Coal water slurry gasifying furnace with five nozzles

A technology of coal-water slurry and gasifier, which is applied in the equipment field of coal-water slurry gasification, can solve the problems that industrial production cannot be used in batches, and the cost of coal-water slurry gasifier is high, so as to achieve long residence time and restrain direct rush Possibility of exit from the bottom of the furnace, strong effects of turbulent mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

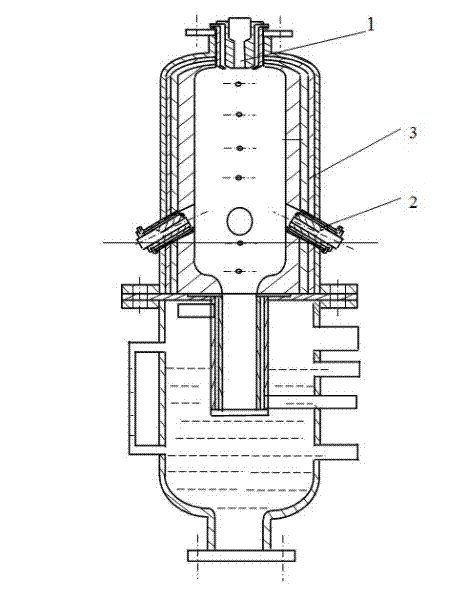

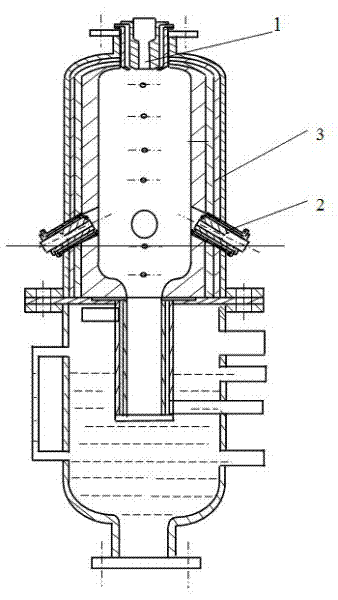

[0014] Embodiment 1: as figure 1 As shown, a five-nozzle coal-water slurry gasifier comprises a furnace body 3, a top nozzle 1 is provided on the top of the furnace body 3, four furnace side nozzles 2 are arranged on the side wall of the furnace body 3, and the furnace side nozzles 2 The feed nozzle is low and the discharge nozzle is high, the angle between the axis of the furnace side nozzle 2 and the horizontal plane is greater than 0° and less than 90°, and the four furnace side nozzles 2 are arranged at the same height of the furnace body 3 .

[0015] The furnace shaft 3 is a hollow cylinder or cuboid.

[0016] The furnace side nozzle 2 can be fixed on the furnace body, or hinged on the furnace body 3 through a hinge shaft, and the angle between the furnace side nozzle 2 and the horizontal plane can be adjusted in the hinge structure.

[0017] The present invention adopts the form of multi-nozzle inlets on the top of the furnace and the side of the furnace, and the adapta...

Embodiment 2

[0018] Embodiment 2: the angle between the axis of the furnace side nozzle 2 and the horizontal plane is 10°, and other structures are the same as in Embodiment 1.

Embodiment 3

[0019] Embodiment 3: the angle between the axis of the furnace side nozzle 2 and the horizontal plane is 20°, and other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com