Secondary concentration double-nozzle micro-oil pulverized coal igniting device

A secondary concentration and micro-oil technology, which is applied in the direction of burning powder fuel burners, burners, combustion ignition, etc., can solve the problems of difficult ignition, ignition failure, high calorific value of ignition, etc., and achieve the effect of easy ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

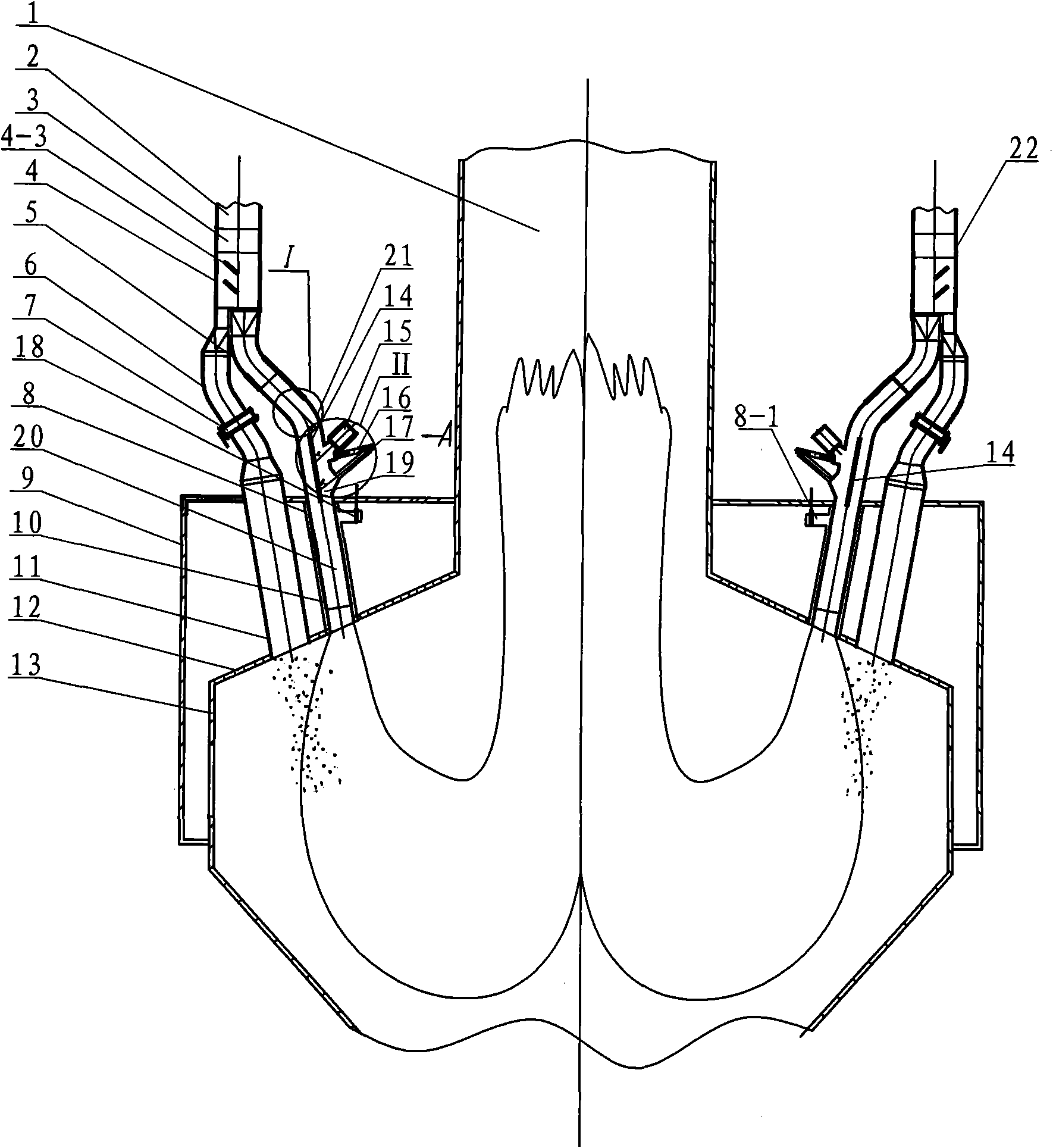

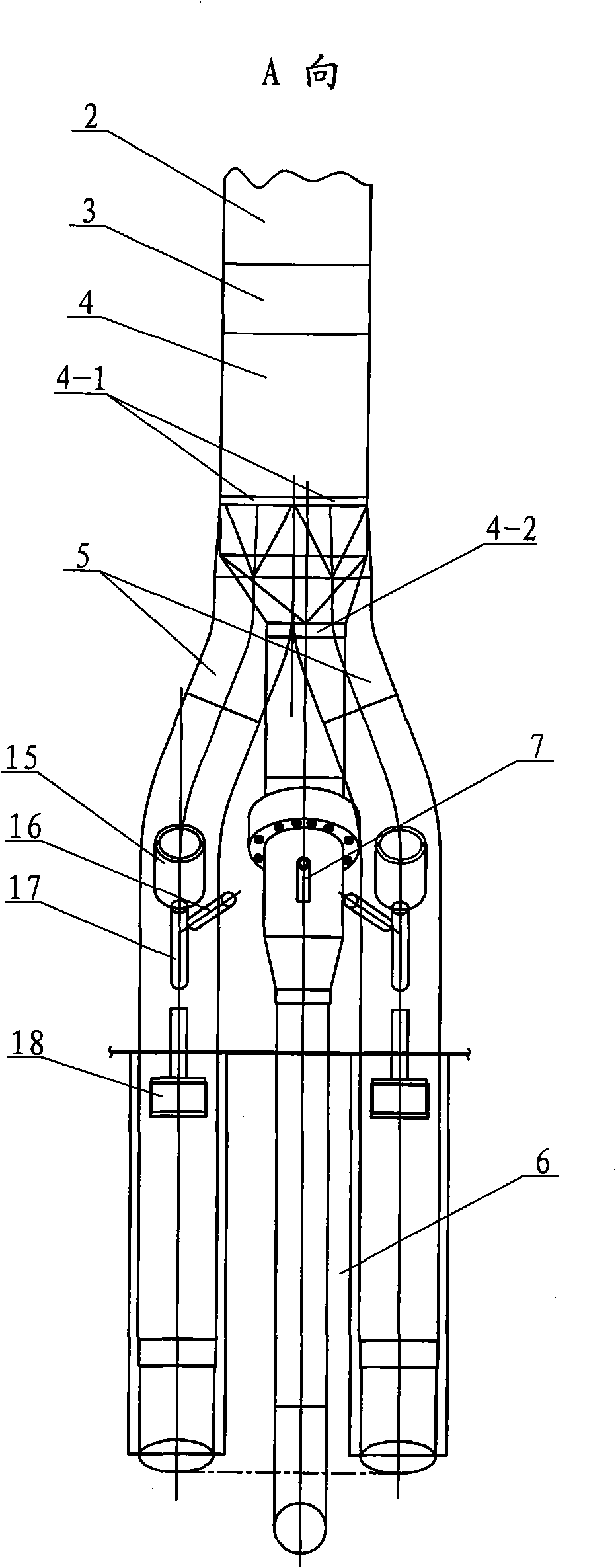

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment comprises upper furnace 1, secondary air box 9, two furnace arches 12, lower furnace 13 and two burners 22, upper furnace 1 is connected with lower furnace 13 through furnace arch 12, each furnace The arch 12 is sequentially provided with two dense coal powder air flow nozzles 10 and light coal powder air flow nozzles 11 from the inside to the outside. On the top, the secondary air box 9 is fixed on the outer wall of the upper furnace 1 and the lower furnace 13, and each burner 22 is composed of a primary air duct 2, a grid divider 3, a pulverized coal thick and thin separator 4, and two thick pulverized coal Pipeline 5, light coal powder pipeline 6, light coal powder pipeline baffle 7, cooling jacket 8, partition 14, main oil gun 15, fire detector 16, auxiliary oil gun 17 and cooling jacket baffle 18, grid The inlet end of the equalizer 3 is connected to the primar...

specific Embodiment approach 2

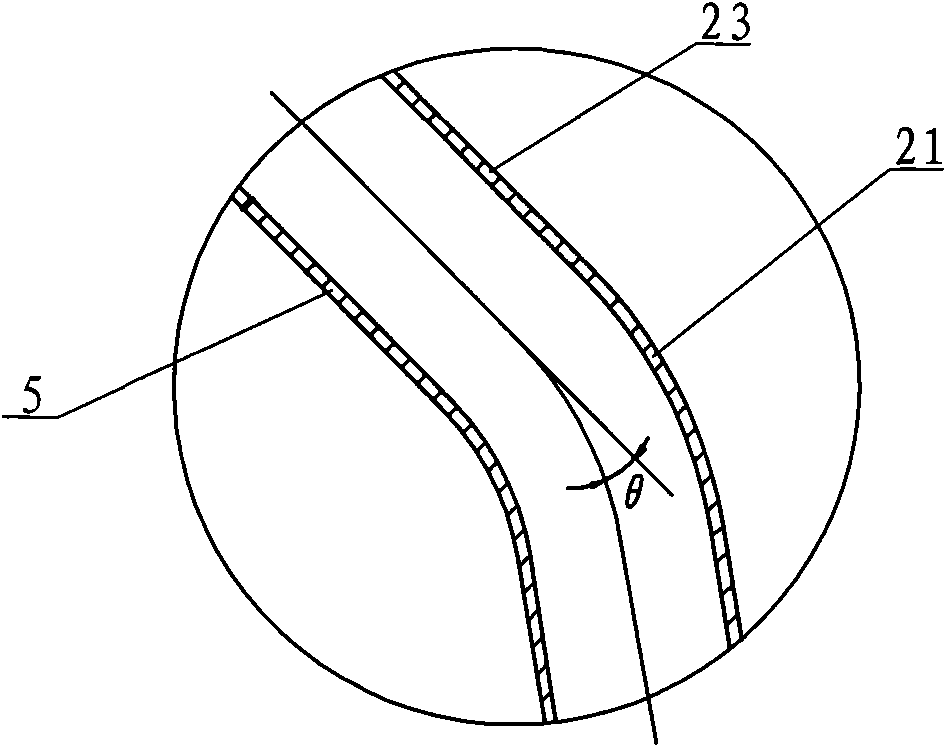

[0008] Specific implementation mode two: combination figure 1 with image 3 To illustrate this embodiment, the included angle θ between the bent pipe section 21 and the straight pipe section 23 on the concentrated pulverized coal pipeline 5 of this embodiment is 50°. When the included angle θ is 50°, the centrifugal force generated when the high-concentration pulverized coal passes through the elbow section 21 is moderate, and the secondary concentration effect is good. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 4 To describe this embodiment, the included angle α between the main oil gun 15 and the centerline of the burner 22 in this embodiment is 60°. Such design enables the main oil gun 15 to directly ignite the high-concentration pulverized coal that has been concentrated twice. Other compositions and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com