Dangerous waste swirl-flow melting system and dangerous waste treatment and recycling method thereof

A hazardous waste and cyclone technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of low combustion efficiency, high carbon content in ash and slag, high dioxin content, and achieve reasonable and simple layout and stable operation. Effective, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

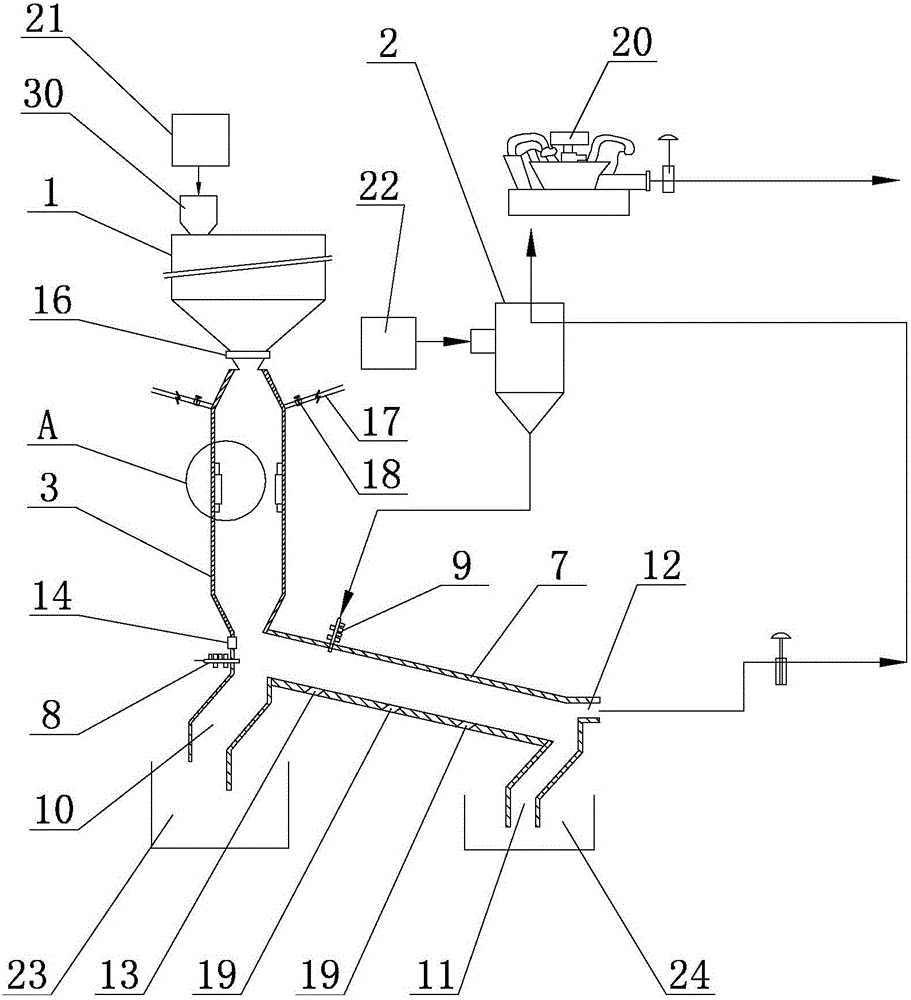

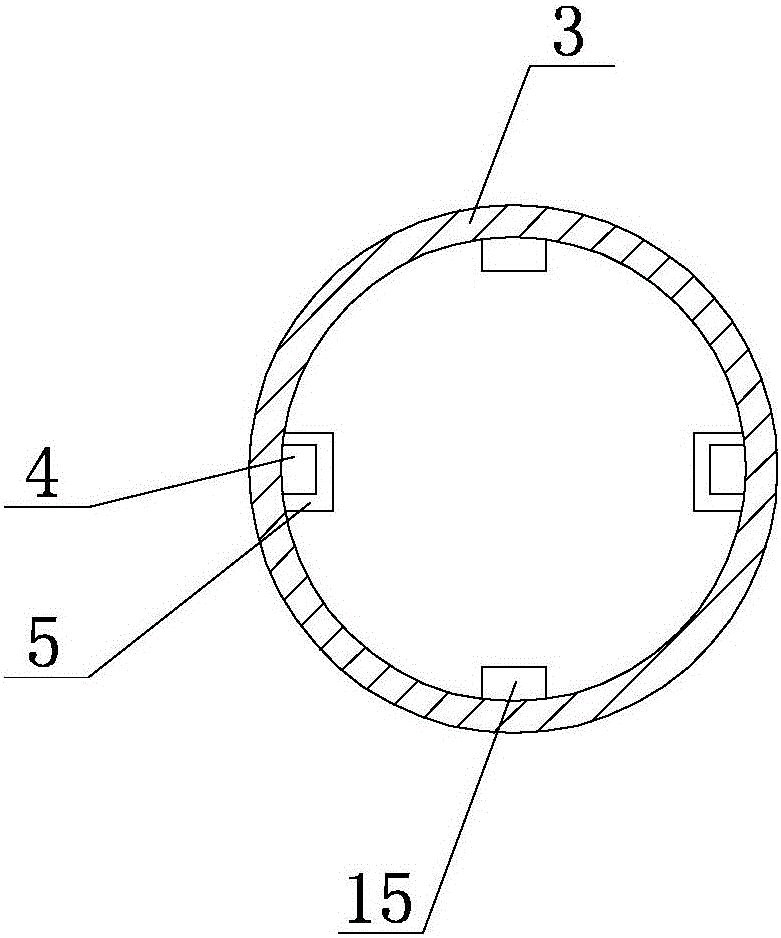

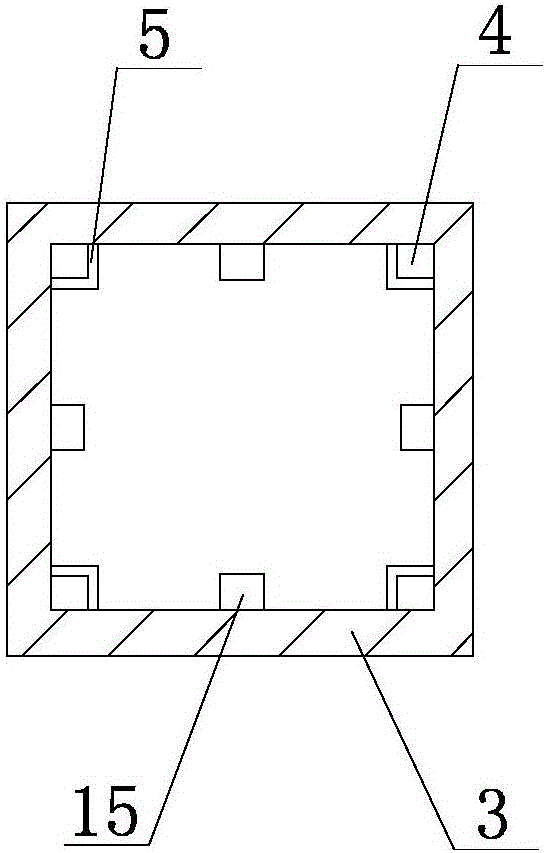

[0033] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4Describe this embodiment, this embodiment includes a vertical combustion chamber assembly, a horizontal combustion chamber assembly, a crushing device 1 and a waste liquid drying device 2, the vertical combustion chamber assembly includes a vertical combustion cylinder 3, the vertical combustion chamber The combustion tube 3 is vertically arranged, and the top of the vertical combustion tube 3 is connected with a crushing device 1, and the wall of the vertical combustion tube 3 is sequentially processed with a plurality of top burn-off air nozzles 4 and a plurality of primary air nozzles. 5 and a plurality of secondary air nozzles 6, the horizontal combustion chamber assembly includes a horizontal combustion cylinder 7, a secondary combustion burner 8, a powder burner 9, a first discharge pipe 10 and a second discharge pipe 11, the The horizontal combustion cylinder 7 is located be...

specific Embodiment approach 2

[0064] Specific implementation mode two: combination figure 2 and image 3 To describe this embodiment, in this embodiment, a plurality of split burn-off air nozzles 15 are also processed on the cylinder wall of the vertical combustion cylinder 3 . This setting cooperates with multiple top burn-off air nozzles 4, multiple primary air nozzles 5 and multiple secondary air nozzles 6 to ensure that the four corners are tangentially circled and generate strong swirling flow, so that the vertical combustion tube 3 can fully burn High melting point characteristics.

[0065] It is feasible for the present invention to reach the temperature condition for melting hazardous wastes without adding auxiliary fuel, but some auxiliary means are needed. The calculation results show that the effect of increasing the furnace temperature by controlling the lower air excess coefficient is very limited. And increasing the air distribution ratio of primary air and secondary air can effectively i...

specific Embodiment approach 3

[0067] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the vertical combustion chamber assembly in this embodiment further includes a sealing sleeve 16 , and a sealing sleeve 16 is provided between the crushing device 1 and the vertical combustion cylinder 3 . In this embodiment, the setting of the sealing sleeve 16 is to ensure the tightness of the crushing device 1 and the vertical combustion cylinder 3, so as to prevent the combustion efficiency of hazardous wastes from being affected by air leakage and ensure efficient combustion in the vertical combustion cylinder 3. Other unmentioned structures and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com