Method for recovering copper in high chlorine copper smoke by wet method

A high chloride copper and smoke technology, applied in the improvement of process efficiency, photography process, instruments and other directions, can solve the problems of inability to achieve green environmental protection, complicated operation procedures, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

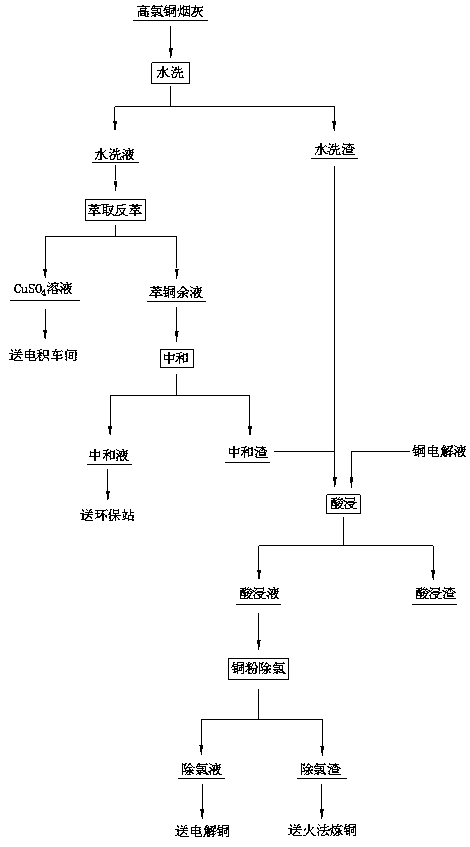

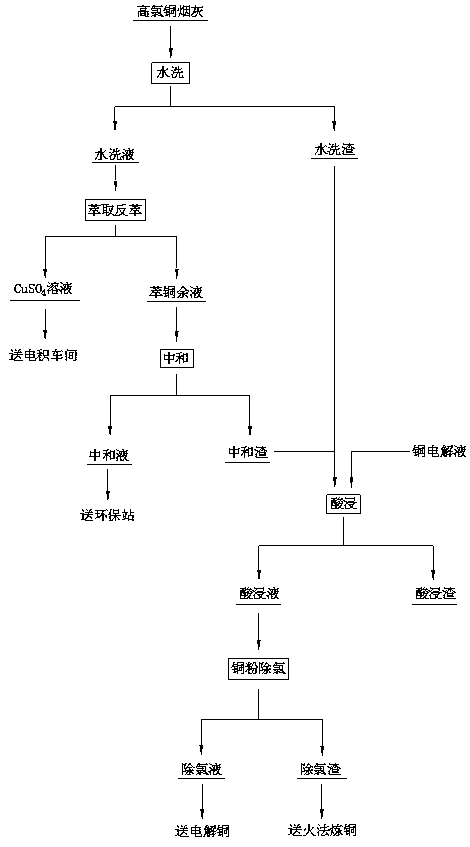

[0025] Such as figure 1 As shown, a wet method for recovering copper in high-chlorine copper fumes includes the following steps: (1) leaching chlorine-containing copper oxide fumes to remove chlorine; (2) extracting copper ions in the water immersion liquid with N902 solvent -Strip electrowinning copper; (3) Acid leaching of water leaching residue; (4) Dechlorination of copper powder in acid leaching solution.

[0026] Among them, the mass ratio of chlorine content in the high-chlorine copper fume is greater than 5%, and the mass ratio of copper content is greater than 20%.

[0027] In step (1), the liquid-to-solid ratio of the water immersion liquid is 3:1 (the liquid-to-solid ratio is specifically the mass ratio of the acid-containing aqueous solution to the copper perchlorate dust), the water immersion temperature is 30-40℃, and the water immersion is 2h, high The soluble chlorine fume in the copper chloride fume enters the water immersion liquid, the pH of the water immersion l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com