Oil field associated gas recycling device and method

A technology of oilfield associated gas and recovery device, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of waste of resources and difficult recovery of associated gas, and achieve the effect of efficient production and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

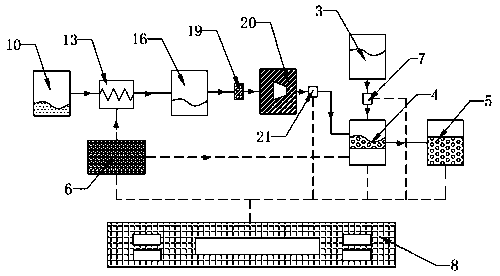

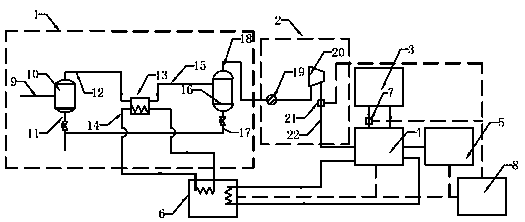

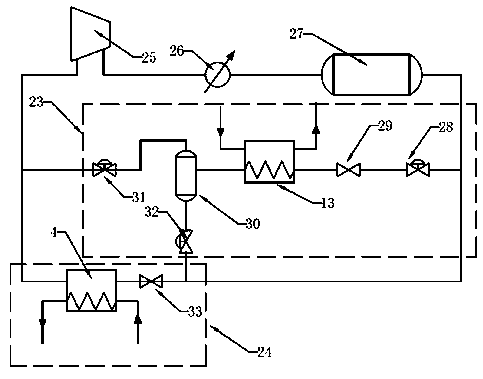

[0073] In this example, figure 1 It is a schematic diagram of an oilfield associated gas recovery device in an embodiment of the present invention, figure 2 It is a flow chart of oilfield associated gas recovery process in the embodiment of the present invention. The oilfield associated gas recovery device includes a heavy hydrocarbon removal unit 1, a pressurization unit 2, a liquid storage unit 3, a hydration reaction unit 4, a hydrate slurry output processing unit 5, a refrigeration unit 6, a first flow meter 7, and a data monitoring unit 8 ;

[0074] The heavy hydrocarbon removal unit 1 includes an associated gas inlet pipe 9, a primary separator 10, a first oil discharge pipe 11, a first exhaust pipe 12, a heat exchanger 13, a refrigerant pipe 14, a second exhaust pipe 15, a low temperature Separator 16, second oil discharge pipe 17, third exhaust pipe 18;

[0075] The supercharging unit 2 includes a filter 19, a supercharging device 20, a second flow meter 21, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com