Patents

Literature

33results about How to "Cost-effective recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

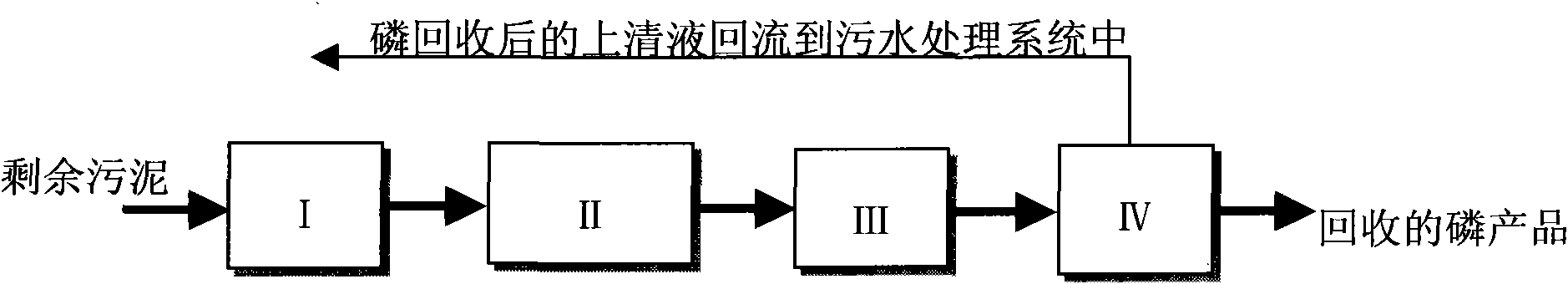

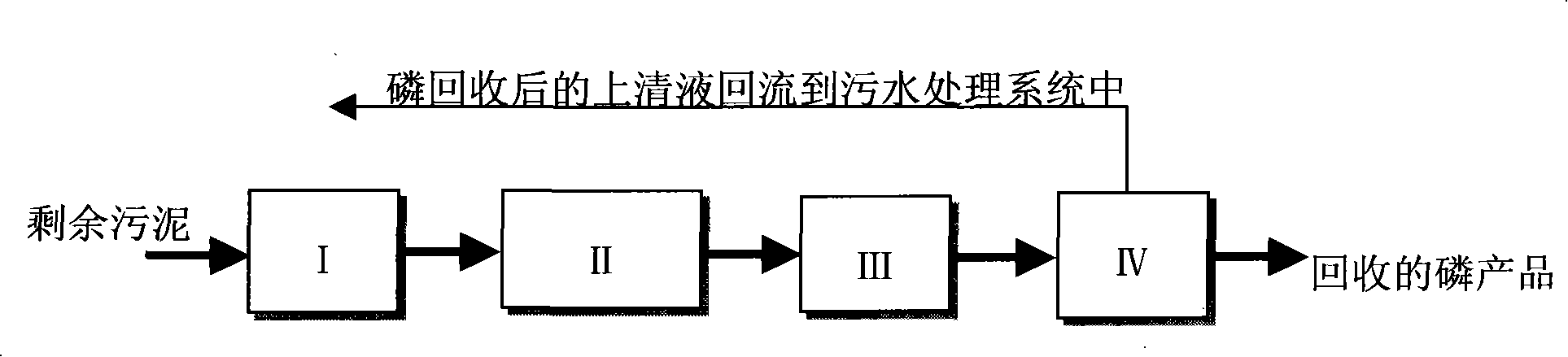

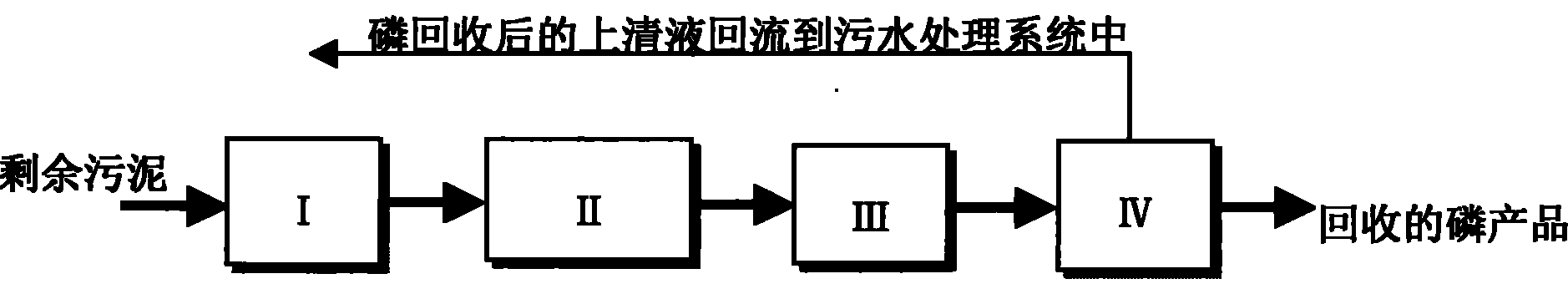

Method for recovering sludge phosphorus from urban sewage treatment plant

ActiveCN101580334ACost-effective recyclingReach reductionSludge treatment by de-watering/drying/thickeningPhosphorus compoundsCalcium biphosphateMunicipal sewage

The invention relates to a method for recovering sludge phosphorus from an urban sewage treatment plant, belonging to the technical fields of sludge treatment and resources. The method comprises the following steps: respectively carrying out gravity thickening on sludge releasing sludge phosphorus, sludge phosphorus releasing on sludge after the gravity thickening, solid-liquid separation on sludge after the sludge phosphorus releasing, sludge phosphorus recovery on supernatant fluid rich of phosphorus after the solid-liquid separation, and the like; the sludge phosphorus releasing on sludge after the gravity thickening is realized by treating the sludge by an acidification and normal-pressure microwave radiation combination method; and the sludge phosphorus recovery on supernatant fluid rich of phosphorus after the solid-liquid separation is realized by treating the supernatant fluid rich of phosphorus by a calcium phosphate crystallization process to obtain the deposit containing calcium phosphate crystal, then filtering the deposit containing calcium phosphate crystal and finally recovering the sludge phosphorus. The method not only can efficiently recover the phosphorus in the sludge from the urban sewage treatment plant, but also can achieve the aims of reducing the sludge and improving the depositing performance of the sludge.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

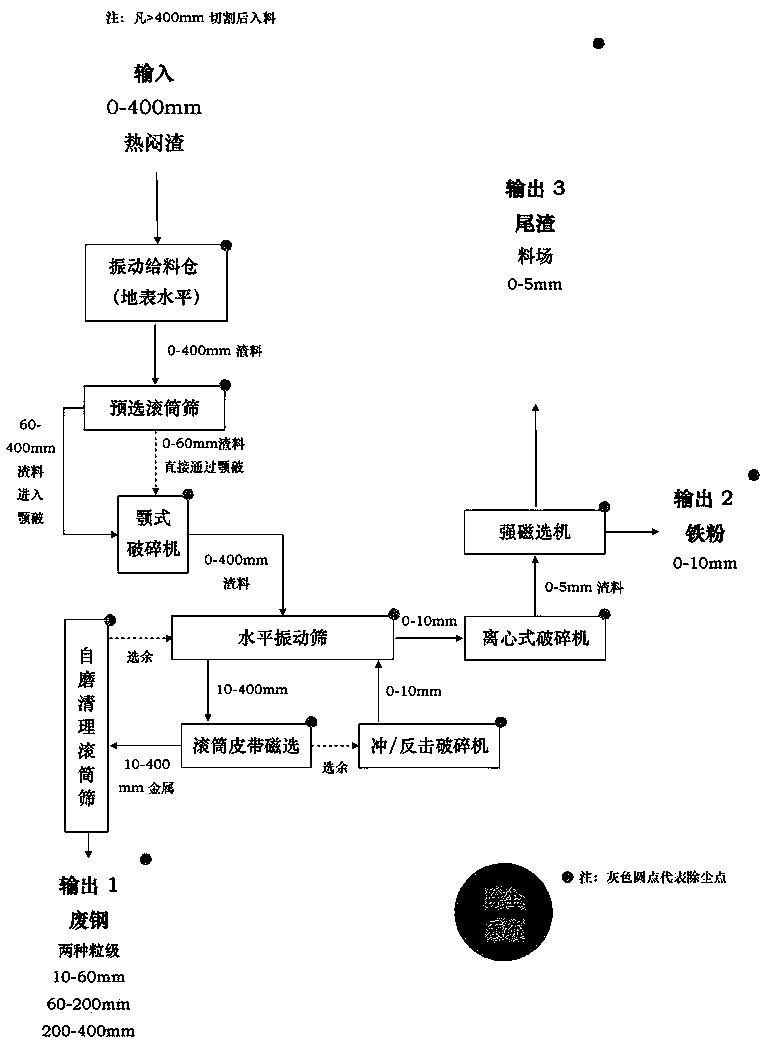

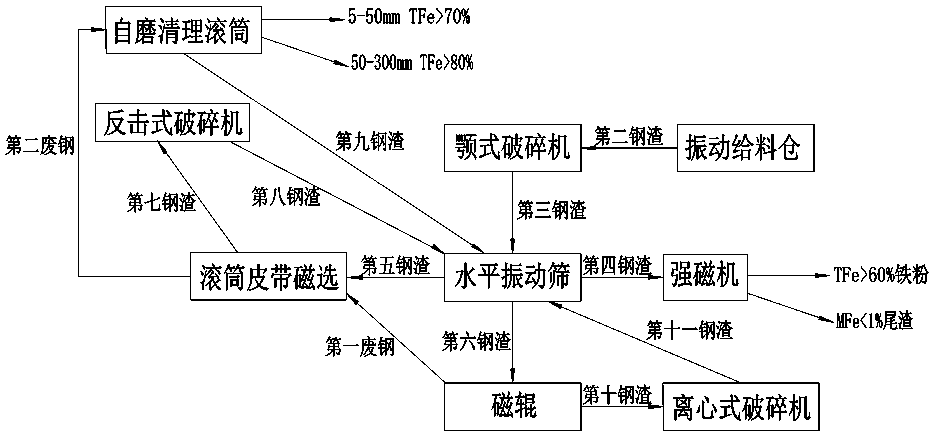

A steel slag advanced treatment process

ActiveCN108187880BCost-effective recyclingFull recoveryCement productionGrain treatmentsSlagRenewable resource

Owner:南京芬钢环保科技有限公司

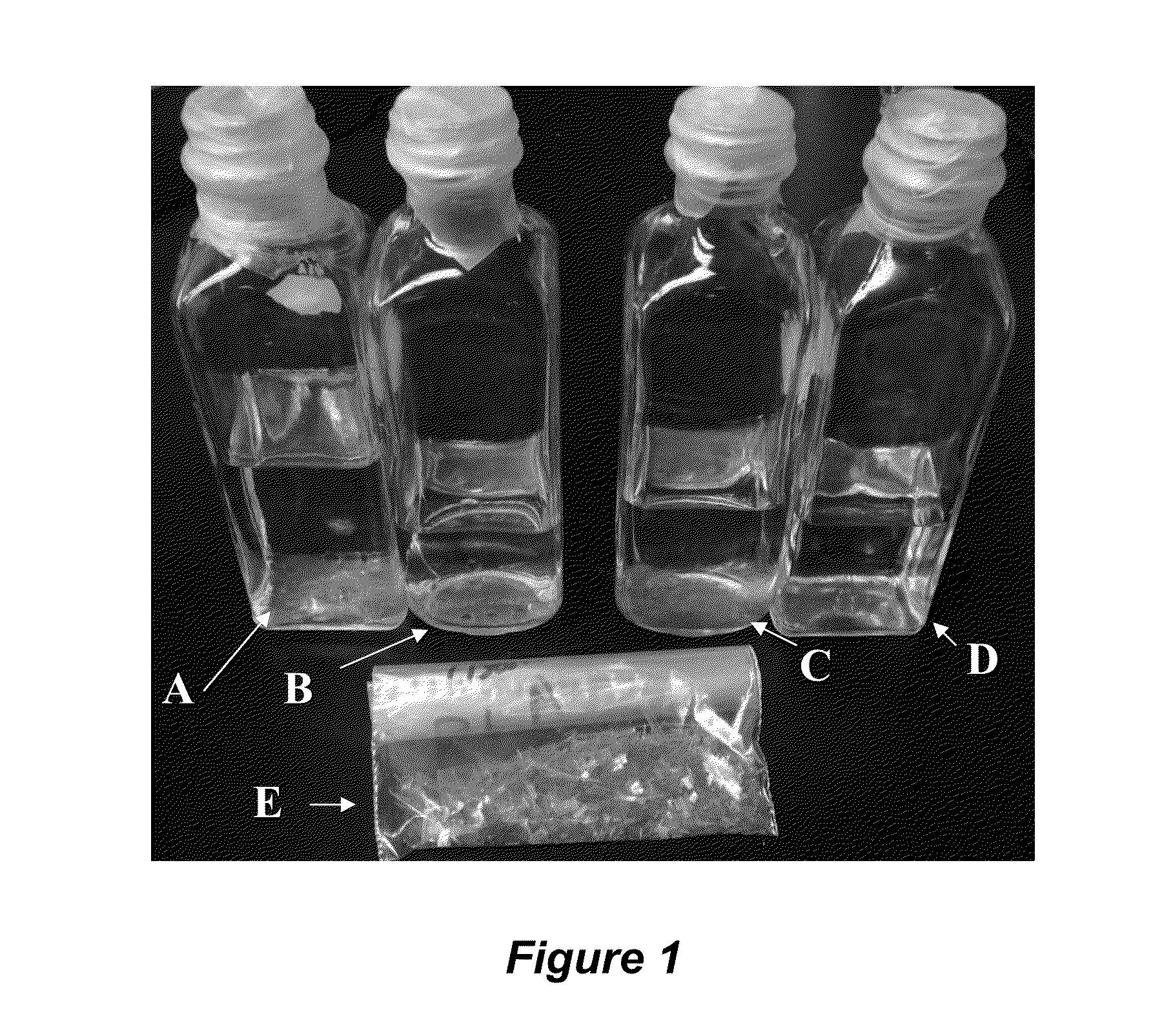

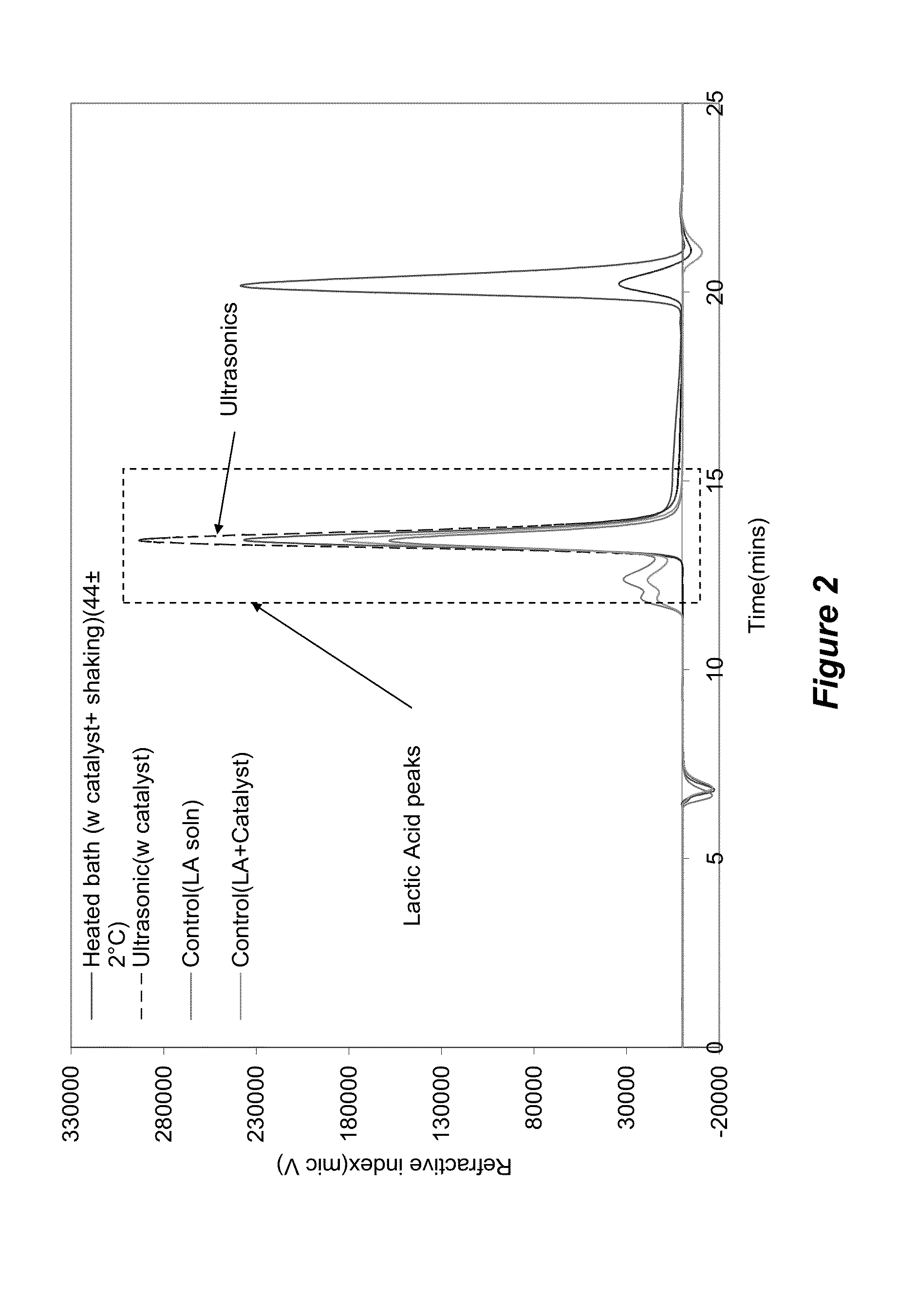

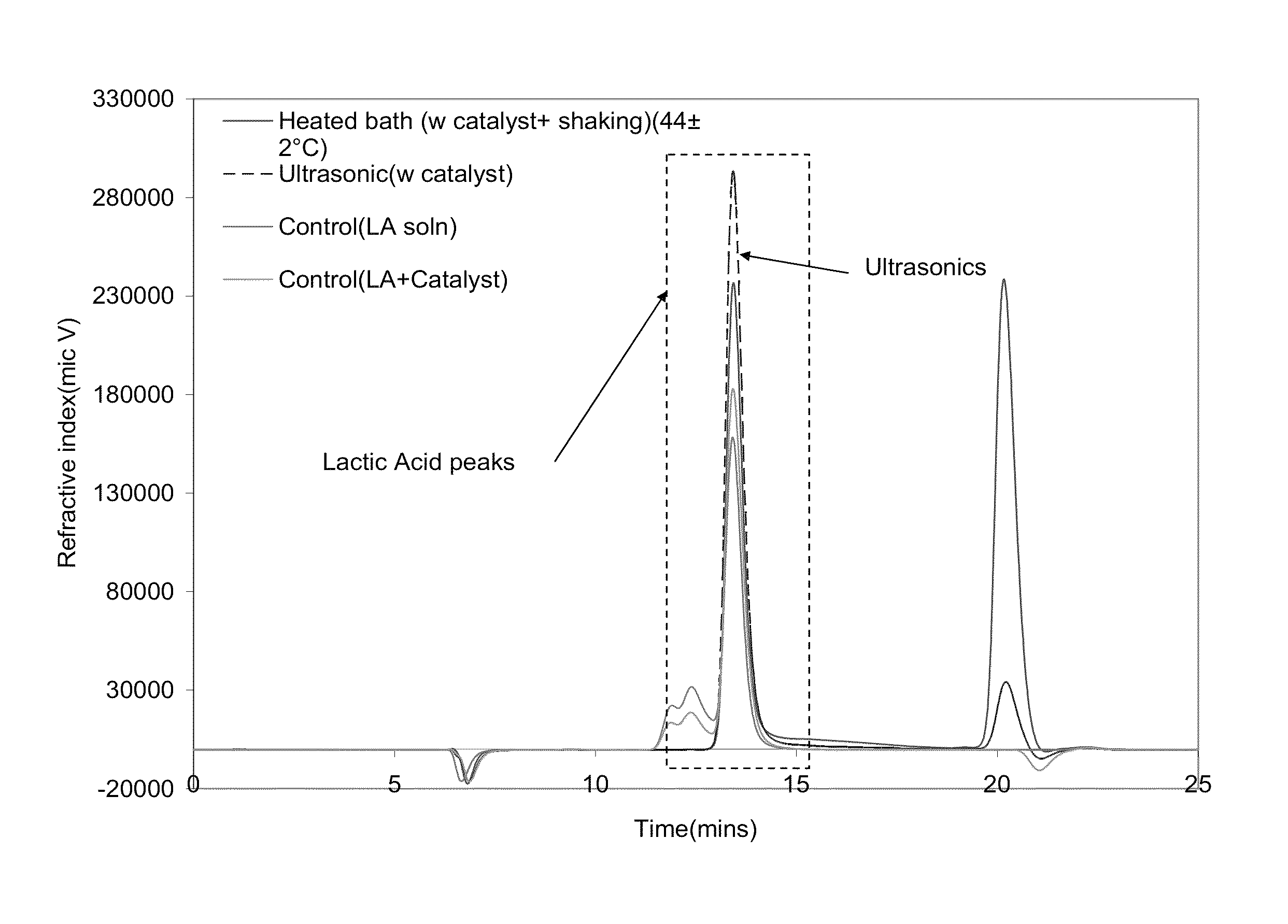

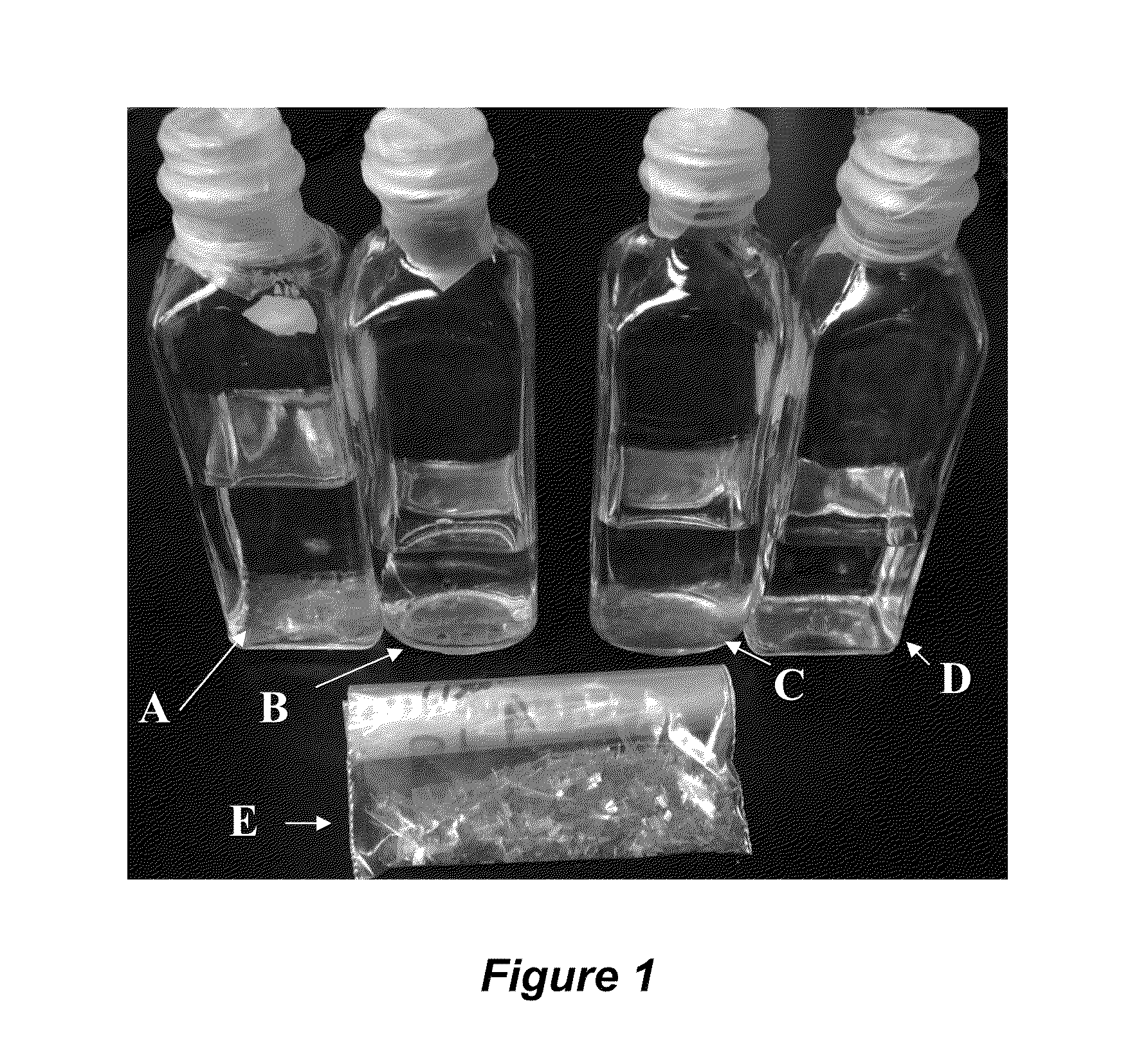

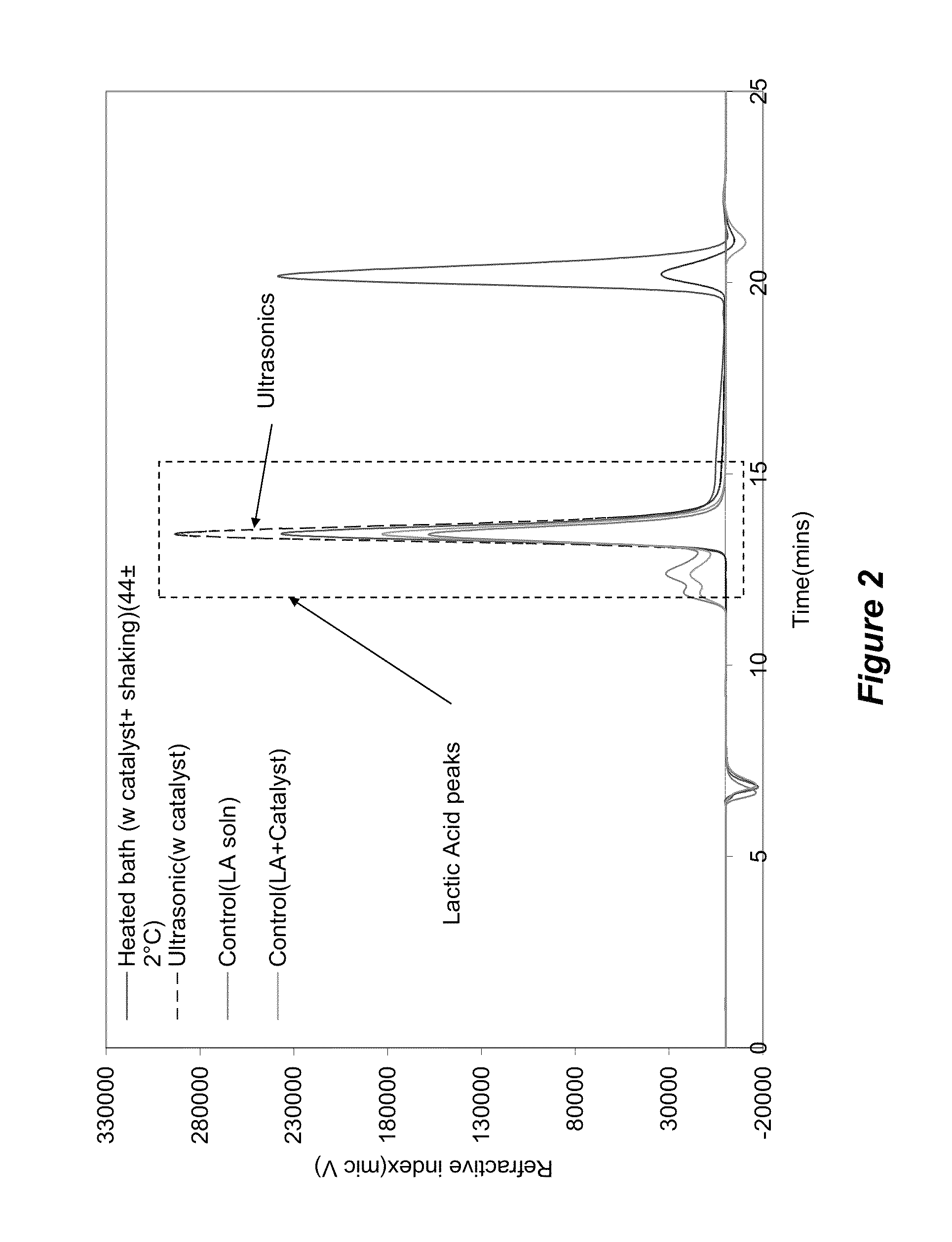

Depolymerization of polylactic acid

InactiveUS20130096342A1Lower energy requirementsReducing greenhouse gas emissionOrganic compound preparationPreparation from carboxylic acid esters/lactonesCyclic processPolyester

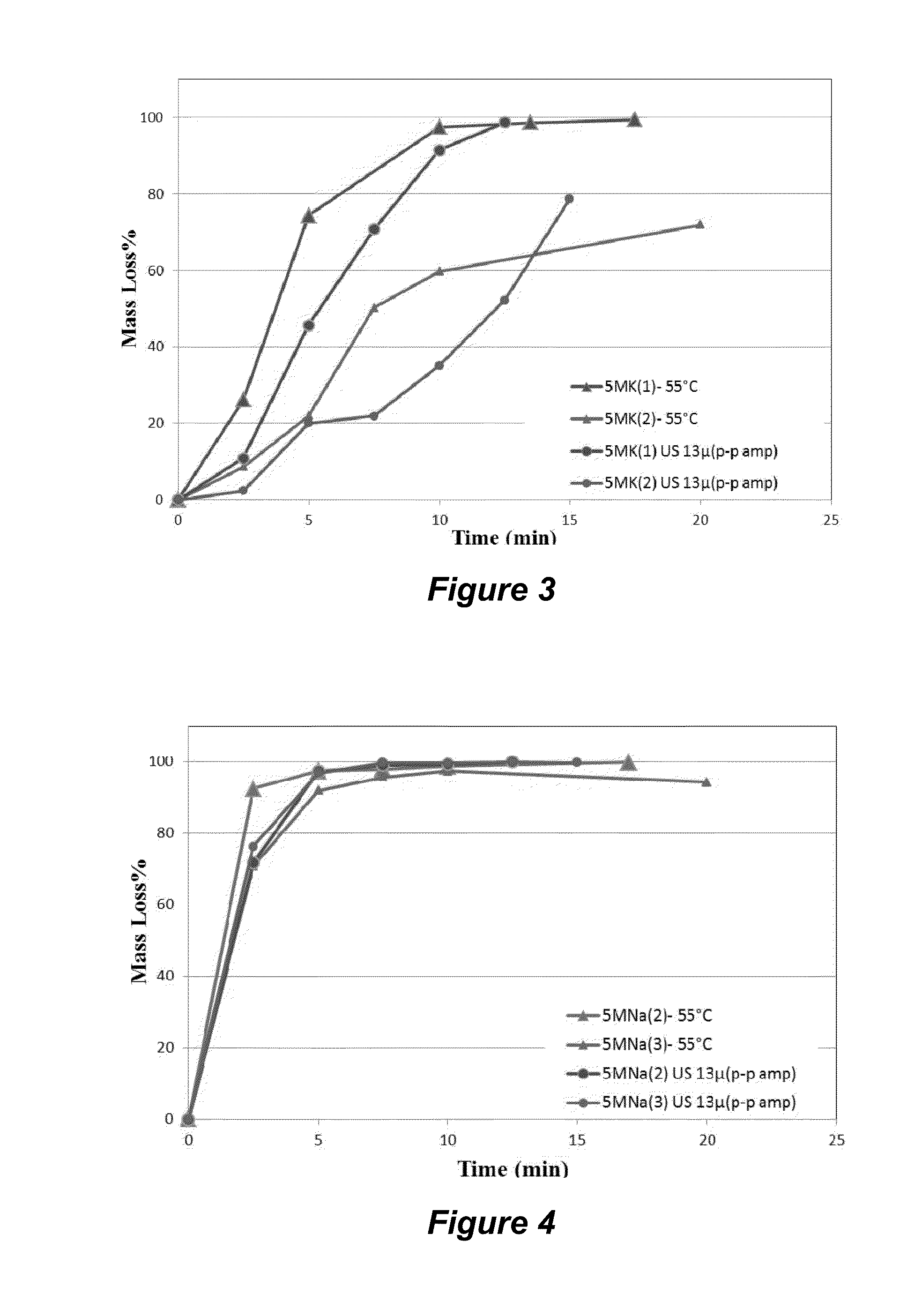

The invention provides energy efficient depolymerization of polyesters such as post-consumer polylactic acid. Ultrasonic induced implosions can be used to facilitate the depolymerization. The expanding market of polylactic acid-based plastic products, such as water bottles and packaging materials, has raised concerns of contaminating the recycling stream, which is largely filled with petroleum-based plastics. Thus the development of an energy efficient and economically viable PLA recycling process is urgently needed. Post consumer PLA was exposed to methanol as the suspension media in the presence of organic or ionic salts of alkali metals such a potassium carbonate and sodium hydroxide as depolymerization catalysts to provide high quality lactic acid monomers in high yield.

Owner:IOWA STATE UNIV RES FOUND

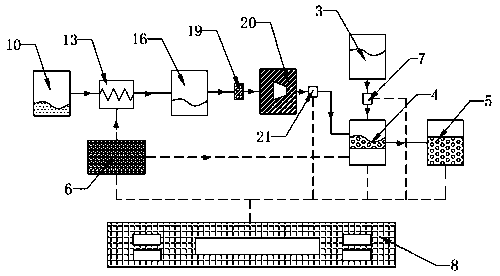

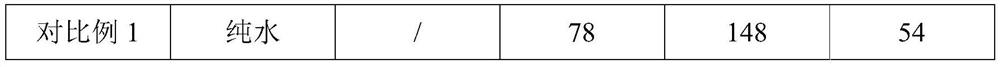

Treatment device and recovering method for pressing alkali

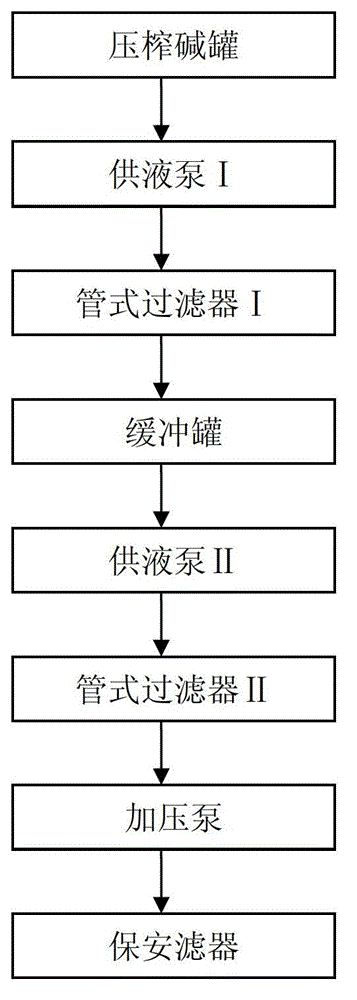

InactiveCN102943322AEfficient separationCost-effective recyclingArtificial filament recoveryTextile/flexible product manufactureEngineeringBuffer tank

The invention discloses a treatment device for pressing alkali. The treatment device for the pressing alkali comprises a pressing alkali tank, a liquid supply pump I, a tubular filter I, a buffer tank, a liquid supply pump II, a tubular filter II, a pressurizing pump and a safety filter. A recovering method for the treated pressing alkali comprises the following steps of: step a, injecting the pressing alkali into the tubular filter I through the liquid supply pump I, intercepting greater semi-fibers by a filtering element and enabling alkali liquor to enter the next-stage buffer tank; step b, enabling the alkali liquor subjected to primary separation to enter the tubular filter II for further separating semi-fiber impurities; and step c, pressurizing the alkali liquor and removing fine particles in the alkali liquor by the safety filter so as to ensure the quality the alkali liquor at an outlet. According to the treatment device disclosed by the invention, on the principle of not changing the properties of original alkali liquor, the current treating device for the pressing alkali is improved and intensified for overcoming the defects; and by optimizing a treatment process of the traditional device, the complete device is compact in structure, effective separation of the semi-fibers from the alkali liquor is realized and the pressing alkali liquor is recovered efficiently and economically.

Owner:大连山元机械制造有限公司

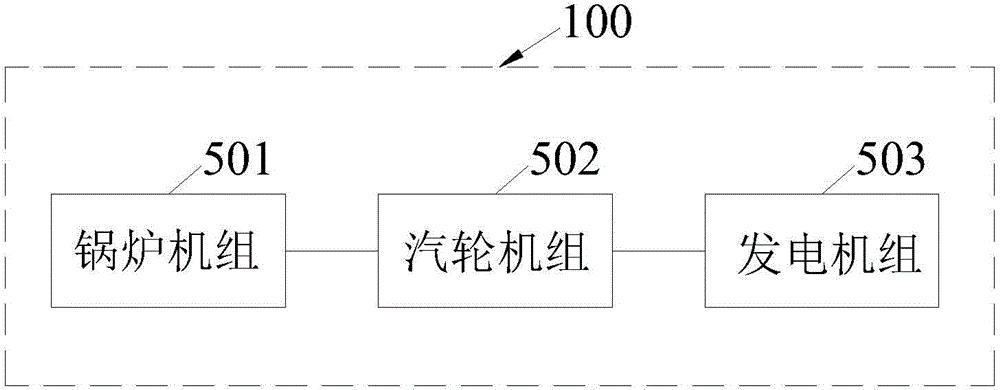

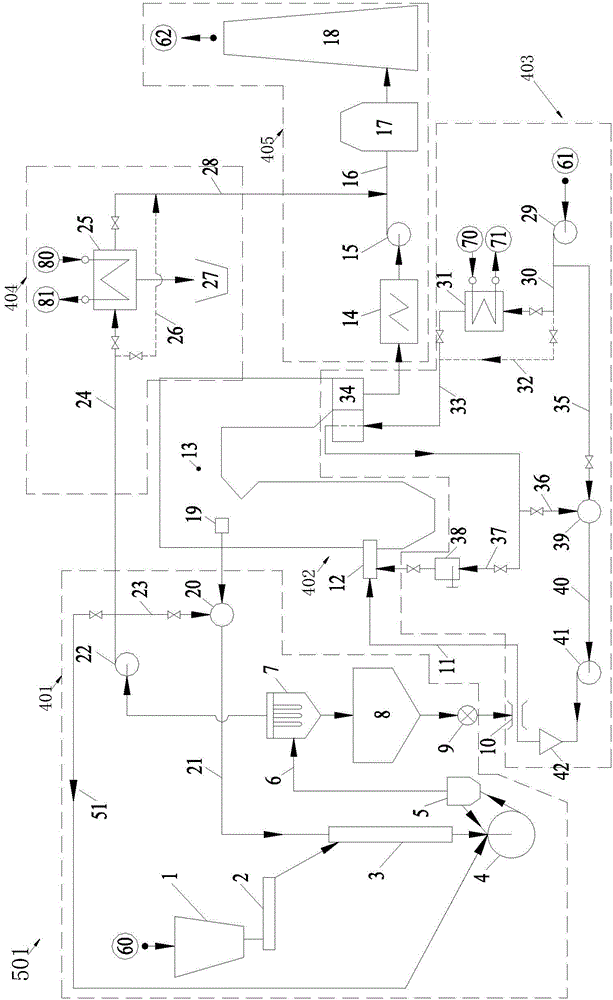

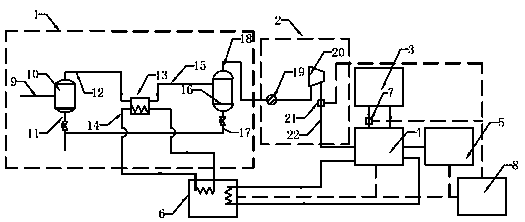

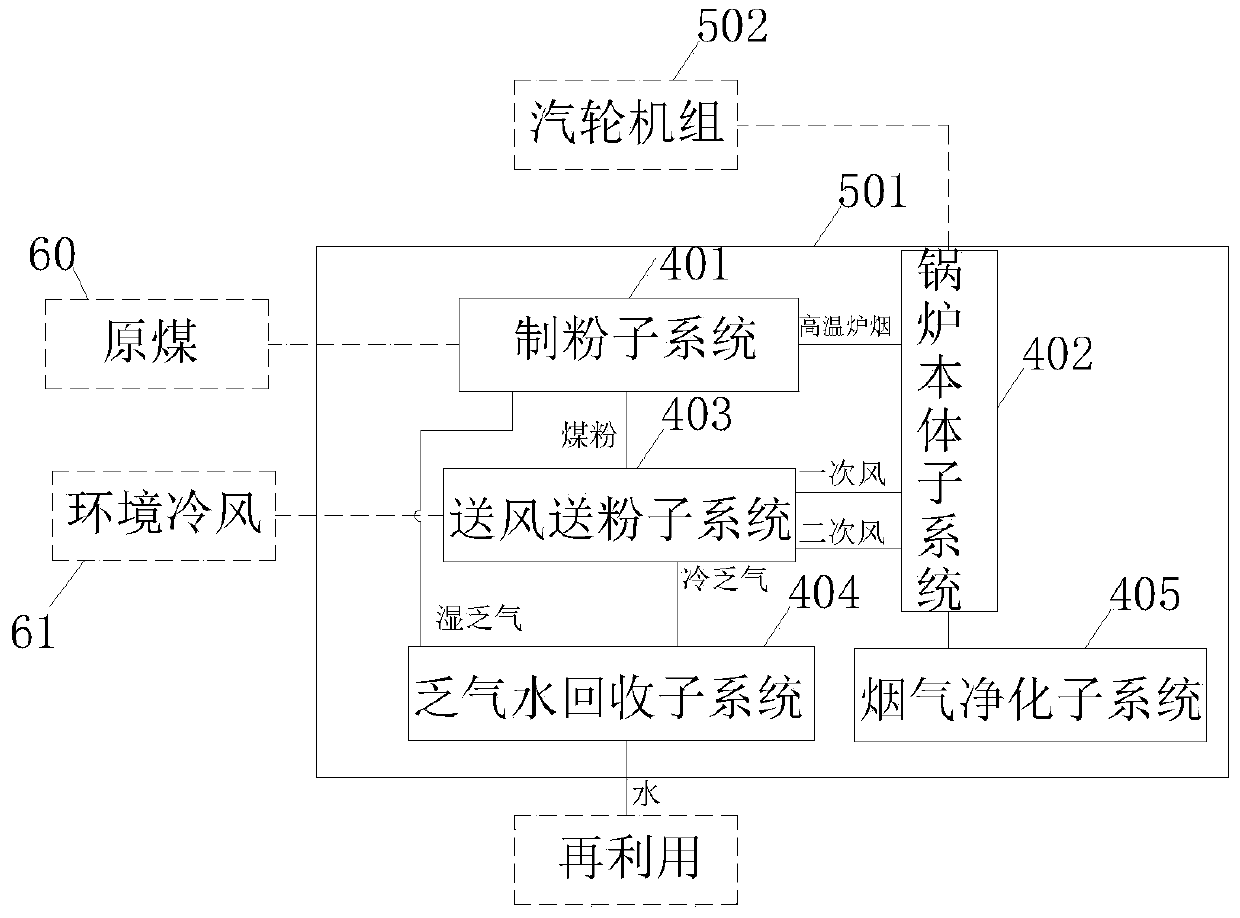

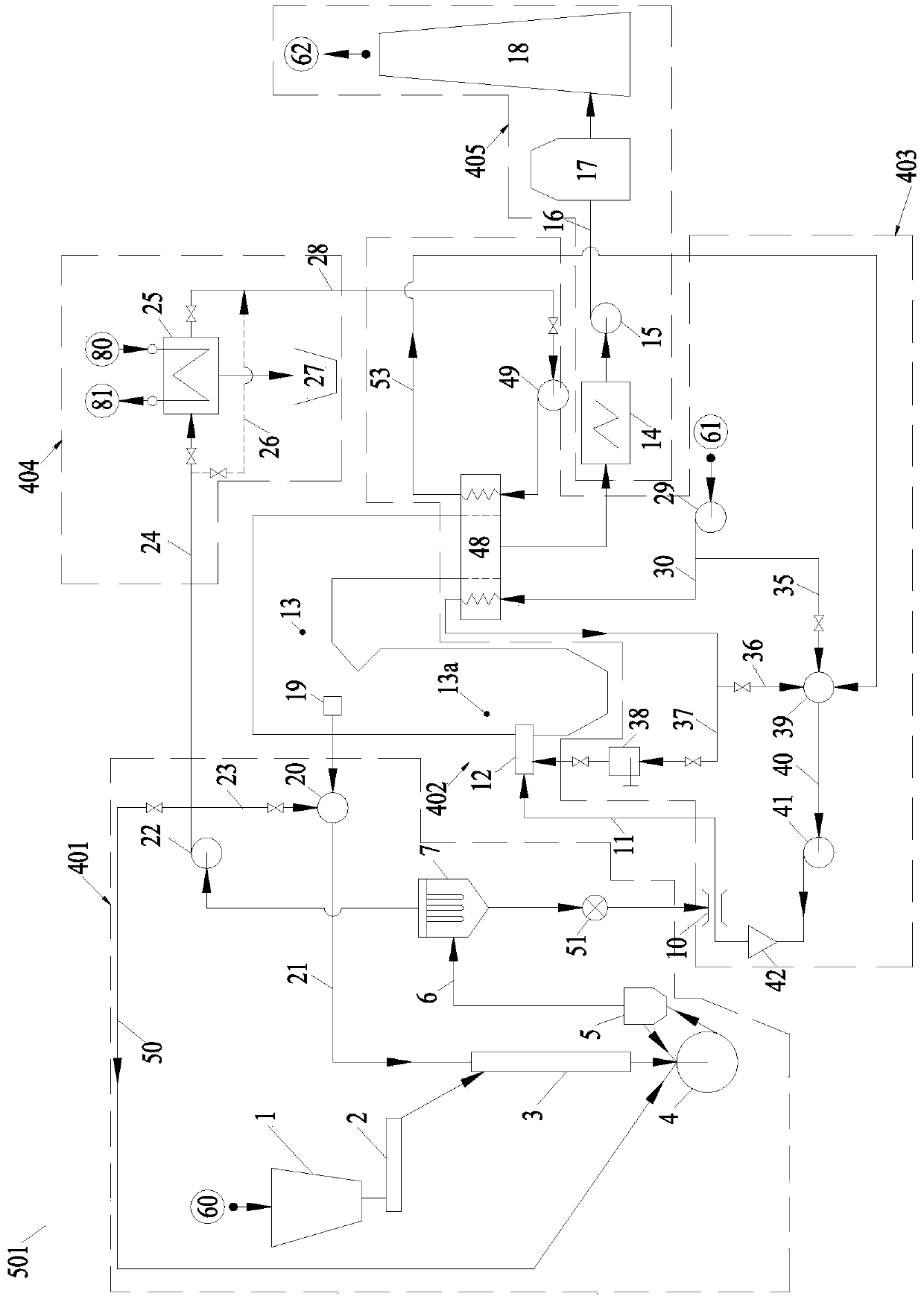

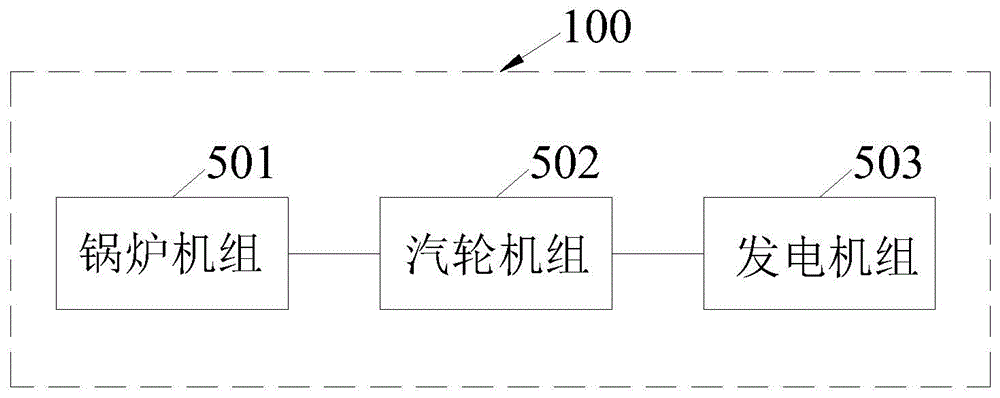

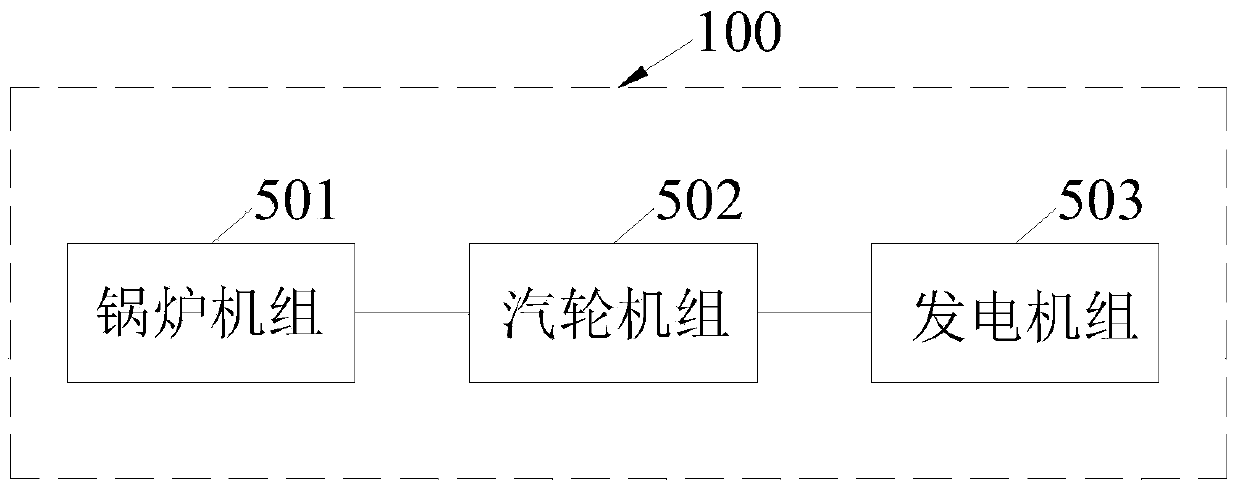

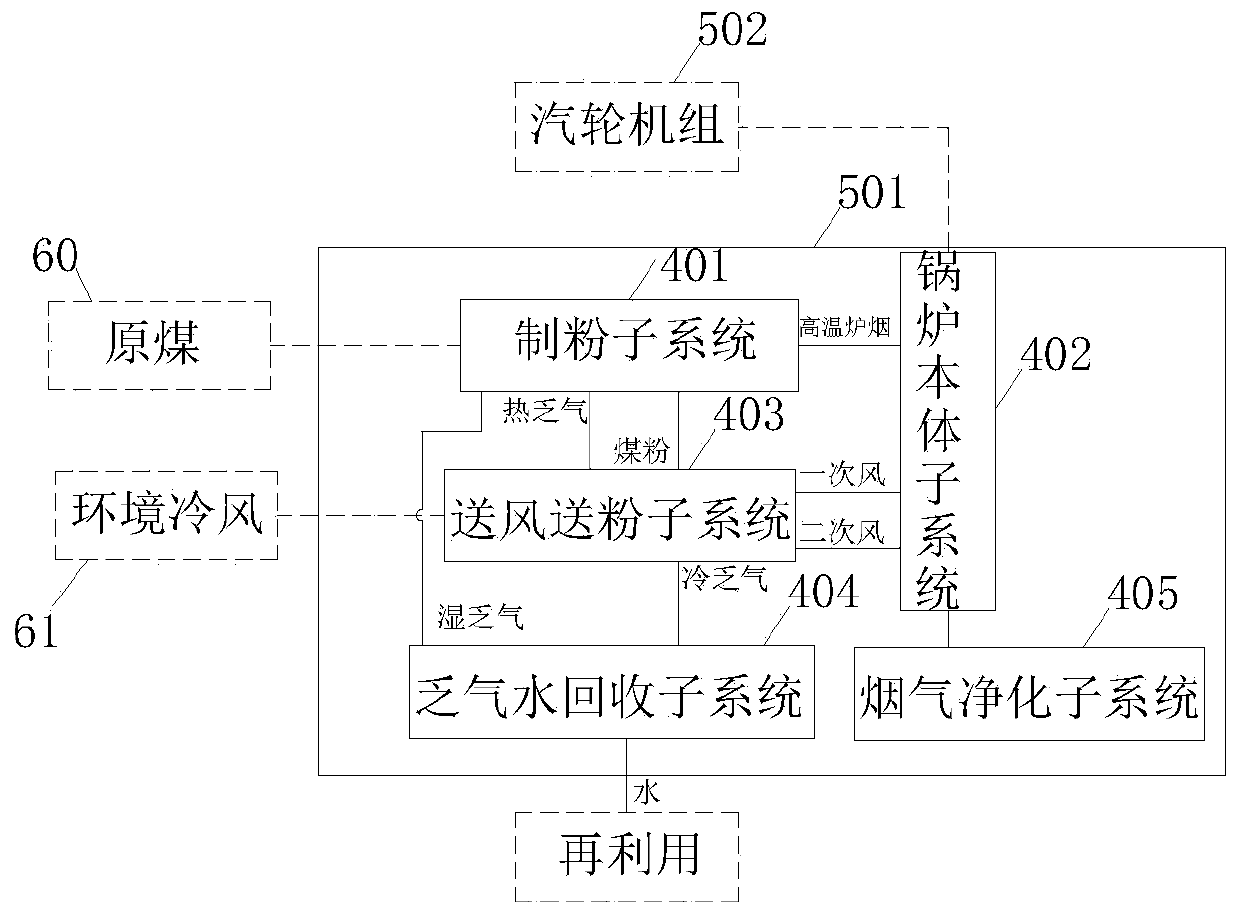

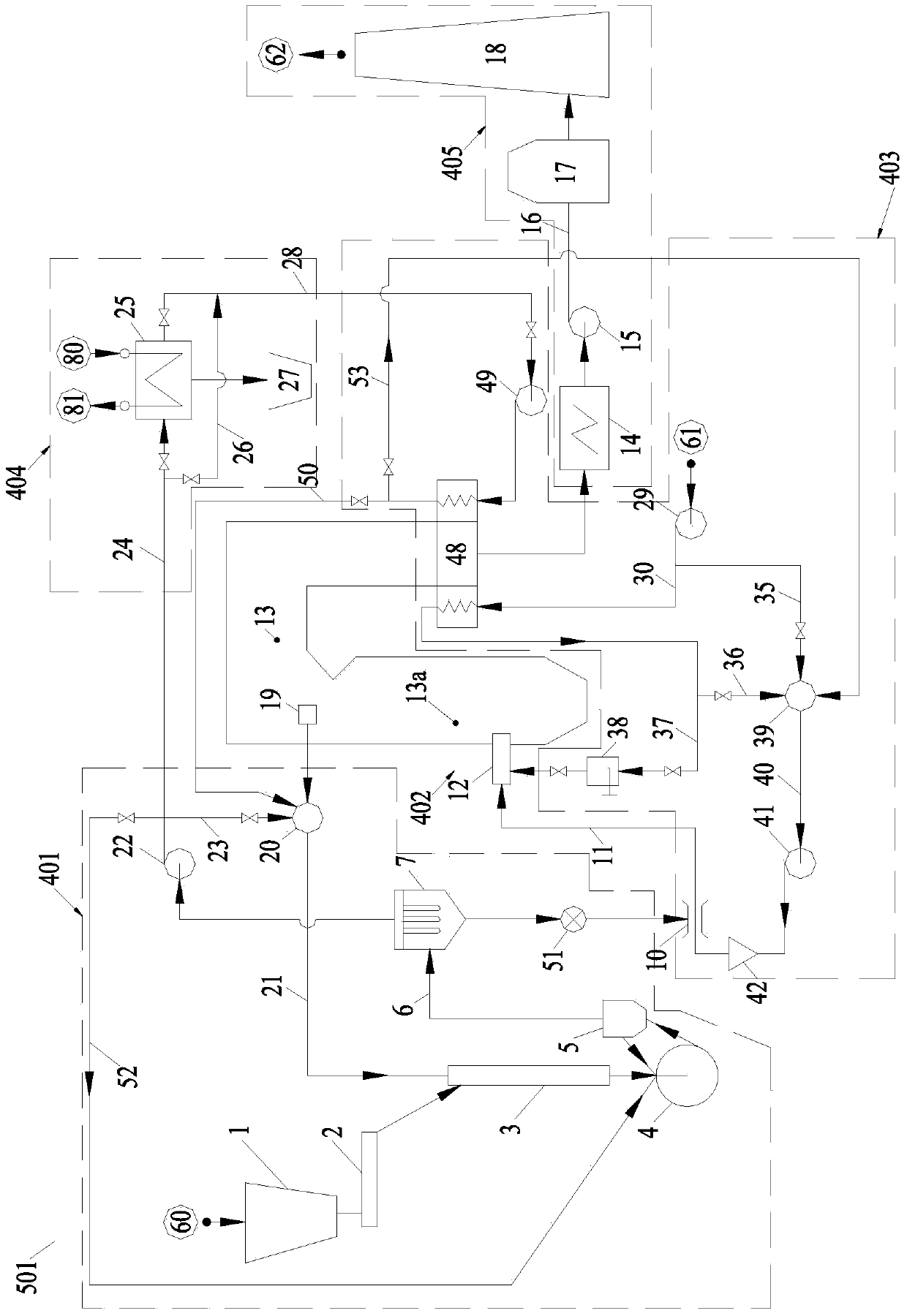

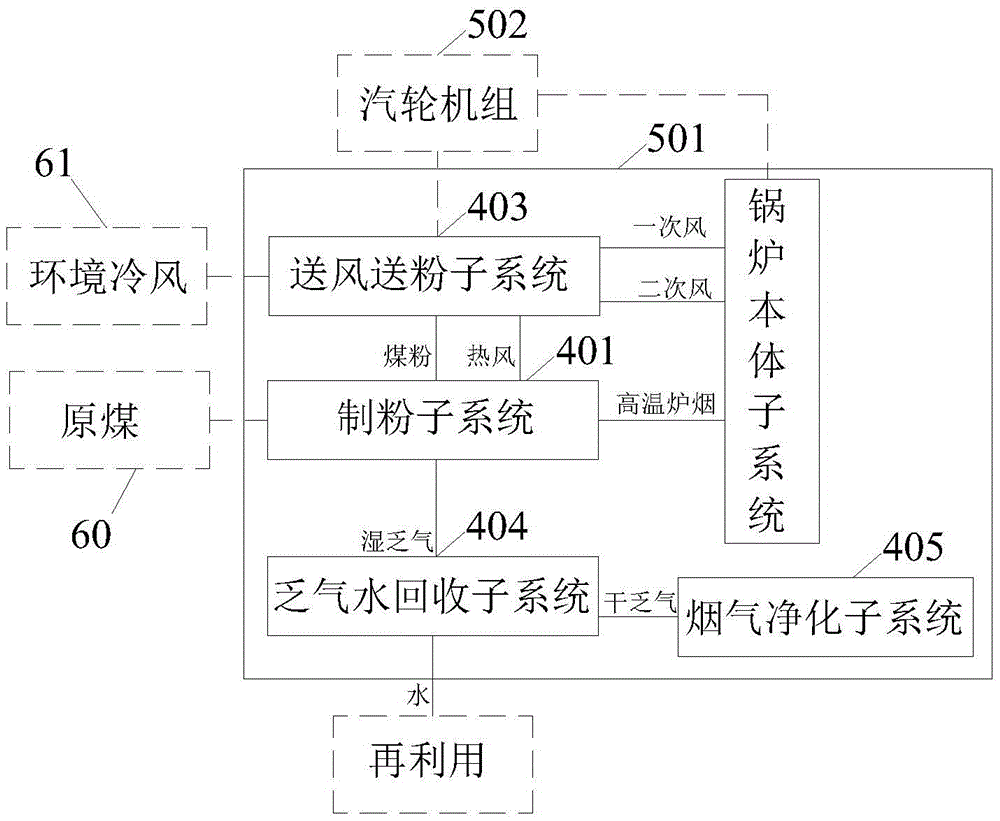

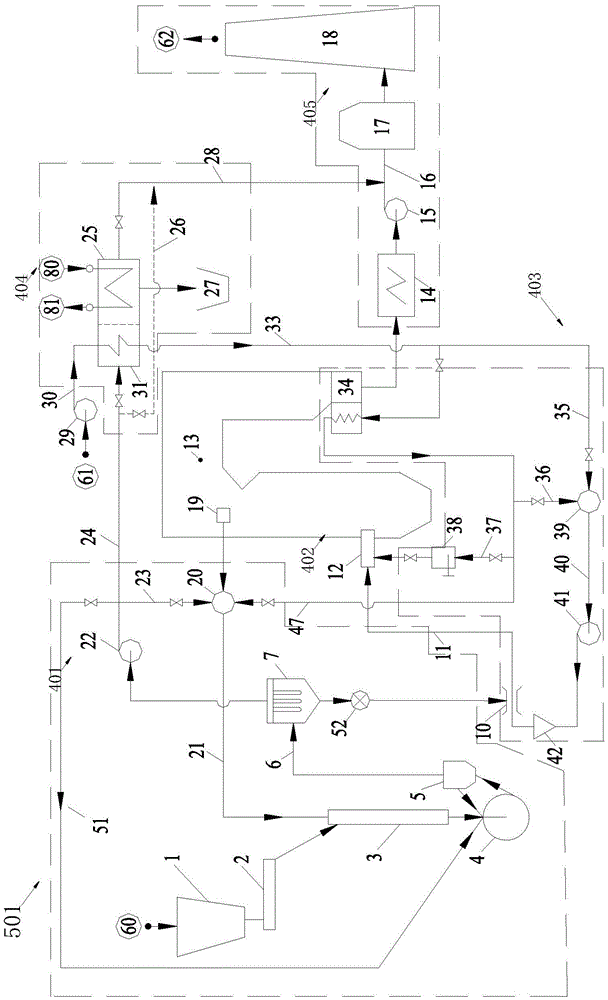

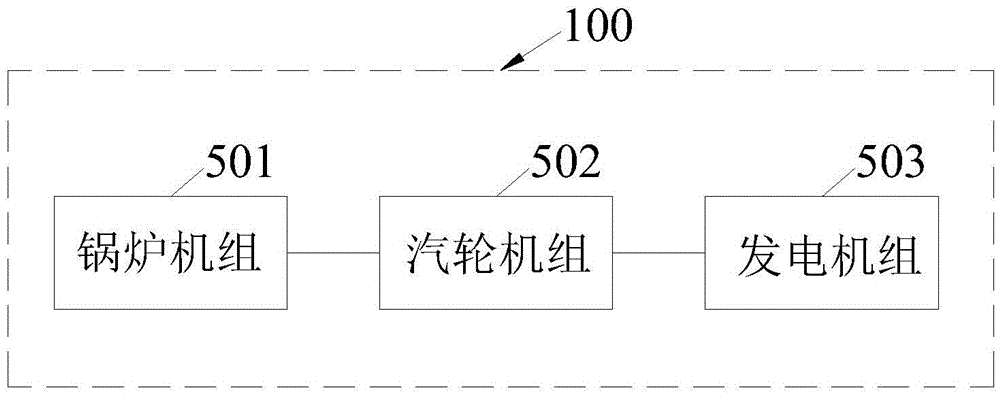

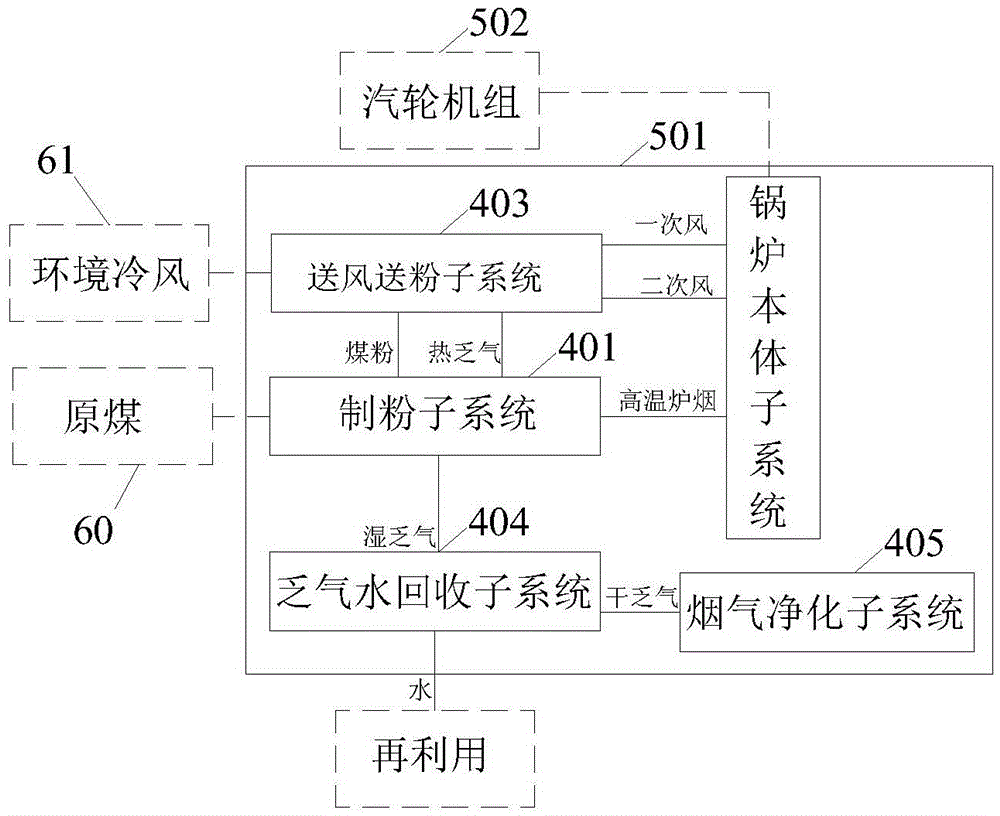

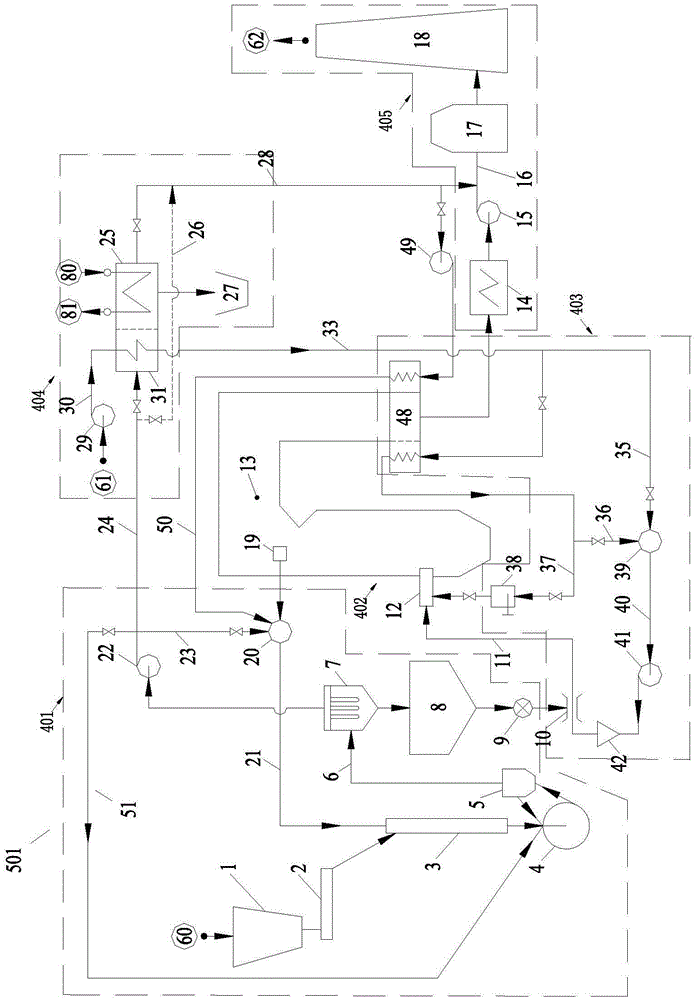

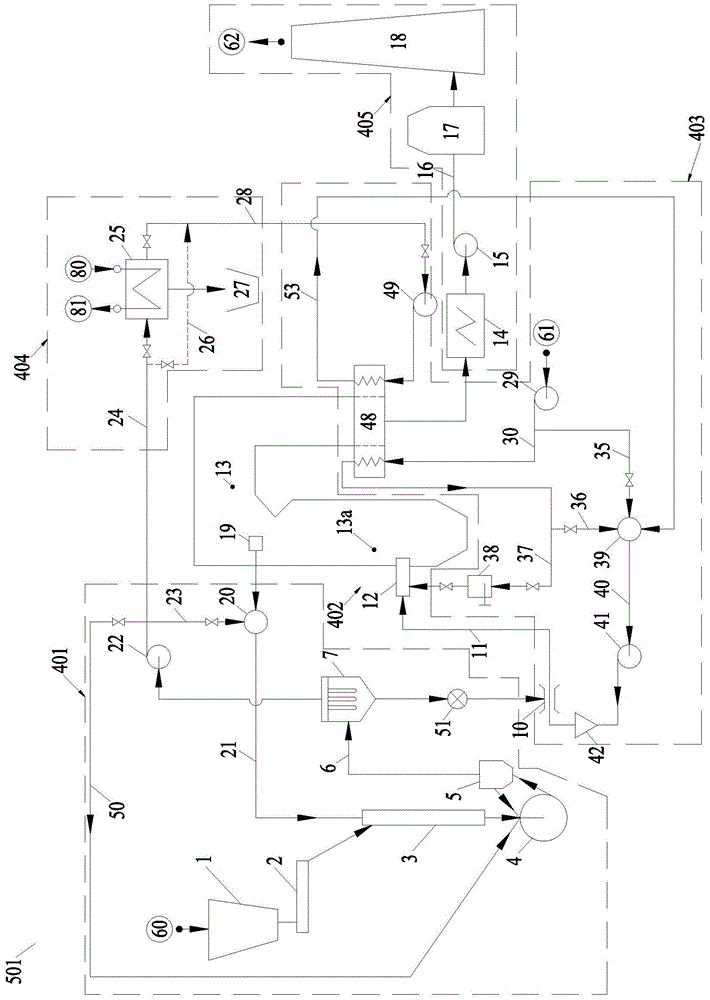

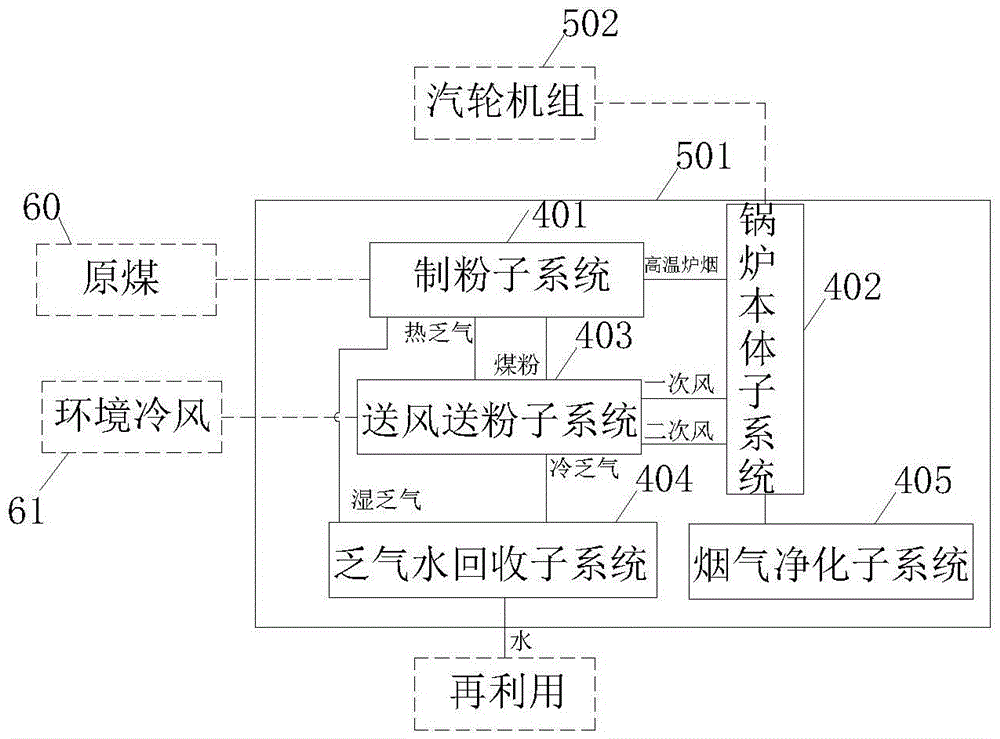

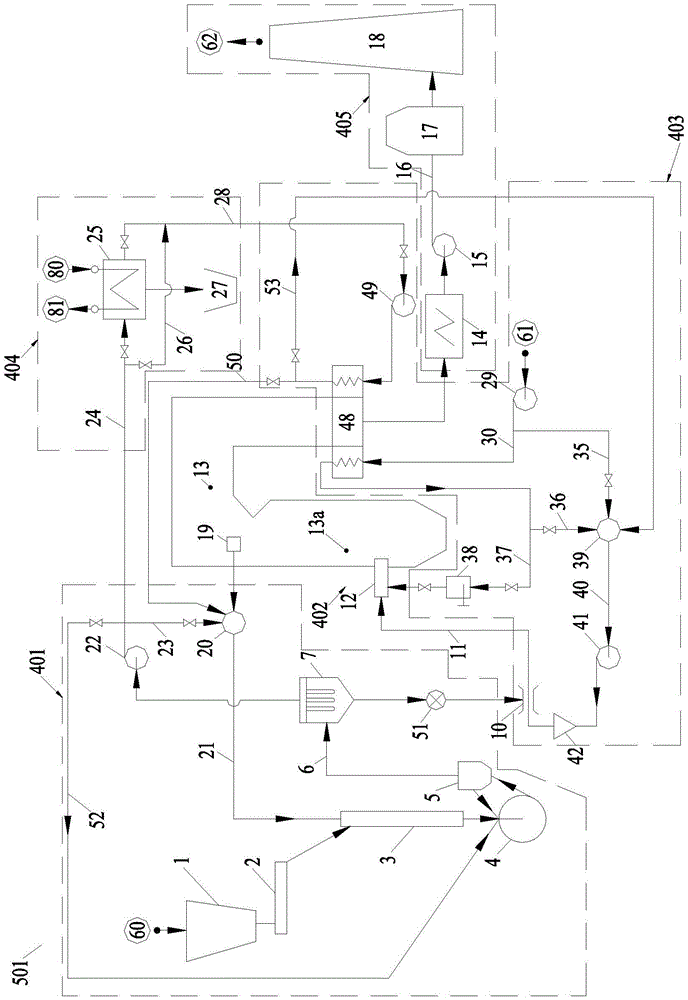

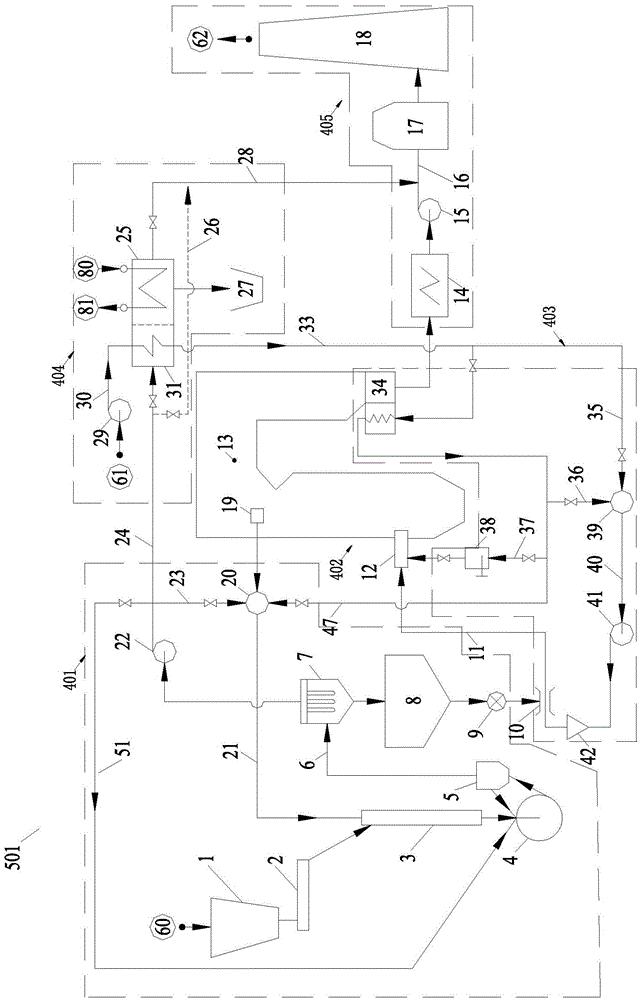

Open powder making steam warm air type boiler unit and power generation system thereof

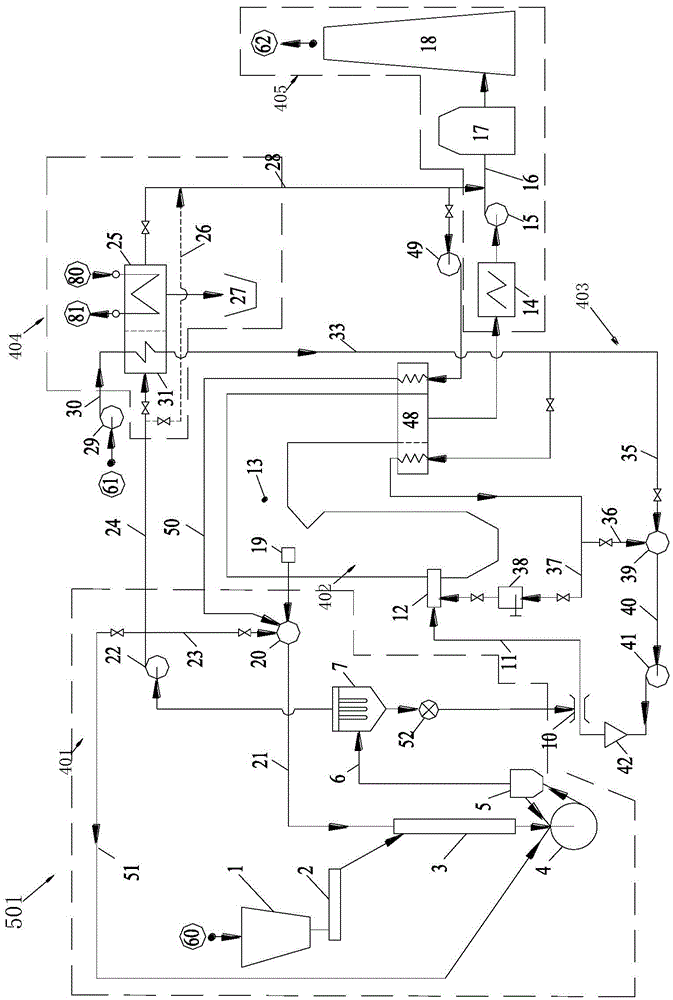

InactiveCN104132364AHigh implementabilityCost-Effective RecyclingIndirect carbon-dioxide mitigationSteam engine plantsCold airAir preheater

The invention provides an open powder making steam warm air type boiler unit used for burning raw coal and being connected with a turbine unit with a turbine. The open powder making steam warm air type boiler unit is characterized in that a drying agent mixing chamber is connected with a smoke extraction opening and a gas outlet of a coal powder collector, a first part exhaust extracted from exhaust and part of smoke extracted out of the smoke extraction opening are mixed and used as drying agents to be fed to a raw coal pre-drying device, a cold air pre-heating device preheats environment cold air to obtain warm air through low-pressure steam extracted out of a steam extraction opening of the turbine, an air preheater further heats the warm air to obtain hot air, one part of the hot air and the environment cold air are mixed to be used as primary air, an air and powder mixer mixes the primary air and coal powder to obtain air and powder mixtures, and the other part of the hot air is used as secondary air to be directly fed in a coal powder burner. The invention further provides a power generation system including the open powder making steam warm air type boiler unit and the turbine unit with the turbine.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

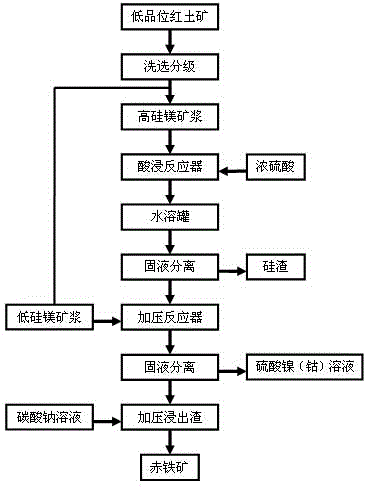

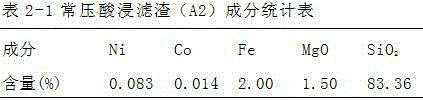

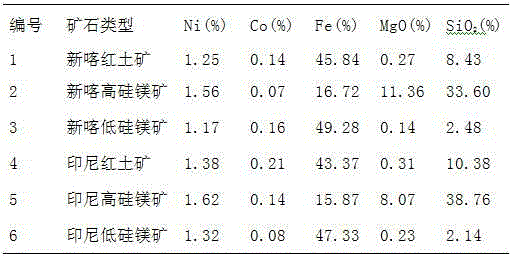

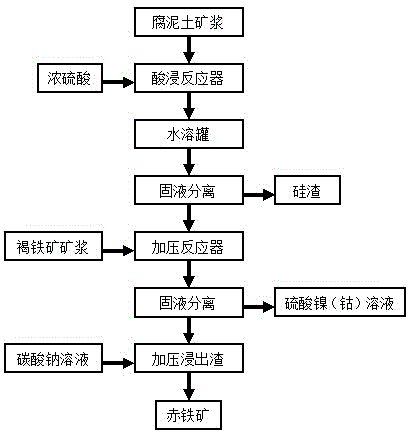

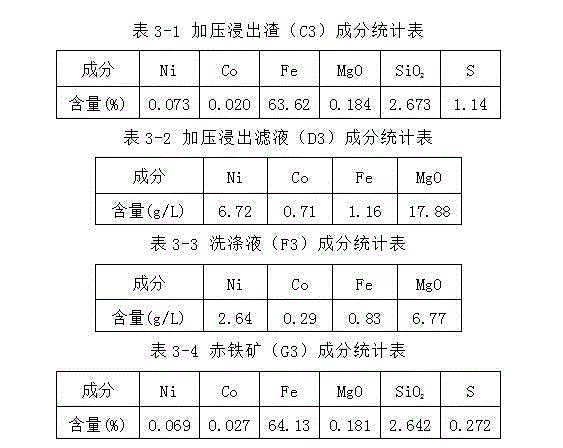

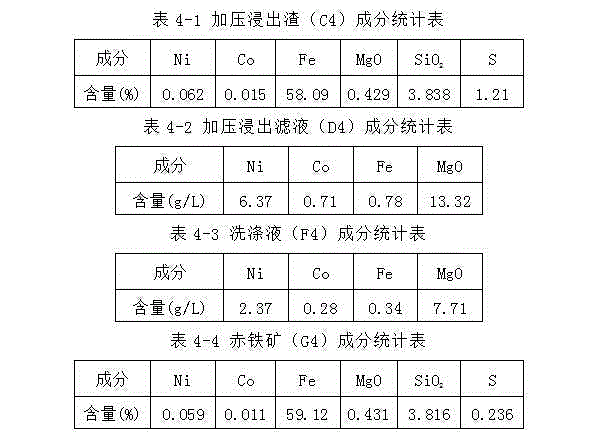

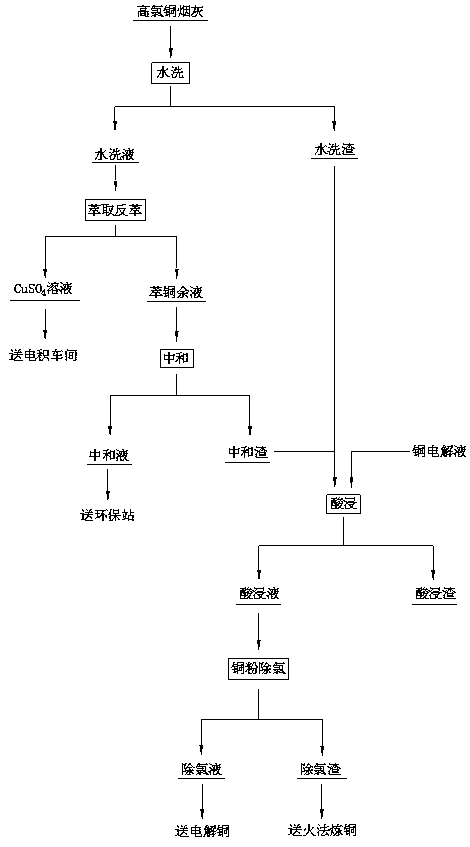

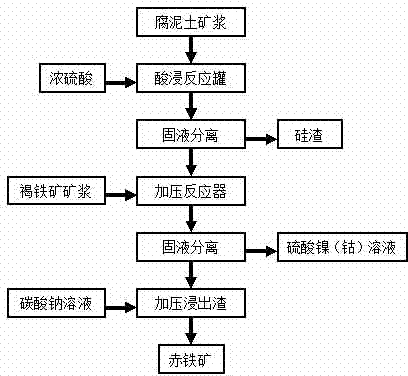

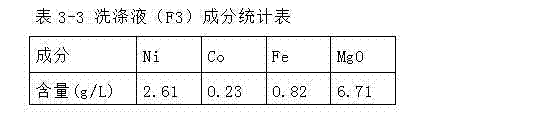

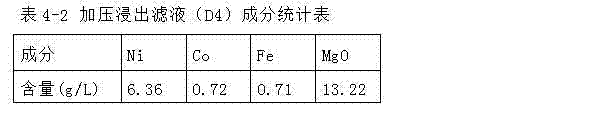

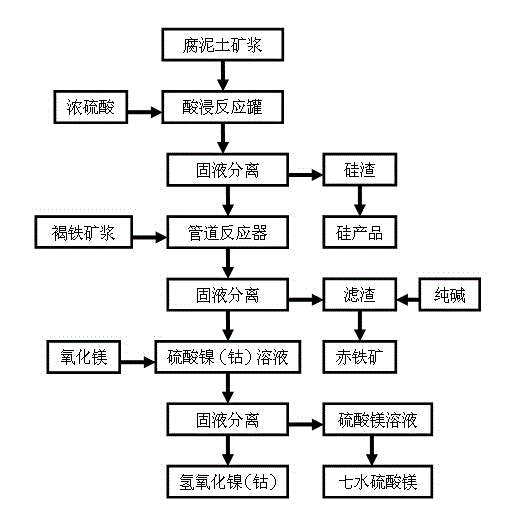

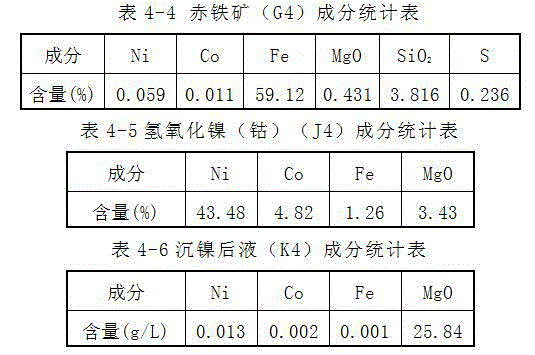

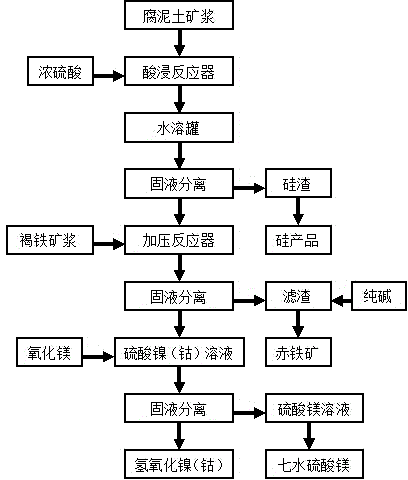

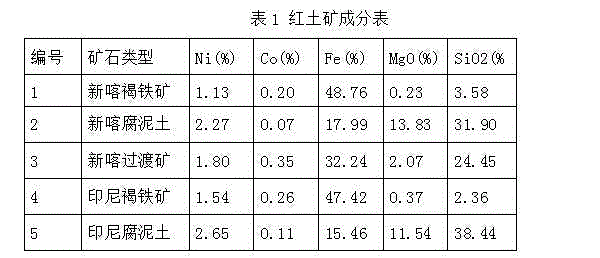

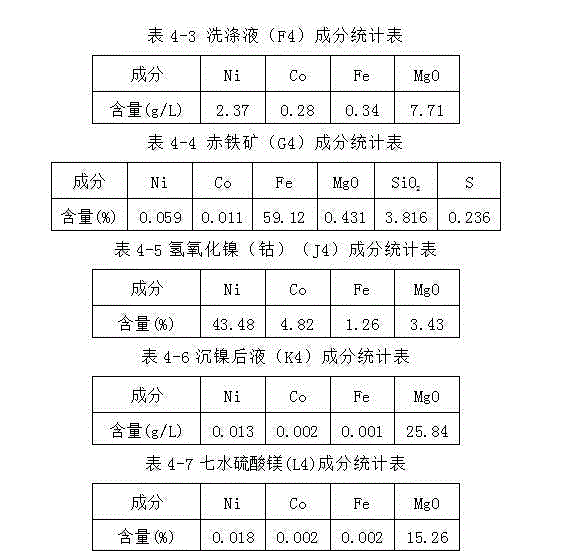

Method of recycling nickel, cobalt and iron from low-grade laterite-nickel ore

InactiveCN104831061AReduce investment and operating costsSimple operation and maintenanceProcess efficiency improvementMagnesiumLow graded

A method of recycling nickel, cobalt and iron from low-grade laterite-nickel ore includes following steps: (1) performing washing classification to obtain high-silicon and -magnesium ore and low-silicon and -magnesium and high-iron ore; (2) adding enough concentrated sulfuric acid to the high-silicon and -magnesium ore slurry, and performing a reaction at 160-280 DEG C; (3) performing solid-liquid separation to obtain a normal-pressure leached residue and a normal-pressure leached liquid; (4) adding the normal-pressure leached liquid and the low-silicon and -magnesium and high-iron ore slurry according to proportion and performing pressurized leaching to the mixture at 195-240 DEG C; (5) purifying a pressurized-leached filtrate; (6) recycling nickel and / or cobalt through precipitation of sulfides or hydroxides or other recycling methods; and (7) washing the normal-pressure leached residue with a 10% sodium carbonate solution and drying the normal-pressure leached residue to obtain an iron concentrate powder product. The method is wide in adaption range of the laterite, is high in leaching rate of the nickel and the cobalt, is small in normal-pressure leaching device, is short in time and is high in efficiency. The normal-pressure leaching device is a middle-low pressure device, thereby avoiding defects that a high-pressure kettle is high in cost and is liable to scale. The method is quite low in sulfuric acid consumption. The main component, iron, in the ore can be recycled economically and effectively. The method is less in amount of waste residue and can effectively utilize the waste residue.

Owner:JINCHUAN GROUP LIMITED

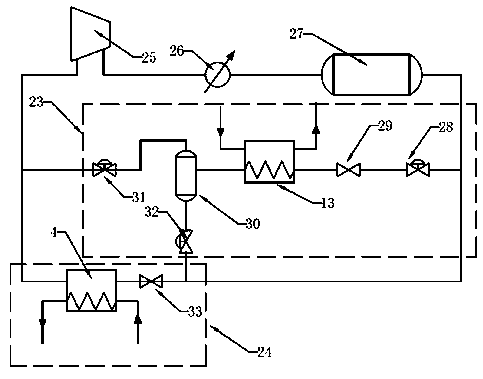

Oil field associated gas recycling device and method

The invention relates to an oil field associated gas recycling device and method, and belongs to the technical field of natural gas hydrate application. Through the improved design of a low-temperature separator structure, oil field associated gas enters the low-temperature separator to realize multi-section removal of heavy hydrocarbon after primary separation and low-temperature cooling; a firstrefrigerating system and a second refrigerating system are designed, so that flow of each pipeline refrigerant is regulated and controlled through a data monitoring unit; a field process is combined,a hydrate prizing production device integrating heavy hydrocarbon removal, boosting, liquid storage, hydration reaction, hydrate slurry external conveying treatment and a refrigerating unit is provided. According to the oil field associated gas recycling device and method provided by the invention, oil field associated gas is converted into hydrate, so that associated gas heavy hydrocarbon removal, hydrate quick preparation, hydrate generation speed calculation, generation amount control and the like can be realized, so that part of the resource waste problems due to the fact that associatedgas of a far oil field without pipeline facilities or not worthy of laying pipelines can be effectively solved.

Owner:SOUTHWEST PETROLEUM UNIV

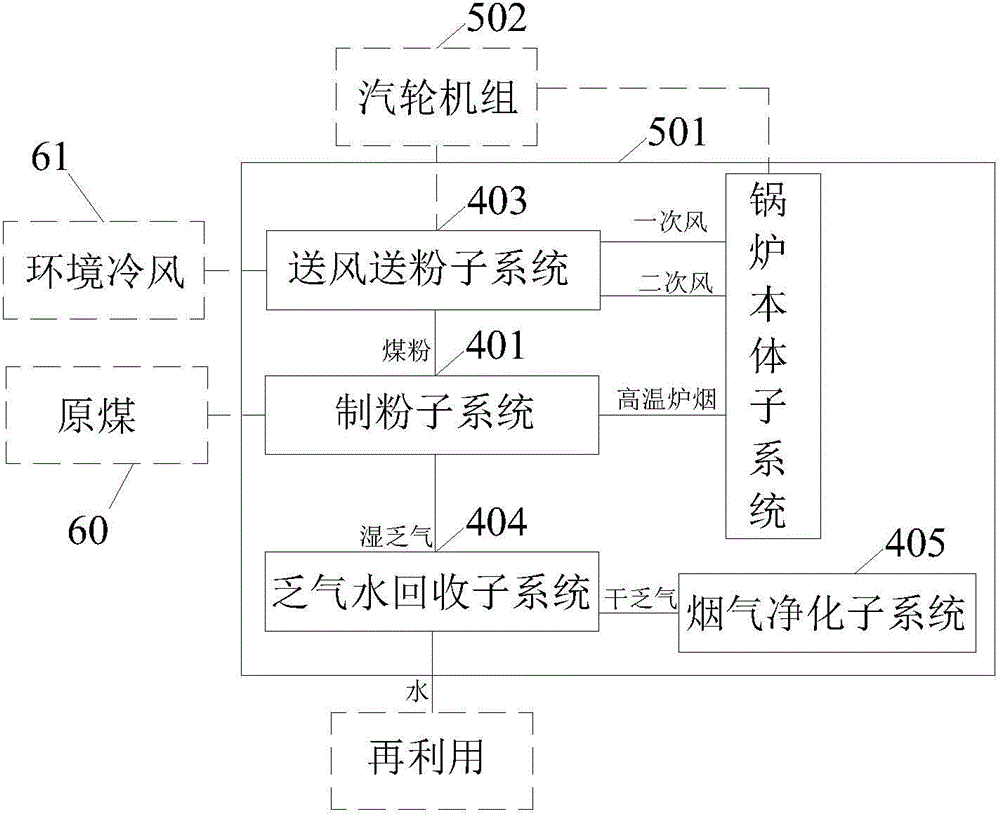

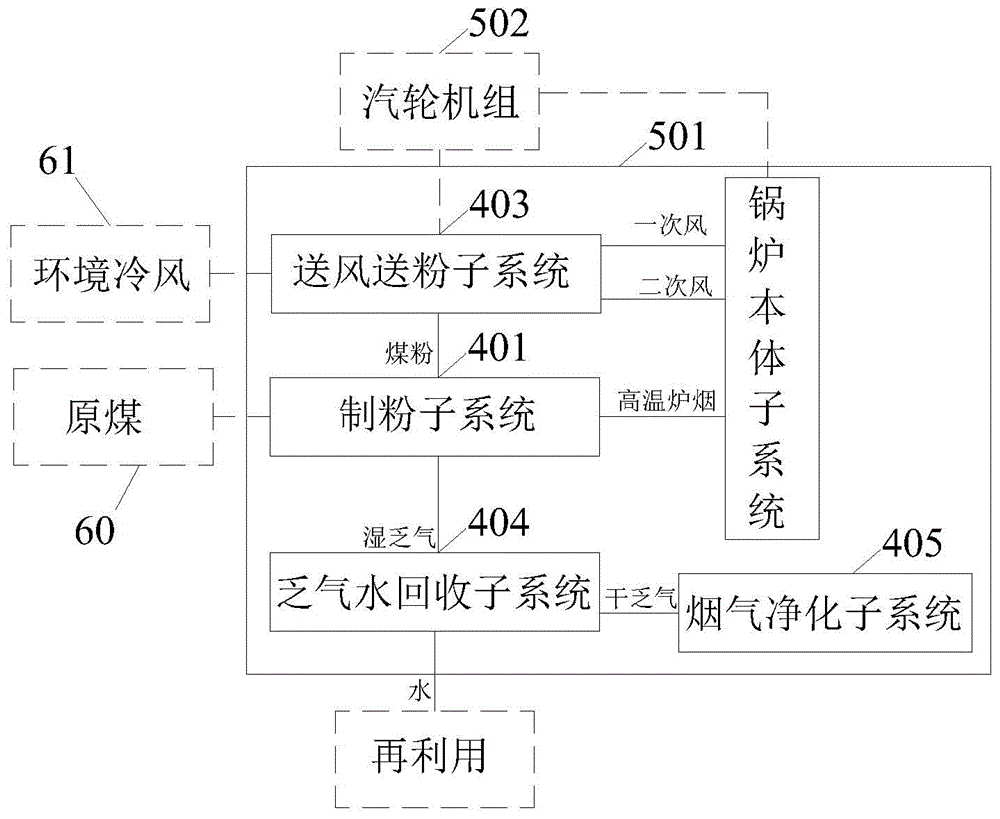

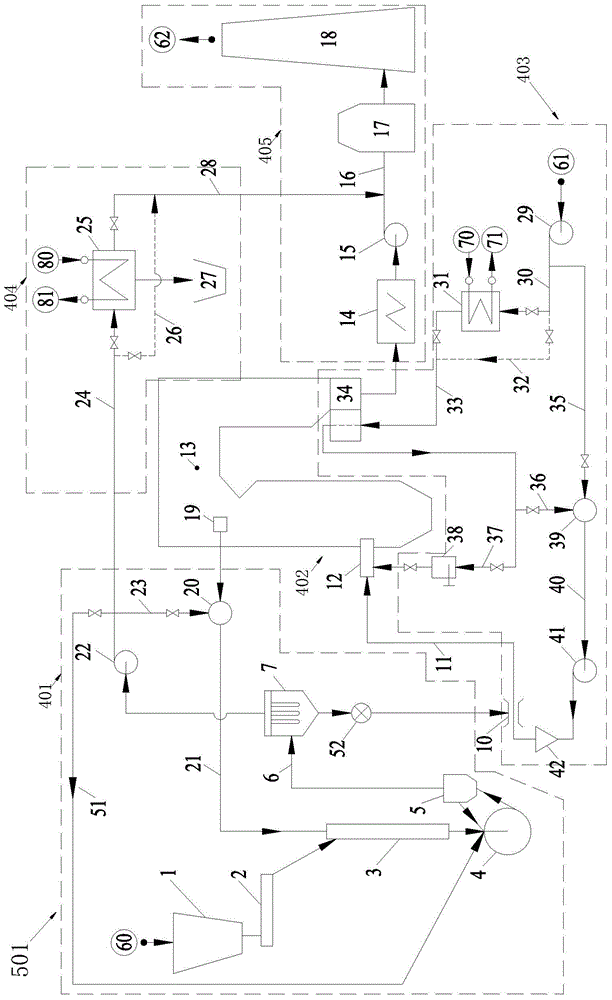

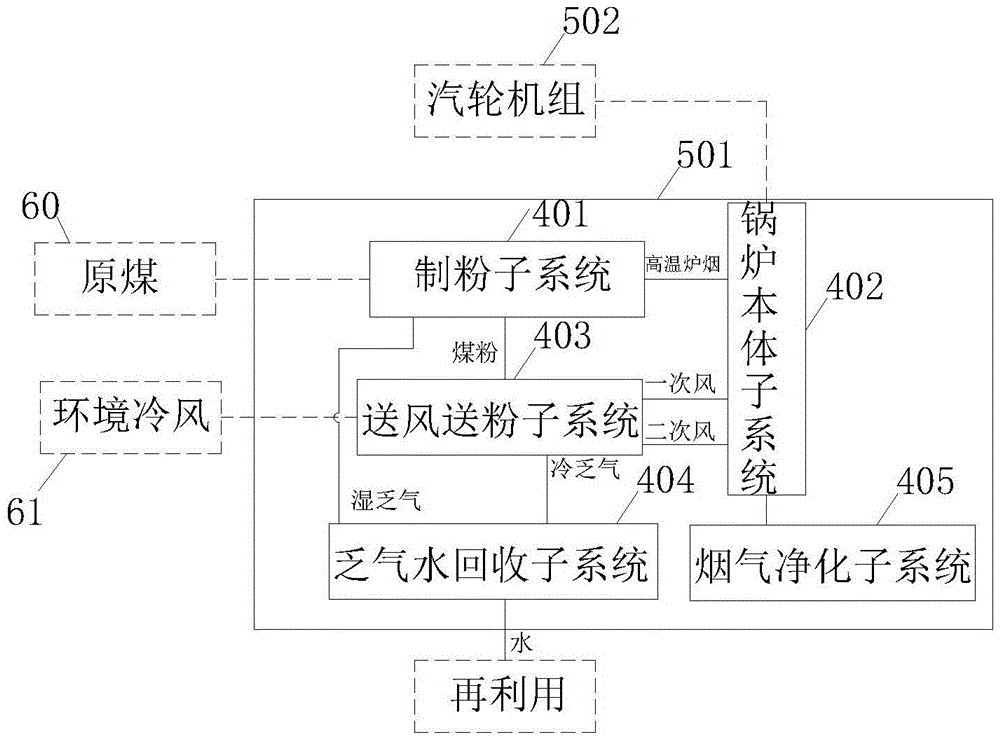

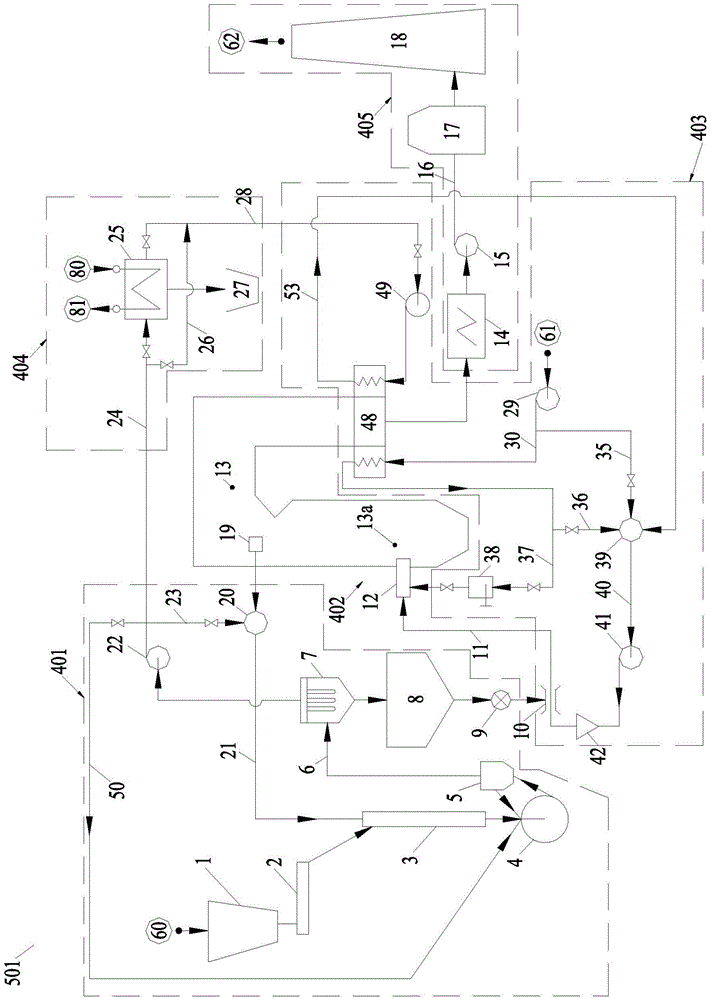

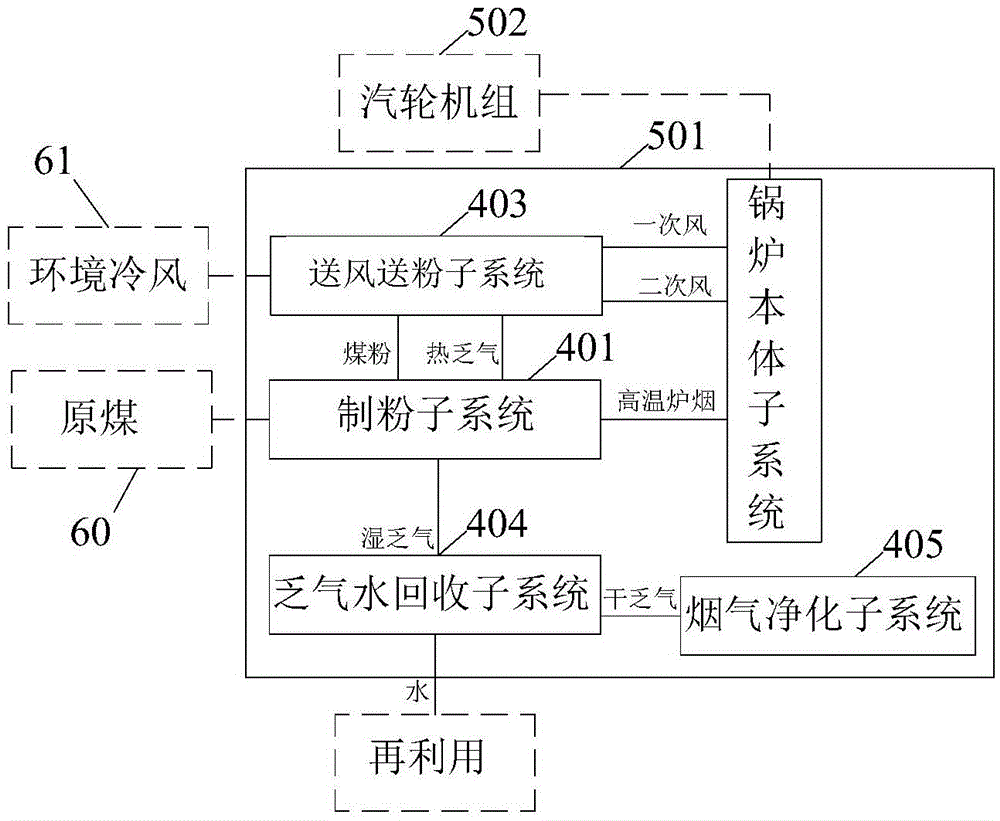

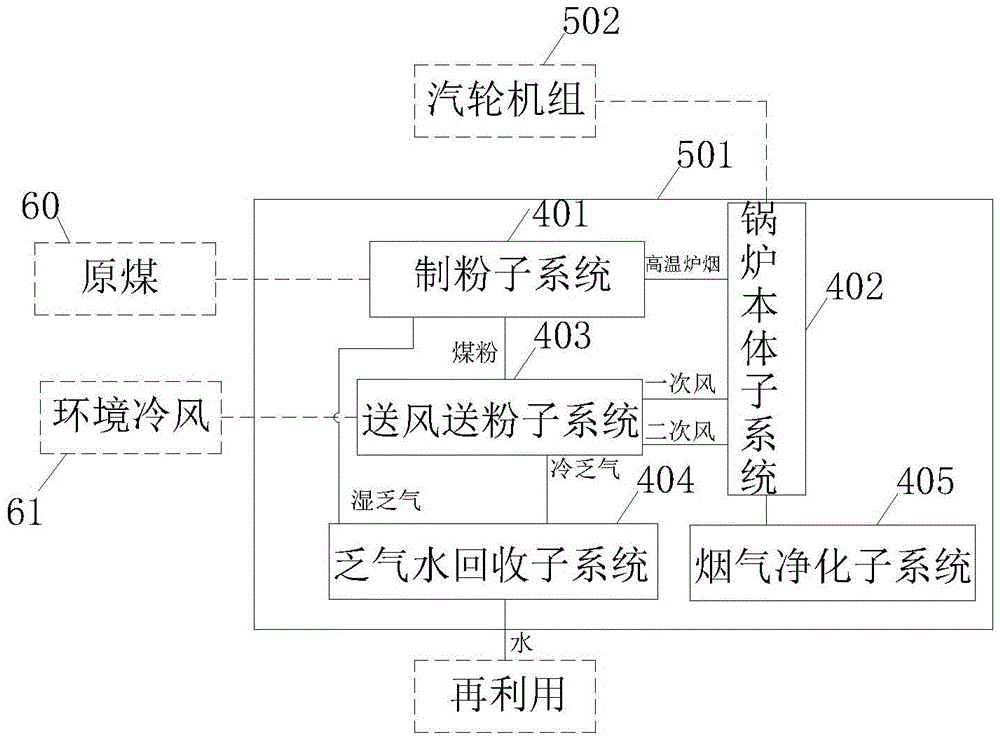

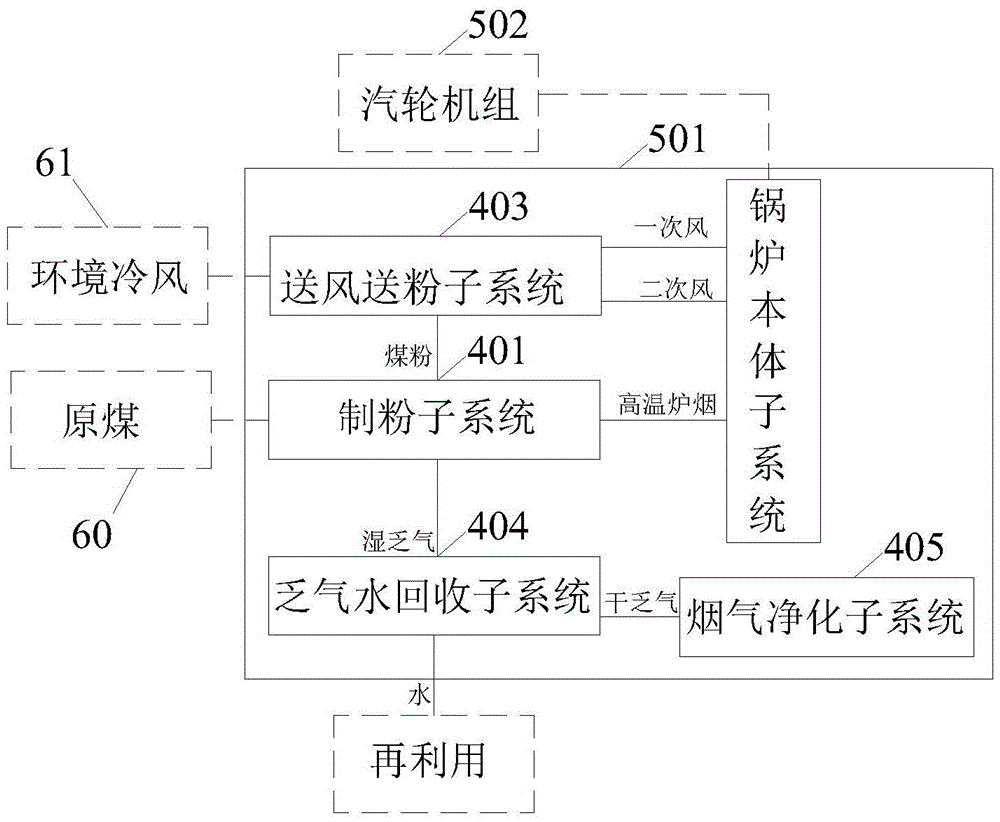

Fume-dried closed pulverization coal-fired boiler unit with function of exhaust water recovery

InactiveCN104197362AHigh implementabilityCost-effective recyclingIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionCold airThermodynamics

The invention provides a fume-dried closed pulverization coal-fired boiler unit with a function of exhaust water recovery. The fume-dried closed pulverization coal-fired boiler unit is characterized in that a weighing coal feeder weighs coal fed into a boiler and performs adjustment control, an air-locking powder feeder is provided, a drier mixing chamber is connected with a fume suction opening and a gas outlet of a pulverized coal collector and allows a first part extracted from exhaust and a part of fume extracted from the fume suction opening to be mixed into drier which is fed to a raw coal pre-drying device, an exhaust water recovery device cools high-humidity exhaust discharged by a pulverization subsystem so as to obtain a great deal of condensate and discharge cold exhaust, an air exhaust preheater heats a part of ambient cold air into hot air and heats the cold exhaust into hot exhaust, a part of the hot air, the other part of the ambient cold air and the hot exhaust are mixed into primary air, an air-powder mixer mixes the primary air and pulverized coal into air-powder mixture, and the other part of the hot air is used as secondary air directly supplied to a pulverized coal burner.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Depolymerization of polylactic acid

InactiveUS8895778B2Shorten the timeImprove economyOrganic compound preparationPreparation from carboxylic acid esters/lactonesCyclic processPolyester

The invention provides energy efficient depolymerization of polyesters such as post-consumer polylactic acid. Ultrasonic induced implosions can be used to facilitate the depolymerization. The expanding market of polylactic acid-based plastic products, such as water bottles and packaging materials, has raised concerns of contaminating the recycling stream, which is largely filled with petroleum-based plastics. Thus the development of an energy efficient and economically viable PLA recycling process is urgently needed. Post consumer PLA was exposed to methanol as the suspension media in the presence of organic or ionic salts of alkali metals such a potassium carbonate and sodium hydroxide as depolymerization catalysts to provide high quality lactic acid monomers in high yield.

Owner:IOWA STATE UNIV RES FOUND

Open powder making steam warm air type boiler unit and power generation system thereof

InactiveCN104132360AImprove operational safetyHigh implementabilityIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionAir preheaterCold air

The invention provides an open powder making steam warm air type boiler unit connected with a turbine unit with a turbine. The open powder making steam warm air type boiler unit is characterized in that a weighing coal feeder meters, adjusts and controls the raw coal weight corresponding to the boiler coal supply quantity fed in a hearth, a coal powder collector separates air and powder mixtures to obtain coal powder and exhaust, an air lock is used for preventing the coal powder against air channeling so as to keep the coal powder smooth in circulation, a cold air pre-heating device preheats environment cold air to obtain warm air through low-pressure steam drawn out of a steam extraction opening of the turbine, an air preheater further heats the warm air to obtain hot air, one part of the hot air and part of the environment cold air are mixed to be used as primary air, an air and powder mixer mixes the primary air and the coal powder to obtain the air and powder mixtures, the other part of the hot air is used as secondary air to be directly fed into a coal powder burner, and the first part of the exhaust and part of smoke extracted out of a smoke extraction opening are mixed to be fed into a raw coal pre-drying device through a drying agent mixing chamber.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

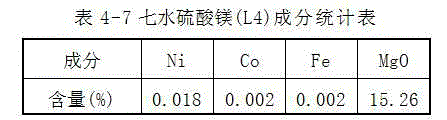

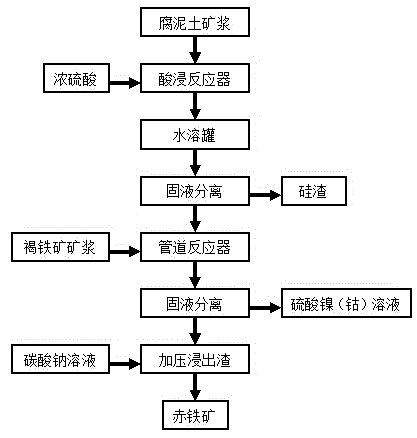

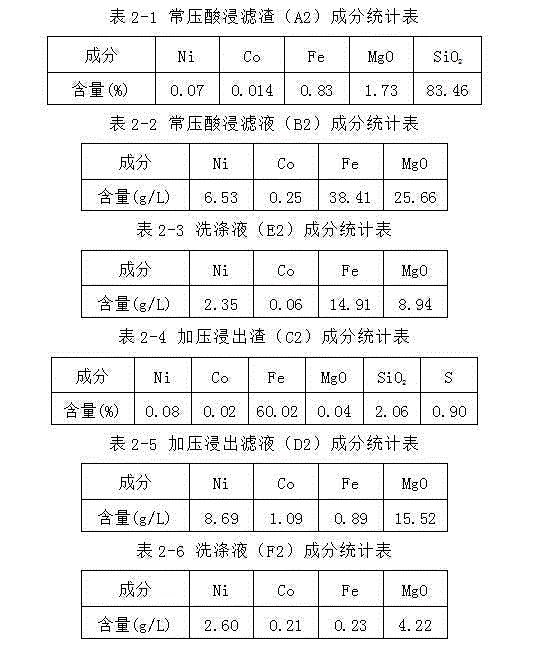

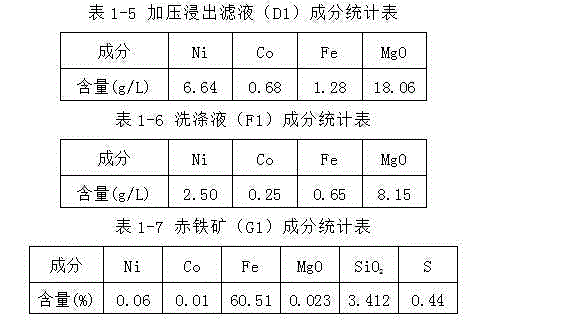

Method for recovering nickel, cobalt and iron from laterite-nickel ores

InactiveCN104651634ALow investment costLow running costProcess efficiency improvementSoluble ironMetal

The invention relates to the technical field of a hydrometallurgy process of laterite-nickel ores and in particular relates to a method for recovering nickel, cobalt and iron from laterite-nickel ores. The method comprises the following steps: adding sufficient concentrated sulfuric acid to muck soil pulp to carry out reaction at a high temperature of 95-120 DEG C so as to dissolve most soluble nonferrous metals and soluble iron; carrying out solid-liquid separation to obtain atmospheric pressure leaching residues and atmospheric pressure leachate; proportionally adding the atmospheric pressure leachate and limonite pulp to a pressurized reactor to undergo pressure leaching at 195-240 DEG C; carrying out solid-liquid separation to obtain pressure leaching residues and pressure leachate; purifying the pressure leaching filtrate to recover nickel and cobalt; washing and then drying the pressure leaching residues to obtain fine iron powder products. The method has the advantages that the method can be used for simultaneously treating muck soil and limonite; the nickel and cobalt recovery rate is high; atmospheric pressure leaching equipment is small, is short in time and has high efficiency; waste residues are small in quantity and can be effectively utilized.

Owner:JINCHUAN GROUP LIMITED

Method for recovering sludge phosphorus from urban sewage treatment plant

ActiveCN101580334BCost-effective recyclingReach reductionSludge treatment by de-watering/drying/thickeningPhosphorus compoundsCalcium biphosphateMunicipal sewage

The invention relates to a method for recovering sludge phosphorus from an urban sewage treatment plant, belonging to the technical fields of sludge treatment and resources. The method comprises the following steps: respectively carrying out gravity thickening on sludge releasing sludge phosphorus, sludge phosphorus releasing on sludge after the gravity thickening, solid-liquid separation on sludge after the sludge phosphorus releasing, sludge phosphorus recovery on supernatant fluid rich of phosphorus after the solid-liquid separation, and the like; the sludge phosphorus releasing on sludge after the gravity thickening is realized by treating the sludge by an acidification and normal-pressure microwave radiation combination method; and the sludge phosphorus recovery on supernatant fluid rich of phosphorus after the solid-liquid separation is realized by treating the supernatant fluid rich of phosphorus by a calcium phosphate crystallization process to obtain the deposit containing calcium phosphate crystal, then filtering the deposit containing calcium phosphate crystal and finally recovering the sludge phosphorus. The method not only can efficiently recover the phosphorus in thesludge from the urban sewage treatment plant, but also can achieve the aims of reducing the sludge and improving the depositing performance of the sludge.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

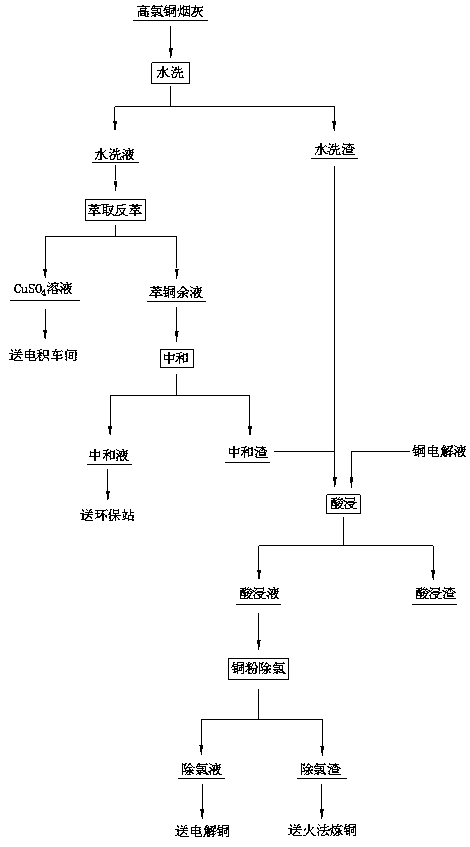

Method for recovering copper in high chlorine copper smoke by wet method

InactiveCN110029228ACost-effective recyclingEliminate hazardsPhotography auxillary processesProcess efficiency improvementHigh concentrationElectrolysis

The invention relates to a method for recovering copper in high chlorine copper smoke by a wet method; and the method comprises the following steps of: (1) carrying out water leaching and chlorine eliminating to chlorine-containing copper oxide smoke; (2) extracting copper ions in a water leaching solution by N902 solvent - reverse extraction electro-deposit copper; (3) acid leaching of water leaching slag; (4) eliminating chlorine of copper powder in an acid leaching solution; The dechlorination slag obtained by the method treating the high chlorine copper smoke can be used as a raw materialfor pyrometallurgical copper; the harm of chlorine to electrolytic copper is eliminated; and the use value is improved; The process has short flow and strong operability. The neutralized liquid can return to a washing process to wash chlorine; after chlorine ions are concentrated to a higher concentration, a multi-effect evaporator can be adopted; and the chloride can be recovered by concentrationand crystallization, so that the non-industrial waste water discharge and the non-hazardous waste slag production can be realized; and the method is a green and environment-friendly process technology.

Owner:江西自立环保科技有限公司

Method for recovering nickel, cobalt and iron from laterite-nickel ore

The invention relates to the technical field of wet metallurgy of laterite-nickel ore, and concretely relates to a method for recovering nickel, cobalt and iron from laterite-nickel ore. The method comprises the following steps: adding enough concentrated sulfuric acid into a saprolite ore slurry, and reacting at a high temperature of 95-120DEG C to dissolve most soluble non-ferrous metals and soluble iron; carrying out solid-liquid separation to obtain normal pressure leached slag and normal pressure leachate; adding the normal pressure leachate and a limonite ore slurry into a pressure reactor in proportion, and carrying out pressure leaching at 195-240DEG C; carrying out solid-liquid separation to obtain pressure leached slag and pressure leachate; purifying the pressure leachate to recover nickel and cobalt; washing the pressure leached slag, and drying to obtain a fine iron powder product; and processing the normal pressure leached slag to obtain a high grade silica product and building sand. The method has the advantages of simultaneous treatment of saprolite and limonite, high nickel and cobalt recovery rate, realization of small size, short time and high efficiency of a normal pressure leaching device, and realization of small amount and effective utilization of waste slag.

Owner:JINCHUAN GROUP LIMITED

Method for recovering nickel, cobalt, iron, silicon and magnesium from laterite-nickel ores

InactiveCN104651610ALow costLow running costSilicaProcess efficiency improvementHydrometallurgyLaterite

The invention relates to the technical field of a hydrometallurgy process of laterite-nickel ores and in particular relates to a method for recovering nickel, cobalt, iron, silicon and magnesium from laterite-nickel ores. The method comprises the following steps: adding sufficient concentrated sulfuric acid to muck soil pulp to carry out reaction at a high temperature of 95-120 DEG C so as to dissolve most soluble nonferrous metals and soluble iron; carrying out solid-liquid separation to obtain atmospheric pressure leaching residues and atmospheric pressure leachate; proportionally adding the atmospheric pressure leachate and limonite pulp to a pressurized reactor to undergo pressure leaching at 195-240 DEG C; carrying out solid-liquid separation to obtain pressure leaching residues and pressure leachate; purifying the pressure leaching filtrate to recover nickel and cobalt; washing and then drying the pressure leaching residues to obtain fine iron powder products; carrying out sieving treatment on the atmospheric pressure leaching residues to obtain a high-grade silicon dioxide product and building sand. The method has the advantages that the method can be used for simultaneously treating muck soil and limonite; the nickel and cobalt recovery rate is high; atmospheric pressure leaching equipment is small, is short in time and has high efficiency; waste residues are small in quantity and can be effectively utilized.

Owner:JINCHUAN GROUP LIMITED

Method for recovering nickel, cobalt and iron from laterite-nickel ores

InactiveCN104651609ALow costLow running costSilicaProcess efficiency improvementHydrometallurgyLaterite

The invention relates to the technical field of a hydrometallurgy process of laterite-nickel ores and in particular relates to a method for recovering nickel, cobalt and iron from laterite-nickel ores. The method comprises the following steps: adding sufficient concentrated sulfuric acid to muck soil pulp to carry out reaction at a high temperature of 95-120 DEG C so as to dissolve most soluble nonferrous metals and soluble iron; carrying out solid-liquid separation to obtain atmospheric pressure leaching residues and atmospheric pressure leachate; proportionally adding the atmospheric pressure leachate and limonite pulp to a pressurized reactor to undergo pressure leaching at 195-240 DEG C; carrying out solid-liquid separation to obtain pressure leaching residues and pressure leachate; purifying the pressure leaching filtrate to recover nickel and cobalt; washing and then drying the pressure leaching residues to obtain fine iron powder products. The method has the advantages that the method can be used for simultaneously treating muck soil and limonite; the nickel and cobalt recovery rate is high; atmospheric pressure leaching equipment is small, is short in time and has high efficiency; waste residues are small in quantity and can be effectively utilized.

Owner:JINCHUAN GROUP LIMITED

Steel slag multi-stage treatment method

ActiveCN109092844BCost-effective recyclingFull recoverySolid waste disposalMagnetic separationIron powderSlag

The invention provides a steel slag multistage treatment method. The method comprises crushing steel slag circulation, screening and magnetic separation, so as to finally obtain iron powder with the TFe content greater than 60% and tailings with the MFe content being less than 1%. The tailing powders can be used as a roadbed cushion layer, a water-stable layer instead of gravel aggregate, and isused as a raw material of commercial concrete and mortar; or be used as an auxiliary material to prepare pellets and be used as a mixture steel scrap pressing block. The method has the advantages thatthe metal recovery rate is 99% or above, and zero emission is really realized.

Owner:南京芬钢环保科技有限公司

Fume and hot exhaust dried closed pulverization coal-fired boiler unit with function of exhaust water recovery

InactiveCN104197356AHigh implementabilityImprove operational safetyIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyCold airPowder mixture

The invention provides a fume and hot exhaust dried closed pulverization coal-fired boiler unit with a function of exhaust water recovery. The fume and hot exhaust dried closed pulverization coal-fired boiler unit is characterized in that a weighing coal feeder controls coal feed for a boiler, an air-locking powder feeder is used for conveying pulverized coal and preventing the pulverized coal from channeling with air, an air exhaust preheater heats a part of ambient cold air into hot air, a part of the hot air, the other part of ambient cold air and a part of hot exhaust are mixed into primary air, the primary air and the pulverized coal are mixed in an air-powder mixer into air-powder mixture, the other part of the hot air is used as secondary air to be fed into a pulverized coal burner, an exhaust water recovery device cools high-humidity exhaust discharged by a pulverization subsystem so as to obtain a great deal of condensate and discharge cold exhaust, an air exhaust preheater is connected with the exhaust water recovery device and heats the cold exhaust into hot exhaust, and fume extracted from a fume suction opening and the other part of the hot exhaust are mixed into drier which is then fed into a raw coal pre-drying device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

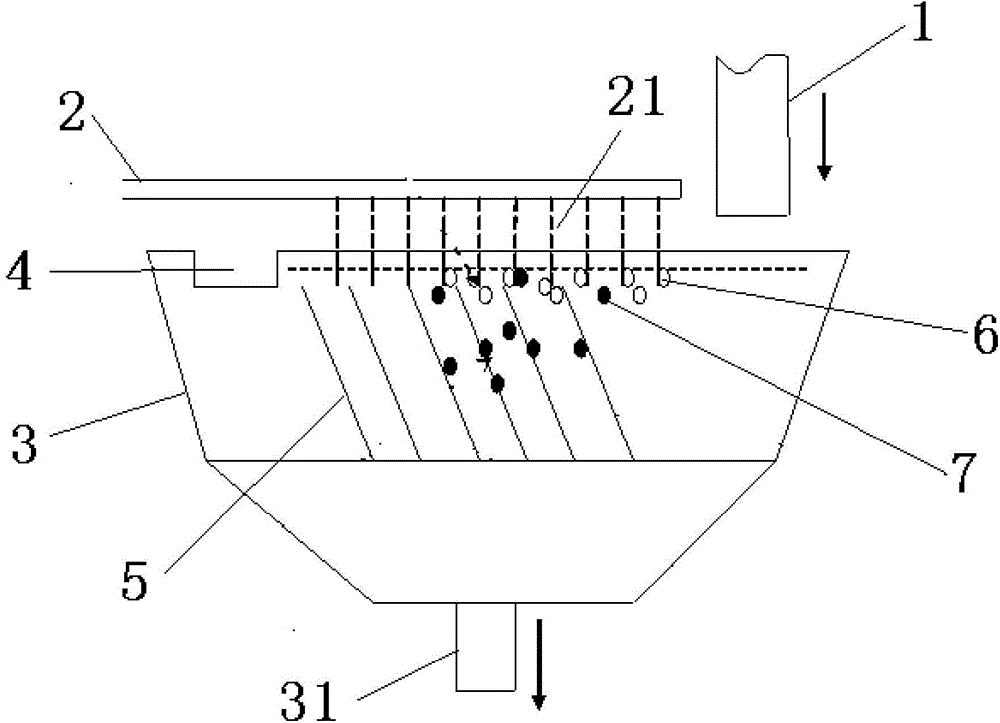

Micro-fine particle grade titanium ore recovery apparatus

InactiveCN104474747APrevent overflowCost-effective recyclingLiquid degasificationSedimentation settling tanksSpray nozzleWater flow

The invention relates to the field of micro-fine particle grade titanium ore recovery equipment, and especially relates to a micro-fine particle grade titanium ore recovery apparatus. The to-be solved technological problem is to provide a micro-fine particle grade titanium ore recovery apparatus capable of timely eliminating foam in a micro-fine particle grade titanium ore liquid and relatively fully recovering micro-fine particle grade titanium ore in mine tailing. The micro-fine particle grade titanium ore recovery apparatus comprises a condensation bucket with a port at the bottom, an inlet arranged above the condensation bucket, and a high-pressure spray pipe arranged above the condensation bucket, and one side, facing to the condensation bucket, of the high-pressure spray pipe is provided with at least one high-pressure nozzle. The conception of the technical scheme is based on the problem in practice that foam carries ore particles, the destroy effect of a high-pressure water flow on foam is ingeniously utilized, the purpose of economically efficiently recovering a large amount of micro-fine particle grade titanium ore is realized, the recovery apparatus has prospect of large-scale popularization, and is especially applicable to recover mineral products taking micro-fine particle titanium ore as the representative.

Owner:攀枝花钢城集团瑞矿工业有限公司

A method of recovering nickel, cobalt, iron, silicon and magnesium from lateritic nickel ore

The invention relates to the technical field of hydrometallurgical processes of lateritic nickel ore, and particularly relates to a method of recovering nickel, cobalt, iron, silicon and magnesium from lateritic nickel ore. The method includes following steps: adding sufficient concentrated sulfuric acid into saprolite pulp, and reacting at 95-120 DEG C to dissolve most of soluble non-iron metals and soluble iron; performing solid liquid separation to obtain atmospheric-pressure leaching slag and atmospheric-pressure leachate; adding the atmospheric-pressure leachate and limonite ore pulp into a pressurized reactor according to a ratio and performing pressure leaching at 195-240 DEG C; performing solid liquid separation to obtain pressure leaching slag and leachate of pressure leaching; purifying the leachate of pressure leaching to recover the nickel and the cobalt; washing pressure leaching slag and drying to obtain a fine iron powder product; and screening the atmospheric-pressure leaching slag to obtain a high-grade silicon dioxide product and building sand. The method can achieve treatment of the saprolite and the limonite at the same time, and is high in nickel and cobalt leaching rates, small in atmospheric-pressure devices, short in time and high in efficiency. Waste slag is low in amount and can be effectively utilized.

Owner:JINCHUAN GROUP LIMITED

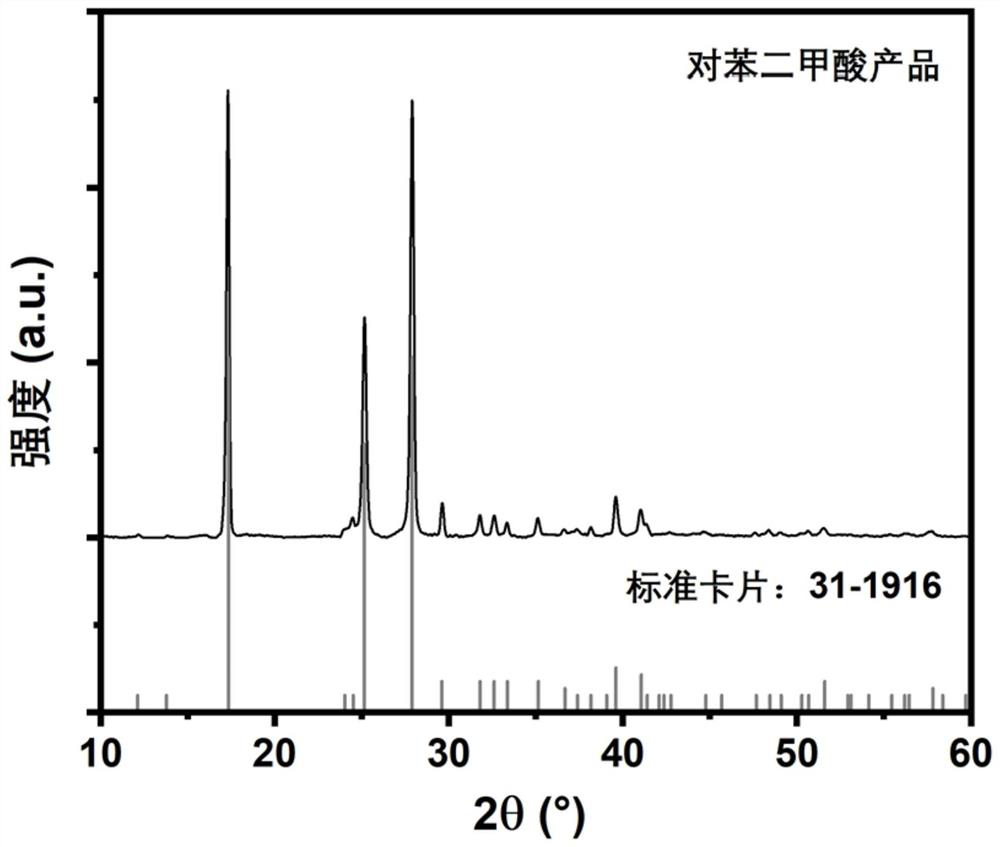

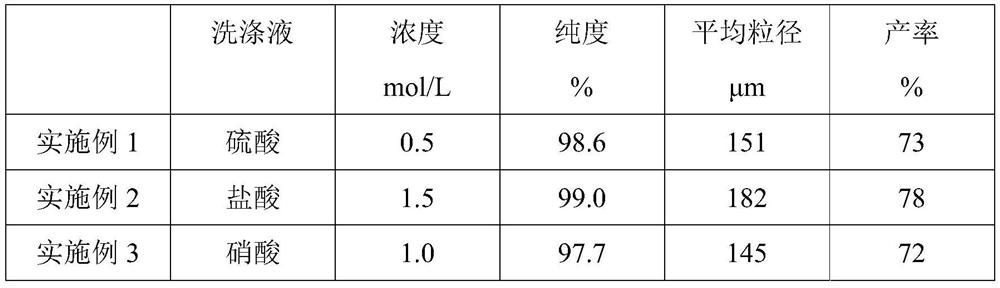

Method for hydrothermally recovering high-purity terephthalic acid from printing and dyeing white mud

PendingCN113831234APromote growthHigh purityOrganic compound preparationCarboxylic compound separation/purificationTextile printerActive agent

The invention discloses a method for hydrothermally recovering high-purity terephthalic acid from printing and dyeing white mud, which belongs to the technical field of solid waste recycling in the textile printing and dyeing industry. The recovering method comprises the following steps of washing the alkali-decrement white mud by using a dilute acid solution containing a surfactant, and then carrying out solid-liquid separation to obtain a white mud filter cake, dispersing the white mud filter cake in water, adjusting the pH value, and carrying out a hydrothermal reaction in a hydrothermal kettle, carrying out solid-liquid separation on the hydrothermal product, and washing an obtained filter cake by using a proper amount of pure water, and carrying out solid-liquid separation again, taking the solid, and drying to obtain the high-purity terephthalic acid. The pure terephthalic acid recovered by the method has the impurity content of less than 1.5% and the average grain size of more than 145 microns, and can be recycled for polyester synthesis or plasticizer synthesis, so that the printing and dyeing white mud is economically and effectively recycled.

Owner:DONGHUA UNIV

A kind of treatment method and device of oil refining alkali residue

ActiveCN113121033BAvoid toxic effectsGuaranteed uptimeGas treatmentWater contaminantsPtru catalystCatalytic oxidation

The invention relates to a treatment method and device for oil refining alkali residue. The alkali residue and sulfuric acid are acidified in two stages in an acidification unit to generate a first waste gas flow and a second waste gas flow; a part of the second waste gas flow is combined with the first waste gas After the reaction is completed, the third waste gas flow is discharged; the third waste gas flow is mixed with the remaining part of the second waste gas flow and sent to the sulfur production unit for reaction, and the fourth waste gas flow is discharged after the reaction; Four exhaust gas flows into SO 2 In the adsorption unit, a fifth waste gas flow is generated, and the regeneration gas is merged into the third waste gas flow; the fifth waste gas flow is sent to the catalytic oxidation dehydrocarbonation unit, and the purified gas is discharged. The invention avoids the toxic effect of sulfide on the catalytic oxidation dehydrocarbon catalyst, can maintain the long-term stable operation of the catalytic oxidation unit, and can recover high-quality sulfur resources with better economy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Furnace smoke drying closed pulverization coal-fired boiler unit with exhaust water recovery

InactiveCN104197360BHigh implementabilityImprove operational safetyIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyCold airPowder mixture

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Separation and recovery method for ultralow-grade refractory copper-molybdenum sulfide ore

InactiveCN114100853AReduce dosageCost-effective recyclingFlotationMagnetic separationSulfidationSulfide

The invention discloses a separation and recovery method for ultralow-grade refractory copper-molybdenum sulfide ore, and belongs to the technical field of dressing and smelting of ultralow-grade copper-molybdenum ore. The technical problem to be solved by the invention is to fully extract resources in ore and solve the current technical problems of high cost, difficult process control and serious environmental pollution of a traditional process method. The invention researches and develops a magnetic separation and flotation combined synergistic separation and recovery process. The method comprises the following steps: firstly, carrying out bulk flotation on copper-molybdenum mixed sulfide ore to obtain copper-molybdenum mixed rough concentrate; the copper-molybdenum mixed rough concentrate is separated in advance through magnetic separation, and magnetic separation concentrate copper sulfide and magnetic separation tailing molybdenum sulfide are obtained; and finally, magnetic concentrate and tailings are enriched again through flotation, and copper sulfide concentrate products and molybdenum sulfide concentrate products are obtained finally. According to the magnetic separation and flotation combined synergistic separation and recovery process, economic and efficient recovery of copper-molybdenum mixed sulfide ore resources of different grades can be achieved, the use amount of sodium sulfide can be greatly reduced, the working environment is improved, and the environmental protection risk is reduced.

Owner:HEILONGJIANG DUOBAOSHAN COPPER LTD +1

Open pulverizing exhaust gas heating type boiler unit

InactiveCN104165371BHigh thermal efficiencyCost-effective recyclingIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionAir preheaterCold air

The invention provides an exhaust warm air type boiler unit for open coal pulverization. The boiler unit is characterized in that a weighing coal feeder is used for measuring, adjusting and controlling raw coal weight corresponding to boiler coal supply amount conveyed into a hearth, an air locking device is used for preventing air cross flow of pulverized coal and maintaining smooth flowing of pulverized coal, a cold air exhaust-air preheating device is used for preheating environment cold air to obtain warm air, an air preheater is used for further heating a part of the warm air to obtain hot air, the first part of the hot air and the other part of the warm air are mixed to be used as primary air, an air-pulverized-coal mixer mixes the primary air and pulverized coal to obtain air-pulverized-coal mixture, the second part of the hot air is used as secondary air to be directly sent into a pulverized coal burner, the third part of the hot air is directly sent into a drying agent mixing chamber, and the second part of exhaust air, a part of smoke extracted from a smoke extracting opening and the third part of the hot air are mixed to be used as a drying agent which is sent into a raw coal pre-drying device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Open pulverizing exhaust gas heating type boiler unit

InactiveCN104197355BImprove operational safetyLow temperature corrosion does not occurIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionPowder mixtureDesiccant

The invention provides an open powder processing waste steam heater type boiler unit. The unit is characterized in that a weighing coal feeder measures, regulates and controls the weight of raw coal corresponding to the boiler coal supply fed into a furnace, a steam locker is used for preventing air crossflow of coal powder and maintaining smooth circulation of coal powder, an air waste steam pre-heater is used for further heating part of warm air to obtain hot air, part of the hot air and the other part of warm air are mixed to serve as primary air, an air and powder mixer mixes the primary air with the coal powder to obtain an air and powder mixture, the other part of the hot air serves as secondary air to be directly fed into a coal powder burner, and a waste steam water recycling device brings in part of waste steam and recycles water in the waste steam; the air waste steam pre-heater is connected with the waste steam water recycling device to heat part of cold waste steam obtained after water recycling to form hot waste steam, and mixes the other part of the waste steam, part of smoke extracted from a smoke extraction port, and the hot waste steam to serve as drying agents which are fed into a raw coal pre-drying device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Open pulverizing exhaust gas heating type boiler unit

InactiveCN104165374BHigh thermal efficiencyGuaranteed safe operationIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionAir preheaterCoal

The invention provides an exhaust warm air type boiler unit for open coal pulverization. The boiler unit is used for burning raw coal and is characterized in that an exhaust air preheater is used for further heating a part of warm air to obtain hot air, a part of the hot air and the other part of the warm air are mixed to be used as primary air, an air-pulverized-coal mixer mixes the primary air and pulverized coal to obtain air-pulverized-coal mixture, the other part of the hot air is used as secondary air to be directly sent into a pulverized coal burner, an exhaust air water recovery device is used for leading a part of exhaust air in and recovering water in the exhaust air, the exhaust air preheater is connected with the exhaust air water recovery device to heat the part of cold exhaust air after water recovery to obtain hot exhaust air, a drying agent mixing chamber is connected with a smoke extracting opening and a gas outlet of the pulverized coal collector respectively, and the other part of the exhaust air, a part of smoke extracted from the smoke extracting opening and the hot exhaust air are mixed and then used as a drying agent to be sent into a raw coal pre-drying device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Furnace smoke drying closed pulverization coal-fired boiler unit with exhaust water recovery

InactiveCN104197362BHigh implementabilityCost-effective recyclingIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionCold airPowder mixture

The invention provides a fume-dried closed pulverization coal-fired boiler unit with a function of exhaust water recovery. The fume-dried closed pulverization coal-fired boiler unit is characterized in that a weighing coal feeder weighs coal fed into a boiler and performs adjustment control, an air-locking powder feeder is provided, a drier mixing chamber is connected with a fume suction opening and a gas outlet of a pulverized coal collector and allows a first part extracted from exhaust and a part of fume extracted from the fume suction opening to be mixed into drier which is fed to a raw coal pre-drying device, an exhaust water recovery device cools high-humidity exhaust discharged by a pulverization subsystem so as to obtain a great deal of condensate and discharge cold exhaust, an air exhaust preheater heats a part of ambient cold air into hot air and heats the cold exhaust into hot exhaust, a part of the hot air, the other part of the ambient cold air and the hot exhaust are mixed into primary air, an air-powder mixer mixes the primary air and pulverized coal into air-powder mixture, and the other part of the hot air is used as secondary air directly supplied to a pulverized coal burner.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Furnace flue heat exhaust gas drying closed pulverizing coal-fired boiler unit with exhaust water recovery

InactiveCN104197356BHigh implementabilityImprove operational safetyIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyWaste heat recovery unitCold air

The invention provides a fume and hot exhaust dried closed pulverization coal-fired boiler unit with a function of exhaust water recovery. The fume and hot exhaust dried closed pulverization coal-fired boiler unit is characterized in that a weighing coal feeder controls coal feed for a boiler, an air-locking powder feeder is used for conveying pulverized coal and preventing the pulverized coal from channeling with air, an air exhaust preheater heats a part of ambient cold air into hot air, a part of the hot air, the other part of ambient cold air and a part of hot exhaust are mixed into primary air, the primary air and the pulverized coal are mixed in an air-powder mixer into air-powder mixture, the other part of the hot air is used as secondary air to be fed into a pulverized coal burner, an exhaust water recovery device cools high-humidity exhaust discharged by a pulverization subsystem so as to obtain a great deal of condensate and discharge cold exhaust, an air exhaust preheater is connected with the exhaust water recovery device and heats the cold exhaust into hot exhaust, and fume extracted from a fume suction opening and the other part of the hot exhaust are mixed into drier which is then fed into a raw coal pre-drying device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Open pulverizing exhaust gas heating type boiler unit

InactiveCN104165375BHigh thermal efficiencyGuaranteed safe operationIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionAir preheaterCold air

The invention provides an exhaust warm air type boiler unit for open coal pulverization. The boiler unit is characterized in that a pulverized coal feeder, a cold air exhaust-gas preheating device and an air preheater are included, the pulverized coal feeder is used for measuring, adjusting and controlling boiler coal supply amount conveyed to an air-pulverized-coal mixer, the cold air exhaust-gas preheating device is used for preheating environment cold air through exhaust warm air in an exhaust warm cavity to obtain warm air, the air preheater is used for further heating a part of the warm air to obtain hot air, the first part of the hot air and the other part of the warm air are mixed to be used as primary air, the air-pulverized-coal mixer mixes the primary air and pulverized coal to obtain air-pulverized-coal mixture, the second part of the hot air is used as secondary air to be directly sent into a pulverized coal burner, the third part of the hot air is directly sent into a drying agent mixing chamber, and the first part of exhaust air, a part of smoke extracted from a smoke extracting opening and the third part of the hot air are mixed to be used as a drying agent which is sent into a raw coal pre-drying device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com