Necking-down type combustion chamber

A combustion chamber, constriction type technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of weak intake vortex and compression vortex, insufficient oil and gas mixing, and unsatisfactory combustion quality, so as to improve the ignition quality. Stability, the effect of accelerating the burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

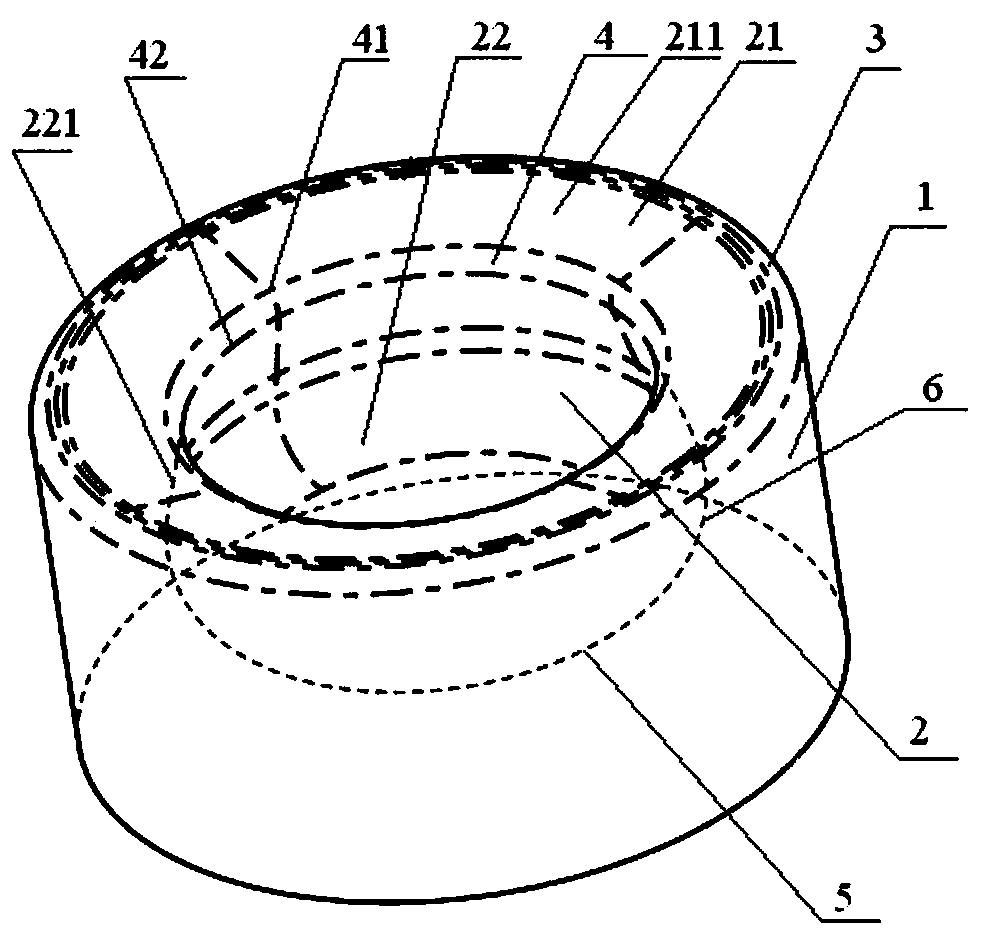

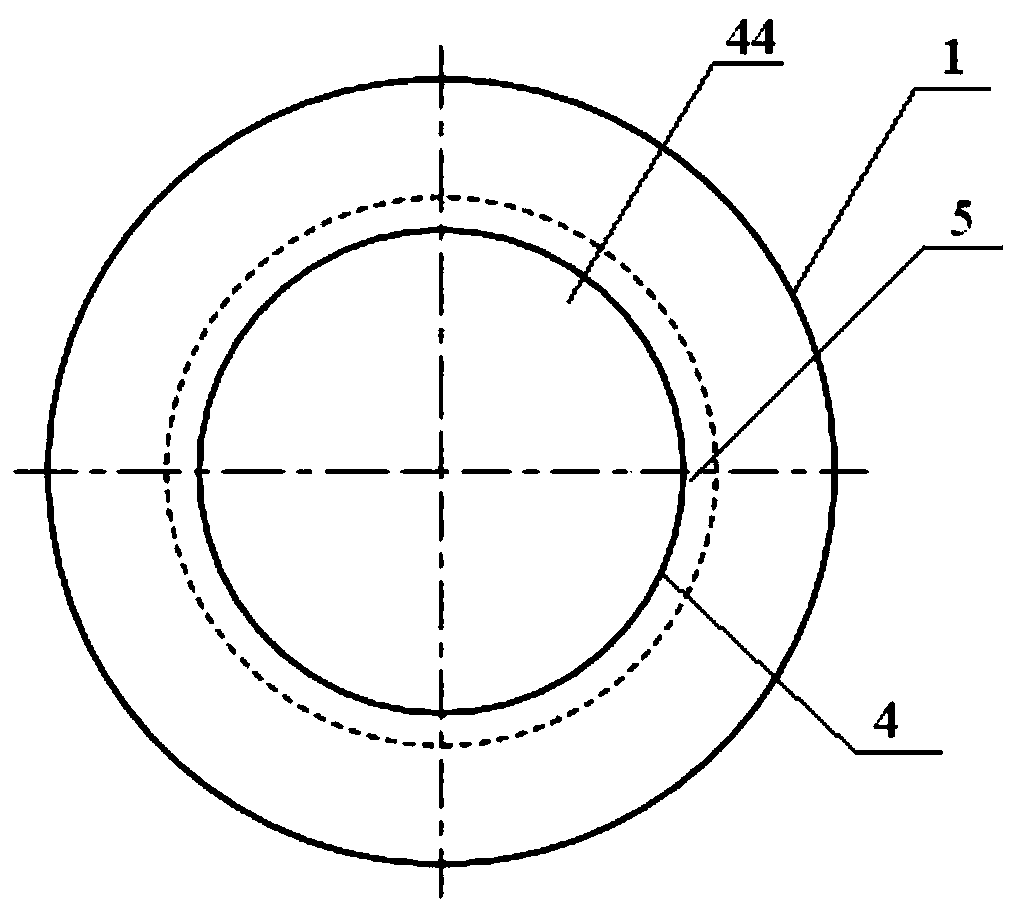

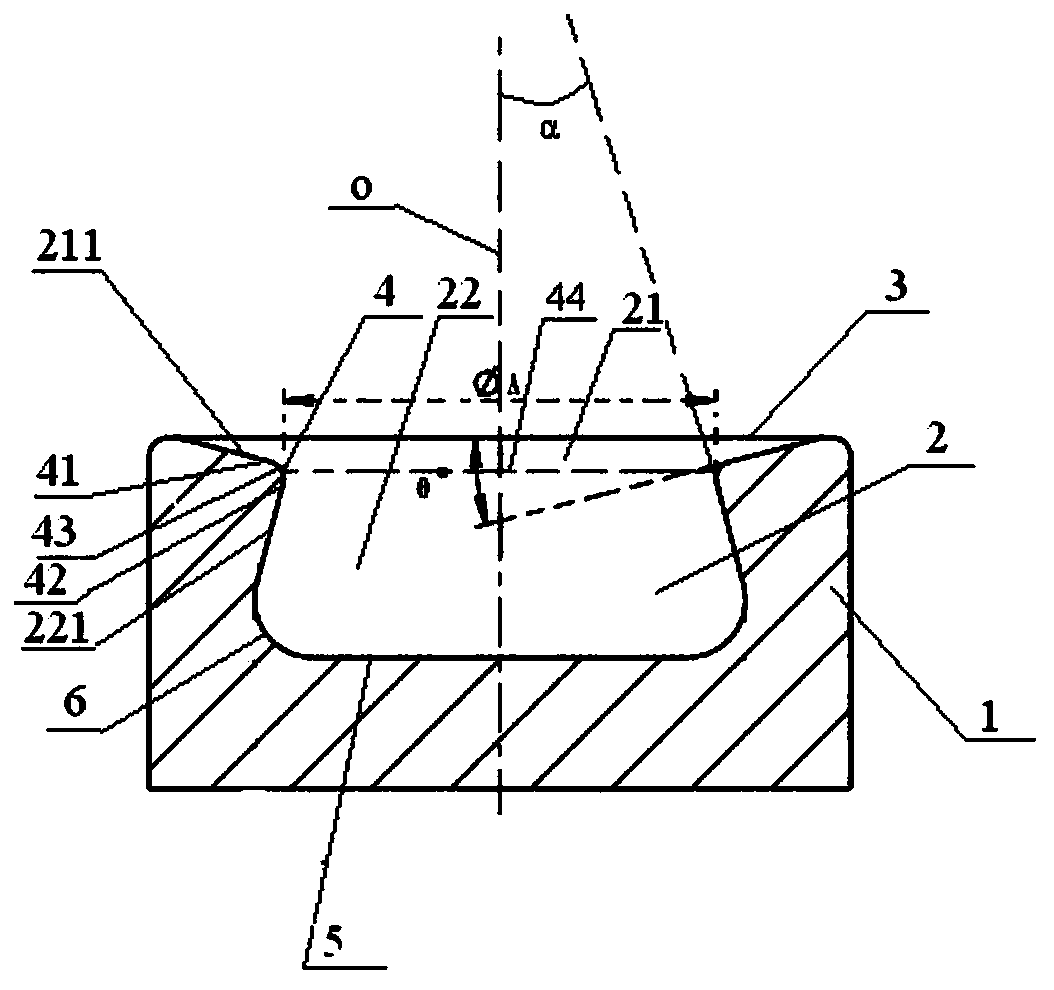

[0021] combine figure 1 As shown, the necking-type combustion chamber of the present embodiment includes a combustion chamber 2 extending from the top surface of the piston 1 to the inside of the piston 1, and the combustion chamber 2 includes an opening 3 located on the top surface of the combustion chamber 2, and an opening 3 located in the middle of the combustion chamber 2. The throat 4 and the bottom surface 5 at the bottom of the combustion chamber 2, the central axis of the combustion chamber 2 coincides with the central axis o of the piston.

[0022] Concrete combination figure 2 with image 3 As shown, the throat 4 includes an upper edge 41 of the throat along its axial direction, a lower edge 42 of the throat, and an annular arc-shaped protrusion 43 transitionally connecting the upper edge 41 of the throat and the lower edge 42 of the throat, and along its radial direction. The throat opening 44, the longitudinal section of the annular arc-shaped protrusion 43 is ...

Embodiment 2

[0027] combine figure 1 , figure 2 with Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 lies in the shape of the flow guide side wall 211. In this embodiment, the longitudinal section of the flow guide side wall 211 is an upwardly convex arc shape.

[0028] Compared with the constricted combustion chamber with the application number 201520598758.X, in the constricted combustion chamber of this embodiment, the diversion side wall of the diversion cavity is designed so that the diameter gradually increases from the throat to the opening The convex curved surface guides the squeeze flow directly into the combustion chamber through the diversion effect of the diversion side wall in the shape of the convex curved surface, avoiding the excessive flow velocity near the spark plug to hinder the formation of the fire core, increasing the turbulent flow intensity in the combustion chamber, and accelerating the combustion speed.

Embodiment 3

[0030] combine figure 1 , figure 2 with Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 lies in the shape of the flow guide side wall 211 . In this embodiment, the longitudinal section of the flow guide side wall 211 is a downwardly concave arc shape.

[0031] Compared with the constricted combustion chamber with the application number 201520598758.X, in the constricted combustion chamber of this embodiment, the diversion side wall of the diversion cavity is designed so that the diameter gradually increases from the throat to the opening The concave curved surface guides the squeeze flow directly into the combustion chamber through the diversion effect of the diversion side wall in the shape of the concave curved surface, avoiding the excessive flow velocity near the spark plug to hinder the formation of the fire core, increasing the turbulent flow intensity in the combustion chamber, and accelerating the combustion speed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com