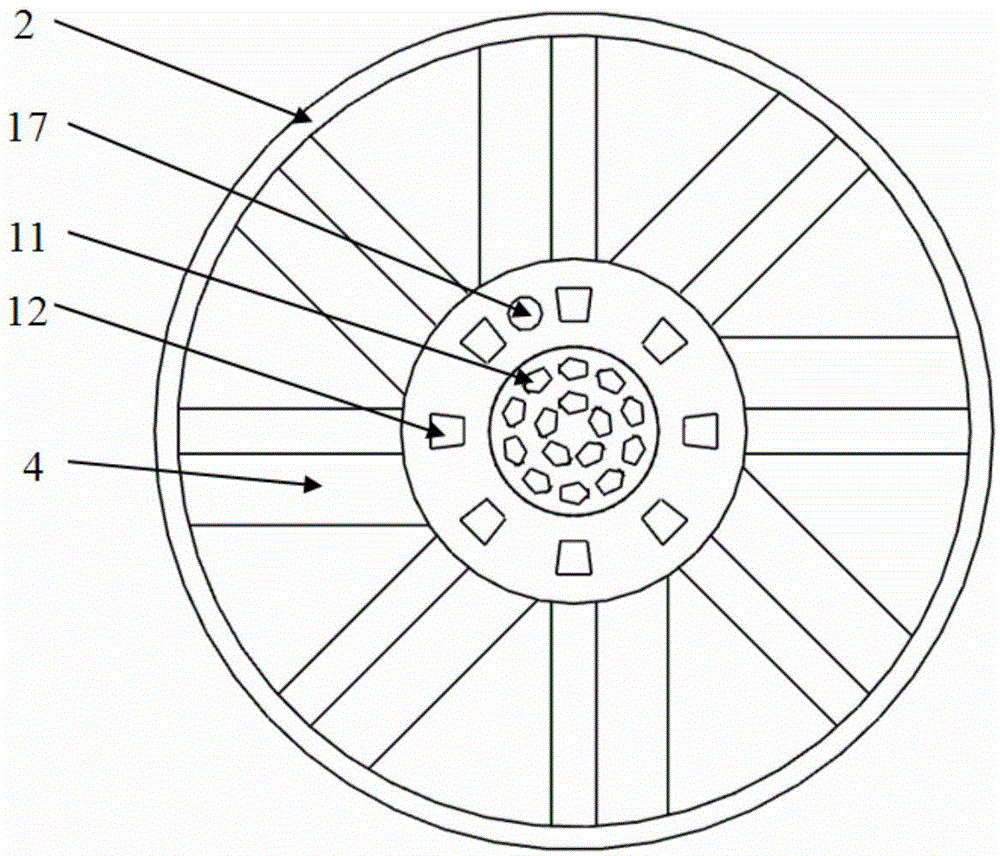

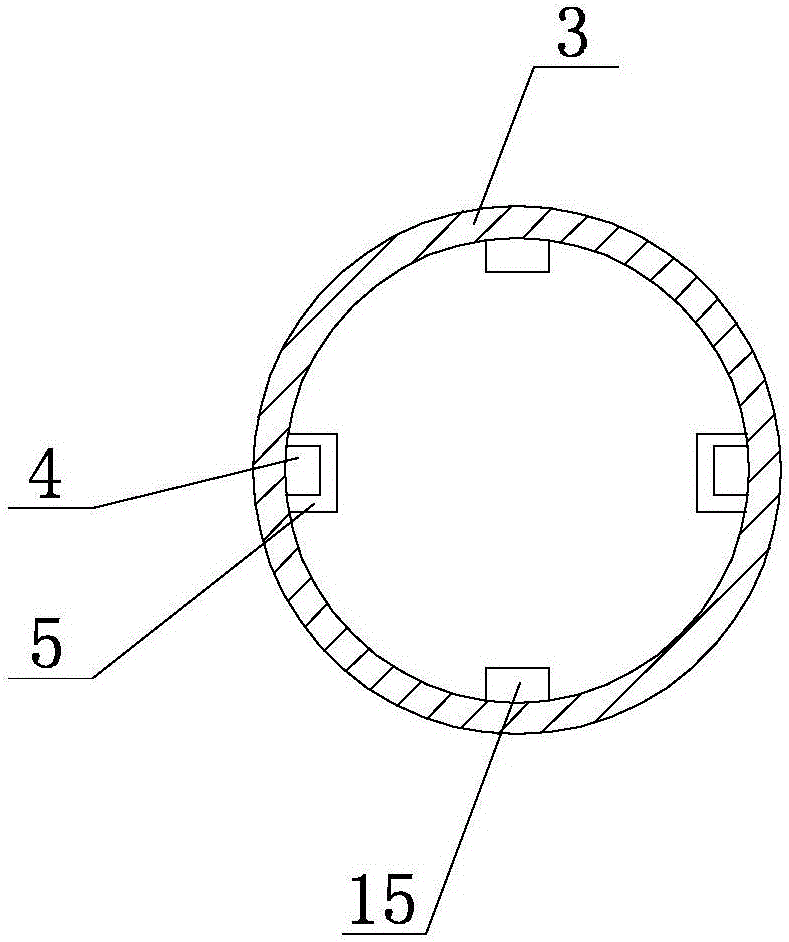

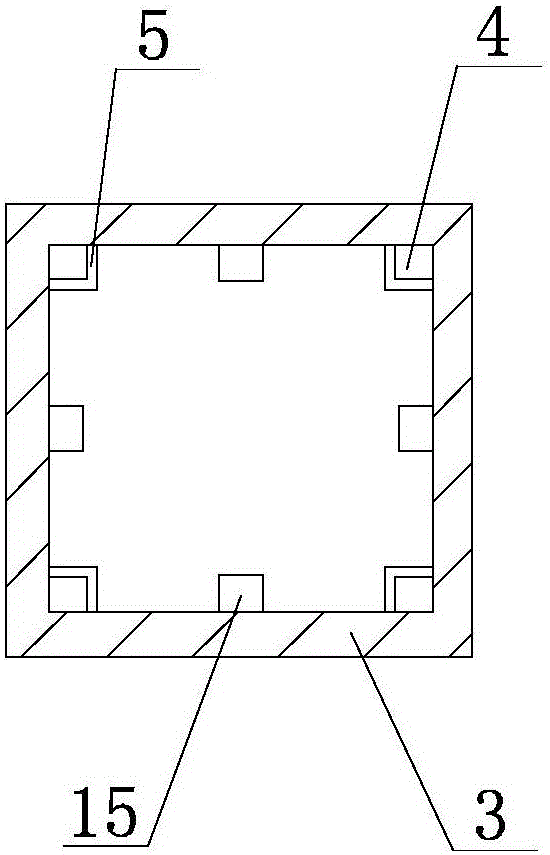

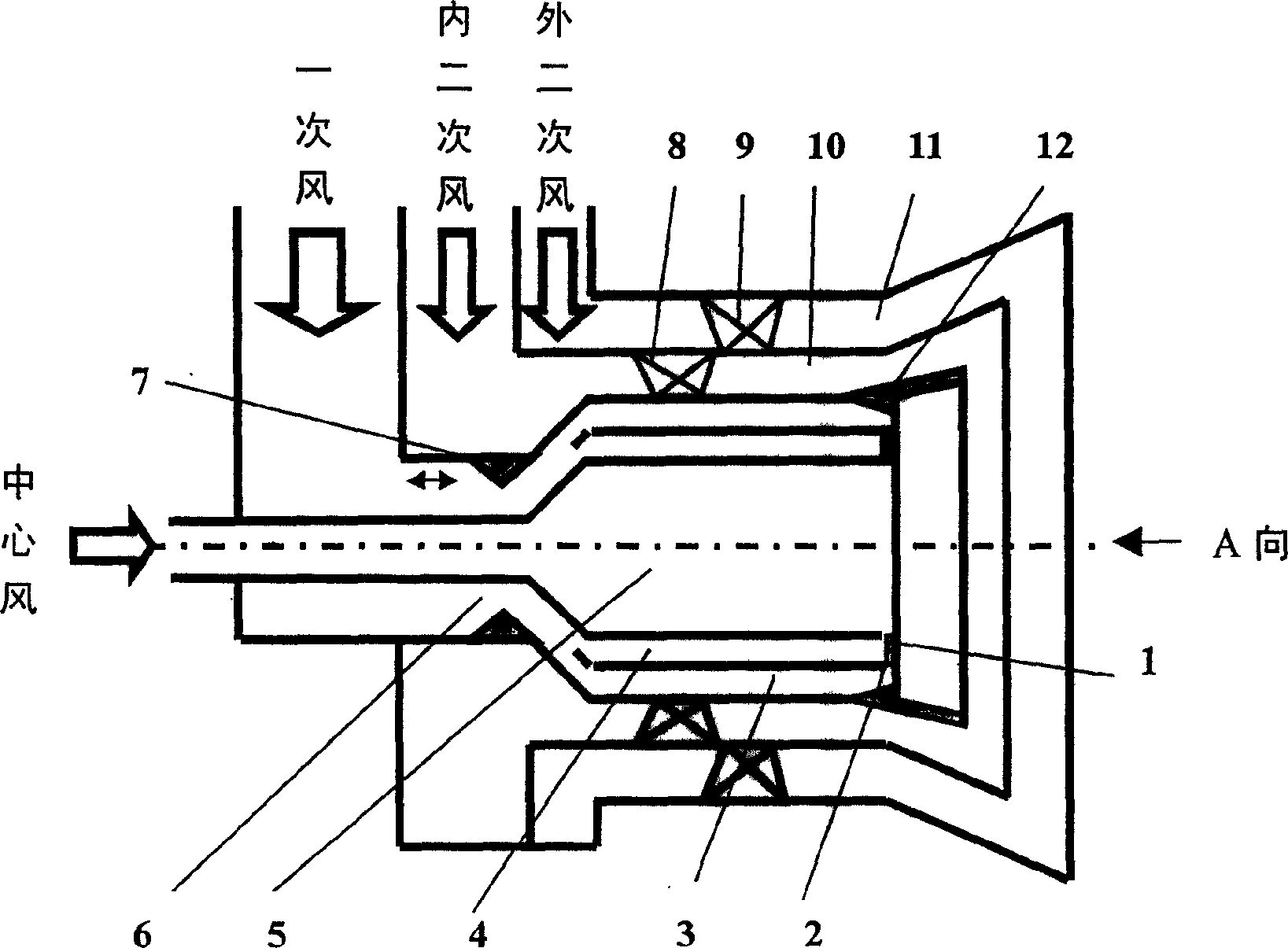

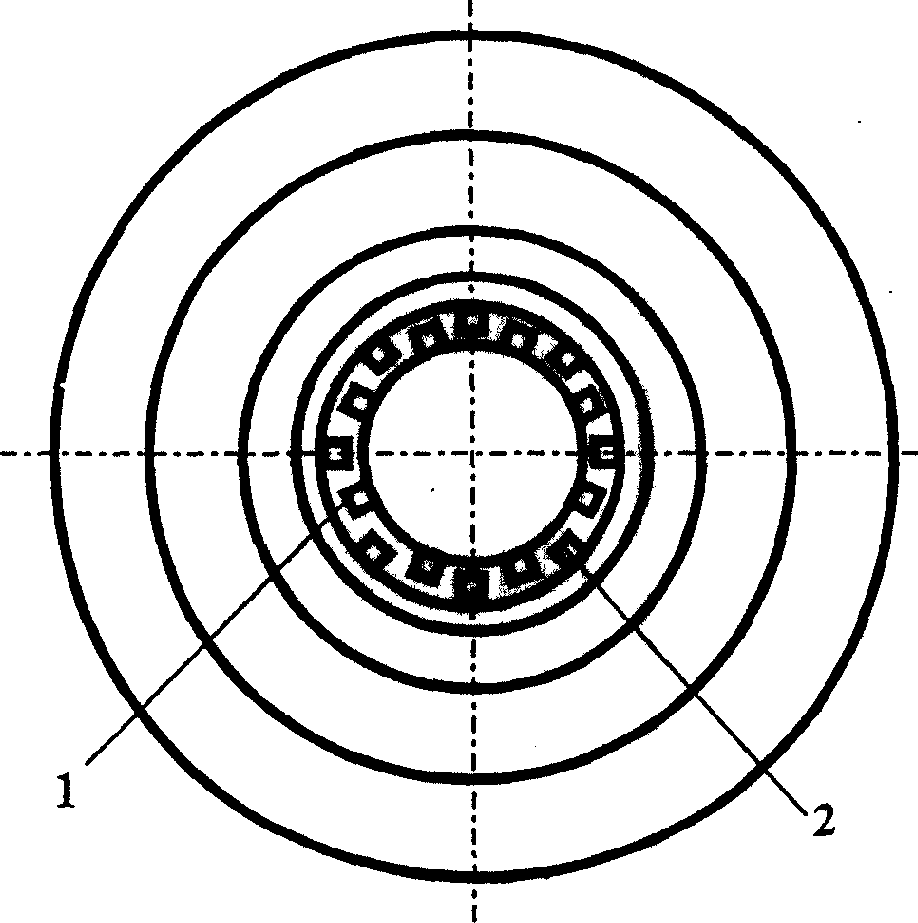

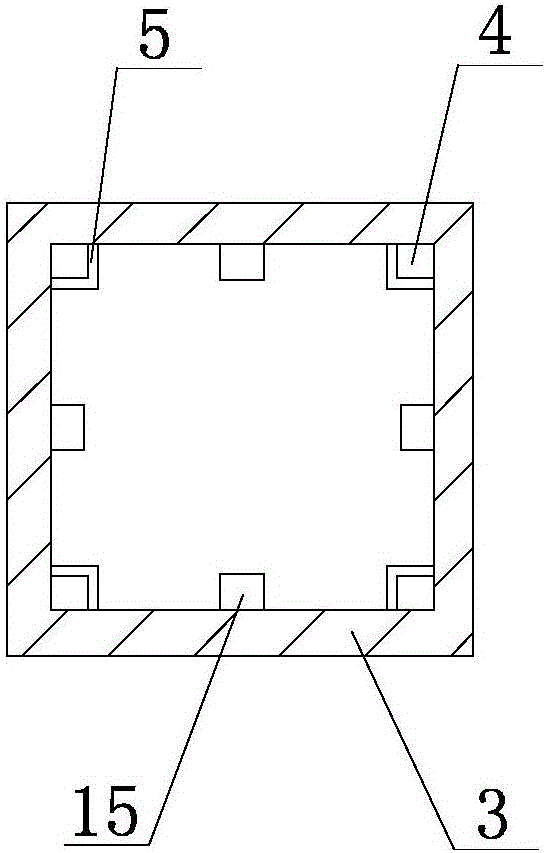

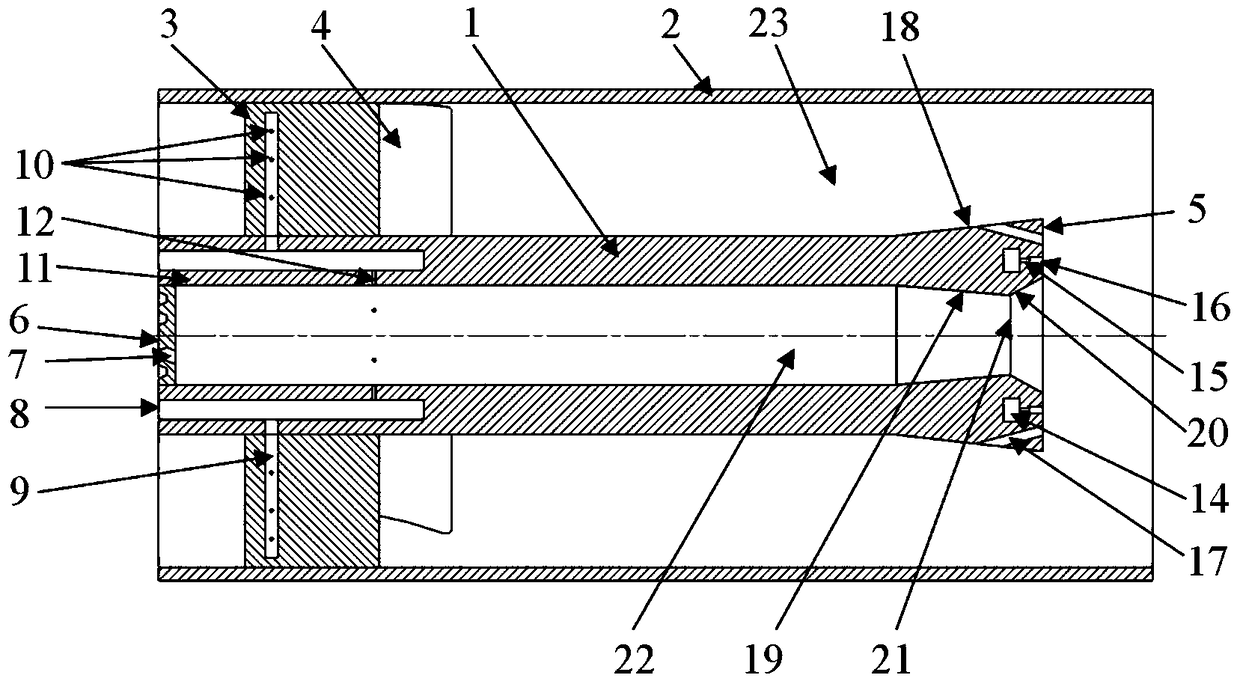

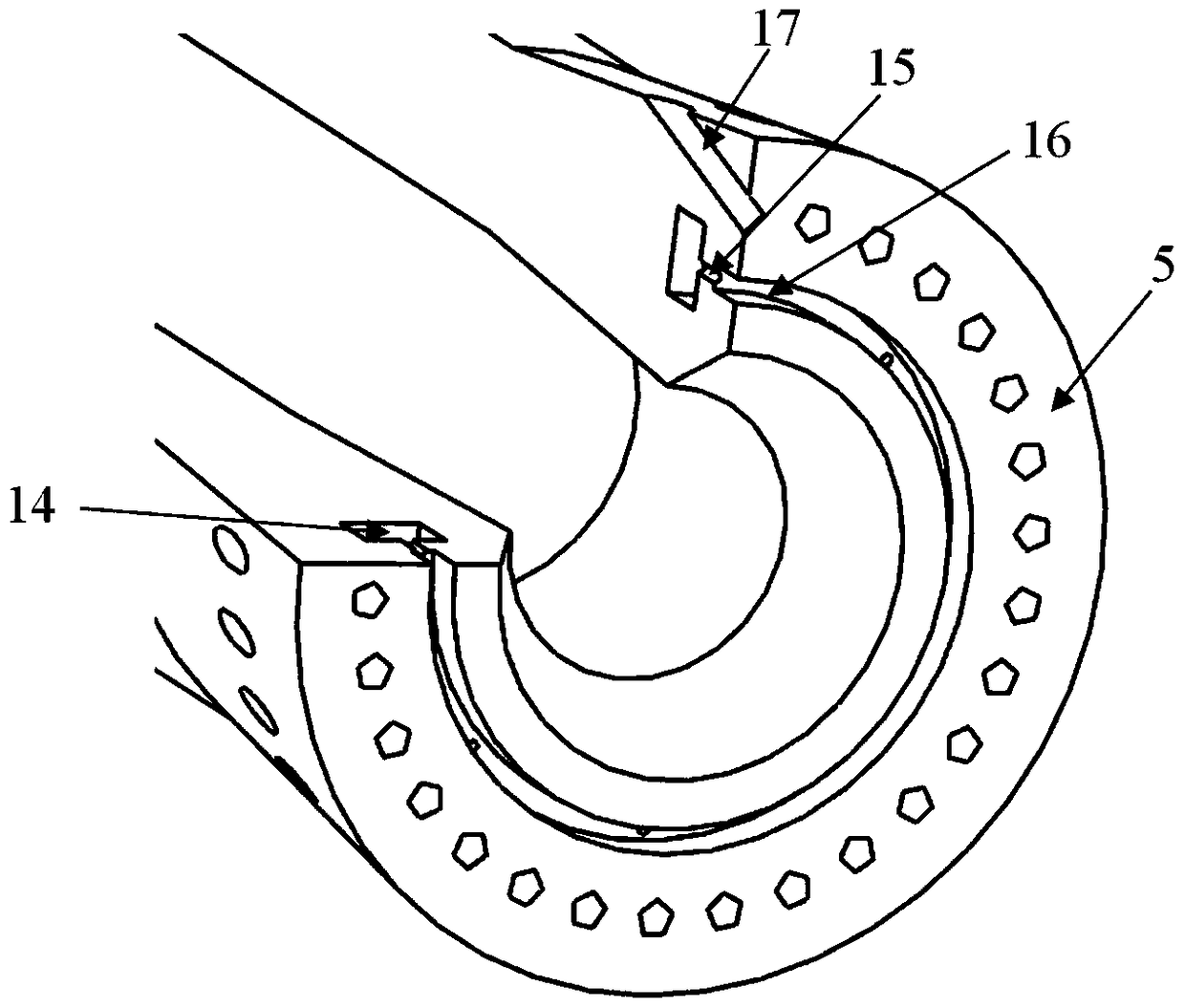

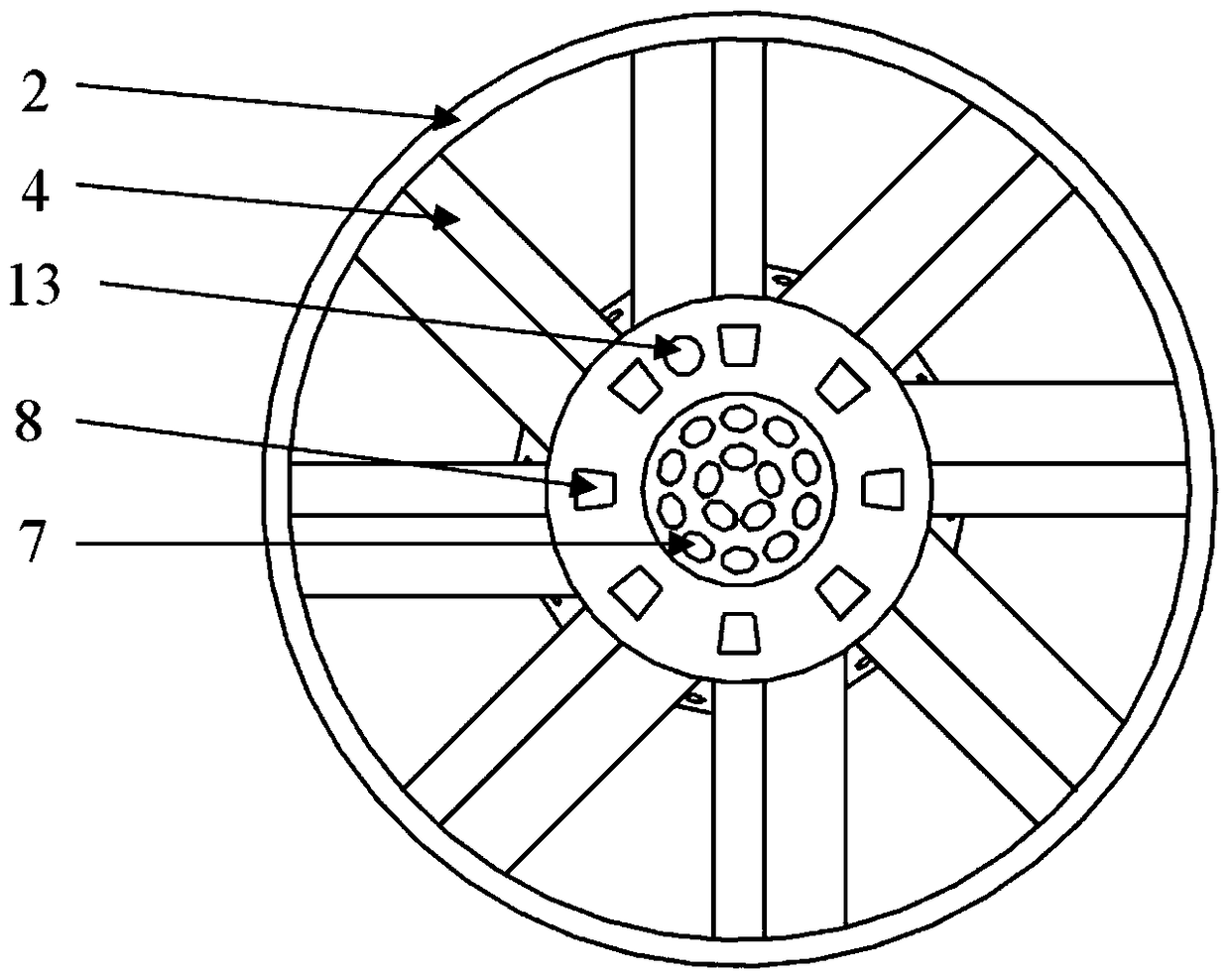

Radial gradient two air-controlled cyclone coal dust combustor

InactiveCN1477330AIncrease concentrationImprove heat transfer performancePulverulent fuel combustion burnersCycloneAir volume

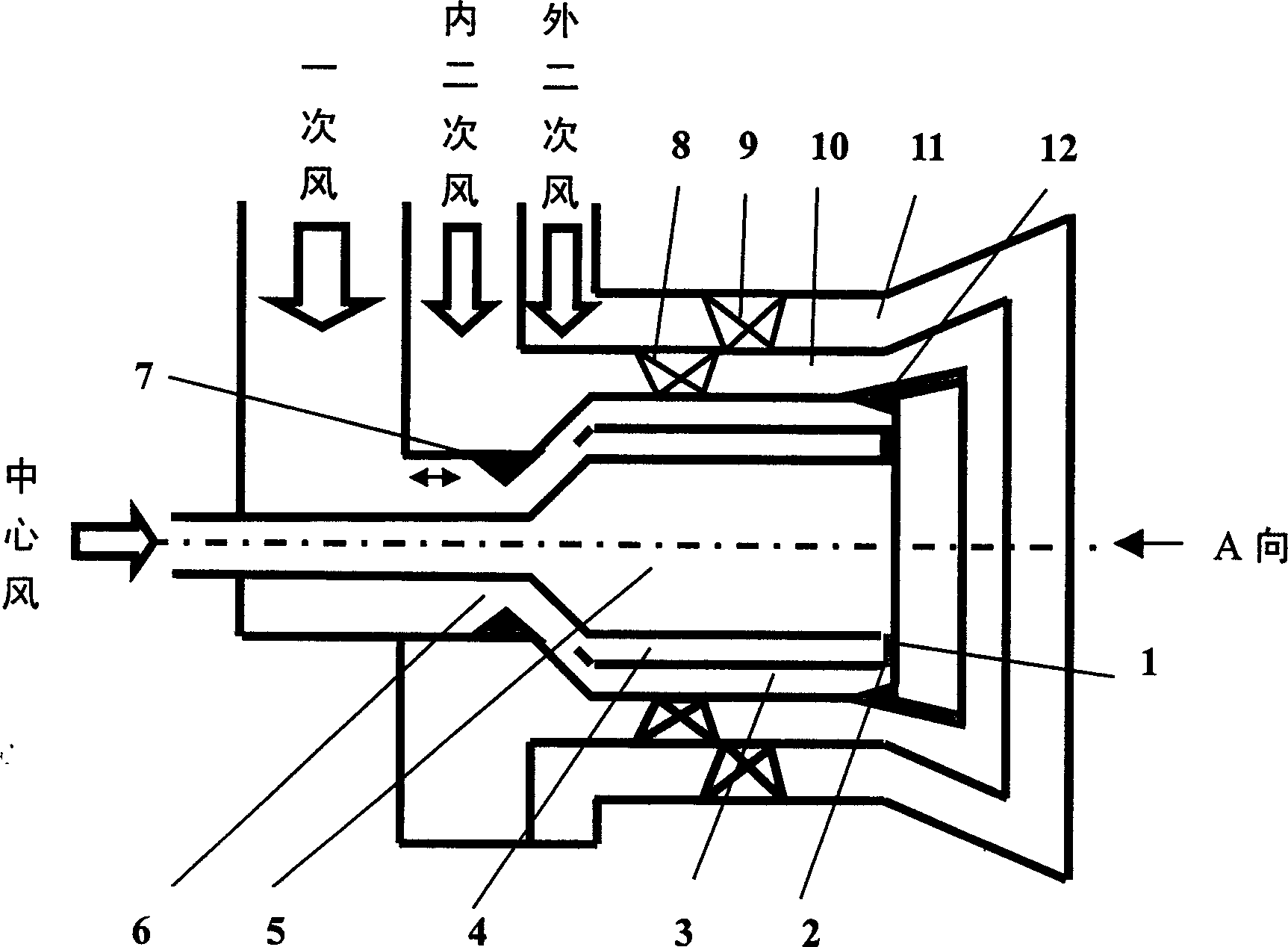

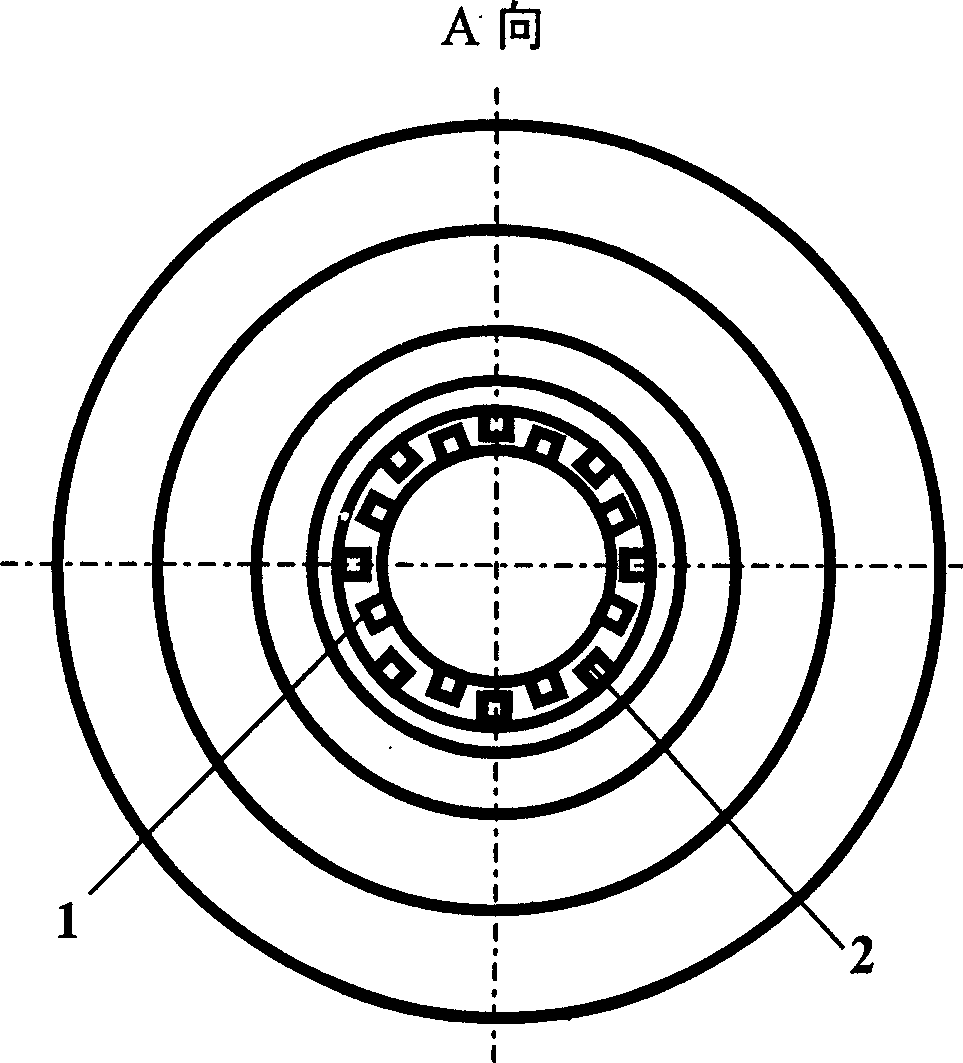

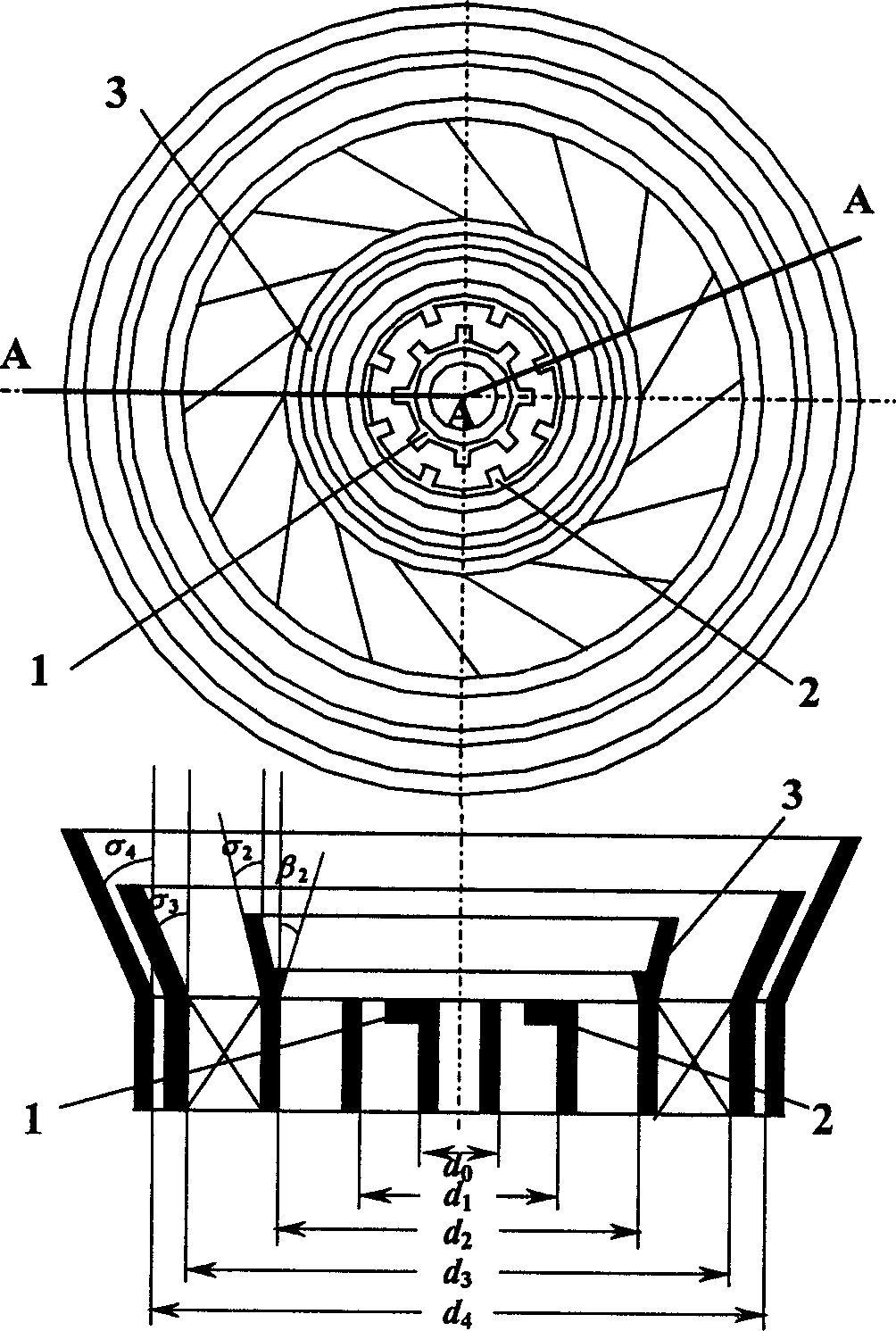

The present invention discloses a radial gradation double air regulation cyclone coal powder burner, including nozzle with burner, internal first air channel, external first air channel, internal second air channel, external second air channel, internal tooth profile combustion-stabilizing ring, external tooth profile combustion-stabilizing ring, double-cone flare, stopper coal powder concentrator and central pipe cyclone coal powder burner. It utilizes two air channels to implement radial gradation combustion.

Owner:XI AN JIAOTONG UNIV

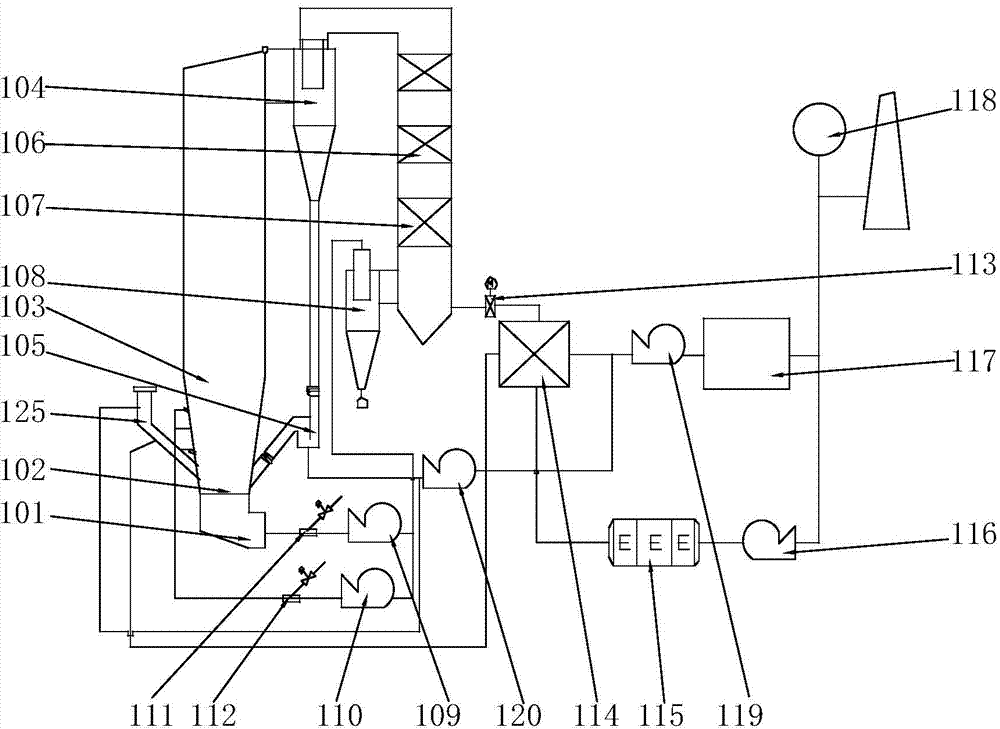

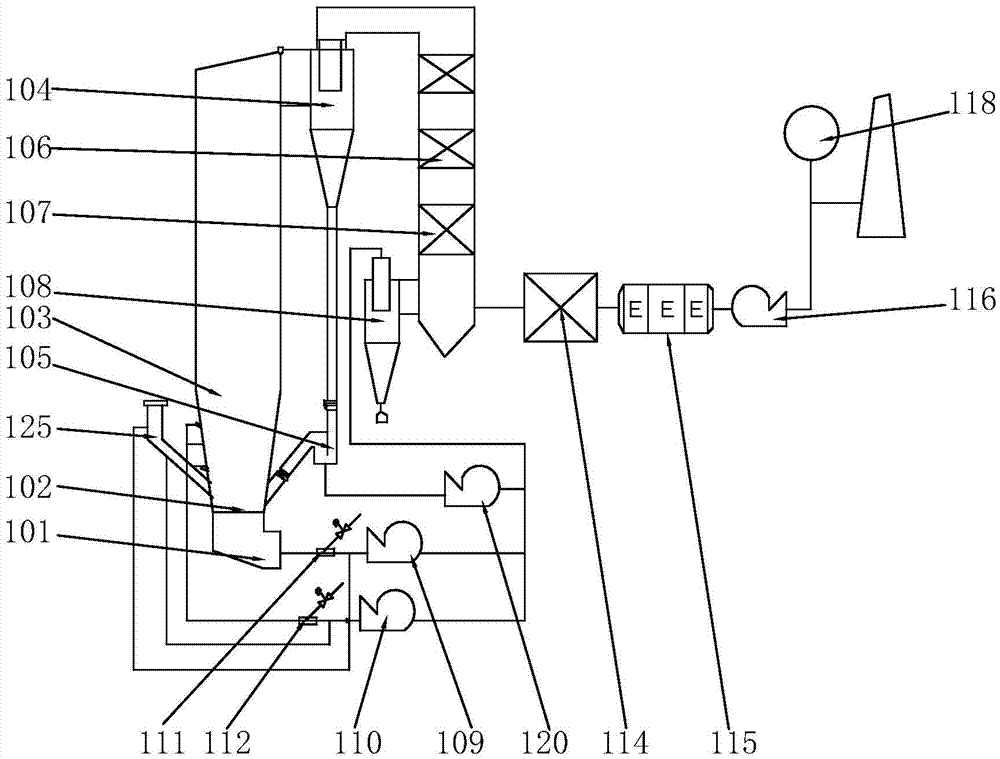

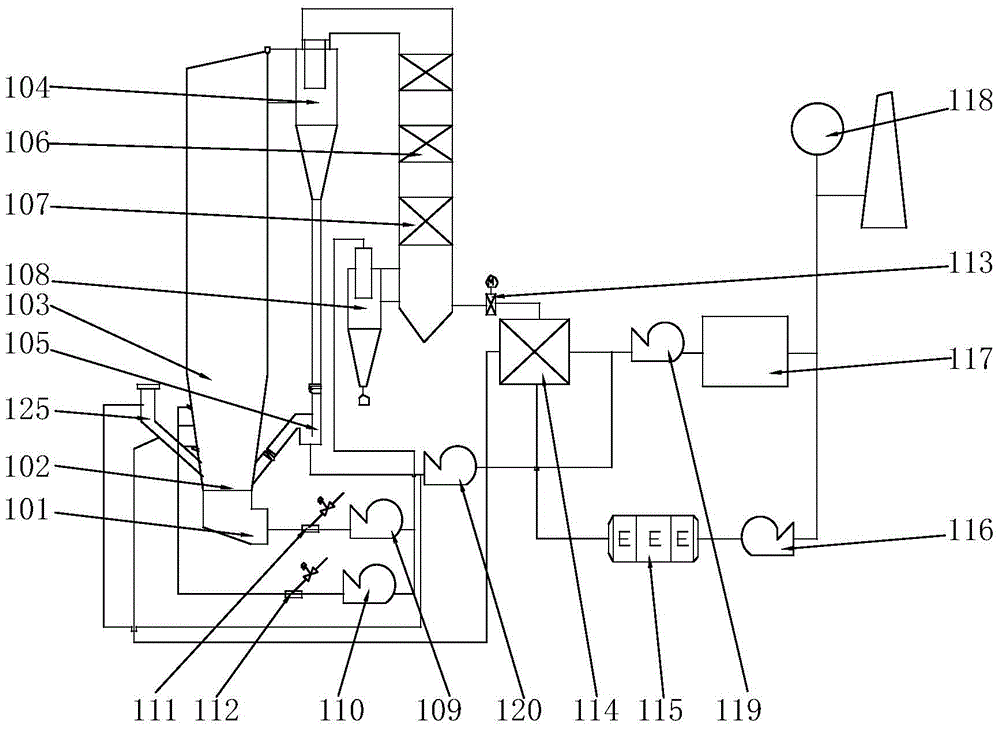

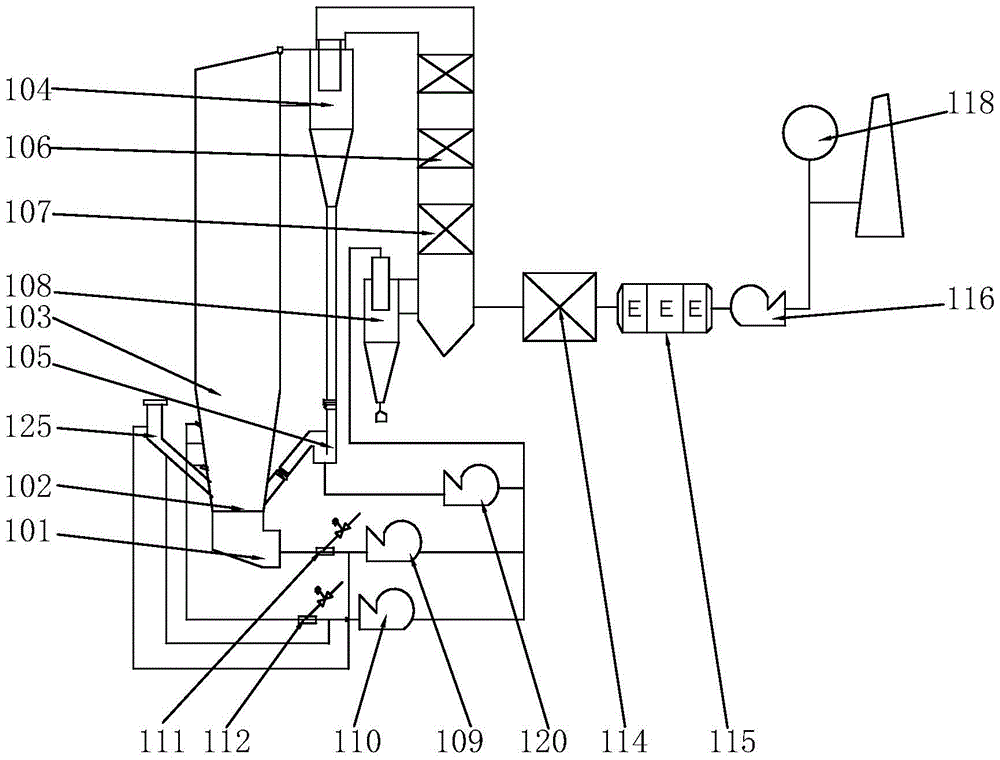

Recirculating fluidized bed oxygen-enriched combustion apparatus and operation method thereof

ActiveCN104848213AUniform fluidizationAvoid depositionFluidized bed combustionIndirect carbon-dioxide mitigationCycloneCombustion

The invention discloses a recirculating fluidized bed oxygen-enriched combustion apparatus, which comprises an air compartment, an air distribution device arranged above the air compartment and a hearth arranged above the air distribution device; the upper part of the hearth is connected with a high-temperature cyclone separator; the upper part of the high-temperature cyclone separator is connected with a heating surface; the lower part of the heating surface is connected with an economizer. The invention further discloses an operation method of the recirculating fluidized bed oxygen-enriched combustion apparatus. The recirculating fluidized bed oxygen-enriched combustion apparatus and the operation method thereof, disclosed by the invention, overcome the defects in the prior art, and intermediate temperature flue gas is used as primary air and secondary air which respectively enter the hearth to serve as recirculating air, in addition, oxygen is injected into the primary air and the secondary air, and the oxygen injection amount can be adjusted, meanwhile, an oxidizing agent is provided for combustion in the hearth, the concentration of CO2 discharged from a boiler of a recirculating fluidized bed can be enriched to more than 80%, and the capture of the CO2 in the flue gas after combustion of coal is facilitated.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

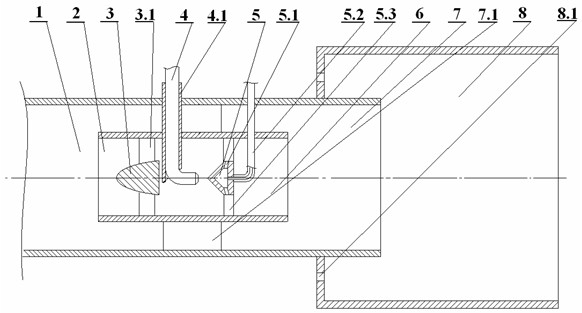

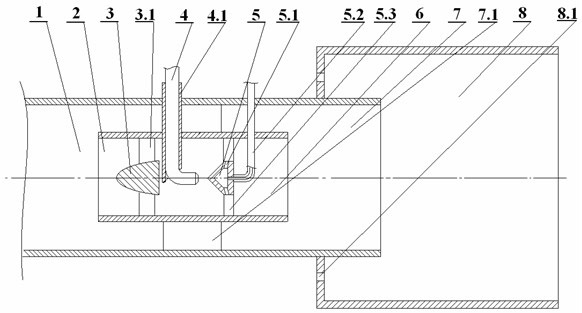

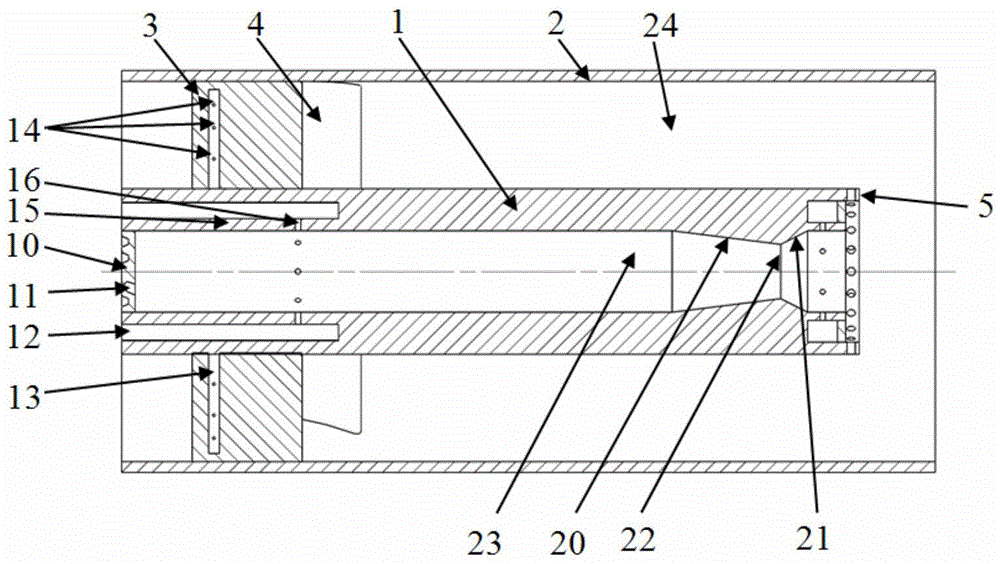

Central diffusion type tiny-oil ignition combustor

InactiveCN102537951AHeating fastExtended stayPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a central diffusion type tiny-oil ignition combustor. An inner primary air pipe is mounted in a main primary air pipe, one section of the main primary air pipe extends into a tertiary pulverized coal combustion chamber, another section of the main primary air pipe is mounted in the inner primary air pipe, a pulverized coal concentration cone and a vortex-controllable flameexpanding blunt body are sequentially mounted in the inner primary air pipe along a flowing direction of fluid, and are coaxially installed; a small section of an L-shaped ignition oil gun in an abrasion-resistant sleeve is aligned with a cone of the vortex-controllable flame expanding blunt body, a small section of an L-shaped air inlet pipe is aligned with the bottom end of the vortex-controllable flame expanding blunt body in a hollow structure, air outlet holes are circumferentially uniformly distributed at the bottom end of the vortex-controllable flame expanding blunt body, and a plurality of circular secondary air inlet holes are equidistantly arranged on a closed end surface of the tertiary pulverized coal combustion chamber. High-temperature flame ejected by the ignition oil gun is ejected onto the flame expanding blunt body, and is obliquely diffused along the outer edge of the blunt body to a wall surface of a round pipe, ignition around a ring surface is realized, and ignition efficiency is greatly improved. In addition, the vortex-controllable flame expanding blunt body can control the size of a high-temperature backflow area formed at an outlet of a primary combustion chamber, so that fuel adaptability can be enhanced.

Owner:CHINA JILIANG UNIV

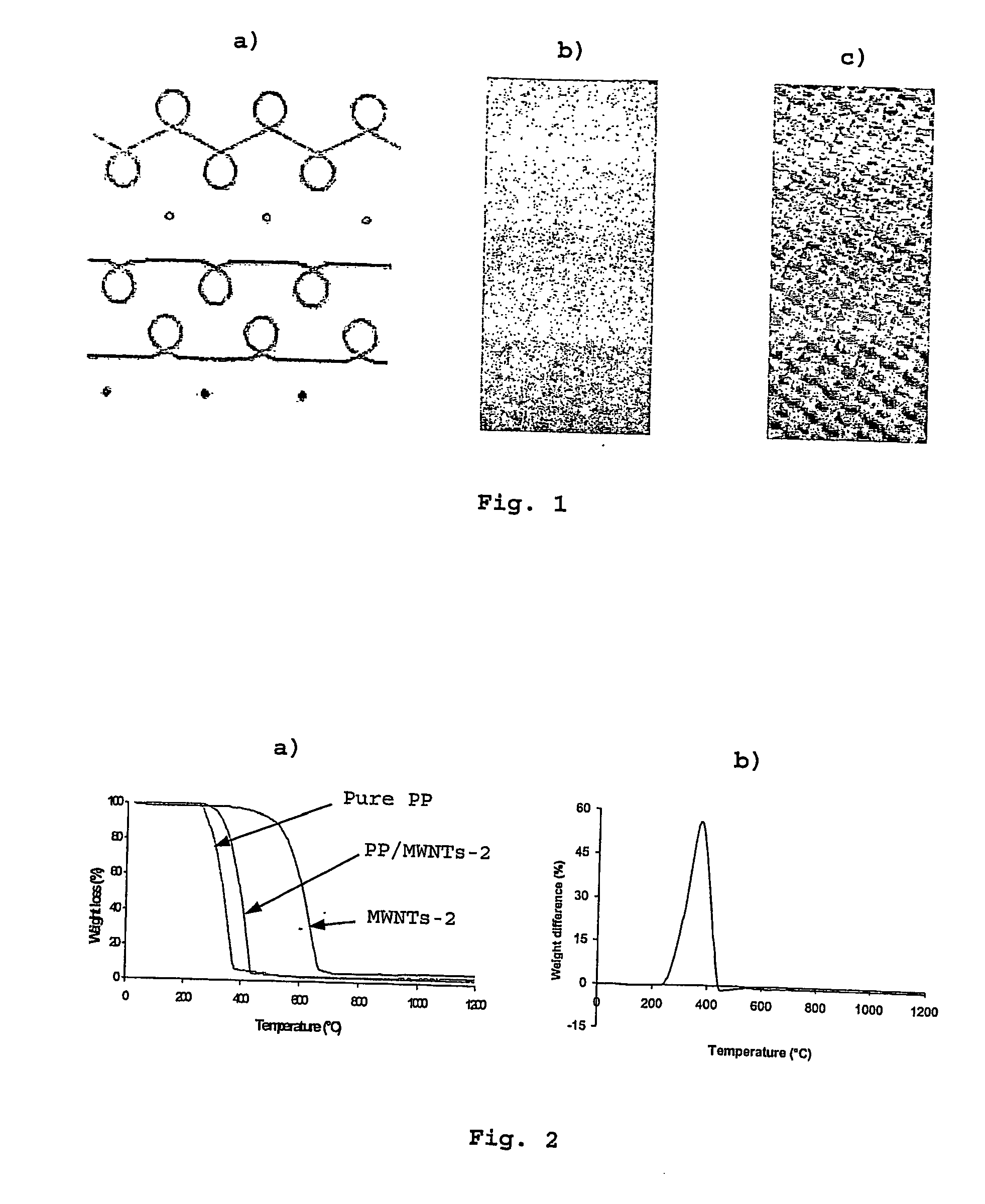

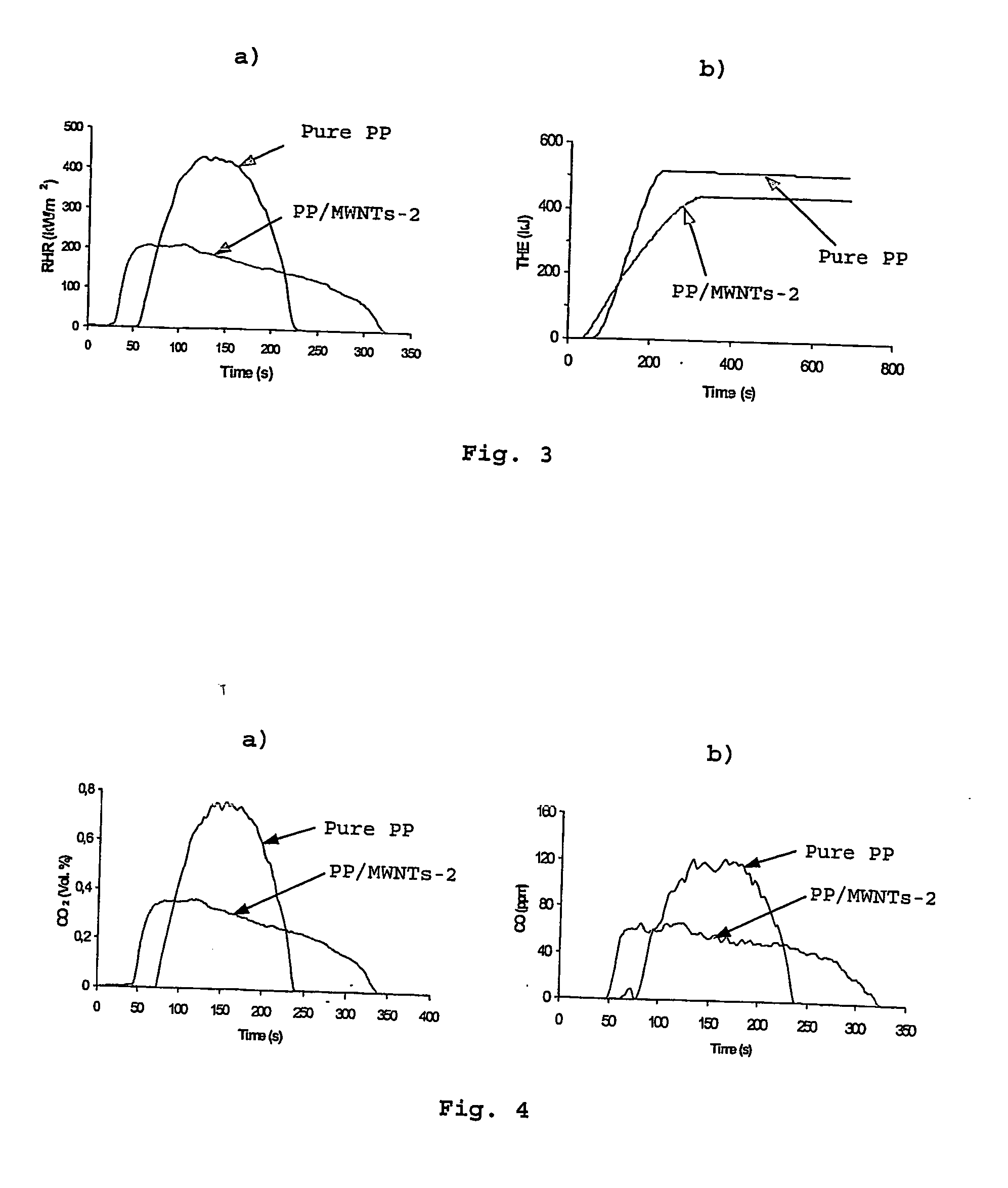

Continuous textile fibers and yarns made from a spinnable nanocomposite

InactiveUS20070031662A1Improve fire stabilityImprove thermal stabilityMaterial nanotechnologyFlame-proof filament manufactureTextile fiberPolymer science

The present invention is related to a multifilament continous textile yarn made by melt spinning of a nanocomposite comprising as components at least one polymer and carbon nanotubes, and to its uses, in particular in the textile industry.

Owner:NANOCYL SA

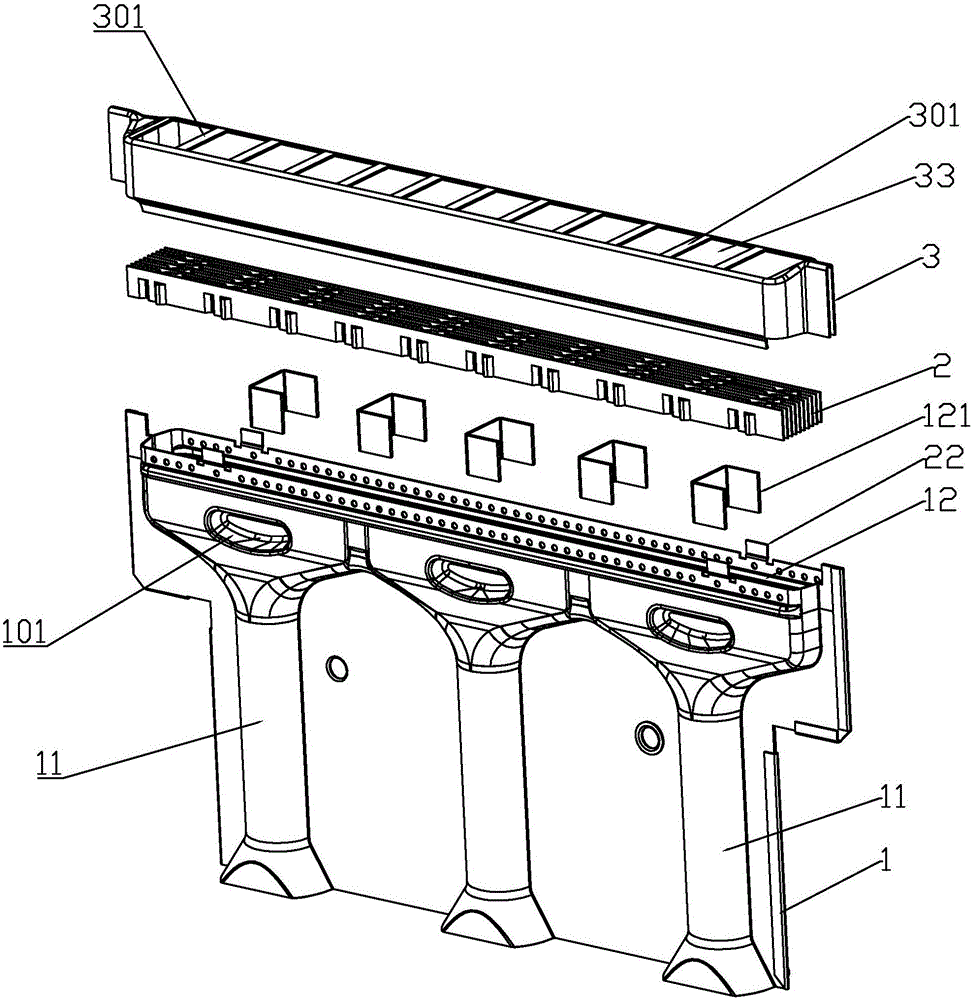

Low nitrogen oxide burner of fuel gas heating water heater

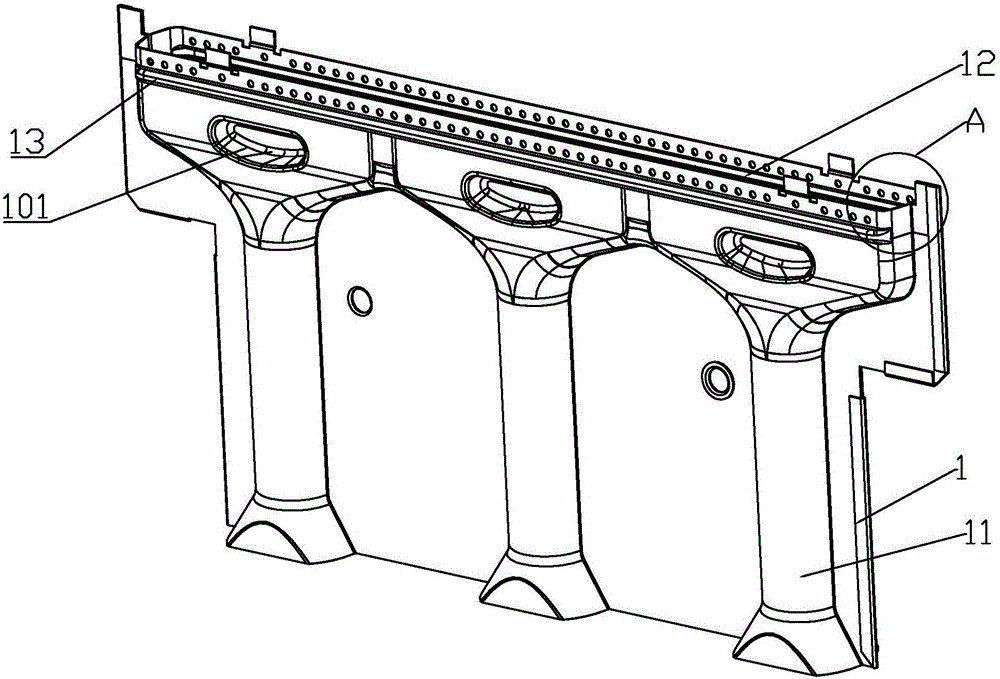

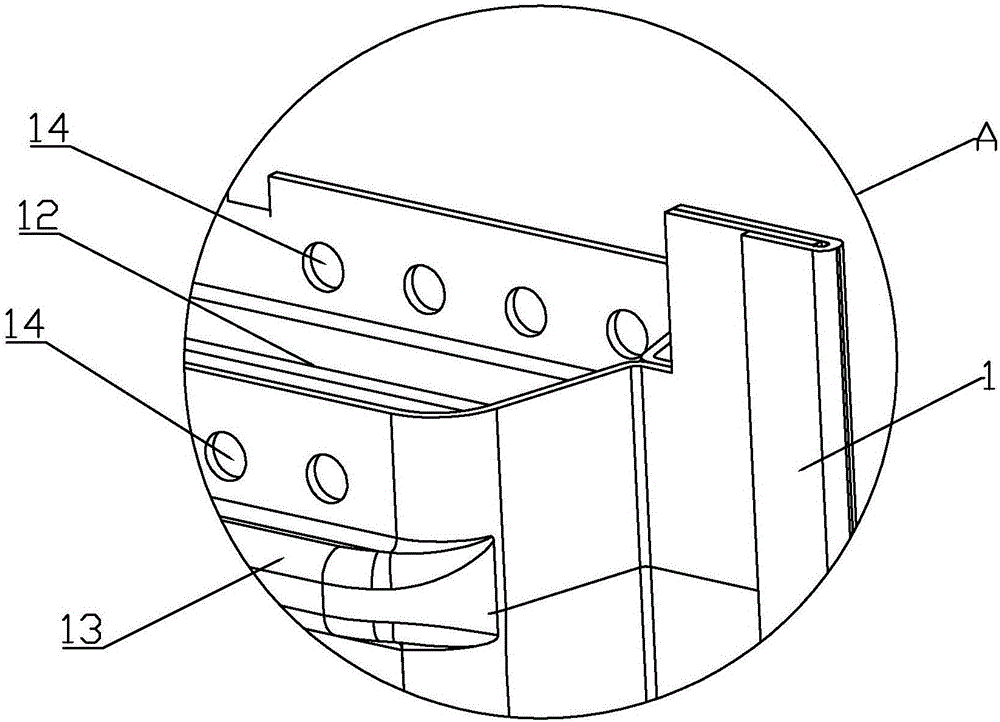

ActiveCN106642109AImprove fire stabilityThe overall thickness is thinGaseous fuel burnerCombustorLow nitrogen

The invention discloses a low nitrogen oxide burner of a fuel gas heating water heater. When the low nitrogen oxide burner is applied, fuel gas and air mixed gas directly rushes upwards through a fuel gas mixing inlet injection pipe; when the fuel gas and air mixed gas collides a fuel gas guide concave bag, due to blocking of the fuel gas guide concave bag, a part of fuel gas and air mixed gas flows to the two sides, the other part of fuel gas and air mixed gas is directly upwards to enter a mixed gas groove, part of fuel gas and air mixed gas is straightly upwards to burn at the top of a fire dividing hole, the other small part of fuel gas and air mixed gas is blocked by a fire receiving hole separating plate to generate positive pressure, and under the influence of the positive pressure, part of gas enter an outer side fuel gas mixing gas dividing groove from a transverse fuel gas and air mixing air flow outlet hole and burns in an outer side burning hole; and the top of a burner shell cover is provided with a plurality of flame burning holes through a plurality of transverse plates in a mesh dividing manner, and the fire power of fire behaviors generated by burning is strong; meanwhile, the flame area is greatly increased, and burning is more sufficient.

Owner:黄婉平

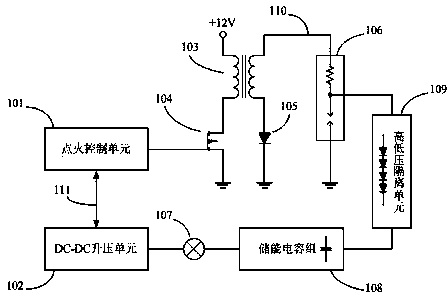

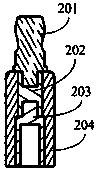

Extra high-energy spark discharge system

ActiveCN103423061AApparent shock phenomenonPromote formationSparking plugsIgnition automatic controlCapacitanceHomogeneous charge compression ignition

The invention discloses an extra high-energy spark discharge system. The system comprises an ignition energy control unit, an inductive discharge unit, a DC (Direct Current)-DC boosting unit, an energy-storage capacitor bank and a combined outward opening-type spark plug. According to the system, by inductive discharge, a spark plug gap is broken down, and a plasma channel is formed between a positive electrode and a negative electrode, and therefore, a high-energy capacitor connected in parallel near the spark plug is caused to discharge. Different from other high-energy ignition systems, the extra high-energy spark discharge system can reach as high as several Joules in single ignition energy, and meanwhile, a stable shock wave can be formed to prompt the formation of a fire core. The extra high-energy spark discharge system can be used for lean combustion occasions with higher flow rate and lower temperature, such as high-latitude gas turbine engine restart, pulse detonation engine start, homogeneous charge compression ignition piston engine ignition, pressurizing direct injection gasoline engine ignition and the like. The combustion stability can be remarkably improved, the combustion efficiency is improved, and pollutant emission during a combustion process is reduced.

Owner:TONGJI UNIV

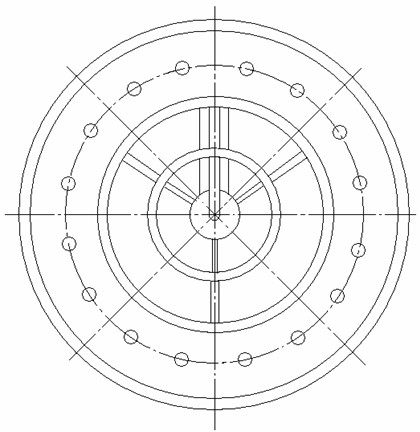

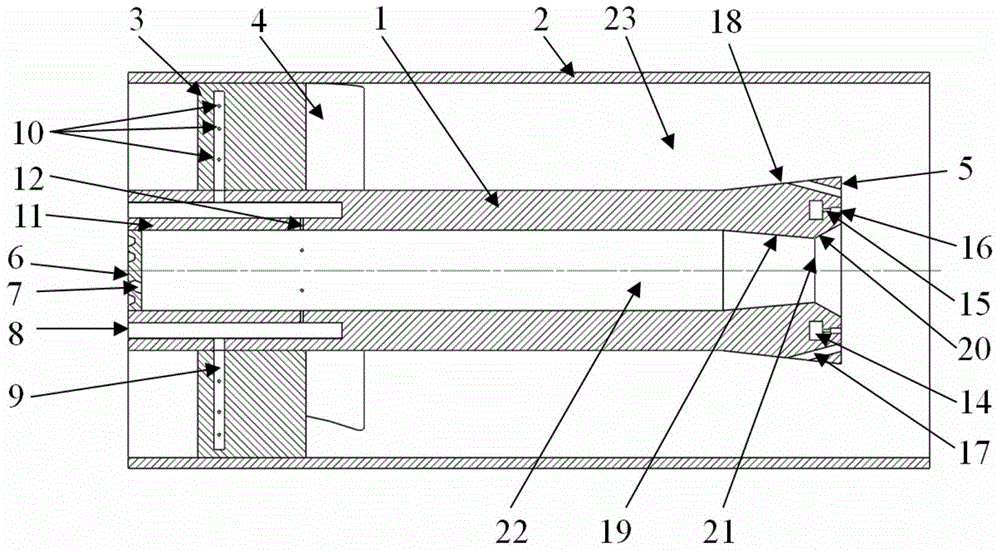

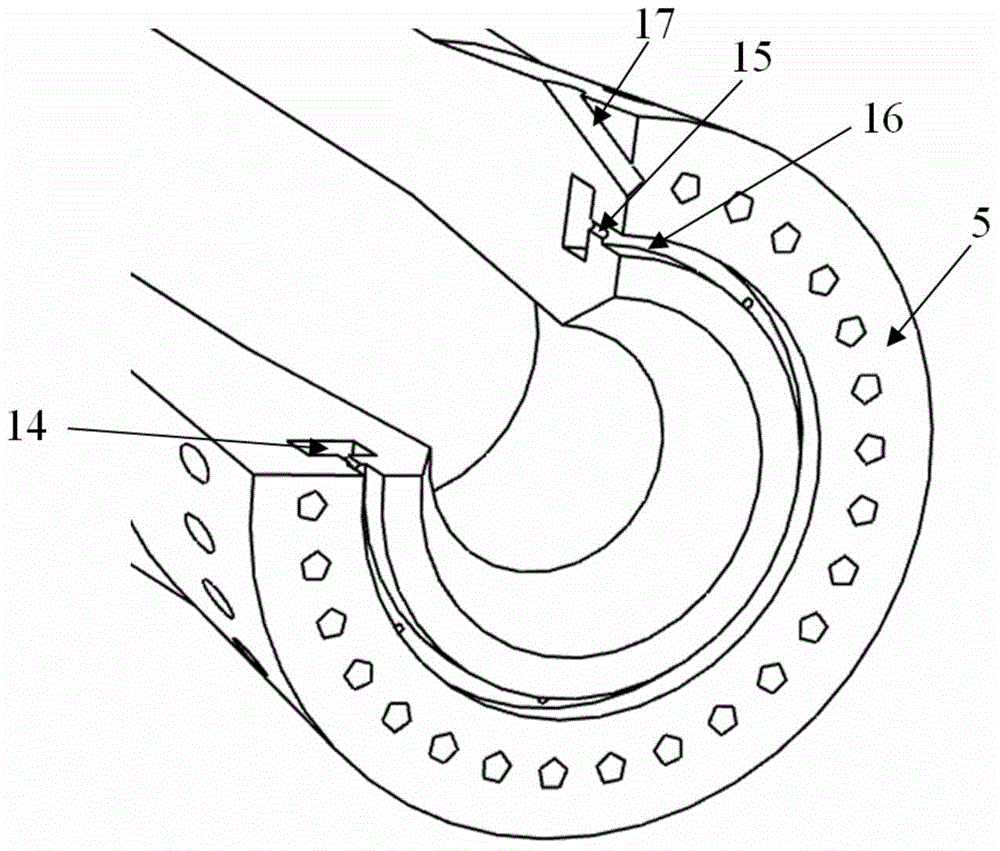

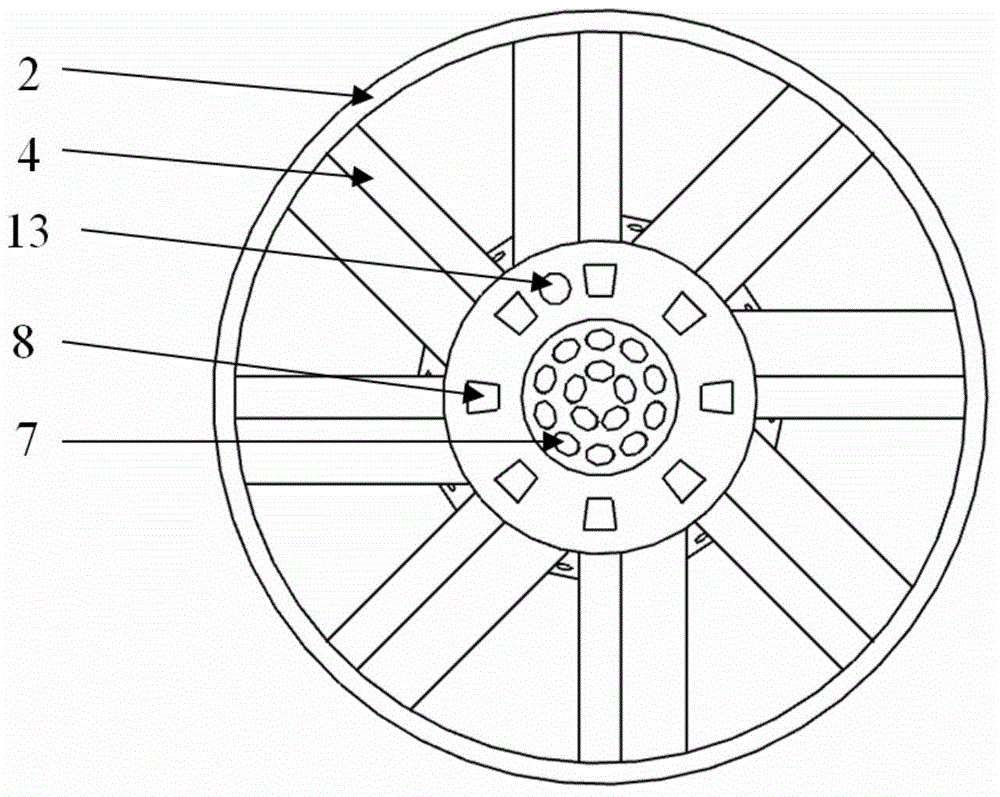

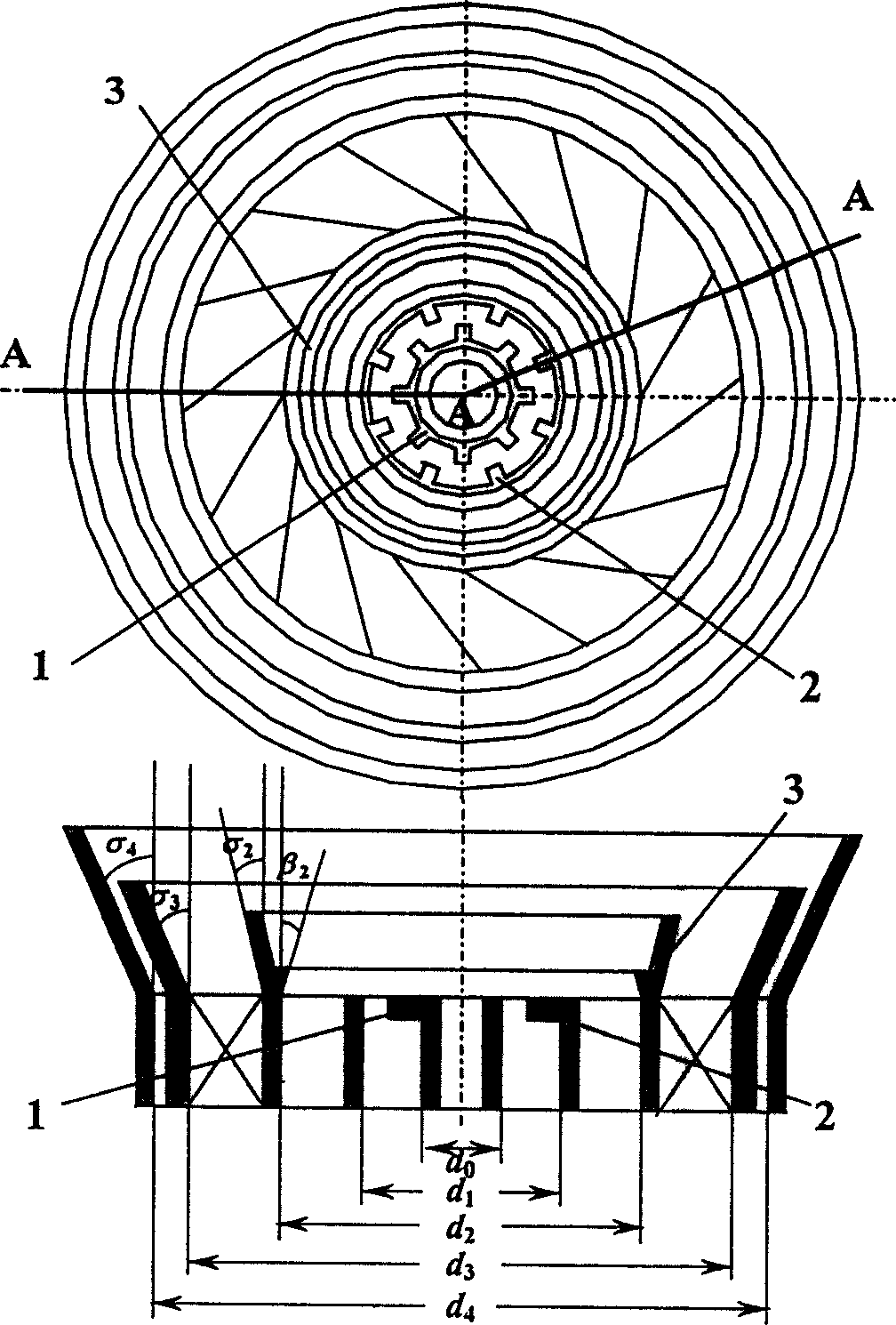

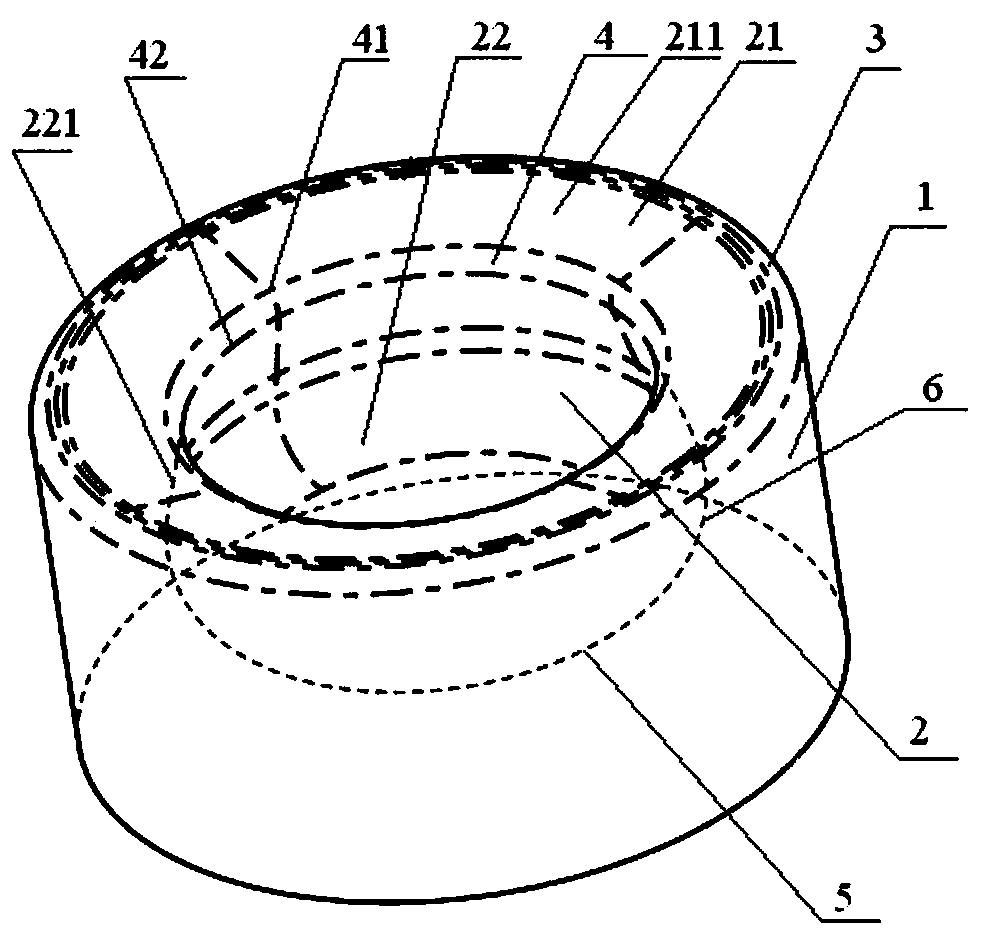

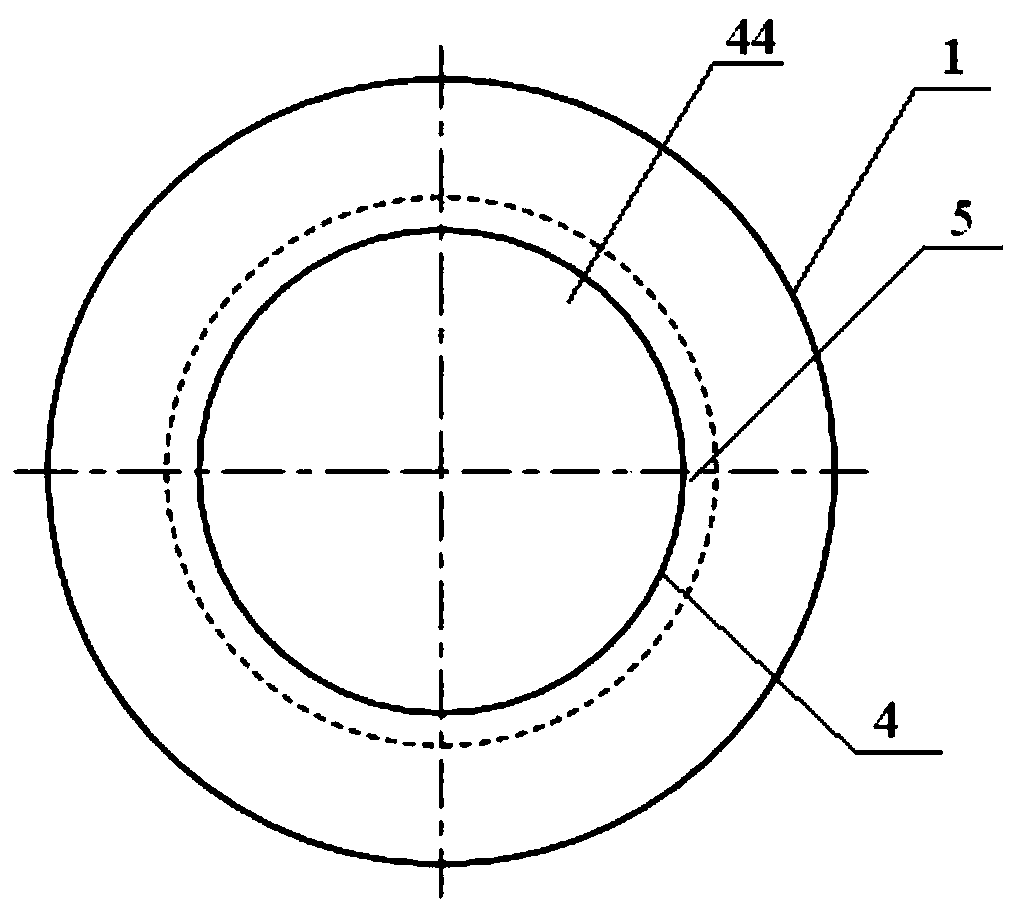

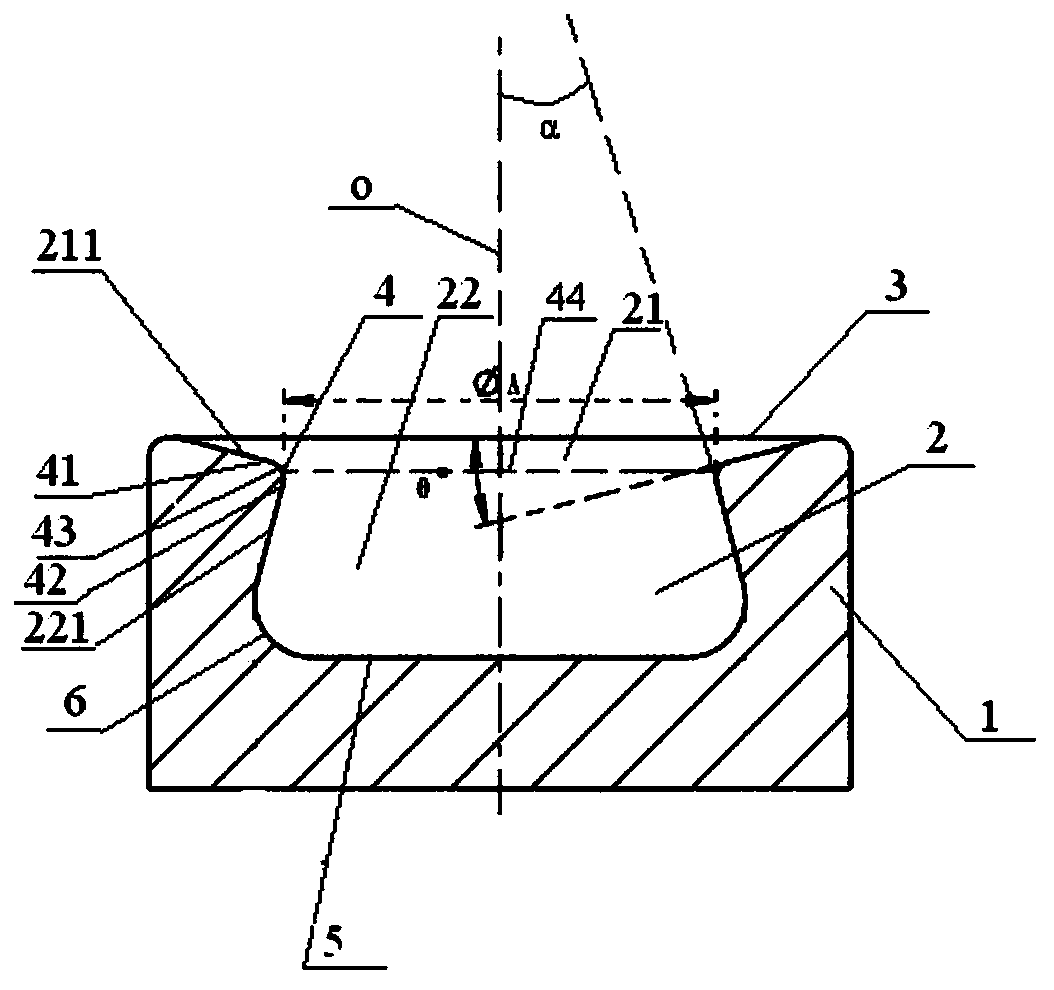

Swirl pulverized coal burner

ActiveCN103629663AEnhanced mixing processEmission reductionPulverulent fuel combustion burnersNon-combustible gases/liquids supplyEngineeringCoal

The invention discloses a swirl pulverized coal burner which comprises a central wind channel, a primary wind channel, a secondary wind channel and a tertiary wind channel. An oil gun pipe with an oil nozzle is arranged in the central wind channel, a combustion stabilizing cover is arranged on the wind outlet of the central wind channel, a pulverized coal inspissator is arranged in the primary wind channel, and secondary wind swirl vanes are arranged in the secondary wind channel. A secondary wind separating layer is arranged between the secondary wind channel and the primary wind channel. Primary wind blocking blocks dividing pulverized coal airflow into multiple channels to be sprayed out are evenly distributed on the wind outlet of the primary wind channel in the peripheral direction, secondary wind blocking blocks with guide rods are evenly distributed on the wind outlet of the secondary wind channel in the circumferential direction, and tertiary wind blocking blocks with guide rods are evenly distributed on the wind outlet of the tertiary wind channel in the circumferential direction. The swirl pulverized coal burner can reduce the discharge value of combustion pollutants (NOx), improve adaptability on changes of types of coal, and enhance combustion stability, and the application range of the swirl pulverized coal burner is wide.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

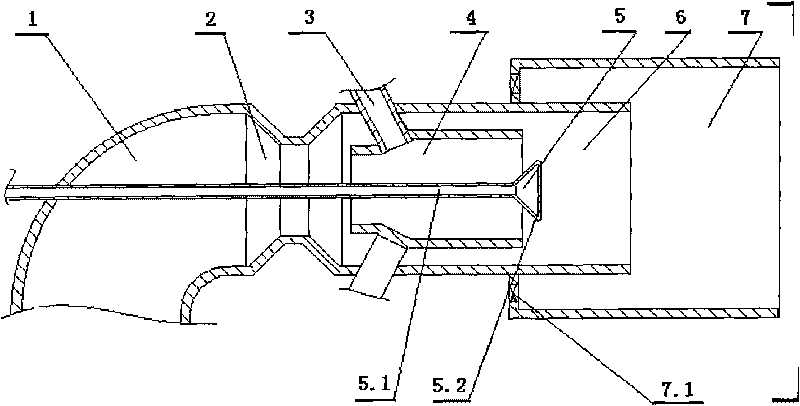

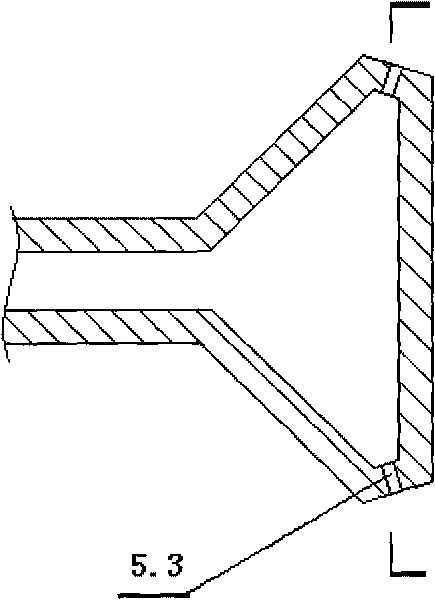

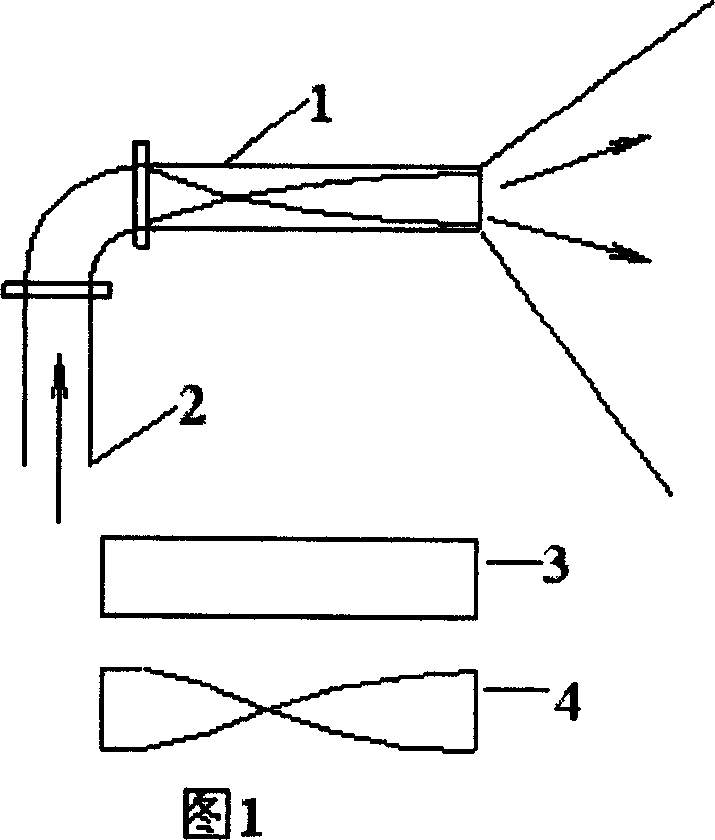

Coal type less oil ignition burner capable of controlling vortex width

InactiveCN101696802AHeating fastExtended stayPulverulent fuel combustion burnersCombustorCombustion chamber

The invention discloses a coal type less oil ignition burner capable of controlling the vortex width. A primary air pipeline of the coal type less oil ignition burner is communicated with a second-stage pulverized coal burning chamber through a pulverized coal condenser; a first-stage pulverized coal burning chamber is arranged in the second-stage pulverized coal burning chamber which extends into a third-stage pulverized coal burning chamber; and the lateral surface of the third-stage pulverized coal burning chamber connected with the second-stage pulverized coal burning chamber is equidistantly provided with a plurality of secondary air inlets. One end of a central air duct of a controllable vortex bluff body is a cavity cone; the central air duct passes through the primary air pipeline, the pulverized coal condenser and the first-stage pulverized coal burning chamber; the cavity cone extends out and is positioned outside the first-stage pulverized coal burning chamber; and the circumference at the bottom of the cavity cone is evenly provided with a plurality of round holes and a plurality of oil burning chambers obliquely and equidistantly pass through the second-stage pulverized coal burning chamber and then are arranged on the first-stage pulverized coal burning chamber. By adopting the controllable vortex bluff body, the invention prolongs the stay time of pulverized coal in the burners and improves the ignition stability. The invention is not only can be used as the ignition burner, but also can be used as a main burner and a burner with lower load and stable burning.

Owner:CHINA JILIANG UNIV

Coal water slurry gasifying furnace with five nozzles

InactiveCN102161912AStrong turbulent entrainmentExtended stayCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterEngineering

The invention discloses a coal water slurry gasifying furnace with five nozzles. The furnace comprises a furnace body, wherein the top of the furnace body is provided with a top nozzle; the side wall of the furnace body is provided with four side nozzles; the material inlet nozzles of the side nozzles are lower than material outlet nozzles; an included angle formed by the axis of the side nozzles and a horizontal plane is large than 0 degree and less than 90 degrees; and the four side nozzles are arranged on the lower middle part of the furnace body at the same height. In the technical scheme of the invention, the material feeding mode that a single nozzle at the furnace top and multiple nozzles on the furnace side spray material simultaneously is adopted; and compared with the prior art, the furnace disclosed in the invention has a simple structure and can be used for industrial production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

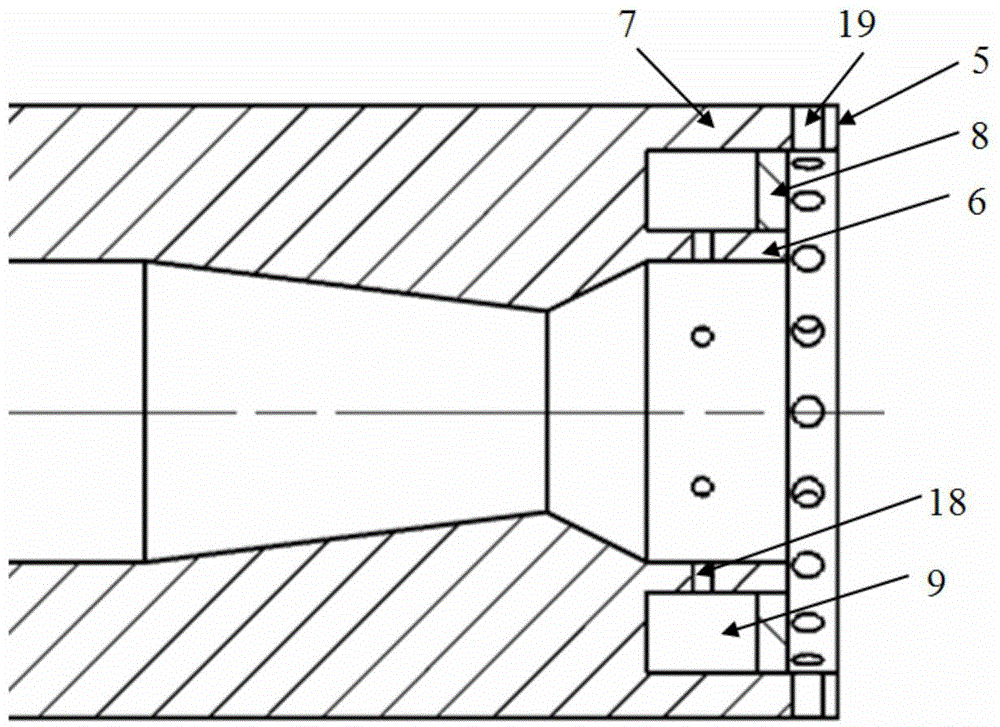

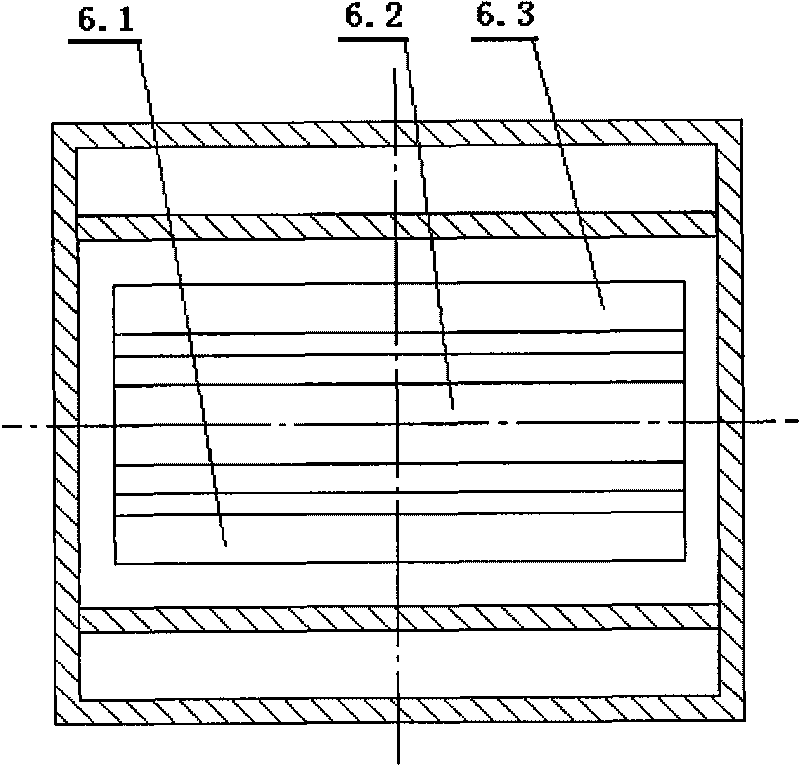

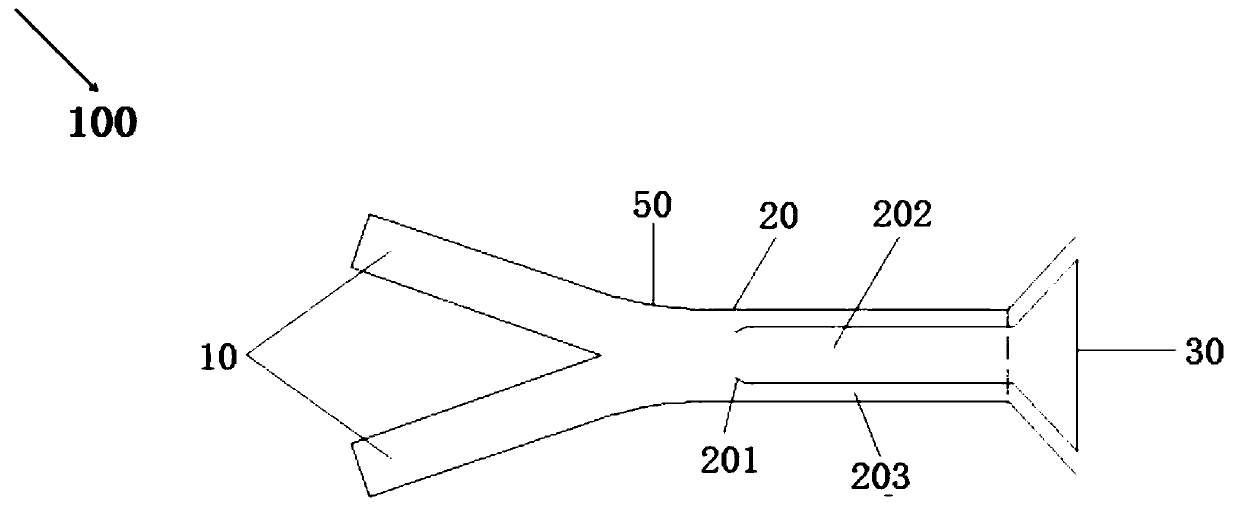

Spray nozzle and gas turbine with same

ActiveCN104566471AImprove fire stabilityImprove combustion efficiencyContinuous combustion chamberPartially premixed combustionPower equipment

The invention relates to the technical field of power equipment, in particular to a spray nozzle and a gas turbine with the same. The spray nozzle comprises a central body, an annular wall and a cyclone device. Premixed fuel channels and a diffused fuel channel which are independent from one another are respectively arranged on the central body; fuel can be respectively sprayed to a central body mixing channel and a peripheral mixing channel by the premixed fuel channels, so that fuel and air mixtures can be formed; fuel can be directly sprayed into the fuel and air mixtures at positions, which are close to the end walls of the central body, by the diffused fuel channel, the fuel and air mixtures are sprayed out of the central body mixing channel, partial premixed combustion flame can be ultimately formed in the center of an outlet of the spray nozzle, the fuel and air mixtures which are sprayed out of the peripheral mixing channel can be ignited, and peripheral premixed combustion flame can be formed. The spray nozzle and the gas turbine have the advantages that the flame stability and the combustion efficiency of the spray nozzle under low-load conditions can be greatly improved under the effect of the partial premixed combustion flame in the center of the outlet of the spray nozzle, and effects of facilitating structure machining and maintaining can be realized.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Spray nozzle and gas turbine

ActiveCN104566472AImprove fire stabilitySimple structureContinuous combustion chamberPower equipmentGas turbines

The invention relates to the technical field of power equipment, in particular to a spray nozzle and a gas turbine. The spray nozzle comprises a central body, an annular wall and a cyclone device. A peripheral mixing channel is formed between the annular wall and the central body, a central body mixing channel is arranged inside the central body, premixed fuel channels and a diffused fuel channel which are independent from one another are further respectively arranged on the central body, fuel can be respectively sprayed to the central body mixing channel and the peripheral mixing channel by the premixed fuel channels, fuel and air mixtures can be formed, fuel can be directly axially sprayed to a flame tube by the diffused fuel channel, and flame modes with middle diffusion combustion flame, inner-layer premixed combustion flame and outer-layer premixed combustion flame can be ultimately formed at an outlet of the spray nozzle. The spray nozzle and the gas turbine have the advantages that the flame stability and the combustion efficiency of the spray nozzle under low-load conditions can be greatly improved under the effect of diffusion combustion; the outlet of the spray nozzle is mainly structurally improved, and accordingly effects of facilitating structure machining and maintaining can be realized.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

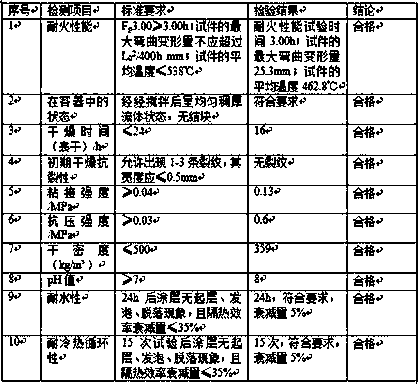

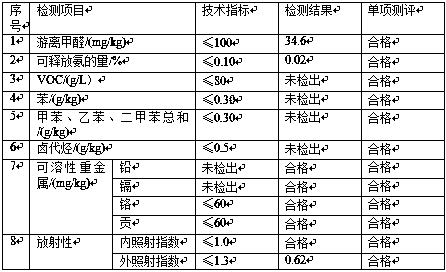

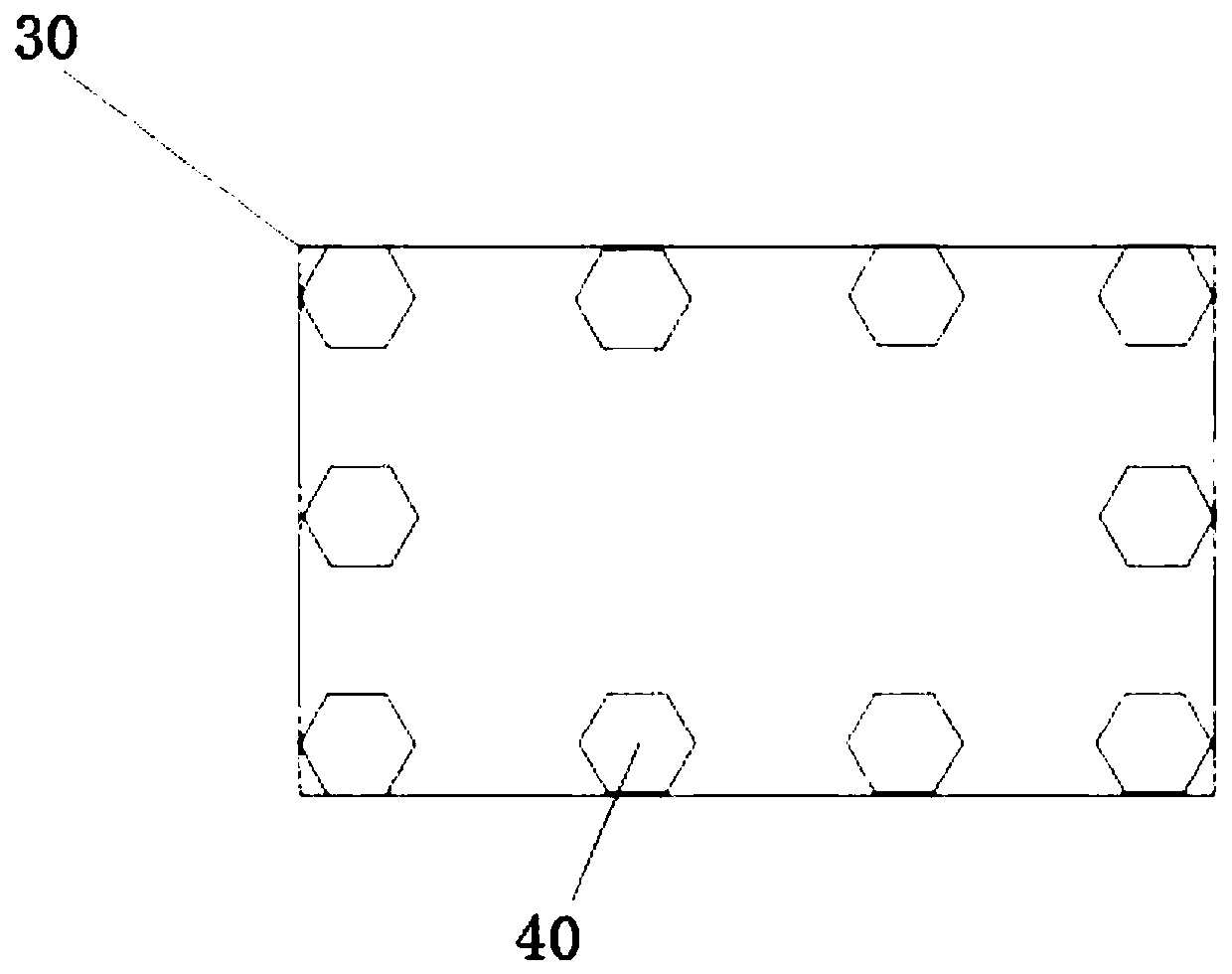

Manufacturing method of wooden fireproof door and wooden fireproof door

ActiveCN110900770AImprove fire performanceEffect on fire resistanceFireproof doorsWood treatment detailsFiberMedium density fiberboard

The invention discloses a manufacturing method of a wooden fireproof door and the wooden fireproof door, and belongs to the fireproof door technology field. The manufacturing method of the wooden fireproof door comprises the following steps that a wooden framework is impregnated with a flame-retardant impregnation liquid and dried, and the flame-retardant wooden framework is manufactured; a firstfireproof decorative plate is bonded to one side of the flame-retardant wooden framework, a filling space is formed in the wooden framework, a fireproof filling material is added into the filling space, and primary pressing is performed; then, a second fireproof decorative plate is bonded to the other side of the flame-retardant wooden framework, secondary pressing is performed, and a door plate core is manufactured; and flame-retardant medium-density fiber boards are bonded on outer surfaces of the first fireproof decorative plate and the second fireproof decorative plate of the manufactureddoor plate core, and press fit is performed. By using the manufacturing method of the wooden fireproof door, the filling space defined by the wooden framework and the fireproof decorative plates is filled with the fireproof filling material, then pressing is performed, and a situation that fireproof performance is affected due to a fact that the fireproof filling material loosens and falls off ina later use process is avoided.

Owner:河南赋安消防器材有限公司

Little oil burner of double-sided ignition combination blunt body

InactiveCN101696801AHeating fastExtended stayPulverulent fuel combustion burnersCombustion chamberCoal dust

The invention discloses a little oil burner of a double-sided ignition combination blunt body. A primary air pipeline is communicated with a secondary coal dust combustion chamber through a section of coal dust concentrator formed by a tapered pipeline with a throat part formed through invagination, a primary coal dust combustion chamber is arranged in the secondary coal dust combustion chamber, and the secondary coal dust combustion chamber extends into a tertiary coal dust combustion chamber. The upper side surface and the lower side surface of the tertiary coal dust combustion chamber connected with the secondary coal dust combustion chamber are provided with a plurality of secondary air inlets in equal intervals, an upper oil combustion chamber and a lower oil combustion chamber are arranged on the primary coal dust combustion chamber after aslant penetrating through the secondary coal dust combustion chamber, a combination blunt body is arranged at the port of the secondary coal dust combustion chamber, and a plurality of through-flow holes are arranged on the upper surface and the lower surface of the second coal dust combustion chamber positioned in the tertiary coal dust combustion chamber. By adopting the top and bottom arrangement of two oil guns, coal dust entering into the primary coal dust combustion chamber are ignited in a double side way, which strengthens turbulent mass and heat exchange of coal dust current and oil flame to rapidly heat the coal dust and form a fire curtain, thereby prolonging the residence time of the coal dust and strengthening the ignition process.

Owner:CHINA JILIANG UNIV

Fusion device capable of simultaneously treating polymorphic hazardous wastes

ActiveCN105716093AEfficient dischargeEffective secondary meltingIncinerator apparatusCombustorCombustion chamber

The invention discloses a fusion device capable of simultaneously treating polymorphic hazardous wastes, and relates to a fusion device. The existing solid or liquid hazardous wastes need classified treatment, and the treatment process is complicated, difficult to realize the effects of effective fusion and non-toxic discharge, low in ignition stability and bad in heat energy utilization rate. The top end of a vertical combustion chamber is an inlet end for thin-particle size hazardous wastes; the interior of the vertical combustion chamber is a vertical combustion hearth; a horizontal combustion chamber is arranged below the vertical combustion chamber in an inclined manner; the high end of the horizontal combustion chamber is communicated with the bottom end of the vertical combustion chamber; a first discharging channel and a second discharging channel are formed in the horizontal combustion chamber in sequence; the interior of the horizontal combustion chamber is a horizontal combustion hearth; the interior of the horizontal combustion chamber is divided into a preliminary fusion chamber and a thermal insulation warming chamber in sequence; a reciprocating grate is arranged in the preliminary fusion chamber; and a plurality of warming combustor are arranged in the thermal insulation warming chamber. The fusion device disclosed in the invention is used for treating hazardous wastes.

Owner:国泥工程中心(哈尔滨)有限公司

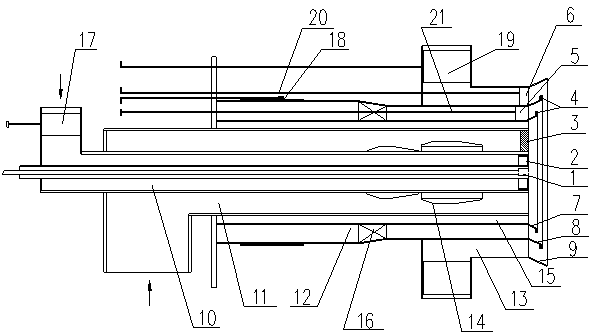

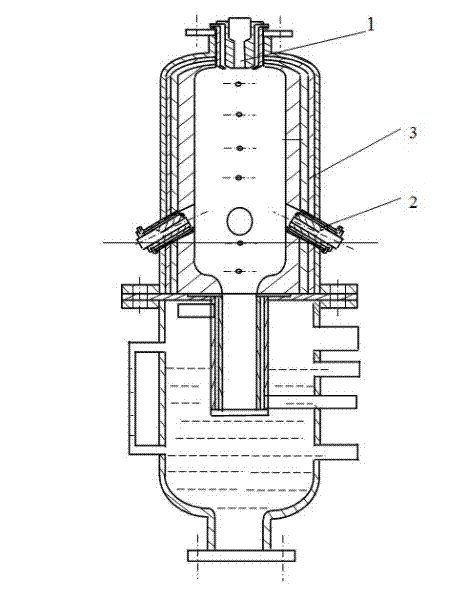

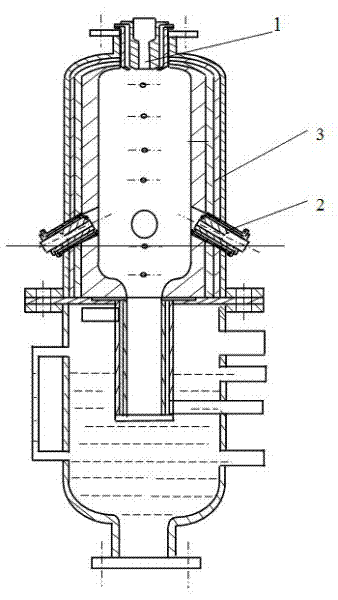

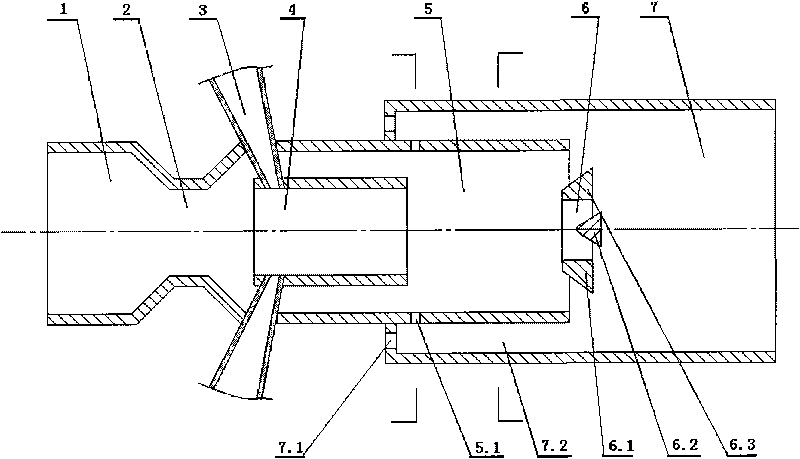

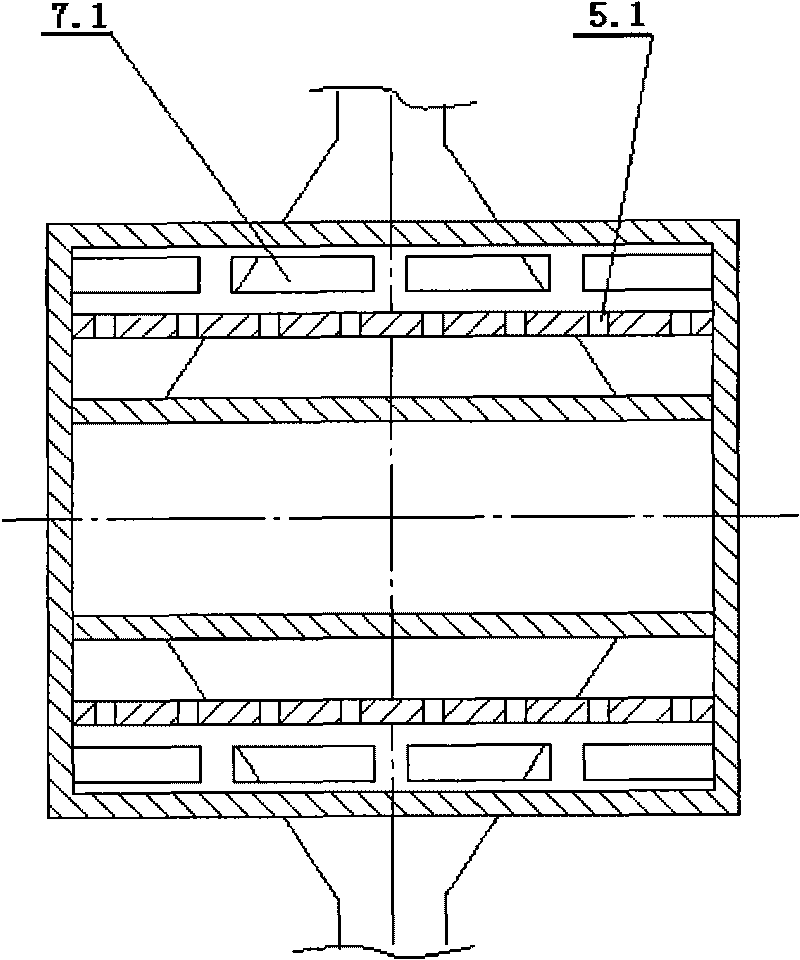

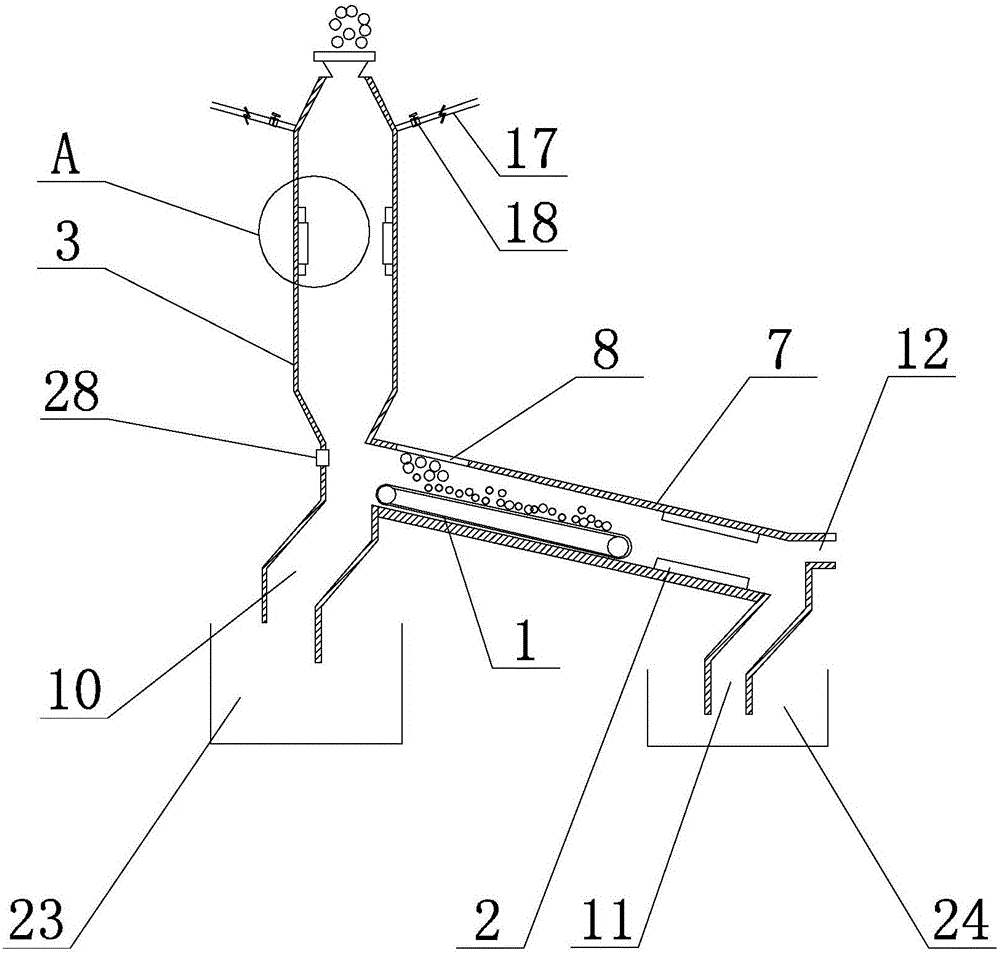

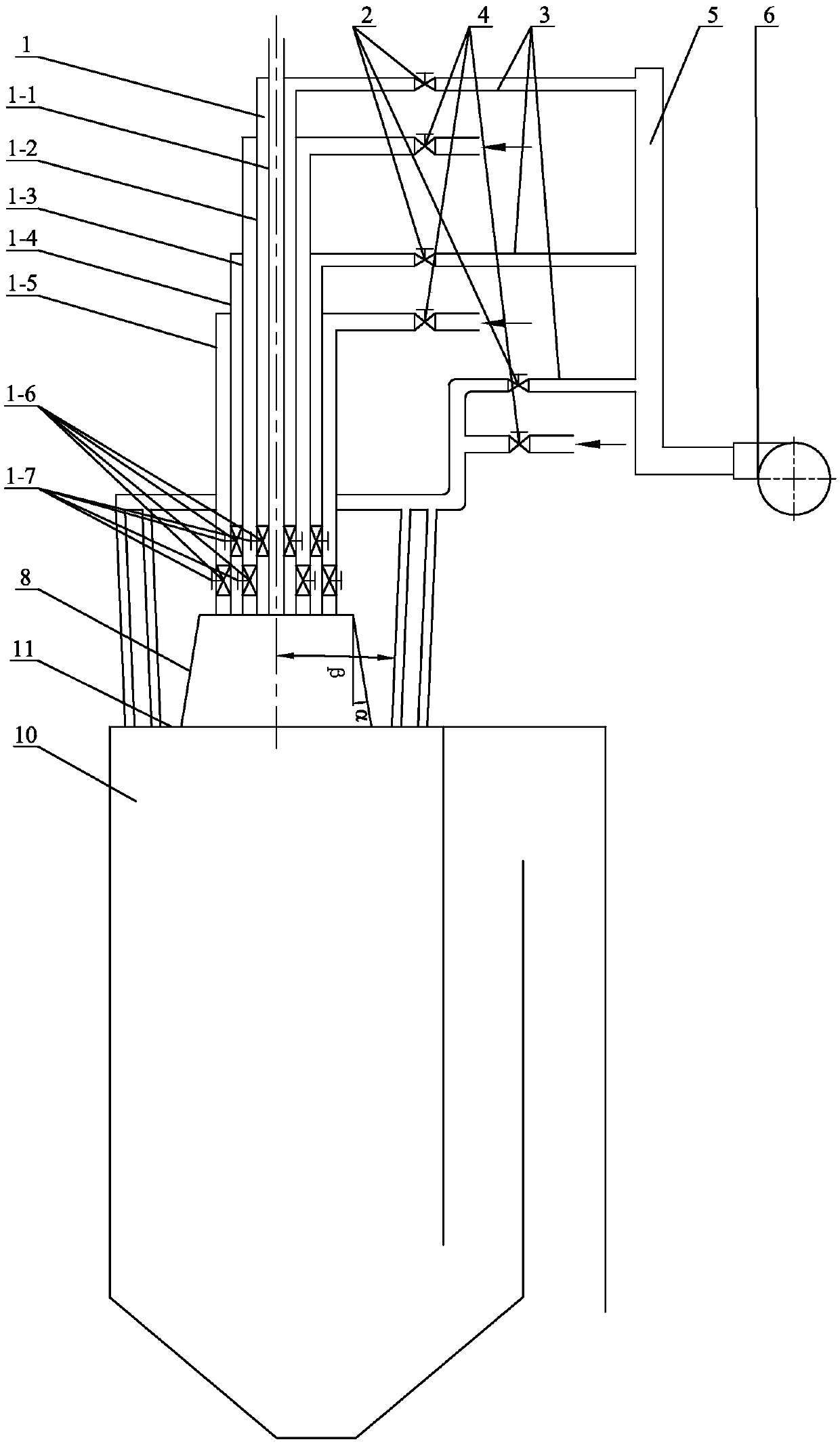

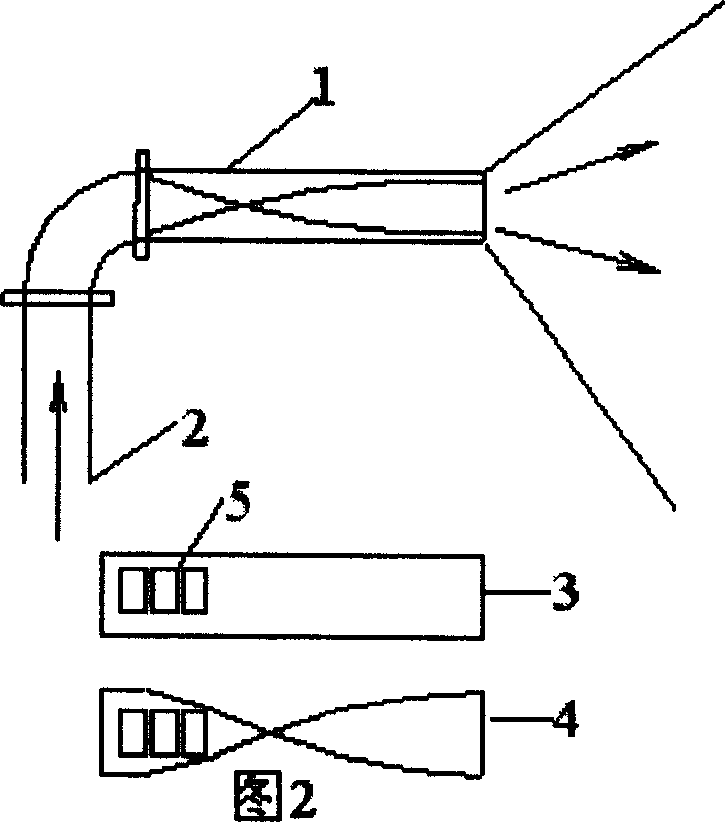

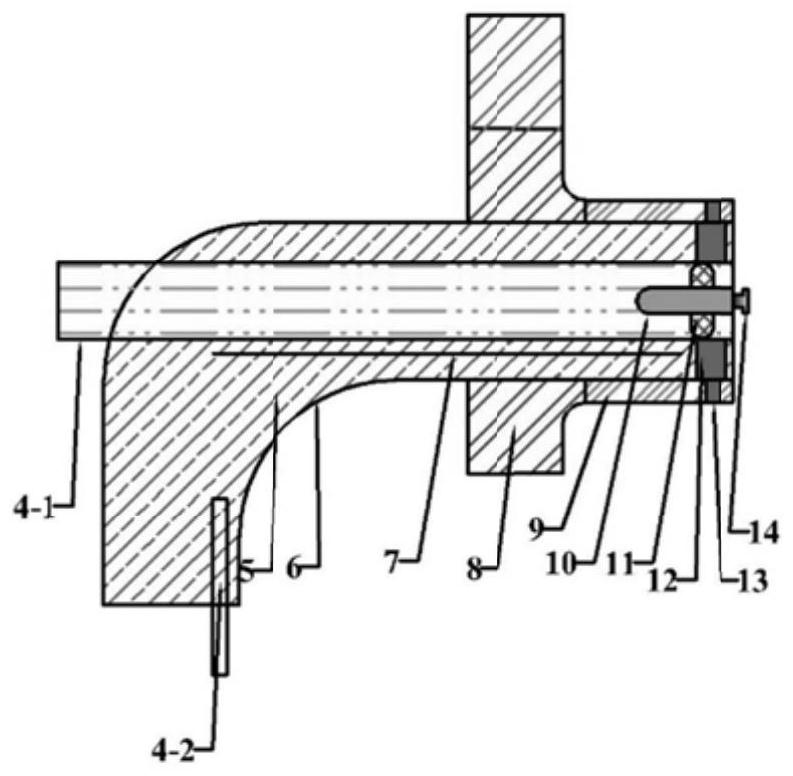

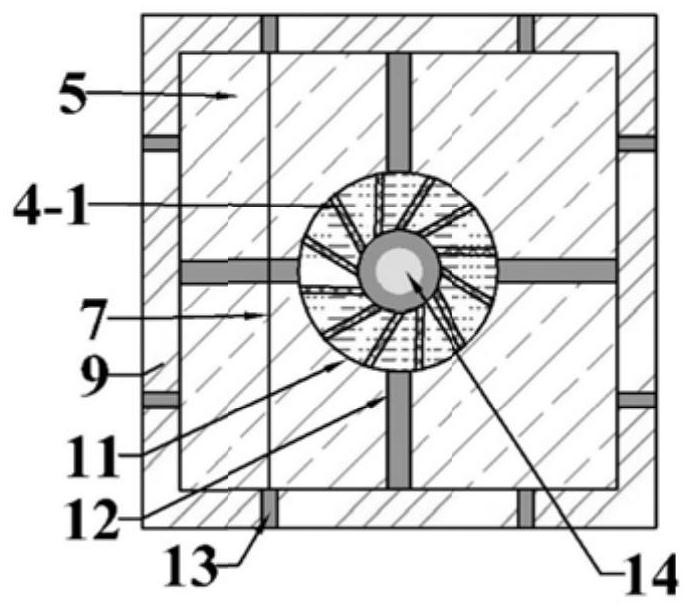

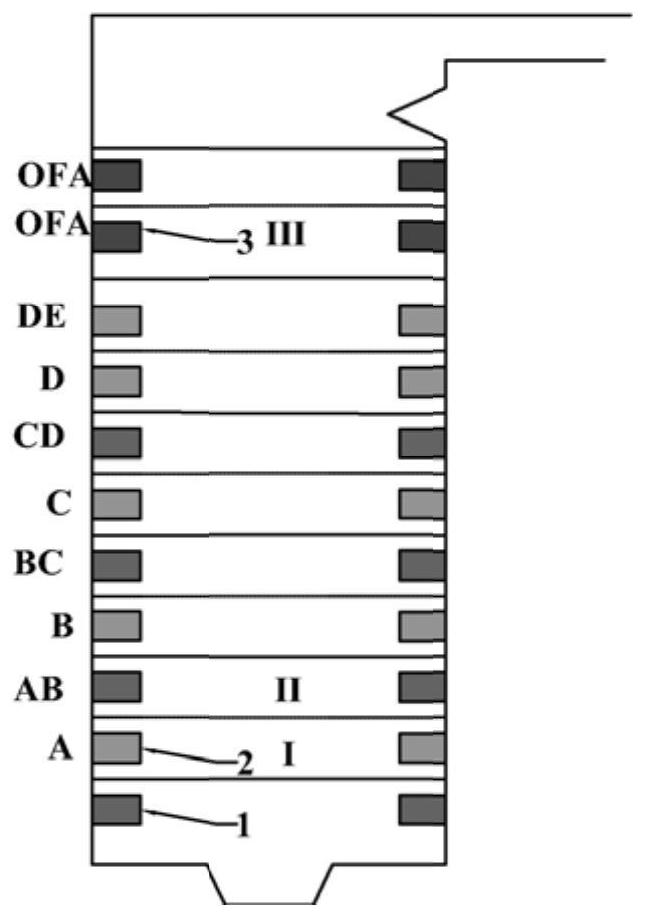

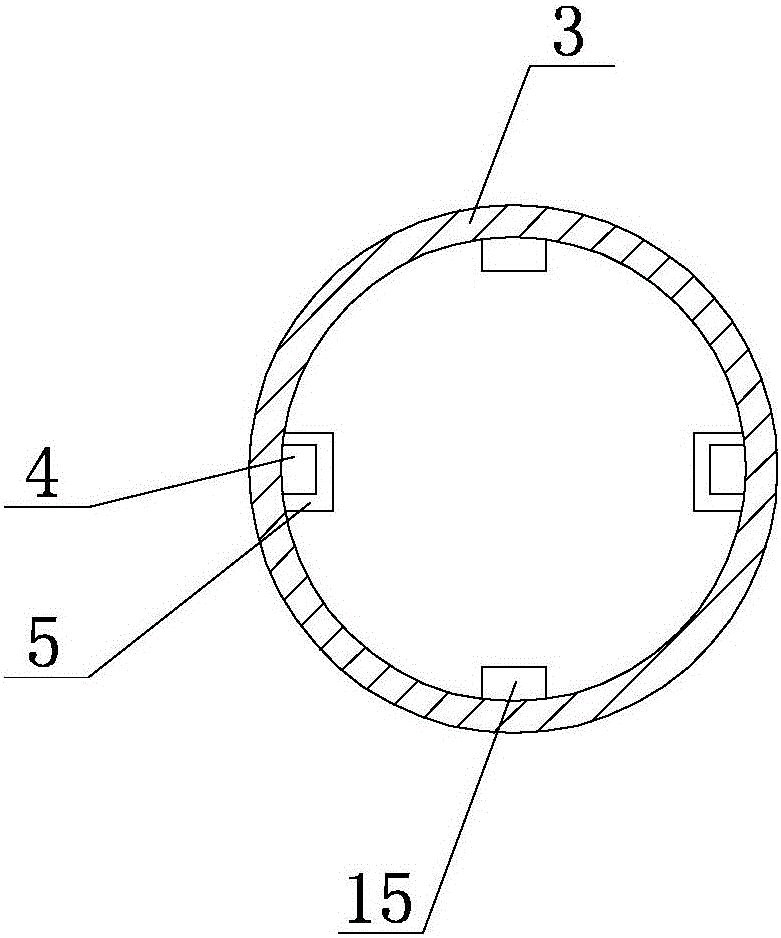

Cyclone pulverized coal combustion device adopting smoke recirculation device and pre-combustion chamber

InactiveCN109654485AReduce NOx productionEnhanced graded combustion degreeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberPre combustion

The invention discloses a cyclone pulverized coal combustion device adopting a smoke recirculation device and a pre-combustion chamber, and relates to the field of industrial pulverized coal boiler combustion devices. The cyclone pulverized coal combustion device solves the problem that in the case of an existing industrial pulverized coal boiler, the NOx emission is large, slagging is serious, the combustible content of fly ash is high, and combustion stability is poor. The cyclone pulverized coal combustion device is characterized in that a cyclone pulverized coal combustor is connected witha boiler through the pre-combustion chamber, an inner-side smoke recirculation air pipe, an inner secondary air pipe, an outer-side smoke recirculation air pipe and an outer secondary air pipe are sequentially and coaxially arranged on a primary air pipe from inside to outside in a sleeving mode, and are internally provided with cyclones, an inlet of the inner-side smoke recirculation air pipe and an inlet of the outer-side smoke recirculation air pipe are connected with the recirculation smoke pipeline correspondingly, a recirculation fan is arranged at the inlet end of a recirculation smokepipeline, the inlet end of a separation secondary air nozzle is connected with the recirculation smoke pipeline and the outer secondary air pipe, and the outlet end of the separation secondary air nozzle is connected with the boiler. The cyclone pulverized coal combustion device is used for reinforcing staged combustion and reducing the concentration of nitric oxide.

Owner:HARBIN INST OF TECH

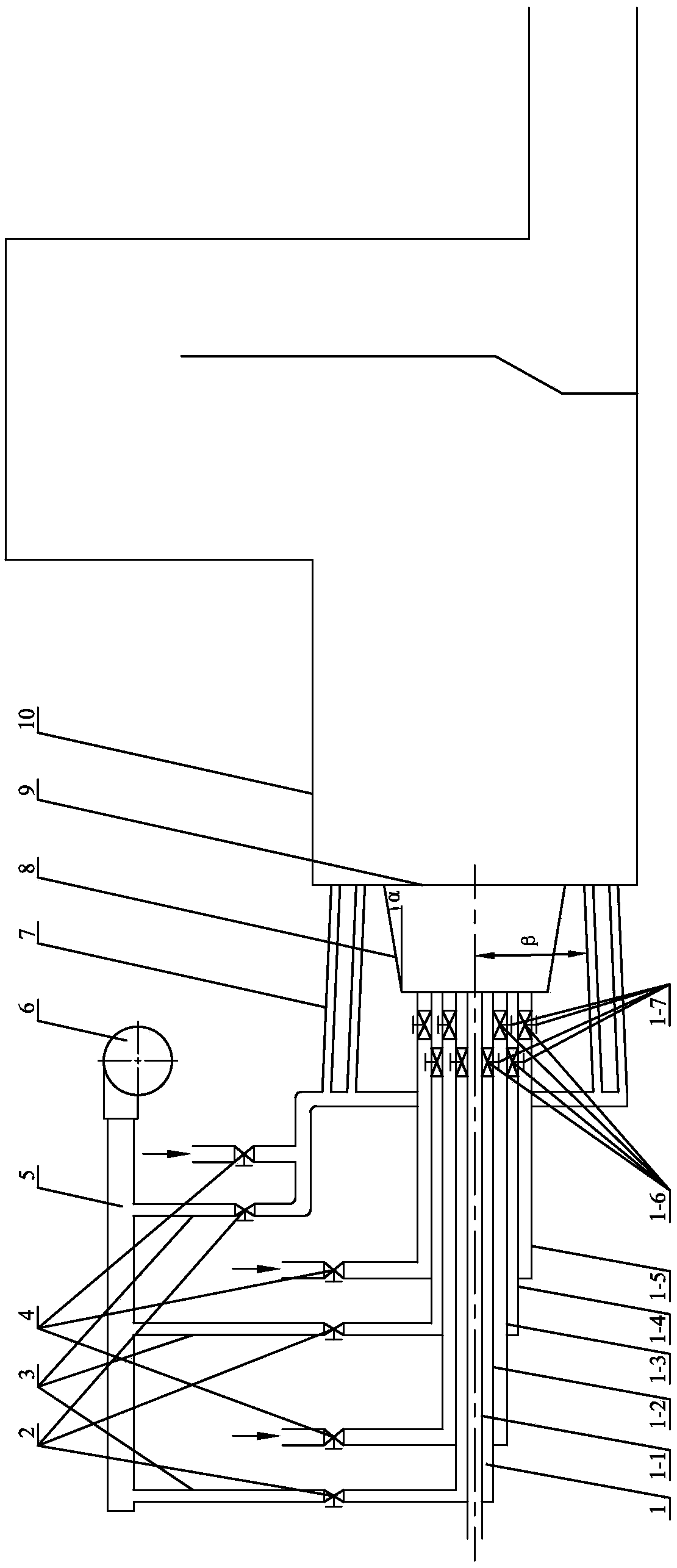

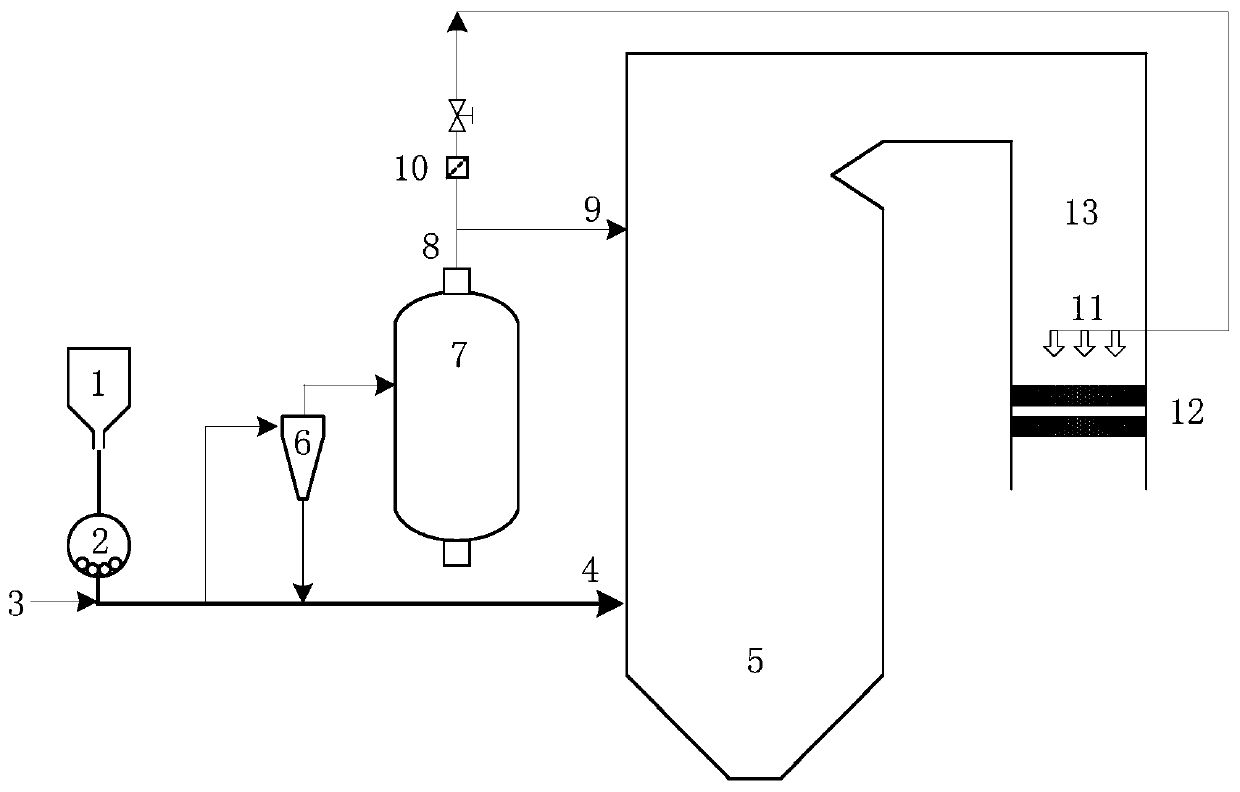

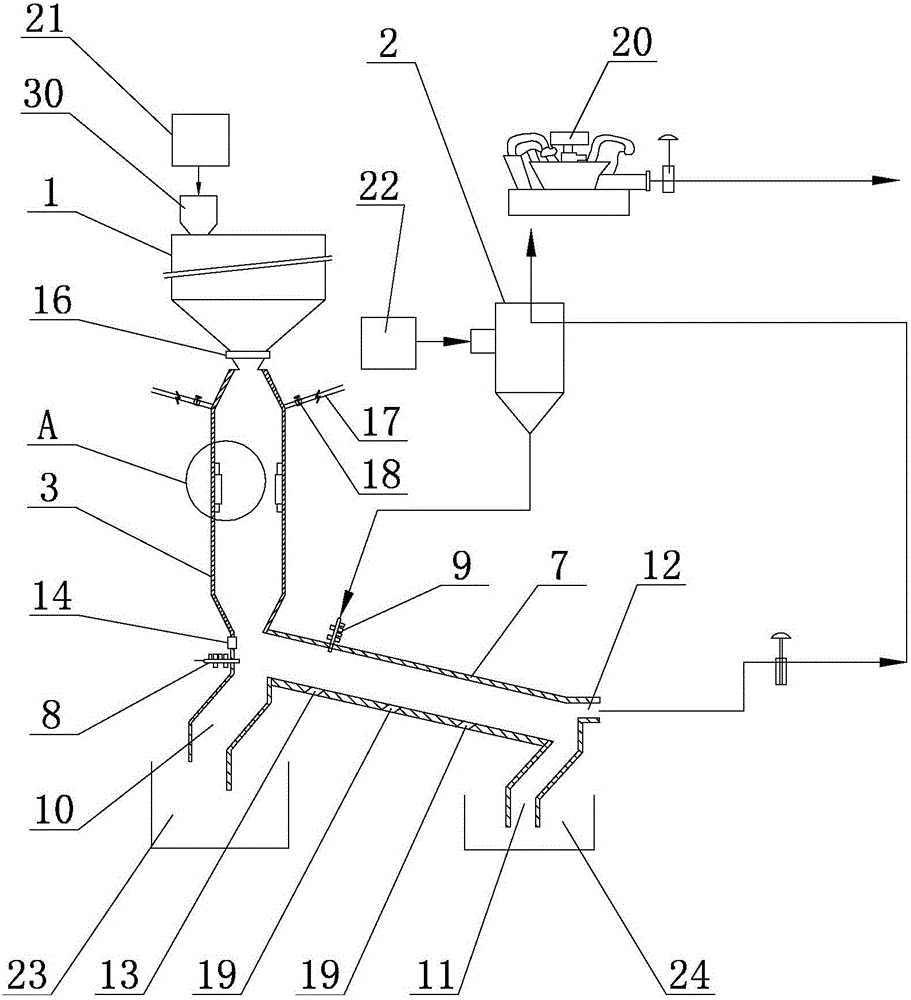

Coal powder partial gasification cooperative denitration system and method

PendingCN111457415AReduce concentrationReduce consumptionGas treatmentDispersed particle separationAir preheaterPtru catalyst

The invention provides a coal powder partial gasification cooperative denitration system and method. The structure is simple, design is reasonable, reformation is convenient, ultra-low emission of nitrogen oxides of a power station boiler can be realized without ammonia injection, and technical economy is high. The coal powder partial gasification cooperative denitration system comprises a coal bin, a coal mill, a boiler, a cyclone separator, a gasification furnace and a filter; a coal outlet of the coal bin is connected with an inlet of the coal mill, a coal powder outlet of the coal mill isrespectively connected with an inlet of the cyclone separator and a burner nozzle arranged in the main combustion area of the boiler, and the coal powder outlet of the coal mill is connected with a primary air pipe; a fine coal powder outlet of the cyclone separator is connected with the burner nozzle, and a coarse coal powder outlet of the cyclone separator is connected with an inlet of the gasification furnace; a coal gas outlet of the gasification furnace is divided into two paths, one path is connected into a flame folding angle area of the boiler through a reburning nozzle, the other pathis connected into a tail flue after passing through the filter, and the tail flue connects the coal gas into the tail flue at the tail of an air preheater through a spray gun; and a catalyst layer isarranged on the downstream part of a spray gun in the tail flue.

Owner:CHINA HUANENG GRP CO LTD +1

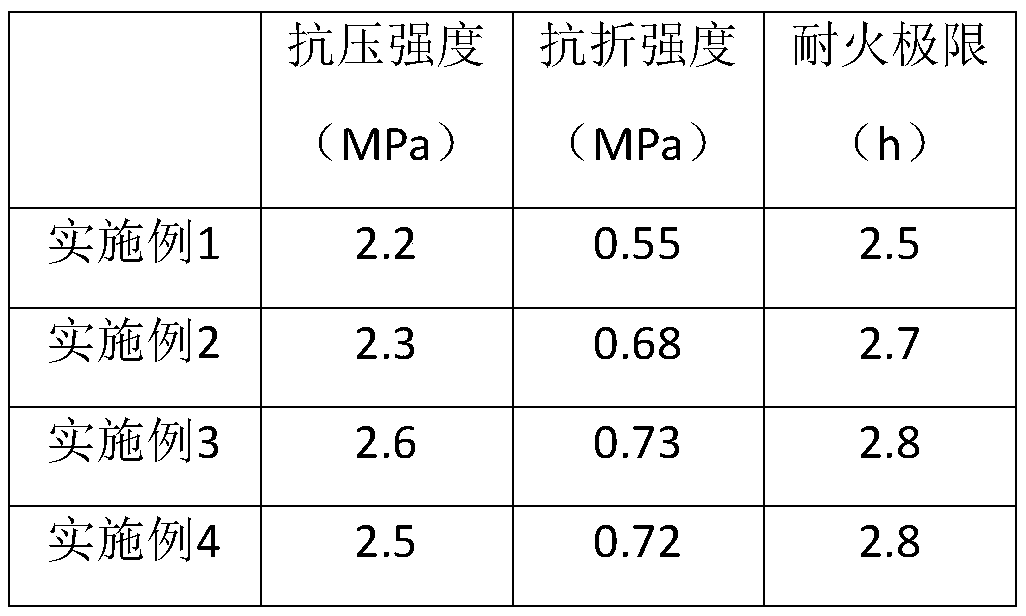

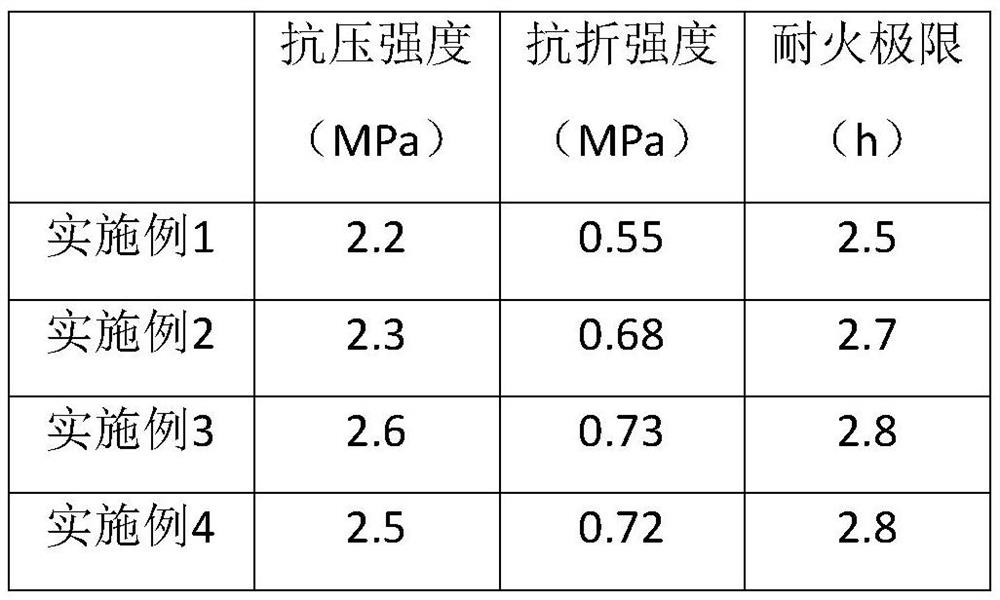

Fireproof material taking gypsum as base material and construction method thereof

The invention relates to a fireproof material taking gypsum as a base material and a construction method thereof, and belongs to the technical field of building materials. The fireproof material taking gypsum as a base material is a two-component system, wherein the component A is prepared from the following materials in parts by weight: 30-80 parts of gypsum, 0-30 parts of polystyrene particles,0-30 parts of vermiculite, 1-15 parts of fiber, 50-100 parts of sodium carbonate, 1-5 parts of graphite, 1-5 parts of alpha-olefin sodium sulfonate, 1-10 parts of gypsum retarder, 1-3 parts of fillerand 1-3 parts of dicalcium silicate; and the component B is modified aluminum hydroxide and accounts for 5-30% of the weight of the component A. By means of the fireproof material, the one-time spraying thickness of a base material can reach 50 mm, and the problem caused by the fact that the thickness requirement is met only when workers conduct spraying on the base material many times is avoided.

Owner:河南中柏防火涂料科技有限公司

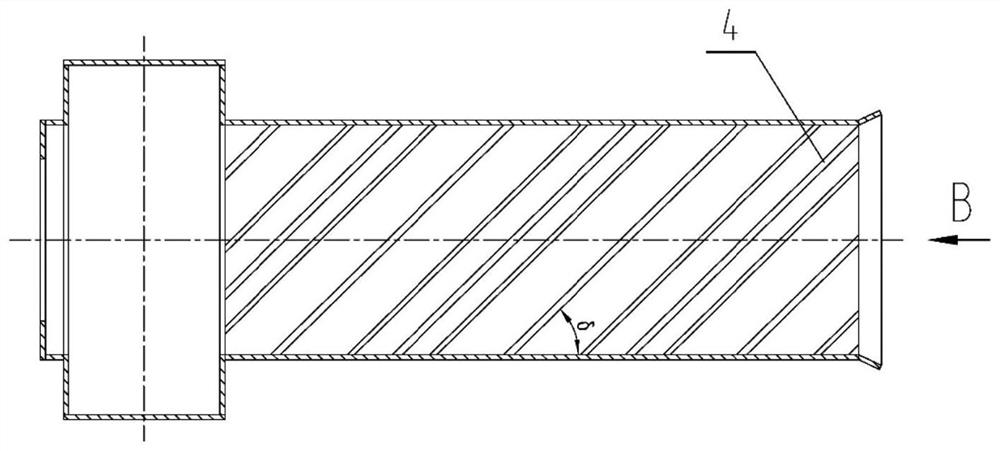

Constant speed retrofitted low NOx coal powder burner

InactiveCN101055076AImprove fire stabilityImprove combustion efficiencyPulverulent fuel combustion burnersCombustorEngineering

A constant velocity shade type low NOx coal powder burner includes a separating blade which is disposed with equalizing pressure grooves. The equalizing pressure grooves are disposed at a place with 0.5-2.5 times equivalent diameter on the separating blade. The number of the equalizing pressure groove is one to five. The separating blade includes a 0 degree flat plate shape separating blade and a 180 degrees helical separating blade. The invention had the following advantages: the constant velocity shade type low NOx coal powder burner is a high efficiency low NOx coal powder burner; the burner conquers the fault that the speed in double passages of the shade burner is unequal, and improves the coal powder concentration of concentrated side by about 20% and reduces the coal powder concentration of the weak side by about 20%. Therefore, the constant velocity shade type low NOx coal powder burner is improved in fire stability, burning efficiency and denitrate rate compared with conventional shade coal powder burner, and is also greatly enhanced in slagging proof and high temperature corrosion proof abilities.

Owner:TONGJI UNIV

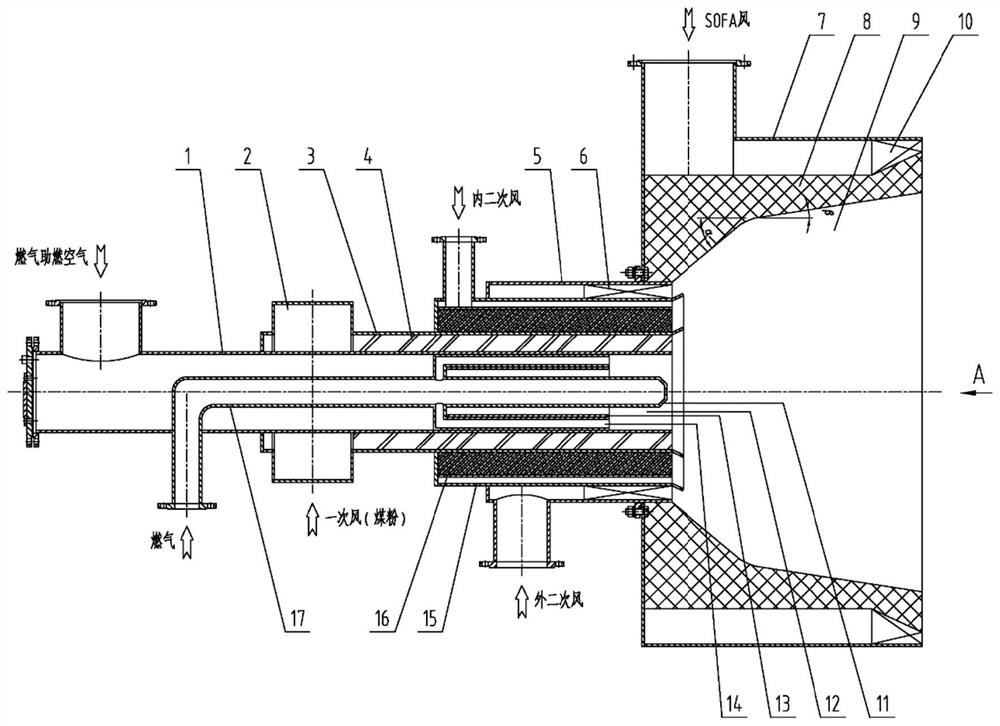

A dual-purpose burner for coal and gas with uniform flow and anti-wear twisted blades

ActiveCN110848693BMeet the requirements of strong adaptabilityEmission reductionPulverulent fuel combustion burnersAir/fuel supply for combustionThermodynamicsFlue gas

The invention discloses a coal and gas dual-purpose burner with flow sharing wear-resistant twisted blades. The coal and gas dual-purpose burner comprises a precombustion chamber arranged on the periphery of an outer secondary air sleeve of the burner and defined by a precombustion chamber shell. The outer side of the precombustion chamber shell is sleeved with an SOFA air sleeve. Convergent SOFAair axial rotational flow blades are arranged at an outlet of the SOFA air sleeve. When the coal and gas dual-purpose burner is used as a pulverized coal burner, the SOFA air axial rotational flow blades enable sprayed SOFA air to form outward diffusion high-speed rotating jet flow around the axis of an outlet of the precombustion chamber. The SOFA air is burned under the condition of MILD combustion, and the formation amount of NOx is remarkably reduced. When the coal and gas dual-purpose burner is used as a gas burner, gas sprayed from gas premixing spray nozzles is rapidly mixed with gas combustion air in a gas premixing channel. High-speed jet inner and outer secondary air entrains a great deal of high-temperature flue gas to flow back. Gas, air and flue gas are dispersed and mixed ina stove chamber and are burned under the MILD condition. The formation amount of NOx is effectively reduced.

Owner:西安交大思源科技股份有限公司

Radial gradient two air-controlled cyclone coal dust combustor

InactiveCN1218140CIncrease concentrationImprove heat transfer performancePulverulent fuel combustion burnersCycloneAir volume

The present invention discloses a radial gradation double air regulation cyclone coal powder burner, including nozzle with burner, internal first air channel, external first air channel, internal second air channel, external second air channel, internal tooth profile combustion-stabilizing ring, external tooth profile combustion-stabilizing ring, double-cone flare, stopper coal powder concentrator and central pipe cyclone coal powder burner. It utilizes two air channels to implement radial gradation combustion.

Owner:XI AN JIAOTONG UNIV

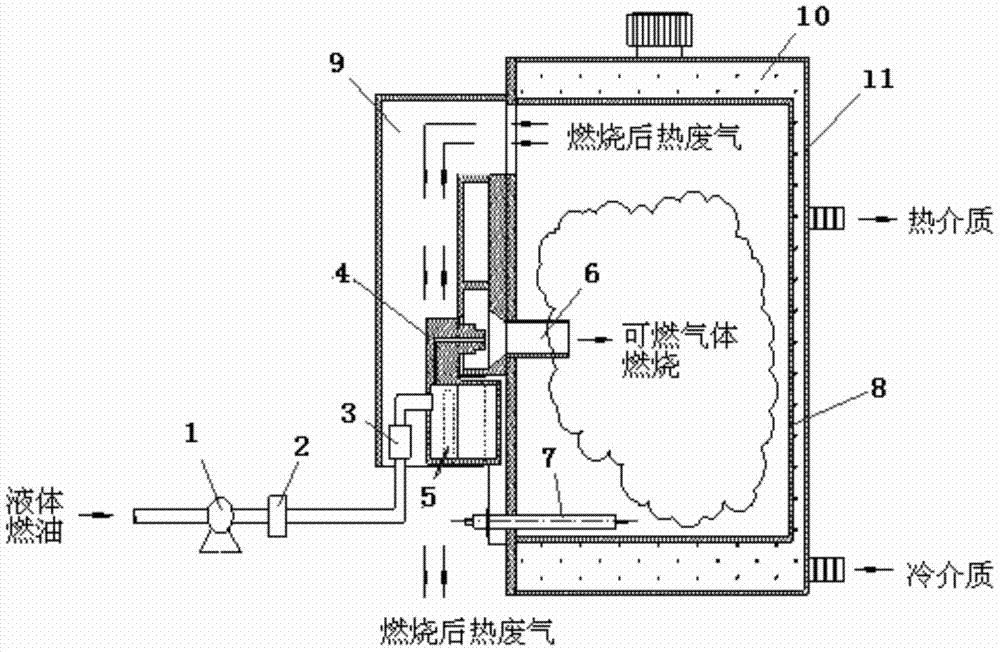

Novel fuel oil heater

ActiveCN104747341ABurn fullyImprove combustion efficiencyAir-treating devicesVehicle heating/cooling devicesCombustion chamberKerosene

The invention discloses a novel fuel oil heater which comprises a fuel oil vaporizing chamber, a preheating electric heater and a combustion chamber. The fuel oil vaporizing chamber is provided with an oil inlet, an oil and gas mixing cavity and a fuel oil vaporizing chamber outlet. The preheating electric heater is arranged in the oil and gas mixing cavity of the fuel oil vaporizing chamber. The combustion chamber is provided with a combustible gas inlet, a combustion waste gas outlet and an ignition device. A spacer region is arranged between the fuel oil vaporizing chamber outlet and the combustible gas inlet of the combustion chamber. Fuel oil gas output from the fuel oil vaporizing chamber and air are mixed in the spacer region. According to the novel fuel oil heater, gasoline, diesel oil and kerosene are used as fuel, fuel oil gasification and combustion are carried out independently, the fuel oil is sufficiently combusted, harmful waste gas emission is reduced, the combustion way is different from the combustion way that gasification and combustion are carried out at the same time by an existing fuel oil heater, ignition and starting are easy at low temperature, ignition is stable, electrical loads of the device are reduced, the structure is simple, micronoise is produced in the starting, working and stopping process, low emission is achieved, and the combustion efficiency is high.

Owner:陈光宁 +3

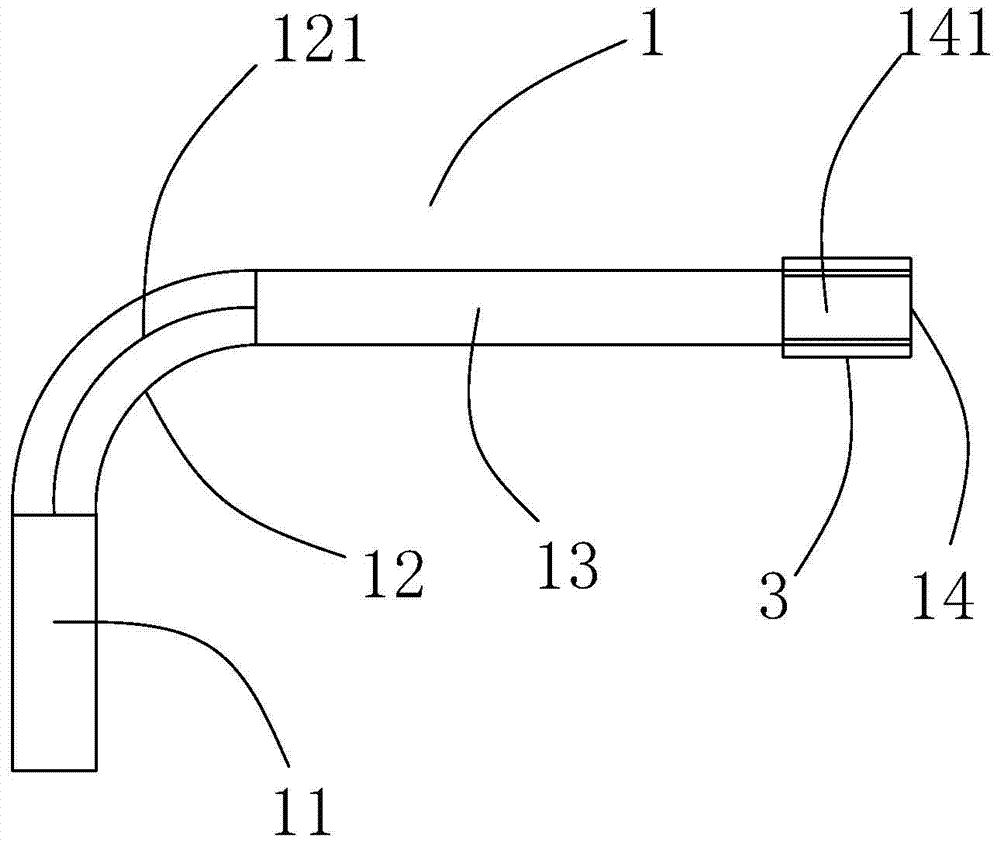

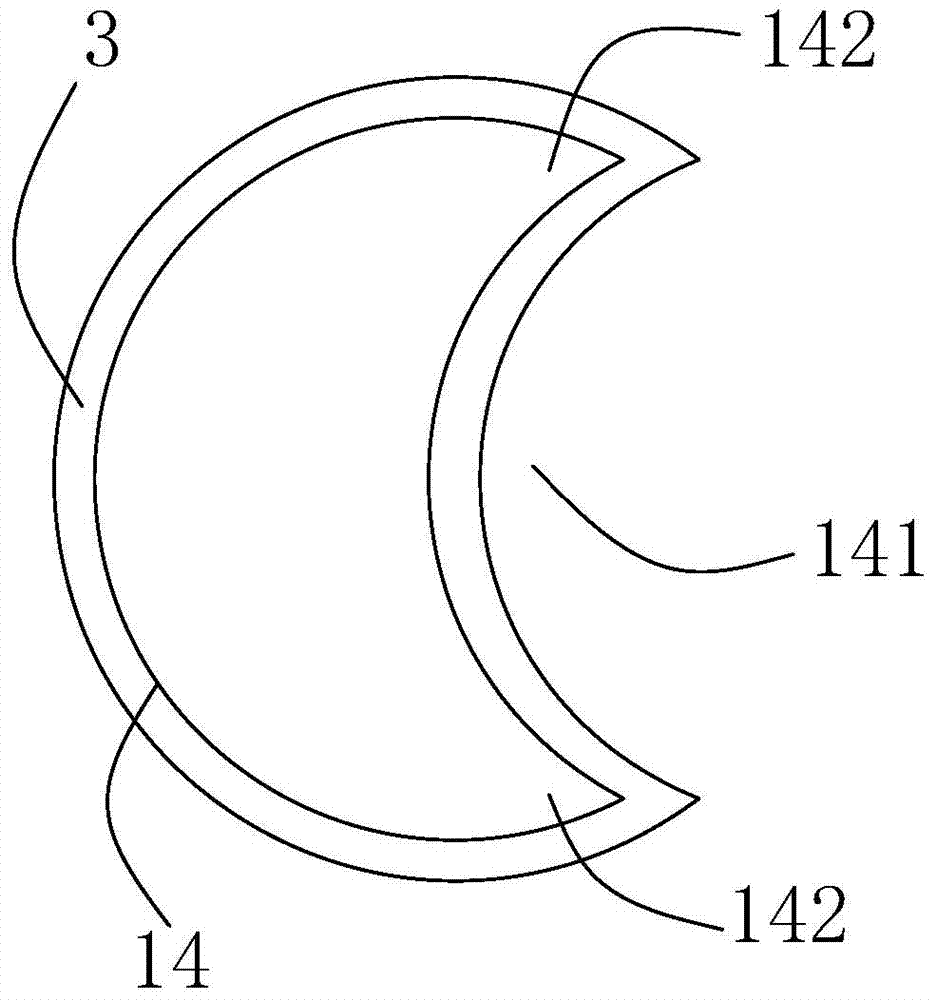

A C-shaped direct-flow burner for pulverized coal furnace

ActiveCN104676585BIncreased ignition surface areaImprove combustion efficiencyPulverulent fuel combustion burnersCombustorAnthracite

Owner:SHANGHAI JIAOTONG UNIV

Coal and ammonia co-combustion burner for corner tangential coal-fired boiler

ActiveCN114738755AWell mixedPrevent wall paintingCombustion using gaseous and pulverulent fuelBurnersCombustorPower station

The invention belongs to the field of combustion equipment and technology, and discloses a coal and ammonia co-combustion burner for a corner tangential coal-fired boiler, which comprises a central air pipe, and a primary air sleeve and a peripheral air sleeve are sequentially sleeved outside the central air pipe; a bluff body supporting column is arranged in the central air pipe, a plurality of axial rotational flow blades are arranged on the bluff body supporting column, a stable combustion bluff body is arranged at the air outlet end of the central air pipe, a plurality of ammonia spraying pipes are arranged at the air inlet end of the primary air sleeve, a flow guide plate and a primary air supporting plate are fixedly arranged in the primary air sleeve, and the flow guide plate is arranged in the axial direction of the central air pipe. The primary air sleeve is connected with the central air pipe through a primary air supporting plate; a peripheral air volute is arranged at the air inlet end of the peripheral air sleeve, a peripheral air supporting plate is arranged in the peripheral air sleeve, and the peripheral air sleeve is connected with the primary air sleeve through the peripheral air supporting plate. The coal-ammonia mixed combustion device is suitable for coal-ammonia mixed combustion, the ignition stability of pulverized coal can be improved, the carbon content of fly ash can be reduced while emission of nitric oxide is not increased, and carbon emission of a power station boiler is reduced.

Owner:XI AN JIAOTONG UNIV

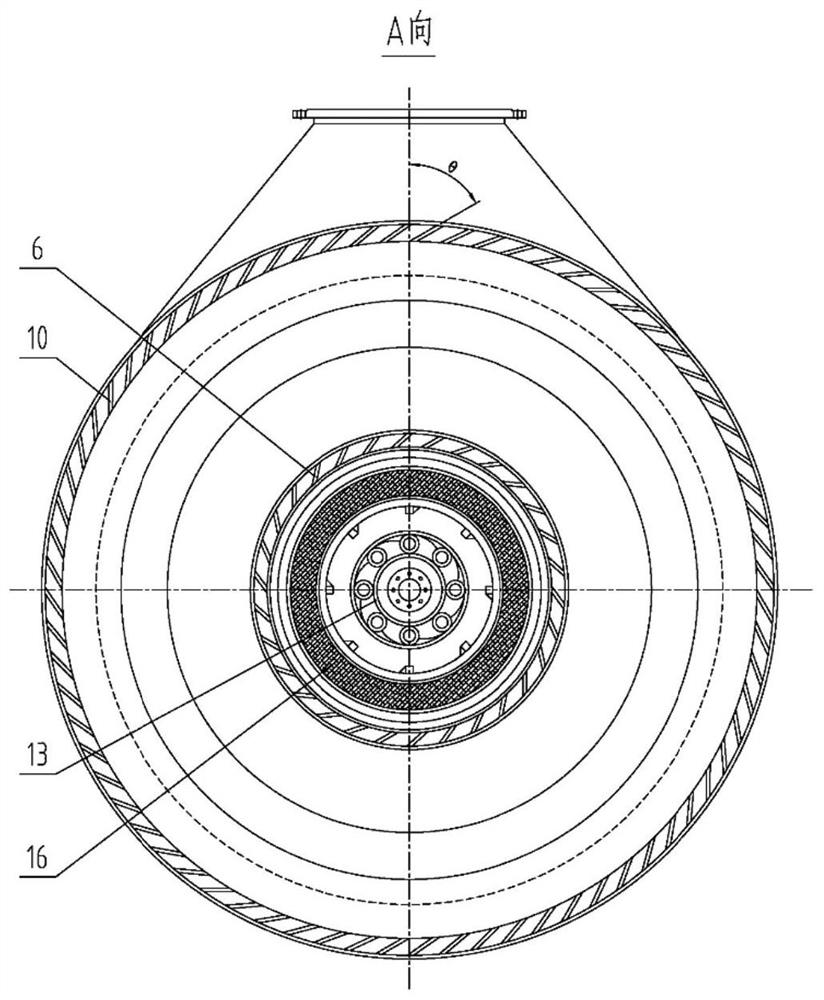

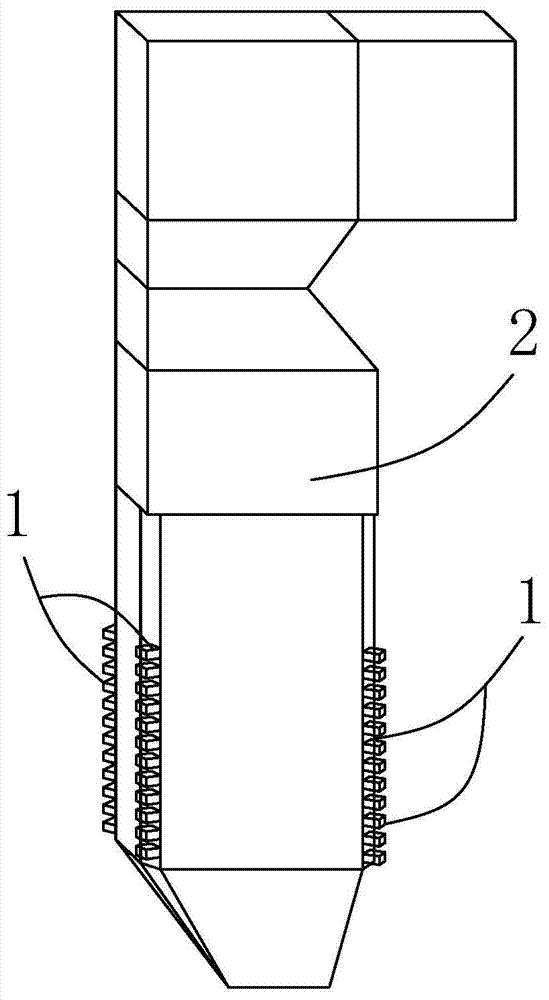

Thick-thin burner

ActiveCN111237750AReduce wearUniform flow fieldPulverulent fuel combustion burnersThermodynamicsCombustor

The invention provides a thick-thin burner. The thick-thin burner comprises two pulverized coal inlet pipelines, a horizontal main pipeline, a spray hole and a plurality of blunt body components, wherein ends of the two pulverized coal inlet pipelines are provided with pulverized coal inlets, and the other ends of the two pulverized coal inlet pipelines are crossed with each other to form a V shape; the horizontal main pipeline is connected to a crossed part of the two pulverized coal inlet pipelines, and a guide plate is arranged inside the horizontal main pipeline, a pulverized coal primarypipeline is arranged inside the guide plate, and a pulverized coal auxiliary pipeline is arranged outside the guide plate; the spray hole is horn-shaped, and is connected to the guide plate; the bluntbody components are distributed at the periphery, close to the outlet end, of the spray hole, the horizontal main pipeline and the pulverized coal inlet pipelines are connected in a 150-degree roundchamfer; through the round chamfer, concentration of pulverized coal at the two sides of the horizontal main pipeline is lower than center concentration, so that primary thick-thin separation of pulverized coal is accomplished; one side, close to the pulverized coal inlet pipelines, of the guide plate and a pulverized coal incoming direction define an angle of 120-150 degrees, so that low-concentration pulverized coal at the two sides of the pulverized coal main pipeline is separated out and enters the pulverized coal auxiliary pipeline; and through the spray hole, pulverized coal cannot be quickly diffused to the boundary, so that center concentration of the pulverized coal at the spray hole is high, and peripheral concentration is low, and therefore, thick-thin separation is accomplished.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

A kind of preparation method of wooden fireproof door and wooden fireproof door

ActiveCN110900770BImprove fire performanceEffect on fire resistanceFireproof doorsWood treatment detailsMedium density fiberboardMechanical engineering

Owner:河南赋安消防器材有限公司

Dangerous waste swirl-flow melting system and dangerous waste treatment and recycling method thereof

ActiveCN105757686AEfficient dischargeEffective secondary meltingIncinerator apparatusRecovery methodCombustor

The invention provides a dangerous waste swirl-flow melting system and a dangerous waste treatment and recycling method thereof, and relates to a dangerous waste melting system and a treatment and recycling method thereof. Effective melting and toxin-free discharging effects of existing solid-state or liquid-state dangerous wastes cannot be easily realized in a treatment process, the ignition stability is not high and the heat energy utilization rate is poor. The top of a vertical type combustion barrel is communicated with a crushing device; a horizontal type combustion barrel is located under the vertical type combustion barrel and one end of the horizontal type combustion barrel is communicated with the vertical type combustion barrel; a primary air inlet is formed in the part, close to a barrel wall at one end of the vertical type combustion barrel, of the horizontal type combustion barrel; a secondary combustion-supporting combustor is located on the barrel wall of the horizontal type combustion barrel and is arranged nearby the primary air inlet; and a waste liquid drying device is located above the horizontal type combustion barrel and is communicated with the horizontal type combustion barrel through a powder combustor. The dangerous waste treatment and recycling method comprises the following steps: step 1: carrying out primary treatment; step 2: carrying out primary melting; step 3: drying waste liquid; step 4: carrying out secondary melting; and step 5, recycling residual heat. The dangerous waste swirl-flow melting system and the dangerous waste treatment and recycling method are used for treating dangerous wastes.

Owner:国泥工程中心(哈尔滨)有限公司

A nozzle and a gas turbine

ActiveCN104566472BImprove fire stabilityImprove combustion efficiencyContinuous combustion chamberLow loadEngineering

The invention relates to the technical field of power equipment, in particular to a nozzle and a gas turbine. The nozzle includes a central body, an annular wall and a swirl device; a peripheral mixing channel is formed between the annular wall and the central body, a central body mixing channel is opened inside the central body, and independent premixed fuel channels are also provided on the central body And the diffusion fuel channel, the premixed fuel channel injects fuel to the central body mixing channel and the peripheral mixing channel respectively to form a fuel-air mixture, and the diffusion fuel channel directly injects fuel to the flame cylinder axial direction, and finally forms a diffusion combustion in the middle at the outlet of the nozzle. Both the flame and the inner and outer layers are in the flame form of a premixed combustion flame. Under the action of diffusion combustion, the flame stability and combustion efficiency of the nozzle are greatly improved under lower load; at the same time, due to the structural improvement mainly at the outlet of the nozzle, the structure can be easily processed and maintained.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Circulating fluidized bed oxygen-enriched combustion device and its operation method

ActiveCN104848213BEasy to captureControl concentration enrichmentFluidized bed combustionIndirect carbon-dioxide mitigationCycloneCombustion

Provided are a circulating fluidized bed flue gas recirculation and oxygen-enriched combustion apparatus and an operation method therefor. The oxygen-enriched combustion apparatus comprises an air chamber (101), an air distribution device (102) arranged above the air chamber (101) and a hearth (103) arranged above the air distribution device (102), wherein the upper part of the hearth (103) is connected with a high-temperature cyclone separator (104), the upper part of the high-temperature cyclone separator (104) is connected with a heated surface (106), the lower part of the heated surface (106) is connected with a coal economizer (107), the lower part of the coal economizer (107) is connected with a medium-temperature cyclone separator (108), the medium-temperature cyclone separator (108) is connected with the air chamber (101) via a primary flue gas recirculation fan (109) and a primary air oxygen injector (111) successively, and the medium-temperature cyclone separator (108) is connected with the air distribution device (102) via a secondary flue gas recirculation fan (110) and a secondary air oxygen injector (112) successively. In the operation method for the oxygen-enriched combustion apparatus, a medium-temperature flue gas is adopted as a primary air and a secondary air, which are respectively brought as a recirculation air into the hearth (103), and oxygen is injected to the primary air and the secondary air respectively, which achieves an adjustment of oxygen injection amount, and at the same time provides an oxidizing agent for the hearth (103).

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

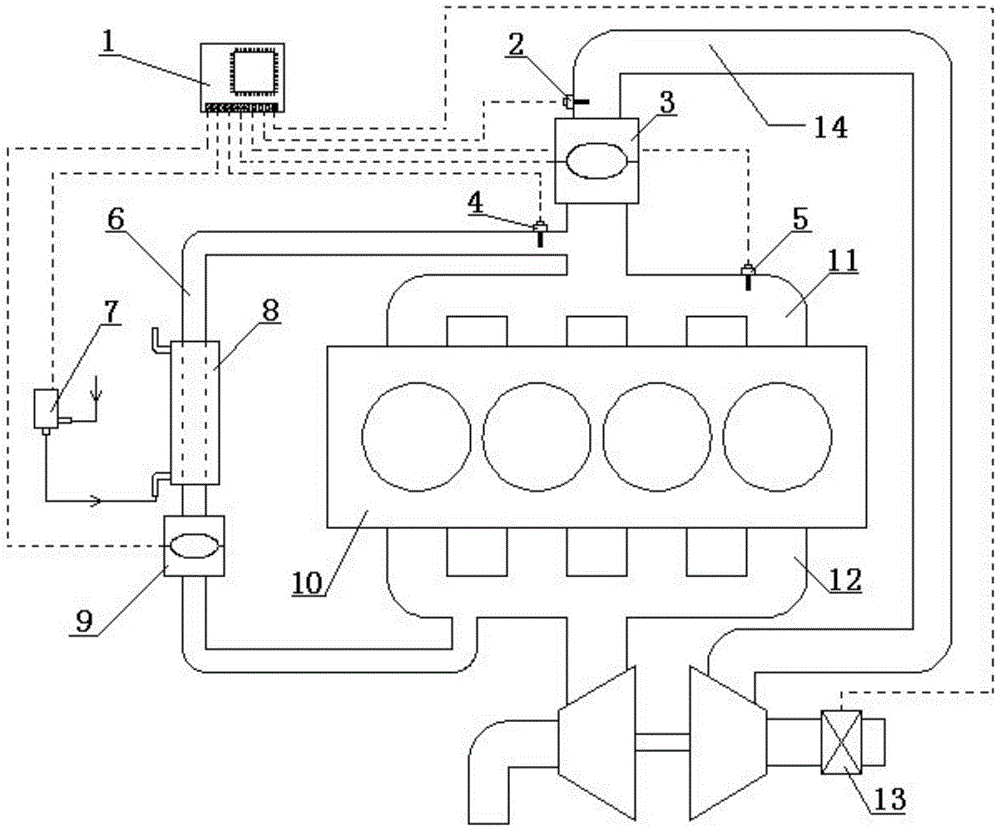

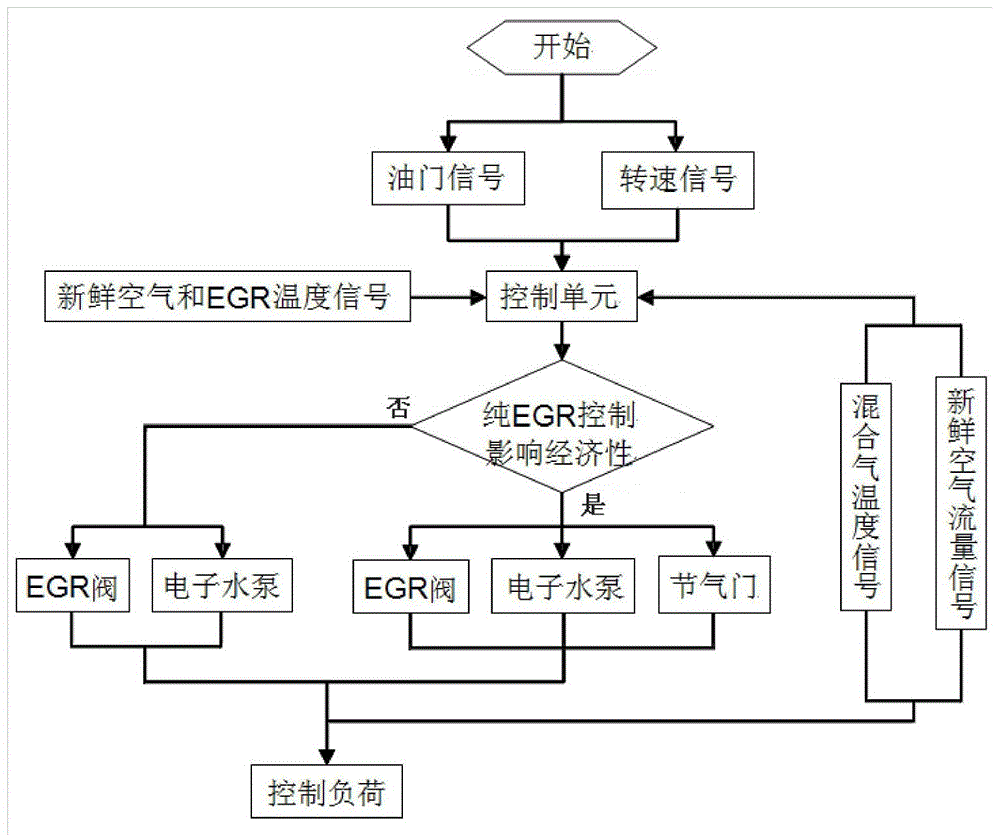

A method and device for adjusting the load of a gasoline engine

InactiveCN103790727BReduced intake throttling lossesImprove fuel economyElectrical controlMachines/enginesGasolineLoad regulation

The invention provides a gasoline engine load adjusting method and device. The gasoline engine load adjusting device comprises a gasoline engine, a throttling valve installed on an air intake pipe of the gasoline engine and an EGR circuit communicated with the gasoline engine. The EGR circuit comprises an EGR valve and an EGR cooler which are connected in sequence. The inlet of the EGR valve is communicated with an exhaust pipe of the gasoline engine. The outlet of the EGR cooler is communicated with the air intake pipe of the gasoline engine. A mixed gas temperature sensor for measuring the temperature of mixed gas is installed on an air intake manifold of the gasoline engine. An EGR cooler electronic circulation water pump is connected between the liquid inlet and the liquid outlet of the EGR cooler and used for controlling the flow of cooling water. The front end of a general air intake pipe of the gasoline engine is provided with an air flow meter for measuring the mass flow rate of the air. The throttling valve, the mixed gas temperature sensor, the EGR cooler electronic circulation water pump, the EGR valve and the air flow meter are connected with a logic control unit. By means of the gasoline engine load adjusting method and device, the economical efficiency when the gasoline engine is partially loaded is improved.

Owner:JILIN UNIV

Necking-down type combustion chamber

PendingCN111502819AHinder formationImprove fire stabilityInternal combustion piston enginesPistonsCombustion chamberMechanical engineering

The invention relates to the field of engines, in particular to a necking-down type combustion chamber. The necking-down type combustion chamber comprises a combustion chamber body. The combustion chamber body comprises an opening, a throat and a bottom face. The throat comprises a throat upper edge, a throat lower edge, an annular arc protrusion and a throat opening part. The plane where the throat opening part is located divides the combustion chamber body into an upper-layer flow guiding cavity and a lower-layer combustion cavity. The flow guiding cavity is defined by a flow guiding side wall arranged between the opening and the throat upper edge. The flow guiding side wall gradually outwards extends to the opening from the throat upper edge. The combustion cavity is defined by a combustion side wall arranged between the throat lower edge and the bottom face, and the combustion side wall gradually shrinks to the throat lower edge from the bottom face. The throat opening part is in acircular shape, and the bottom face is a circular flat bottom face. Through the flow guiding action of the flow guiding cavity, extrusion flow is guided to directly flow into the combustion chamber body, the ignition stability is improved, and the combustion speed is increased.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com