Multi-ejection grading combustion method and W flame boiler device for realizing same

A technology of staged combustion and multiple injection, which is applied in the combustion method, staged combustion, and combustion with various fuels, etc., can solve the problems of high fly ash combustible content, late ignition of pulverized coal gas flow, and poor flame stability. The effect of reduced fly ash combustible content, ignition advance, and enhanced combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

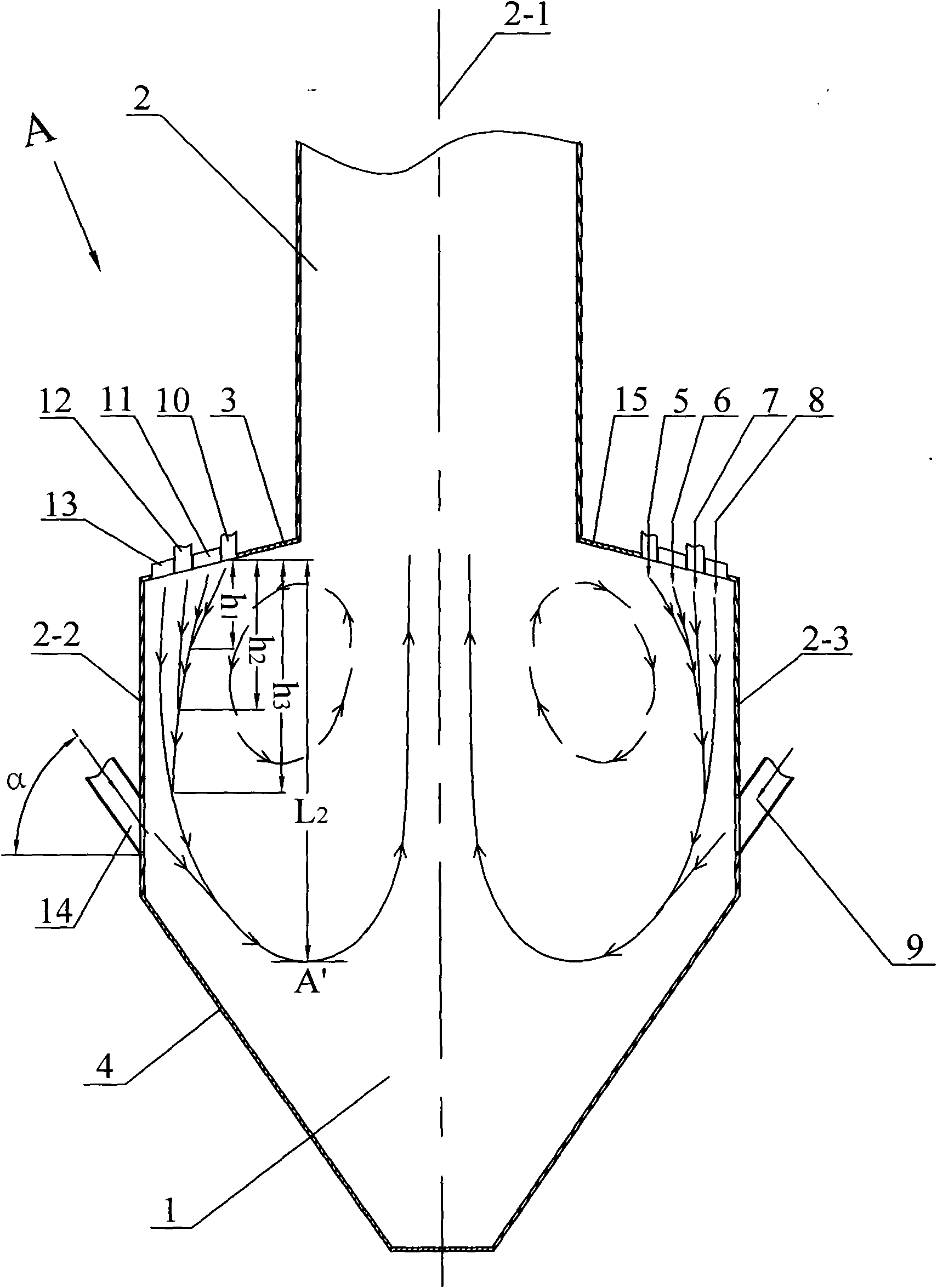

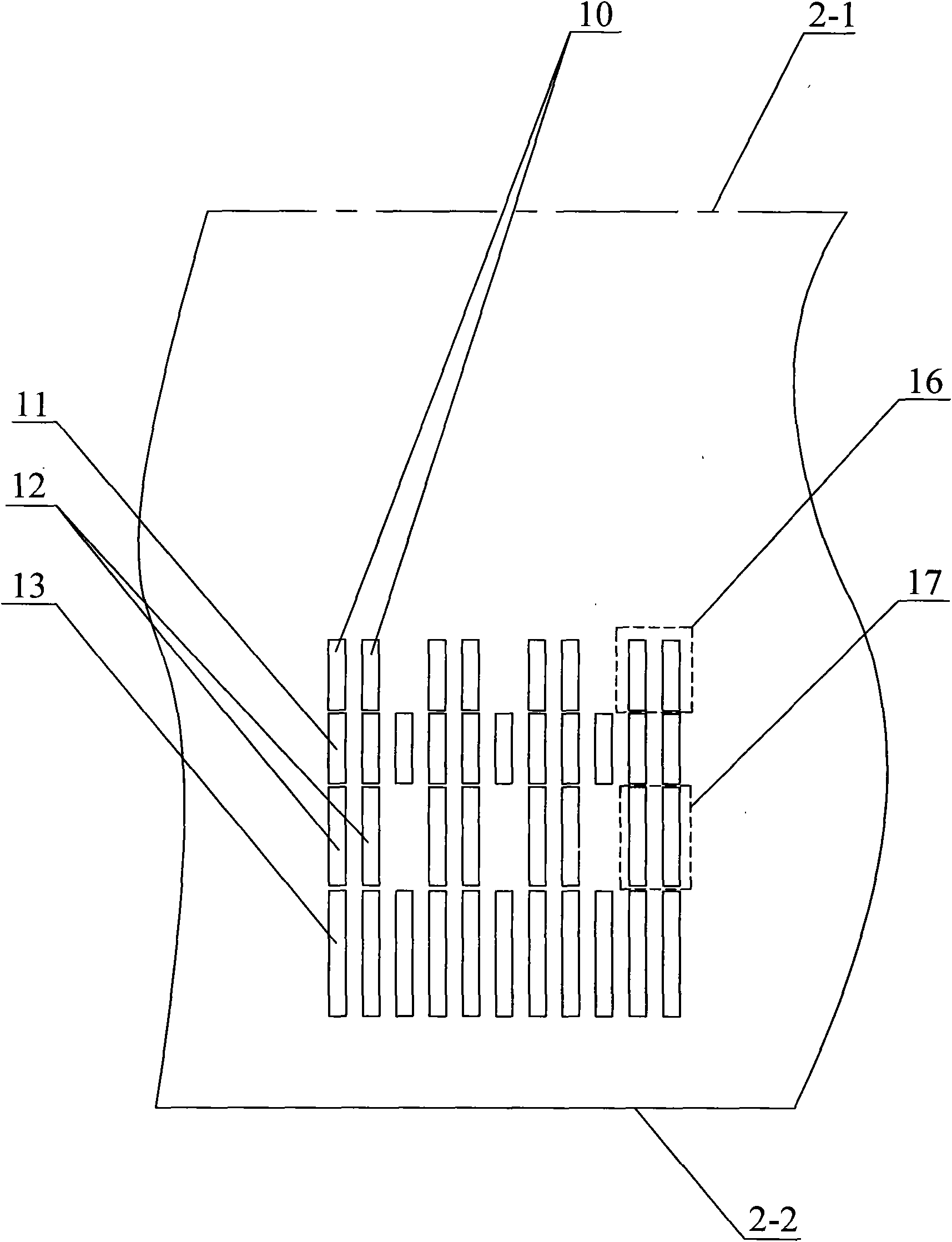

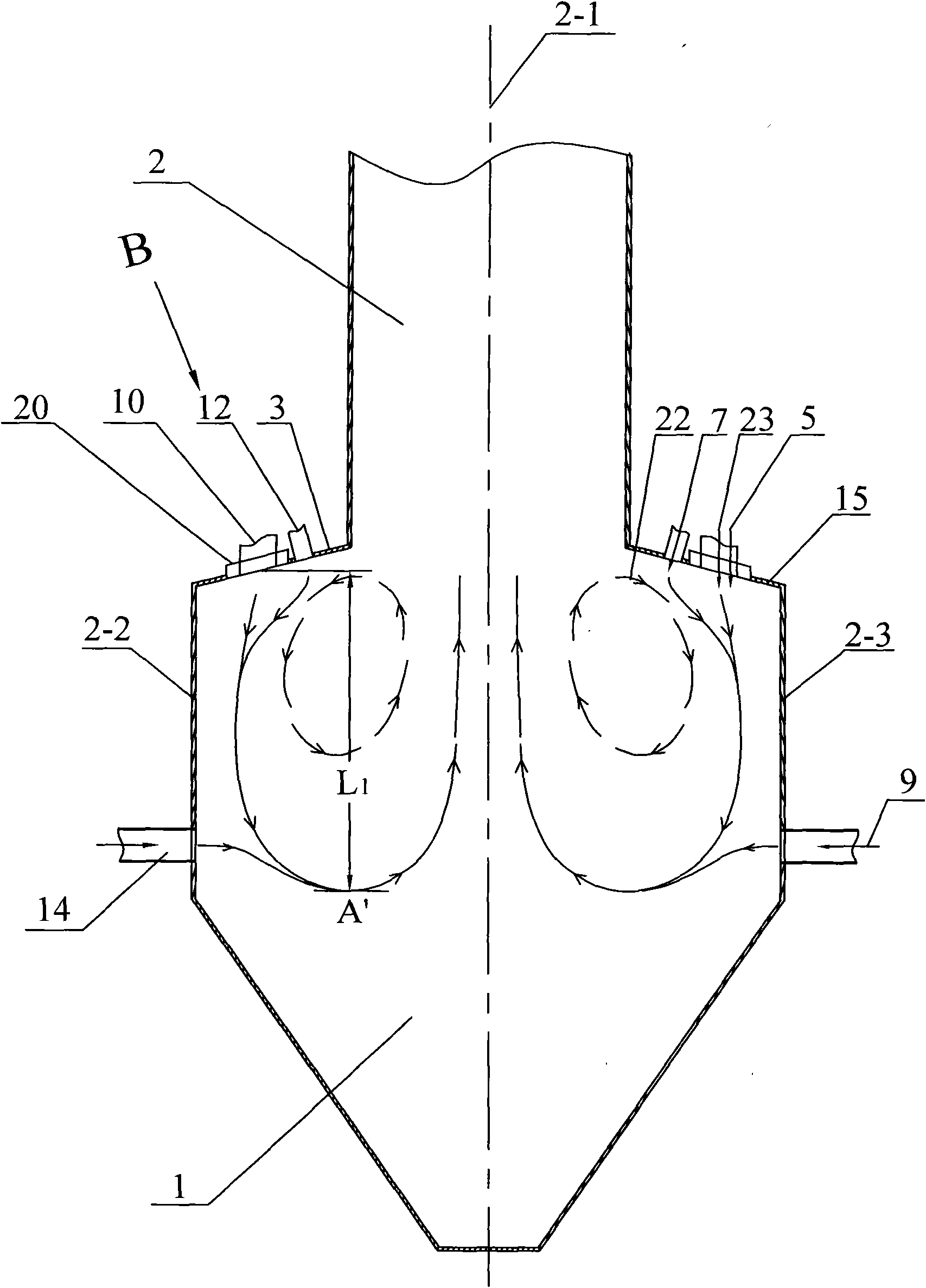

[0021] Specific implementation mode one: combine figure 1 and figure 2 Illustrate this embodiment, a kind of multi-injection staged combustion method of this embodiment is realized in this way: on the front furnace arch 3 of the furnace, from the furnace center 2-1 side to the front wall water-cooled wall 2-2 of the furnace Between the back furnace arch 15 of the furnace and from the furnace center 2-1 side to the rear wall water wall 2-3 of the furnace, there are a plurality of dense pulverized coal airflow nozzles 10 and a plurality of internal secondary air nozzles 11. , a plurality of light pulverized coal airflow spouts 12 and a plurality of outer secondary air spouts 13, the dense coal pulverized airflow 5 is sprayed into the lower furnace 1 by a plurality of thick coal pulverized airflow spouts 10, and the inner secondary air 6 is formed by a plurality of inner secondary air The secondary air nozzle 11 is injected into the lower furnace 1, the light coal powder airfl...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 To describe this embodiment, the included angle α between the center line of the secondary air nozzle 14 under the arch and the horizontal plane in this embodiment is 45°. When the downward deflection angle of the secondary air 9 under arch is too large, it will cause the pulverized coal airflow to shoot down too deeply and scour the cold ash hopper 4, thus causing slagging in the cold ash hopper 4, and the secondary air 9 under arch will deflect downward. Setting it at 45° can not only ensure that the dense pulverized coal airflow 5 has a sufficient downward injection depth in the lower furnace 1, but also avoid slagging of the cold ash hopper 4. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 and figure 2 Illustrate this embodiment, the W-flame boiler device of multi-injection staged combustion of this embodiment comprises the furnace hearth that is made of lower furnace 1, upper furnace 2 and two furnace arches and a plurality of dense pulverized coal air flow spouts 10, a plurality of Light coal pulverized air flow nozzle 12 and a plurality of secondary air nozzles 14 under the arch, the two furnace arches are respectively the front furnace arch 3 and the rear furnace arch 15; the device of this embodiment also includes a plurality of secondary air nozzles arranged in stages, A plurality of secondary air nozzles arranged in stages are respectively a plurality of inner secondary air nozzles 11 and a plurality of outer secondary air nozzles 13; on the front furnace arch 3 from the furnace center 2-1 side to the front wall water wall 2 of the furnace Between -2 and between the rear furnace arch 15 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com