Production method of epoxy palm oil plasticizer

A technology of epoxidized palm oil and production methods, applied in the direction of organic chemistry, etc., can solve problems that have not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1 Take 100 parts of palm oil, 50 parts of 50% hydrogen peroxide, 15 parts of formic acid, and 0.5 parts of concentrated sulfuric acid, react at 10°C for 48 hours, let stand to separate layers, discard the water layer, and use sodium hydroxide solution to neutralize the oil layer Afterwards, it was washed with deionized water until neutral, and the moisture was removed under reduced pressure to obtain the product. The epoxy value was 3.2.

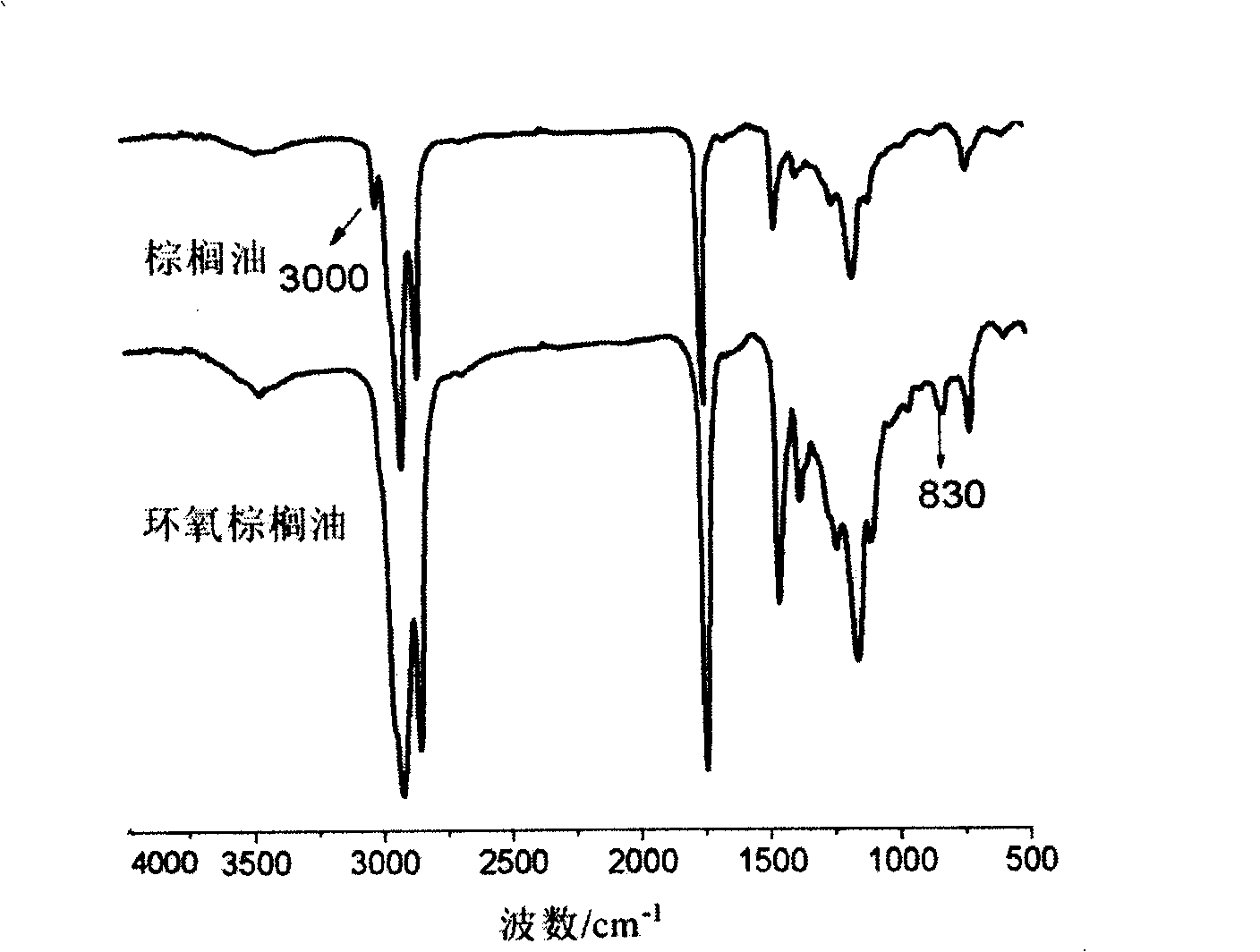

[0011] figure 1 FTIR spectra of palm oil and epoxy palm oil.

[0012] In the FTIR spectrum, 3000cm -1 The stretching vibration absorption peak of C-H on the C=C double bond is at 830cm -1 is the asymmetric stretching vibration absorption peak of the epoxy group, by figure 1 Visible, in palm oil 3000cm -1 There are characteristic absorption peaks, and 830cm -1 There is no absorption peak at , indicating that there are double bonds in palm oil, but no epoxy bonds. And in the FTIR spectrogram of epoxy palm oil, at 3000cm ...

Embodiment 2

[0013] Example 2 Take 100 parts of palm oil, 70 parts of 30% hydrogen peroxide, 20 parts of acetic acid, and 3 parts of concentrated sulfuric acid, react at 100° C. for 0.5 hour, let stand to separate layers, discard the water layer, and use sodium carbonate solution to neutralize the oil layer. Then wash with deionized water until neutral, and remove water under reduced pressure to obtain the product. The epoxy value was 3.8.

Embodiment 3

[0014] Example 3 Take 100 parts of palm oil, 30 parts of peroxyformic acid, 1 part of concentrated sulfuric acid, and 5 parts of phosphoric acid, react at 60°C for 10 hours, leave to separate layers, discard the water layer, and neutralize the oil layer with sodium hydroxide solution , and then washed with deionized water until neutral, and the water was removed under reduced pressure to obtain the product. The epoxy value was 4.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com