Device and method for manufacturing aluminum casting by recycling waste aluminum material

A technology for scrap aluminum and aluminum castings, which is applied in the field of equipment for recycling and manufacturing aluminum castings from scrap aluminum, can solve problems affecting the quality of scrap aluminum smelting, affecting the quality of aluminum castings, and weakening corrosion resistance, so as to improve smelting efficiency, Effect of improving quality and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

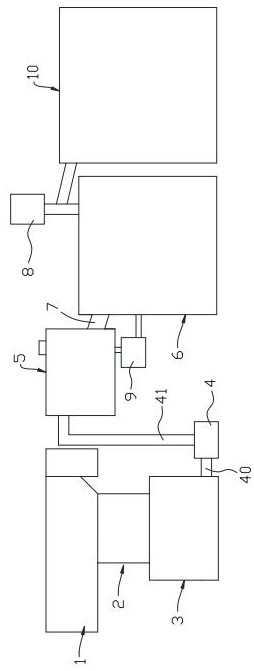

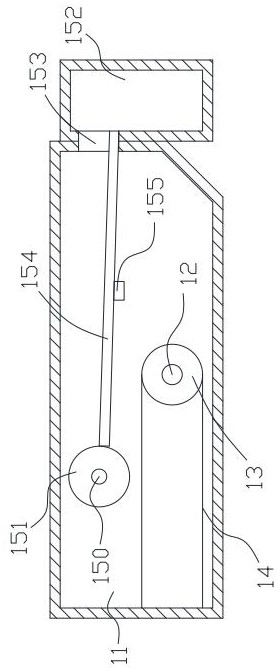

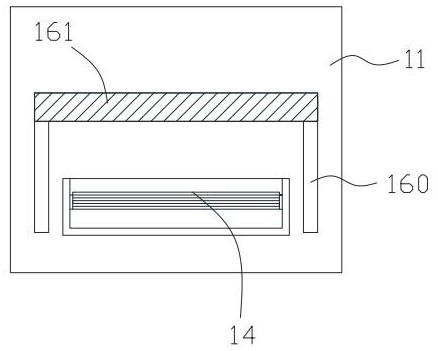

[0039] Such as Figure 1~6 As shown, this embodiment provides a device for recycling and manufacturing aluminum castings from waste aluminum, including: a transmission mechanism 1, an impurity removal and crushing device 2, a dehydration and oil removal mechanism 3, a suction pump 4, a preheating furnace 5, and a melting furnace 6. Feeding device 7, mechanical pump 8, suction pump 9, die casting device 10.

[0040] The conveying mechanism 1 is used for conveying aluminum scraps, and performs preliminary impurity removal treatment on aluminum scraps during the conveying process. The feed end of the impurity removal and crushing device 2 is installed at the outlet of the transmission mechanism 1, the inlet of the dehydration and oil removal mechanism 3 is installed at the outlet of the impurity removal and crushing device 2, and the input end of the suction pump 4 is fixedly connected to one end of the suction pipe 40. The other end of the suction pipe 40 is connected to the ou...

Embodiment 2

[0056] Such as Figure 7 As shown, this embodiment provides a method for recycling waste aluminum to manufacture aluminum castings. The method is realized by the above-mentioned device for recycling and manufacturing aluminum castings from waste aluminum. It is characterized in that the method includes the following steps:

[0057] (1) Preliminary removal of impurities

[0058] The cleaned and air-dried scrap aluminum is placed on the conveyor belt of the conveying mechanism for conveyance. During the conveying process, the impurity removal device conducts preliminary magnetic separation to remove impurities.

[0059] (2) Secondary impurity removal

[0060] The scrap aluminum material after preliminary impurity removal is crushed by the crushing knife of the impurity removal and crushing device, and the crushed waste aluminum material is subjected to secondary magnetic separation and impurity removal by several magnetic devices.

[0061] (3) Dehydration and oil removal

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com