A swirl burner

A technology of swirl burner and stable burner, which is applied in the direction of burner, combustion method, combustion type, etc., and can solve the deviation of smoke temperature and flow rate in horizontal flue, obstacles to reliable operation of superheater and reheater, and slagging in the furnace and furnace water-cooled wall tube high-temperature corrosion and other problems, to achieve the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

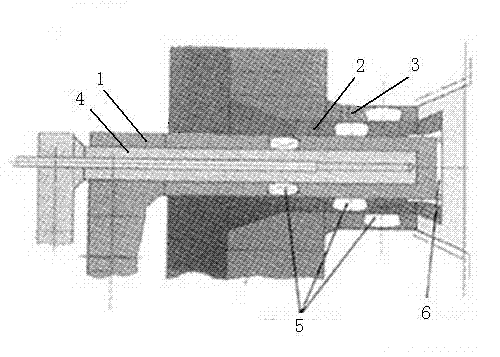

[0008] Such as figure 1 As shown, a swirl burner includes a primary air channel 1, an inner secondary air channel 2, an outer secondary air channel 3 and a central air channel 4, and the inner secondary air channel 2 and the outer secondary air channel 3 connection, the primary air channel 1 is installed in the inner secondary air channel 2, the central air channel 4 is installed in the primary air channel 1, and the tooth ring stabilizer 6 is installed on the primary air channel 1 , the primary air channel 1 is equipped with swirl vanes 5 , the inner secondary air channel 2 is equipped with swirl vanes 5 , and the outer secondary air channel 3 is equipped with swirl vanes 5 .

[0009] The end of the central air channel 4 adopts a straight structure, the end of the primary air channel 1 is equipped with an expanded cone, and the ends of the inner secondary air channel 2 and the outer secondary air channel 3 are also externally expanded, and the externally expanded secondary A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com