Coal powder partial gasification cooperative denitration system and method

A technology for pulverized coal and denitrification, which is applied in separation methods, chemical instruments and methods, granular/powdered fuel gasification, etc. Reduce equipment investment, reduce NOx, and solve the effect of high ammonia slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0032] The present invention is a partial coal gasification synergistic denitrification system and method, which utilizes the CO produced by coal powder gasification to economically and efficiently reduce nitrogen oxides in boiler flue gas, which is completely different from the ammonia commonly used in flue gas denitrification in thermal power plants. As a reducing agent, it avoids the problems of large ammonia consumption and high ammonia escape caused by excessive ammonia injection.

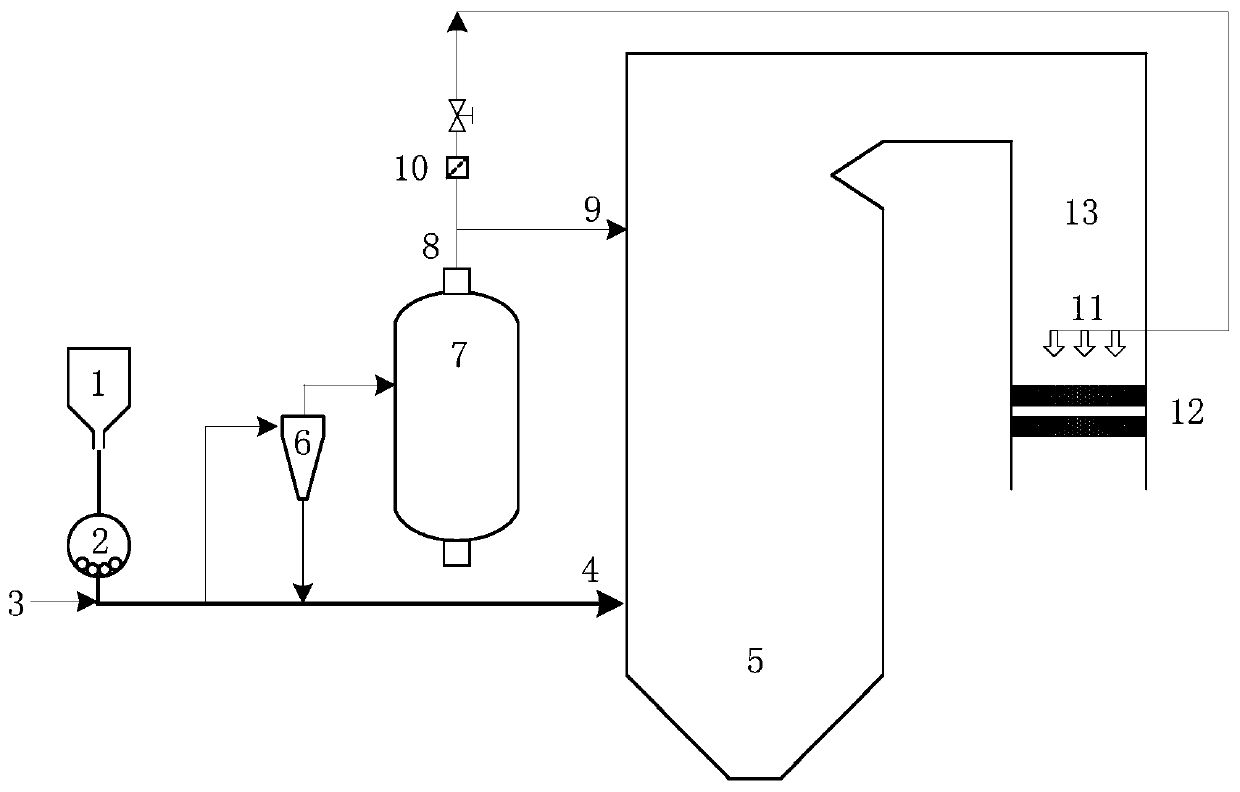

[0033] Among them, the denitrification system such as figure 1 As shown, it includes coal bunker 1, coal mill 2, boiler 5, cyclone separator 6, gasifier 7 and filter 10; the coal outlet of coal bunker 1 is connected to the entrance of coal mill 2, and the coal of coal mill 2 The powder outlet is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com