Micro-fine particle grade titanium ore recovery apparatus

A recovery device and fine particle technology, applied in the direction of settling tanks, chemical instruments and methods, liquid degassing, etc., can solve the problems that the medicine cannot be eradicated and is not conducive to the recycling of resources, etc., and achieve the effect of economical and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

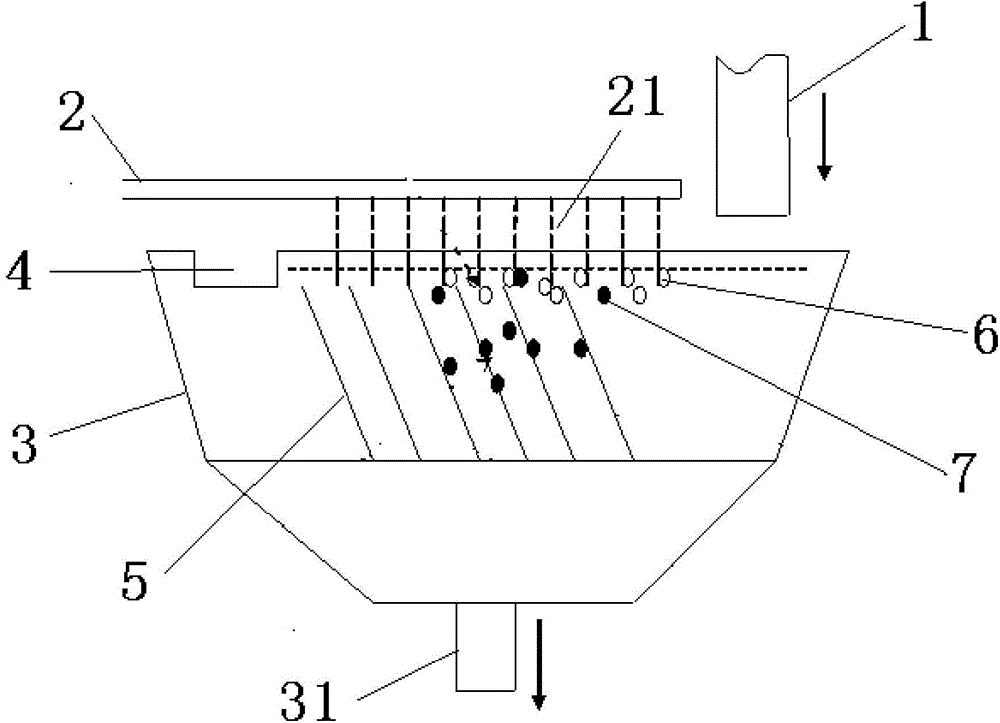

[0015] Such as figure 1 The shown fine-grained titanium ore recovery device includes a concentration hopper 3 provided with an outlet 31 at the bottom, an inlet 1 arranged above the concentration hopper 3, and a high-pressure nozzle 2 arranged above the concentration hopper 3. At least one high-pressure nozzle 21 is arranged on the side of the high-pressure spray pipe 2 facing the concentrating hopper 3 .

[0016] In the recovery of fine-grained titanium tailings, because the liquid in the tailings contains a large amount of chemicals, it is easy to generate foam 6, so the foam 6 will carry away part of the fine-grained titanium tailings 7, resulting in fine-grained titanium tailings 7 waste. When the present invention is applied in practice, the foam 6 on the liquid surface of the fine-grained titanium tailings is pierced through the high-speed water flow ejected fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com