A kind of treatment method and device of oil refining alkali residue

A technology for refining alkali residue and treatment method, applied in separation methods, gas treatment, natural water treatment and other directions, can solve the problems of inability to achieve efficient oxidation of organic sulfur, high cost, and achieve good catalytic oxidation desulfurization effect, high selectivity, and avoidance. effect of poison

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

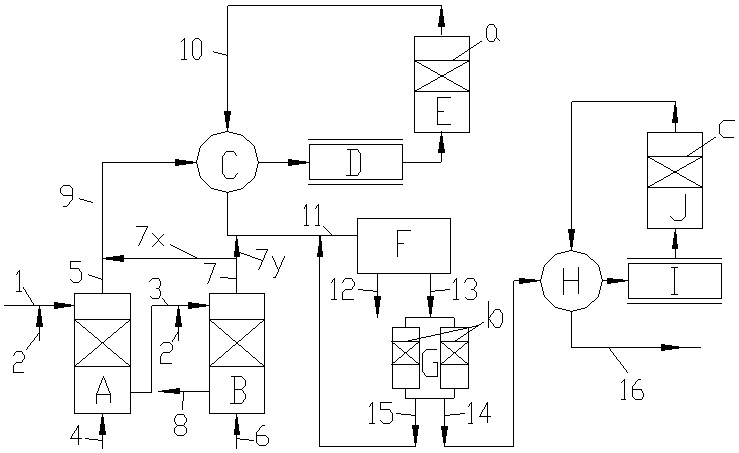

[0045] An oil refinery uses figure 1 The process described acidizing the mixed alkali residue waste liquid of catalytic gasoline and liquid hydrocarbons. The specific process is as follows:

[0046] (1) Use sulfuric acid to acidify the alkali residue waste liquid, the maximum processing capacity of the alkali residue is 1t / h, and air is introduced as degassing, and the pH value of the primary acidification is controlled to be 9-11, and the gas volume of the first waste gas stream is generated. 10-50Nm 3 / h, in which the volume concentration of organic sulfides is 5%-30%, and the total non-methane hydrocarbons are 3000-80000 mg / m 3 , the concentration of volatile phenol is 1000-30000mg / m 3 . After the primary acidification treatment, the waste liquid is mixed with concentrated sulfuric acid into the secondary acidification reactor, and nitrogen is introduced as degassing, and the pH value of the secondary acidification is controlled to be 3-4, and the gas volume of the seco...

Embodiment 2

[0055] The same as in Example 1, the difference lies in that in step (2) the desulfurization reactor is filled with different catalysts. The catalyst preparation process is: the same as the preparation method of the catalyst in Example 1, except that the active component precursor solution is prepared in the molar ratio of V: Cu=1: 1, wherein the concentration of ammonium metavanadate is 0.52 mol / L, and the nitric acid is 0.52 mol / L. The concentration of copper was 0.52 mol / L. In the catalyst, the content of SSZ-13 molecular sieve is 1.2% in terms of honeycomb carrier mass, the content of active components in terms of vanadium pentoxide is 0.136%, and the content of copper oxide is 0.116%. In order to meet the treatment effect of hydrogen sulfide and organic sulfide in the first exhaust gas, it is necessary to reduce the volume space velocity of the catalyst bed of the desulfurization reactor to 10000h -1 , and increase the reaction temperature to 300-320 °C. The device ha...

Embodiment 3

[0057] The same as in Example 1, the difference lies in that in step (2) the desulfurization reactor is filled with different catalysts. The preparation process of the catalyst is as follows: the preparation method of the catalyst in Example 1 is the same, except that the active component precursor solution is prepared according to the molar ratio of V:Ce=1:0.2, wherein the concentration of ammonium metavanadate is 0.52mol / L, and the concentration of nitric acid is 0.52mol / L. The concentration of cerium was 0.104 mol / L. In the catalyst, the content of SSZ-13 molecular sieve is 1.2% in terms of honeycomb carrier mass, the content of active components in terms of vanadium pentoxide is 0.136%, and the content of copper oxide is 0.116%. In order to meet the treatment effect of hydrogen sulfide and organic sulfide in the first exhaust gas, it is necessary to reduce the volume space velocity of the catalyst bed of the desulfurization reactor to 8000h -1 , and the reaction temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com