Swirl pulverized coal burner

A pulverized coal burner and pulverized coal technology are used in burners, burners for burning powder fuel, combustion methods, etc., which can solve problems such as unstable coal quality, achieve enhanced ignition stability, wide application range, and reduce oxygen. effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

[0020] All features disclosed in this specification, or steps in all disclosed methods or processes, except for mutually exclusive characteristics and / or steps, can be combined in any way, unless otherwise stated, they can be used by other equivalent or similar Instead, each feature is intended to be replaced by alternative features, that is, each feature is only one embodiment of a series of equivalent or similar features unless stated otherwise.

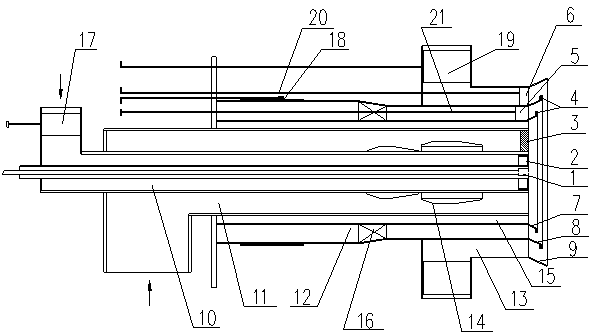

[0021] Such as figure 1 As shown, the swirl pulverized coal burner of the present invention includes a central air passage 10, a primary air passage 11, a secondary air passage 12 and a tertiary air passage 13 arranged in sequence from inside to outside, and is arranged along the central axis in the central air passage 10 An oil gun tube 1 with an oil nozzle, and a combustion stabilization cover 2 is provided at the air outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com