Sound Absorbing Material and Structure Using the Same

a technology structure, applied in the direction of instruments, walls, flooring, etc., can solve the problems of not achieving sufficient sound absorbing effect, heavy weight of sound absorbing material, and needing to widen the spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

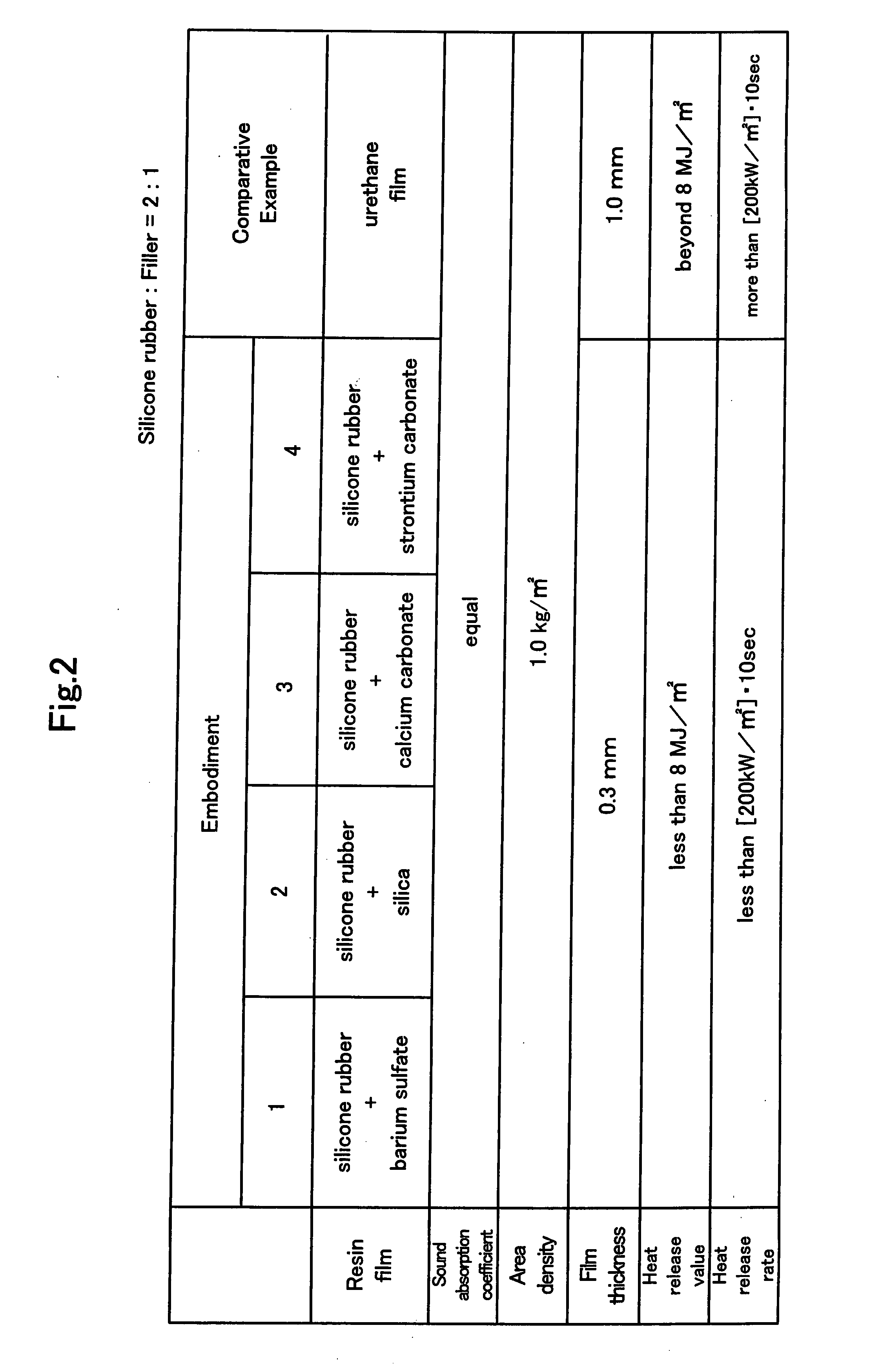

first embodiment

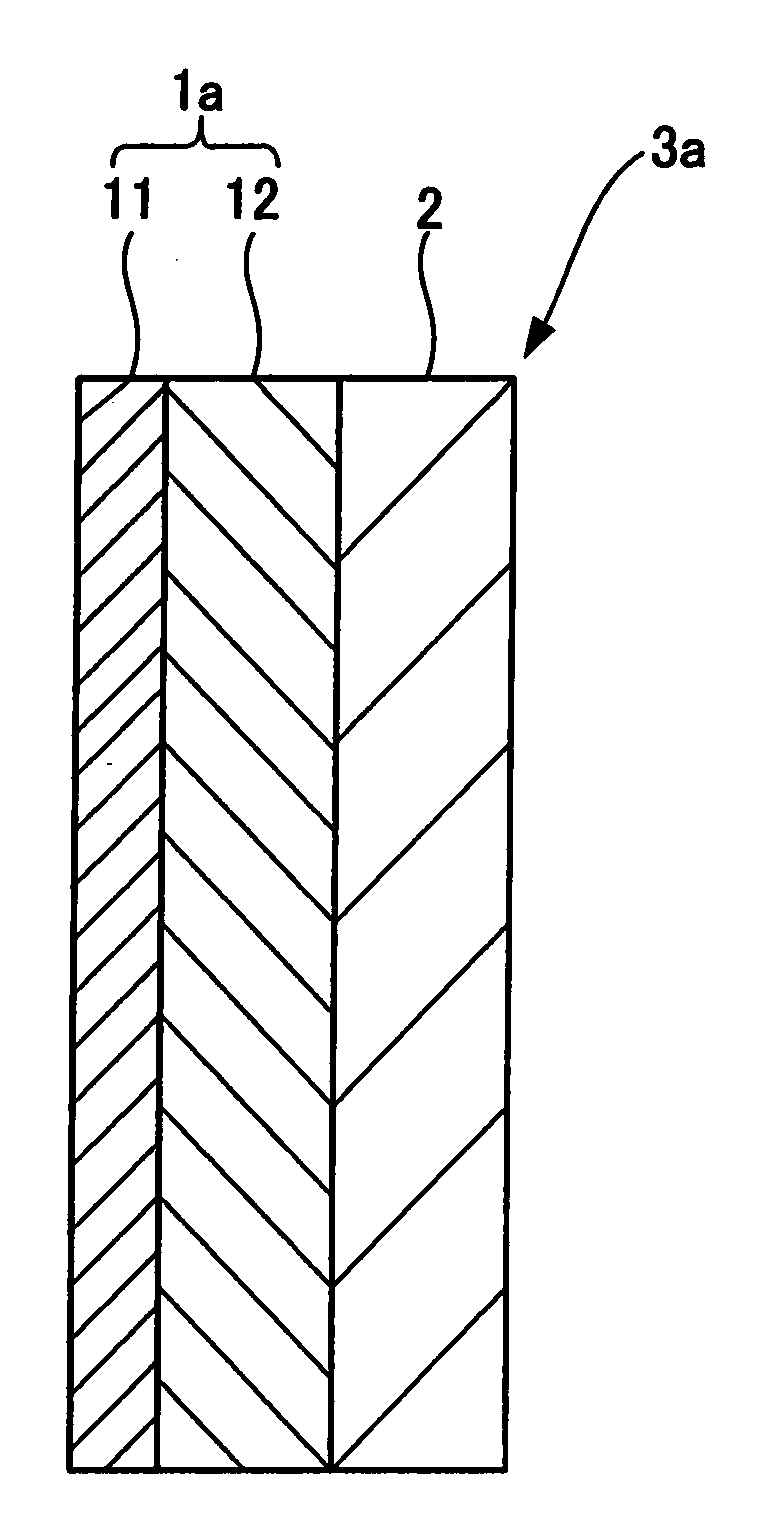

[0048]FIG. 1 is the sectional view which shows the first embodiment of this invention using the sound absorbing material and the structure using the same.

[0049]In this figure, the sound absorbing material 1a of this invention comprises the film 11 composed of the silicone rubber and the porous layer 12 (hereinafter called, “first porous layer”) which is laminated on the back surface of the film 11. Here, the reason to laminate the first porous layer 12 on the back surface of the film 11 composed of the silicone rubber is that the film 11 acts as the mass, that is, the role of the weight, and the first porous layer 12 acts as spring, that is, the role of the air spring, and the sound absorption is performed by membrane vibration.

[0050]In such the sound absorbing material 1a, for a rigid wall 2, by making the first porous layer 12 face the rigid wall 2, and by arranging such the sound absorbing material 1a in parallel with the rigid wall 2, a structure 3a of this invention can be form...

second embodiment

[0068]FIG. 4 shows the sectional view of the structure of the filmy sound absorbing structure which used the sound absorbing material 1a of the first embodiment. Meanwhile, in this figure, the same reference numbers are given to the portions which are common to FIG. 1, and detailed explanation is omitted.

[0069]In FIG. 4, the structure 3b of this invention comprises the rigid wall 2, and the filmy (thickness: about 0.5 mm) sound absorbing material 1a that the first porous layer 12 faces the rigid wall 2 and which is arranged on the sound source side of the rigid wall 2 in parallel with the rigid wall 2 through a pair of supporting members 4a, 4b, and the back air layer 5 which is sectioned between the sound absorbing material 1a and the rigid wall 2.

[0070]In the structure 3b of the filmy sound absorbing structure of such composition, because the back air layer 5 acts as the spring to the mass of the filmy sound absorbing material 1a, the single resonance system is formed. And, when t...

third embodiment

[0071]FIG. 5 shows the sectional view of the structure which applied the sound absorbing material 1a to the sound insulation wall of the first embodiment. Meanwhile, in this figure, the same reference numbers are given to the portions which are common to FIG. 1, and detailed explanation is omitted.

[0072]In FIG. 5, the structure 3c of this invention has the hollow double wall 6 which is placed as the simplified partition, for example on the floor inside the building.

[0073]The hollow double wall 6 comprises the first wall member 6a which is arranged in the sound source side, and the second wall member 6b which is arranged in parallel with the first wall member 6a at the position where predefined length was estranged from the first wall member 6a in the sound receiving side. And, the aforementioned sound absorbing material 1a is arranged in parallel with the first wall member 6a (or the second wall member 6b) between these first and second wall members 6a, 6b.

[0074]According to the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com