Radial gradient two air-controlled cyclone coal dust combustor

A pulverized coal burner and air conditioning technology are applied in burners, burners for burning powder fuel, combustion methods, etc., to achieve the effects of reducing emissions, enhancing heat and mass transfer strength, and improving ignition stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments completed by the inventor.

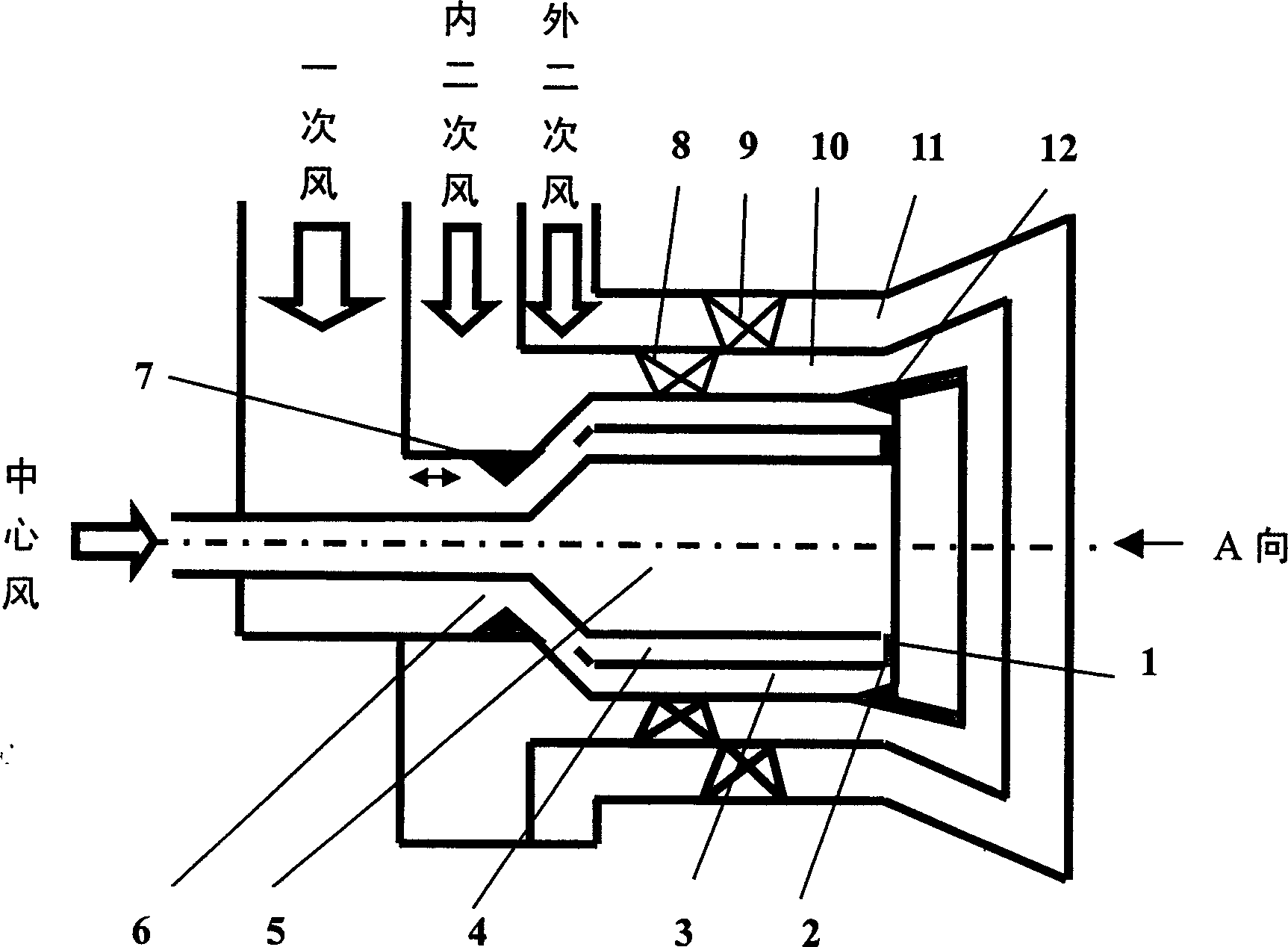

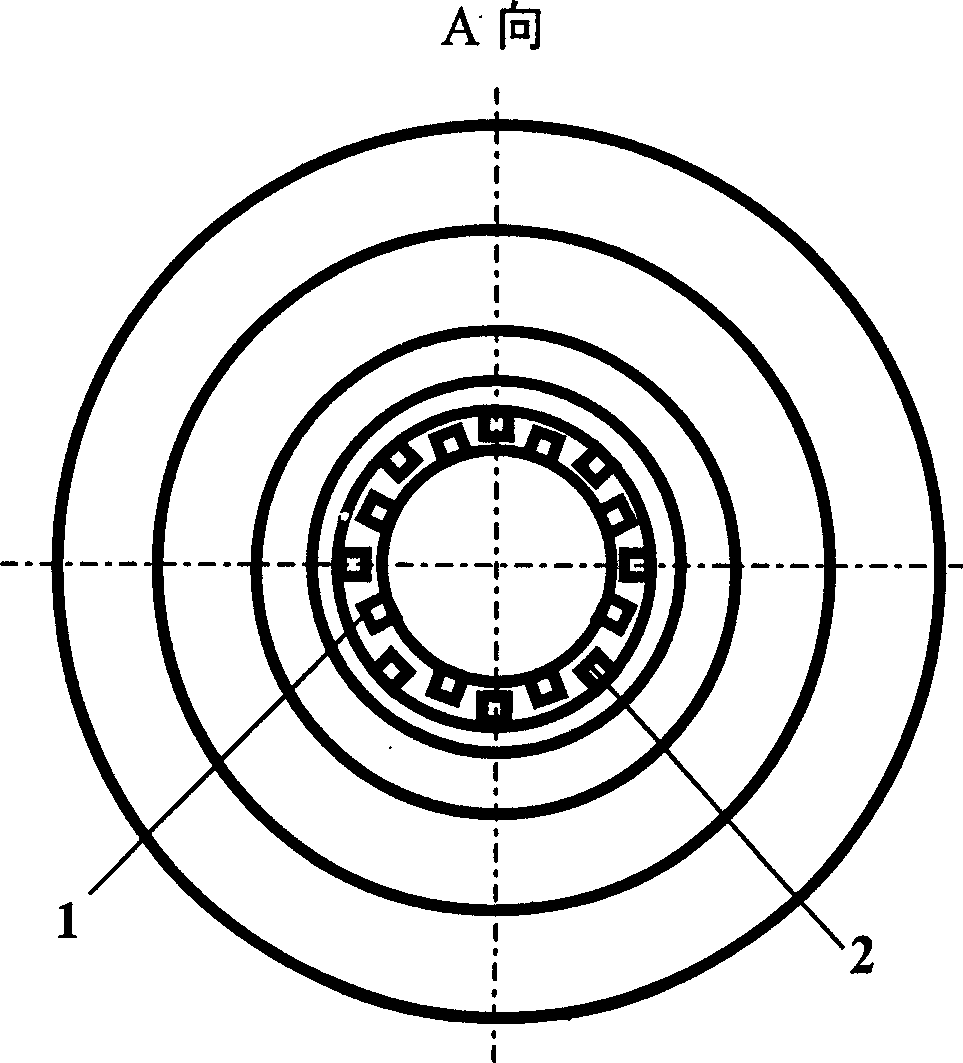

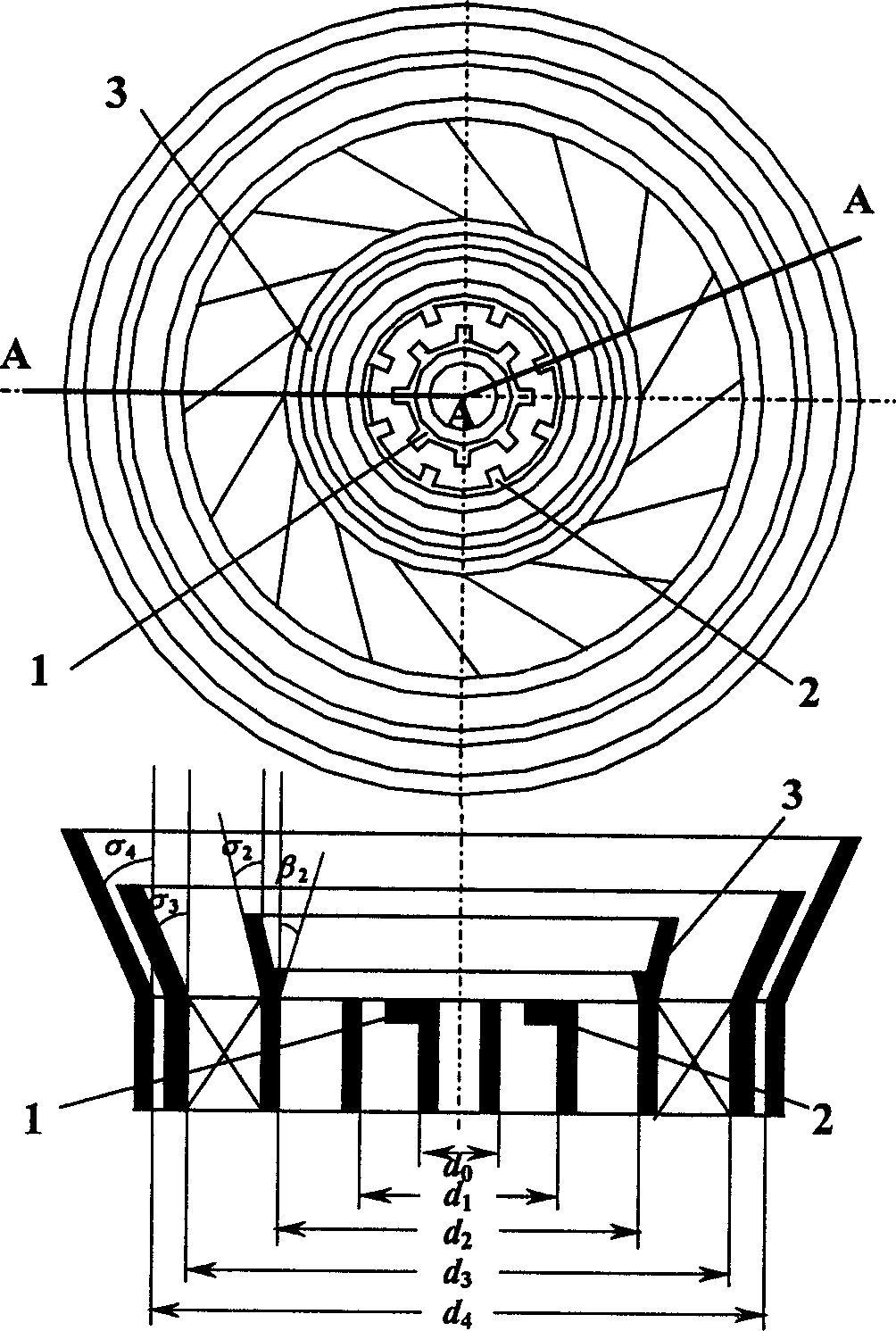

[0010] see figure 1 , 2 , 3, figure 1 It is a structural schematic diagram of the radial thick-thin double-air swirl pulverized coal burner of the present invention; figure 2 Is the A view of Figure 1; Figure 3 is a burner nozzle assembly diagram, is a specific embodiment of the present invention.

[0011] According to the technical solution of the present invention, the radial thick-thin double-air swirl pulverized coal burner includes an inner primary air channel 4, an outer primary air channel 3, an inner secondary air channel 10, an outer secondary air channel 11, and an inner secondary air channel. Secondary air swirl blades 8, outer secondary air swirl blades 9, inner tooth-shaped combustion stabilization ring 1, outer tooth-shape combustion sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com