Washing agent and method for treating copper and copper alloy surface oxidation layer

A technology of surface oxidation and treatment method, applied in the field of metal product surface treatment lotion, can solve the problems of uneven corrosion, polluted production environment, easy damage to the thread of alloy parts, etc., and achieves easy control of process parameters and wide process temperature range. , The effect of cleaning the inner and outer surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

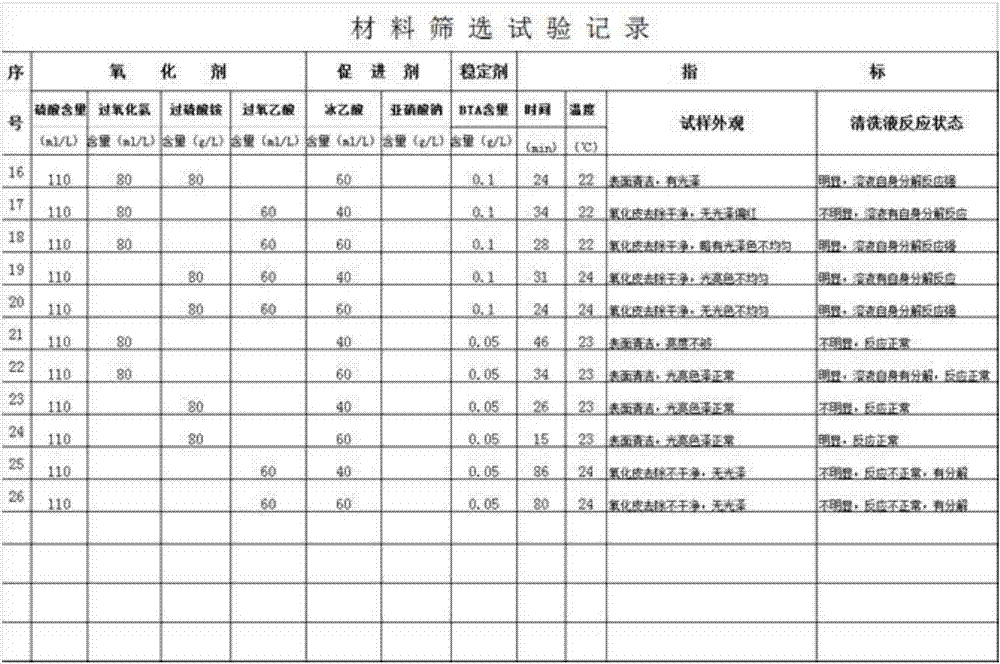

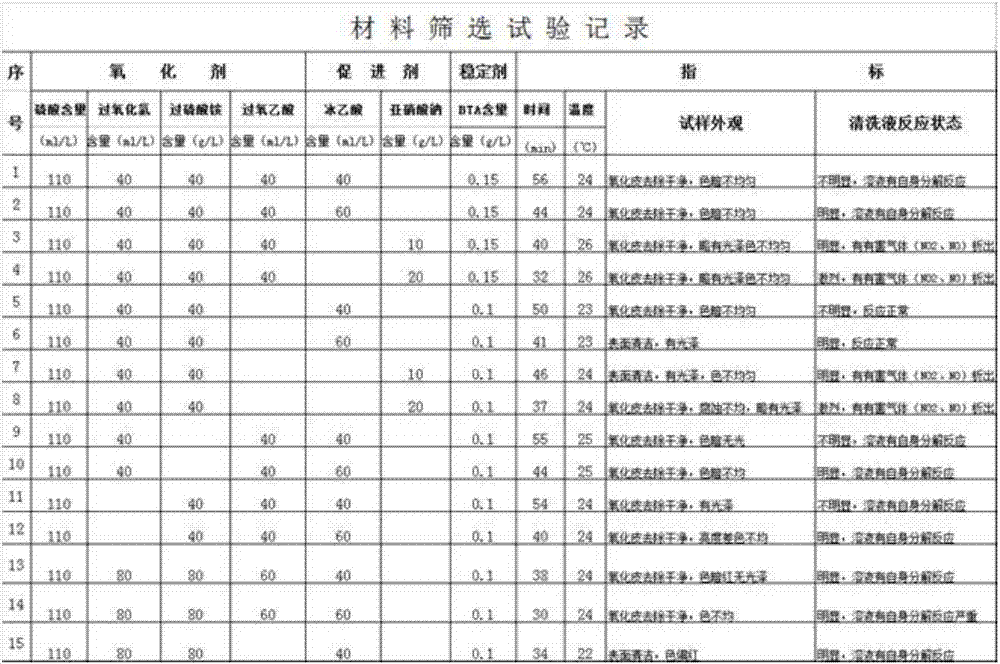

Image

Examples

Embodiment 1

[0028] Embodiment 1: the lotion for processing the oxide layer on the copper alloy surface is made of the following raw materials in parts by weight: 90 parts of sulfuric acid, 40 parts of ammonium persulfate, 40 parts of glacial acetic acid, and 0.05 part of benzotriazole.

[0029] During preparation, the above-mentioned components can be mixed in proportion.

[0030] Adopt the treatment method of the copper and copper alloy surface oxide layer of the lotion of aforementioned treatment copper alloy surface oxide layer, it comprises the steps:

[0031] Step (1): Put the copper and copper alloy products into the stainless steel basket and place them to prevent the air pockets in the tube;

[0032] Step (2): According to the oily state of the surface of copper and copper alloy products, add a degreasing agent on the surface;

[0033] Step (3): Rinse off the acid-base, oxides and impurities remaining on the inner and outer surfaces of the copper and copper alloy products with a ...

Embodiment 2

[0037] Embodiment 2: 220 parts of sulfuric acid, 90 parts of ammonium persulfate, 65 parts of glacial acetic acid, 0.2 part of benzotriazole.

[0038] During preparation, the above-mentioned components can be mixed in proportion.

[0039] Adopt the treatment method of the copper and copper alloy surface oxide layer of the lotion of aforementioned treatment copper alloy surface oxide layer, it comprises the steps:

[0040] Step (1) Put the copper and copper alloy products into the stainless steel basket and place them to prevent the water in the inner cavity of the tube;

[0041] Step (2): According to the oily state of the surface of copper and copper alloy products, add a degreasing agent on the surface;

[0042] Step (3): Rinse off the acid-base, oxides and impurities remaining on the inner and outer surfaces of the copper and copper alloy products with a high-pressure water gun;

[0043] Step (4): Put the copper and copper alloy products treated in step (3) into the afore...

Embodiment 3

[0046] Embodiment 3: 110 parts of sulfuric acid, 80 parts of ammonium persulfate, 60 parts of glacial acetic acid, 0.1 part of benzotriazole.

[0047] In this preparation, the above-mentioned components can be mixed in proportion.

[0048] Adopt the treatment method of the copper and copper alloy surface oxide layer of the lotion of aforementioned treatment copper alloy surface oxide layer, it comprises the steps:

[0049] Step (1) Put the copper and copper alloy products into the stainless steel basket and place them to prevent the water in the inner cavity of the tube;

[0050] Step (2): According to the oily state of the surface of copper and copper alloy products, add a degreasing agent on the surface;

[0051] Step (3): Rinse off the acid-base, oxides and impurities remaining on the inner and outer surfaces of the copper and copper alloy products with a high-pressure water gun;

[0052] Step (4): Put the copper and copper alloy products treated in step (3) into the afor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com