Recirculating fluidized bed oxygen-enriched combustion apparatus and operation method thereof

A circulating fluidized bed and oxygen-enriched combustion technology, which is applied in the direction of fluidized bed combustion equipment, combustion methods, and fuel burned in a molten state, can solve the problems of low capture rate and waste of resources, so as to improve desulfurization efficiency and prevent Effects of deposition, avoidance of slagging and slag leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

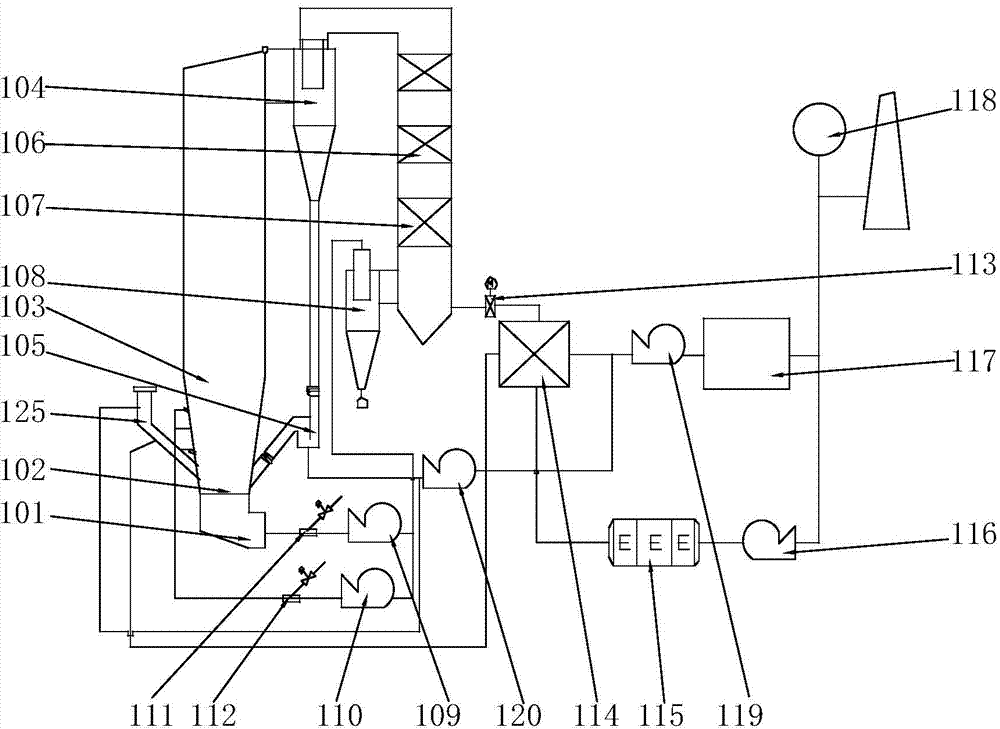

[0043] Such as figure 1 As shown, this embodiment discloses a circulating fluidized bed oxygen-enriched combustion device, including an air chamber 101, an air distribution device 102 arranged above the air chamber 101, and a furnace 103 arranged above the air distribution device 102. The upper part of the furnace 103 is connected with a high-temperature cyclone separator 104, the upper part of the high-temperature cyclone separator 104 is connected with a heating surface 106, and the lower part of the heating surface 106 is connected with an economizer 107, and the lower end of the high-temperature cyclone separator 104 passes through The feeder 105 is connected with the air distribution device 102, and the lower part of the economizer 107 is connected with a medium temperature cyclone separator 108, and the medium temperature cyclone separator 108 passes through the primary flue gas recirculation fan 109 and the primary air oxygen injector 111 in sequence It is connected wit...

Embodiment 2

[0052]In this embodiment, on the basis of Embodiment 1, the cold flue gas recirculation fan 119 is far away from the CO 2 One end of the compression and purification device 118 is connected to a Roots blower 120, and the Roots blower 120 is connected to a feeder 105 and a coal sowing pipe 125 respectively. The output port of the secondary flue gas recirculation fan 110 is connected with the coal sowing pipe 125 .

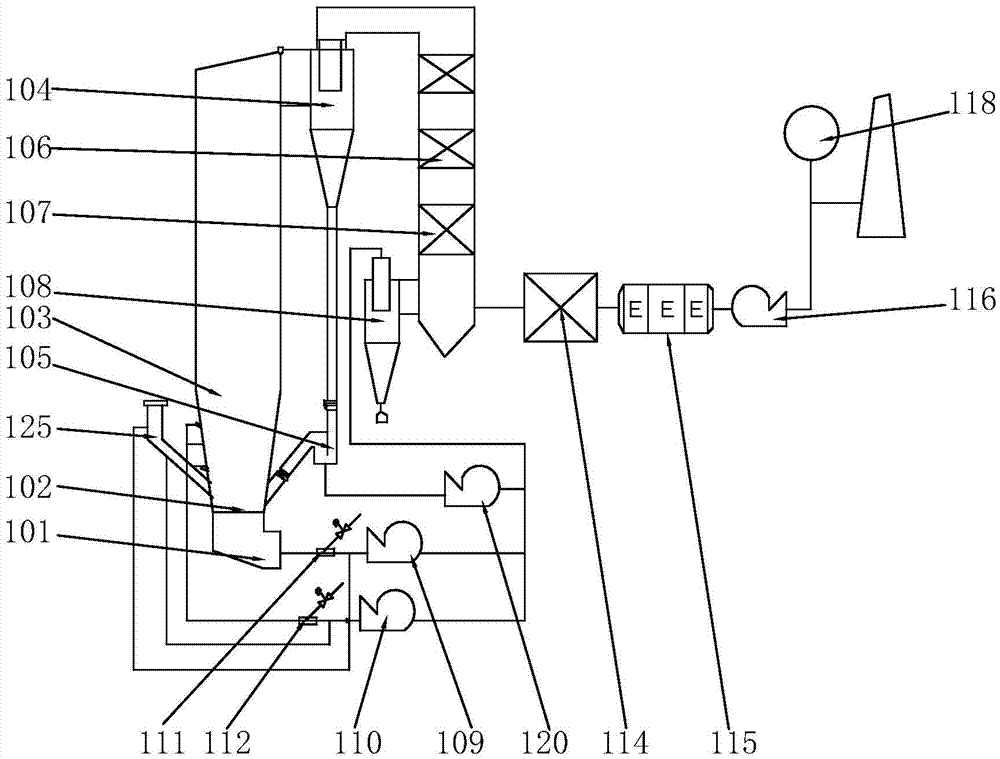

[0053] Such as figure 2 As shown, after the flue gas from the high-temperature cyclone separator 104 passes through the heating surfaces 106 and economizers 107 at various levels, the flue gas is divided into two parts, one part enters the medium-temperature cyclone separator 108 (accounting for about 70% of the flue gas), and the other Part of it enters the CO through the tail dust collector, etc. 2 The compressed purification device 118 compresses and purifies or discharges it into the atmosphere through a chimney. The flue gas dedusted by the medium-temperatu...

Embodiment 3

[0056] In this embodiment, in order to ensure the stable operation of the circulating fluidized bed boiler during the combustion process, the flue gas recirculation rate is set between 65% and 80%, that is, the flue gas separated by the medium temperature cyclone separator 108 accounts for 100% of the high temperature cyclone separator 104 65%~80% of the output flue gas is used as recirculated flue gas and used as primary air and secondary air respectively. By controlling the recirculation ratio within this range, by using medium-temperature flue gas as recirculation air, and recirculating it after oxygen injection, it can be used as bed material fluidization medium and combustion oxidant to effectively control CO in boiler exhaust. 2 The concentration is enriched to more than 80%, which is beneficial to the CO in the flue gas after coal combustion 2 Correspondingly, 20%-35% of the flue gas output by the high-temperature cyclone separator 104 passes through the flue gas prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com