Structure of rotor of three-phase permanent-magnet synchronous motor

A technology of rotor structure and permanent magnet synchronization, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of difficult to keep up with the production progress, difficult to form mass production, troublesome processing, etc., to achieve improved Efficiency, cost saving, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

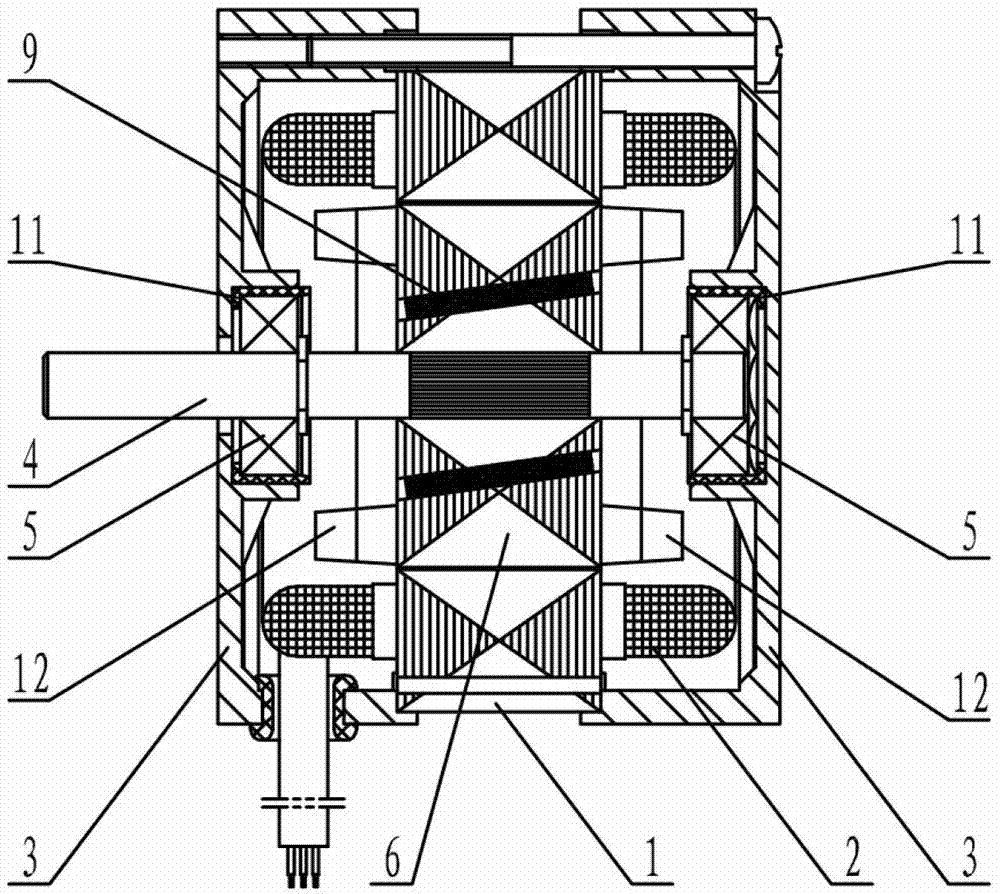

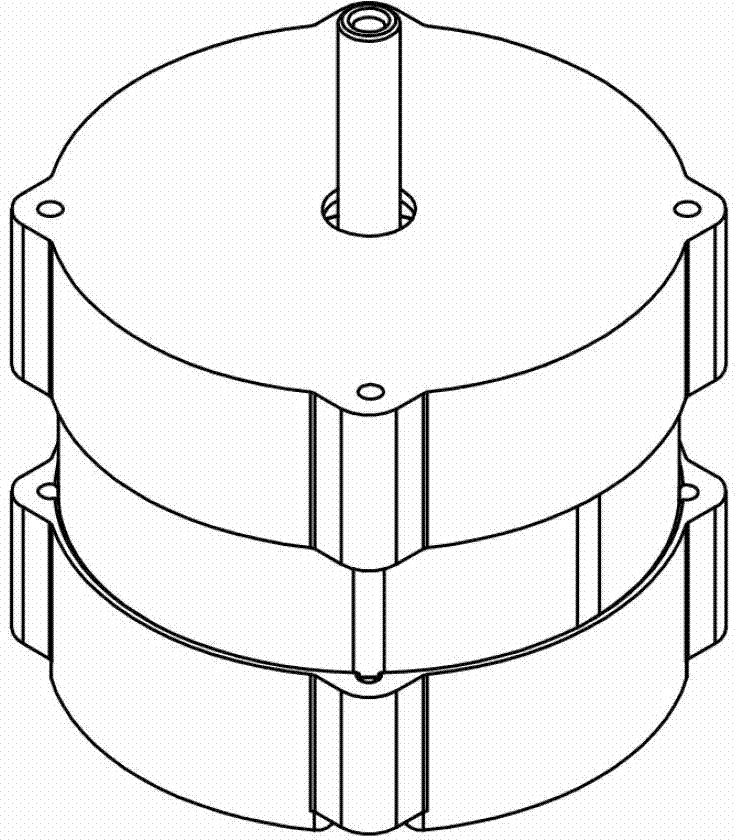

[0025] figure 1 , figure 2 A three-phase permanent magnet synchronous motor adopting the rotor structure of the present invention is shown, which mainly includes a stator core 1 , a coil 2 , an end cover 3 , a rotating shaft 4 and a rotor 6 . Stator core 1 is embedded with coil 2 , both ends are respectively connected with end cover 3 , rotating shaft 4 protrudes from one end of end cover 3 through bearings 5 arranged at both ends, and rotor 6 is connected to rotating shaft 4 .

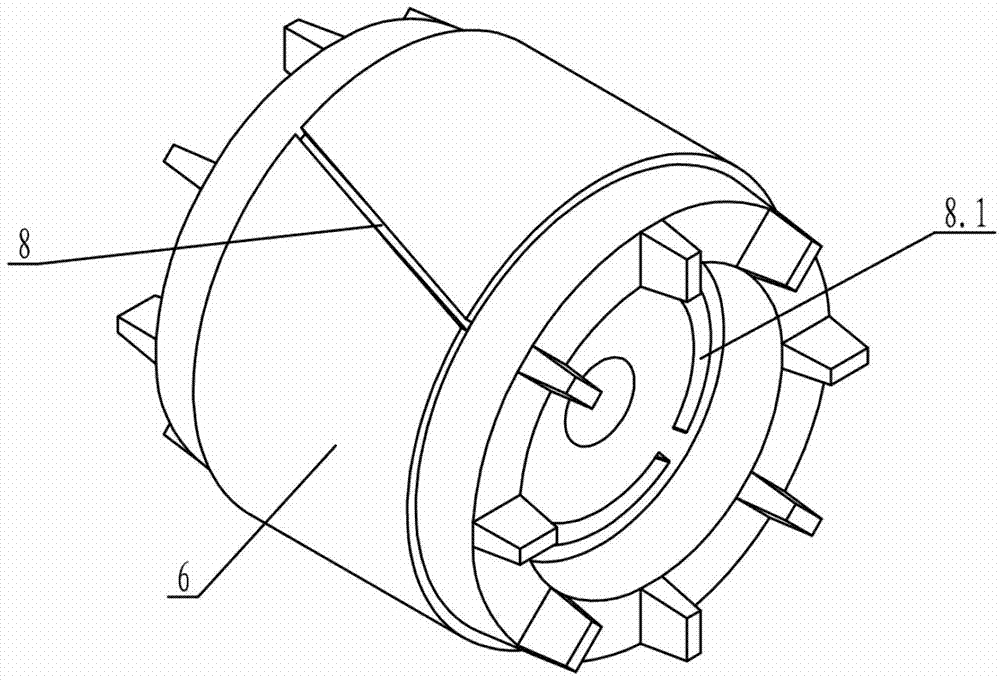

[0026] Such as Figure 3 to Figure 6 As shown, the stator core 1 and the rotor 6 are provided with slot structures that cooperate with each other. The rotor 6 of the present invention is made of silicon steel sheets punched with cast aluminum grooves punched on the outer circumference and arc-shaped magnetic steel grooves punched inside and laminated with cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com