Method for recovering sludge phosphorus from urban sewage treatment plant

A technology for recycling urban sewage and phosphorus, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. performance, cost-effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

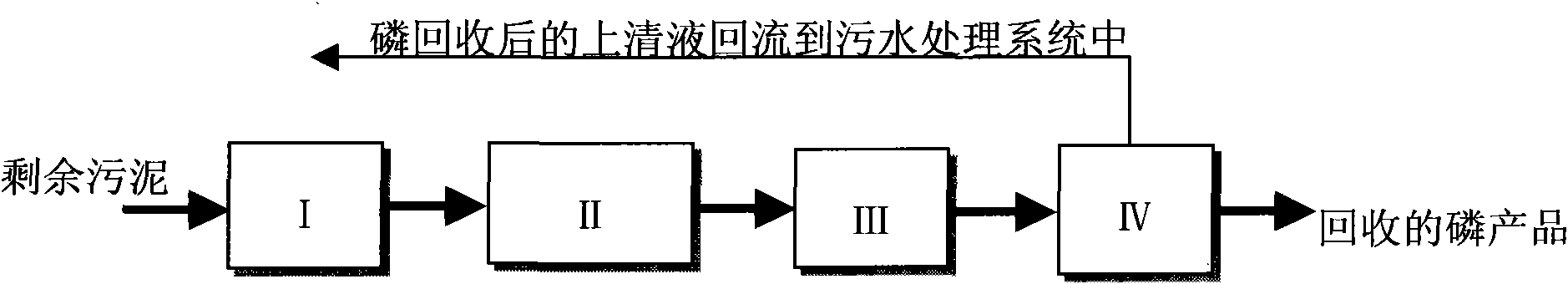

[0021] See figure 1 . The return sludge mixture produced by the activated sludge method was collected in Beijing Fangzhuang Sewage Treatment Plant. The sludge concentration after gravity concentration was 6800-8000mg / L, and the PO of the concentrated sludge supernatant was 4 3- -P and total phosphorus (TP) concentrations were 26.2mg / L and 28.6mg / L, respectively. In the sludge phosphorus release step, at room temperature, first pour 200ml of concentrated sludge into a 500ml beaker, place it on a magnetic stirrer, and add sulfuric acid or hydrochloric acid (with a concentration of 2.5 ~5.0mol / L), control the pH of the acidified sludge=1.0~5.0; then put the acidified sludge into the microwave reactor, the microwave frequency is 2.45GHz, and the maximum output power of the magnetron is 1kw, which can be stepless Adjustable, the volume of the chamber is 25L, with a lifting stirring device and a temperature measuring probe, and the opening time of the magnetron is controlled by a...

Embodiment 2

[0023] See figure 1 . The return sludge mixture was collected in Beijing Fangzhuang Sewage Treatment Plant. The sludge concentration after gravity concentration was 6800-8000mg / L, and the PO of the concentrated sludge supernatant was 4 3- -P and total phosphorus (TP) concentrations were 26.2mg / L and 28.6mg / L, respectively. In the sludge phosphorus release unit, at room temperature, first pour 200ml of concentrated sludge into a 500ml beaker, place it on a magnetic stirrer, and add sulfuric acid or hydrochloric acid (with a concentration of 2.5 ~5.0mol / L), control the pH of the acidified sludge=1.0~5.0; then put the acidified sludge into the microwave reactor, the microwave frequency is 2.45GHz, and the maximum output power of the magnetron is 1kw, which can be stepless Adjustable, the volume of the chamber is 25L, with a lifting stirring device and a temperature measuring probe, and the opening time of the magnetron is controlled by a timing device. Under normal pressure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com