Patents

Literature

82results about How to "Reduce electromagnetic vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

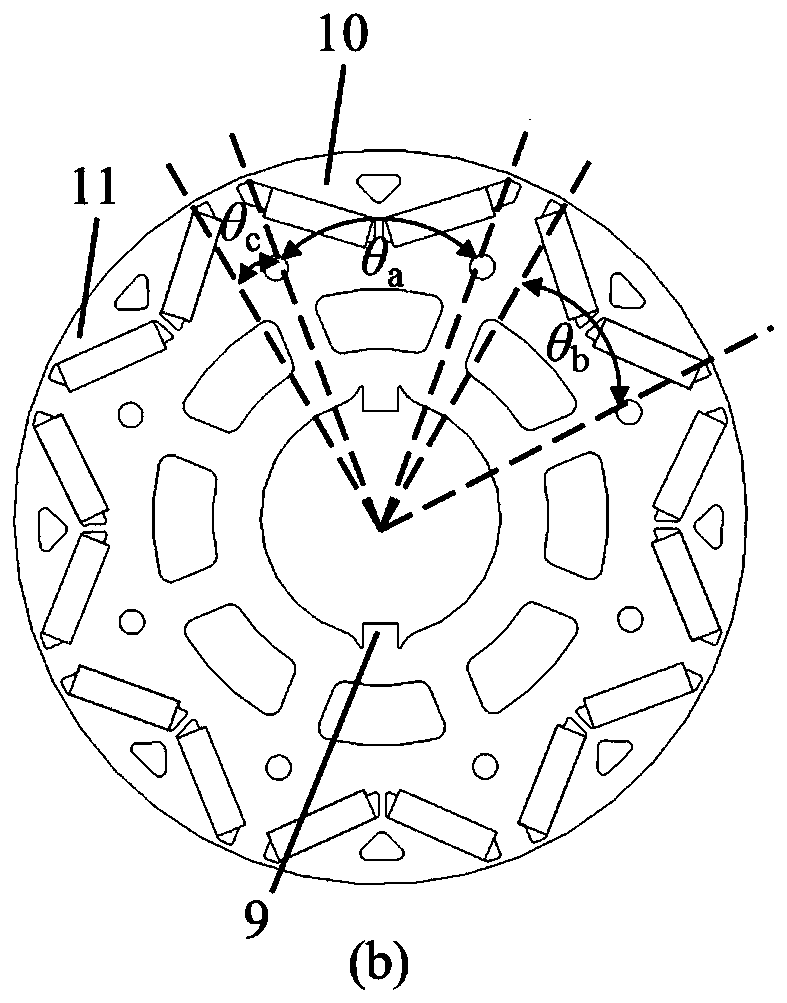

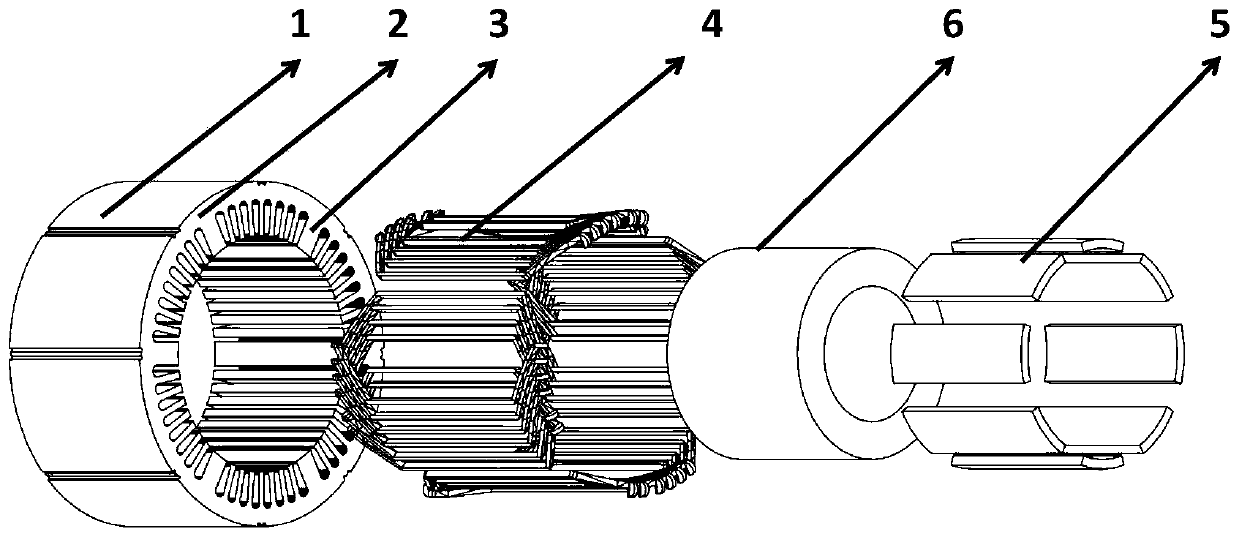

Segmented oblique pole rotor and permanent-magnet synchronous motor

InactiveCN106849431AImprove reliabilityUndercut torqueMagnetic circuit rotating partsSynchronous motorPermanent magnet synchronous motor

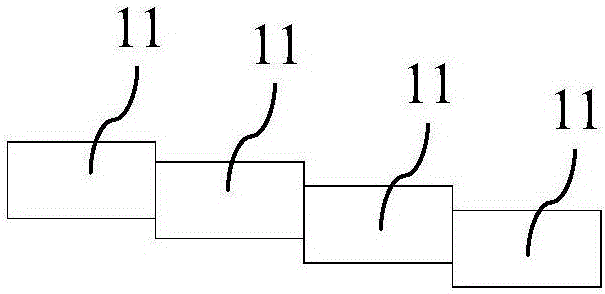

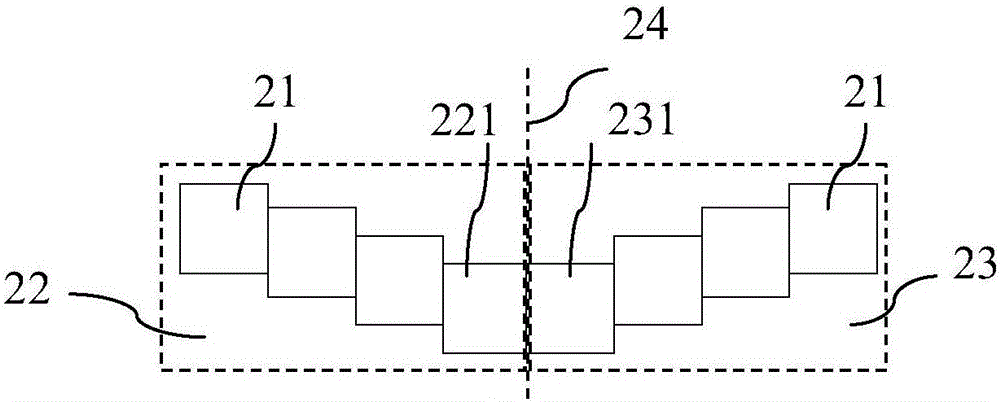

The invention provides a segmented oblique pole rotor and a permanent-magnet synchronous motor. The segmented oblique pole rotor comprises a rotating shaft and a rotor core, wherein the rotor core comprises a first core segment and a second core segment which are adjacently arranged along the axial direction; each of the first core segment and the second core segment comprises a plurality of core units which are arranged along the axial direction; an even number of uniformly distributed magnetic poles are arranged on the periphery of each core unit; started from the joint of the first core unit and the second core unit, a preset angle difference exists between like magnetic pole center lines of two adjacent core units in the first core segment along a first rotating direction in sequence; a preset angle difference exists between like magnetic pole center lines of two adjacent core units in the second core segment along a second rotating direction in sequence; and the first rotating direction is opposite to the second rotating direction. Like magnetic pole centers of the core units of the rotor core are sequentially staggered in a mirror symmetry manner and the axial additional force is eliminated, so that the reliability of the permanent-magnet synchronous motor is improved.

Owner:SUZHOU INOSA UNITED POWER SYST CO LTD

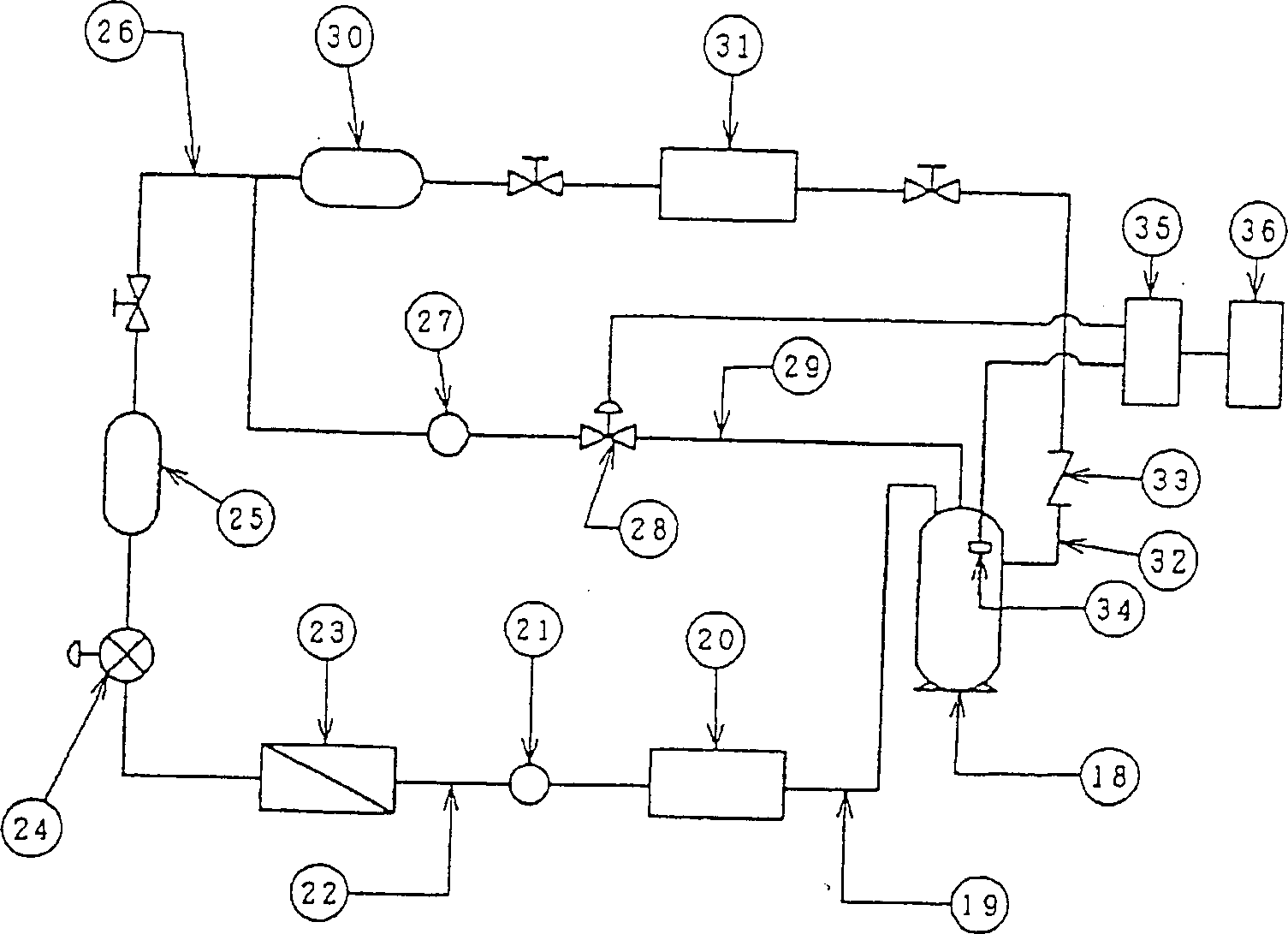

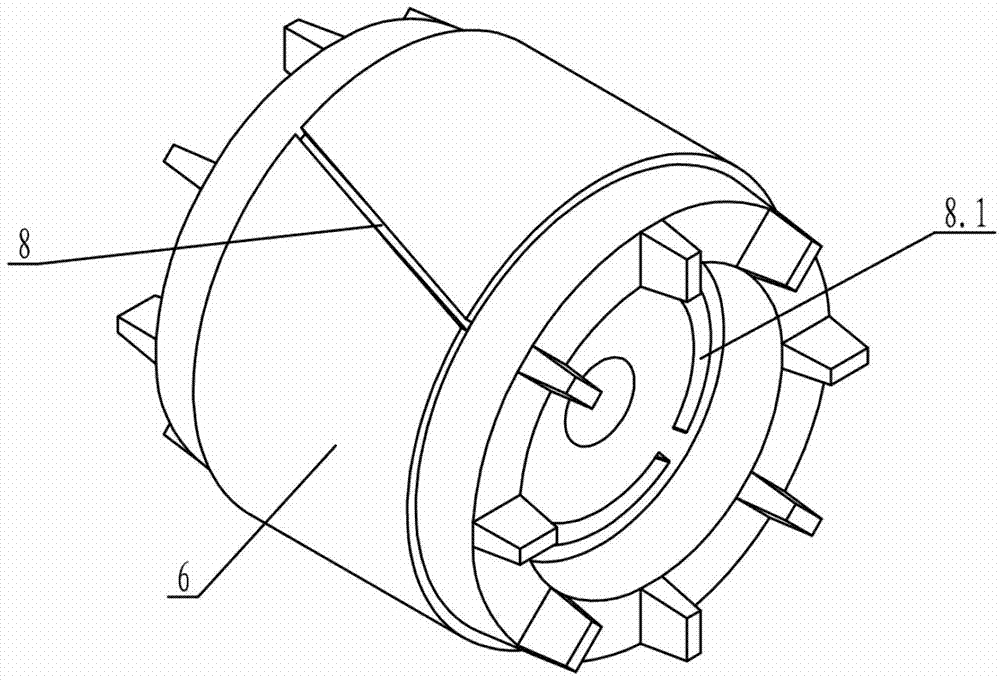

Vortex compressor and refrigerator using ammonia-like as refrigrant

InactiveCN1405951AJet easyImprove efficiencyRotary/oscillating piston combinations for elastic fluidsWindings insulation materialEngineeringRefrigerant

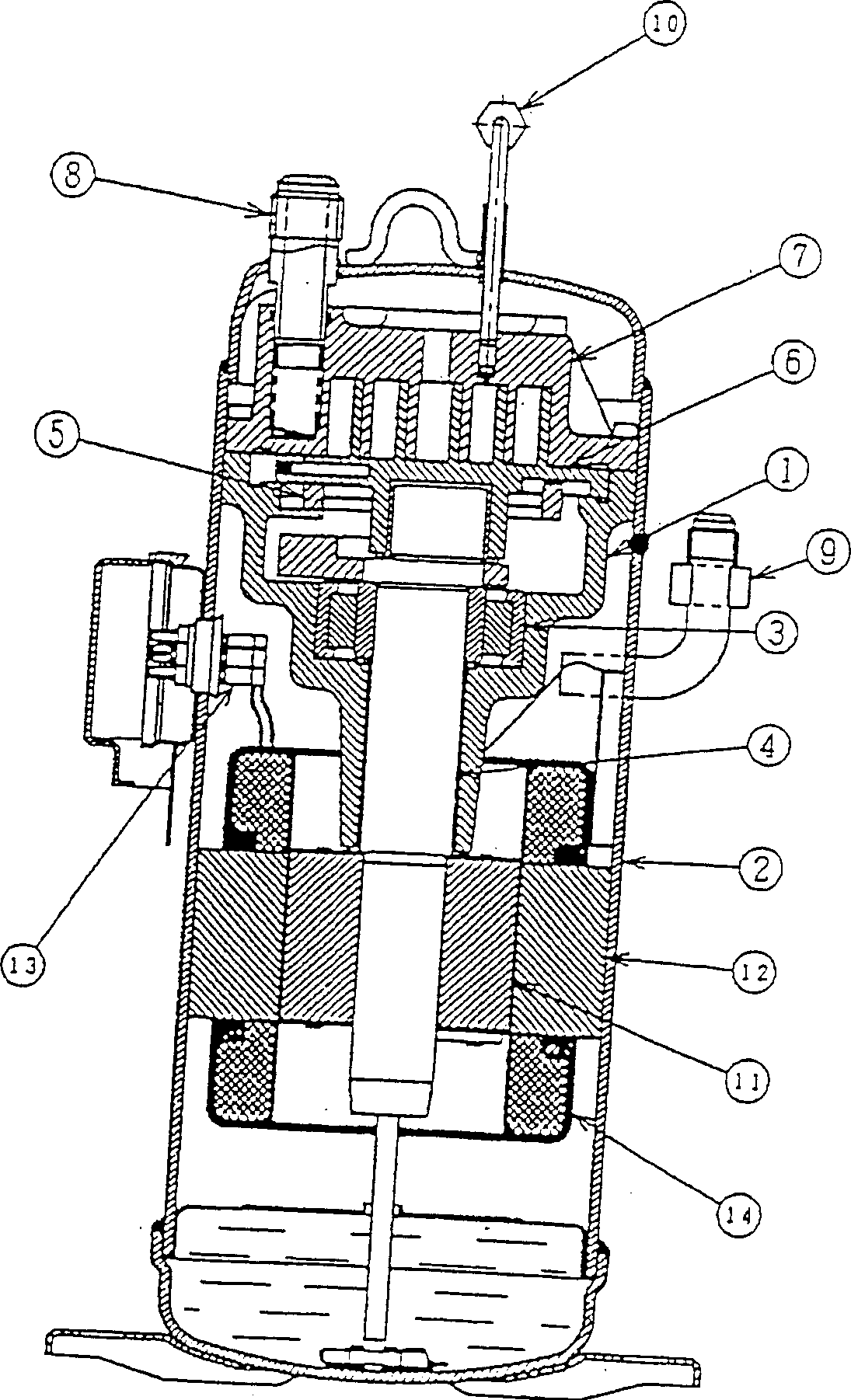

The scroll compressor includes a scroll compression mechanism portion in combination of an orbiting scroll and a fixed scroll, a frame for supporting the compression portion, a rotary shaft fitted in the orbiting scroll, a motor portion coupled to the rotary shaft, and a hermetic chamber incorporating the above-mentioned components. Windings of a stator of a motor in the motor portion are formed of aluminum wires which are coated with fluororesin compound, that is, the aluminum wires are coated with fluororesin and is molded with a resin material. Ammonia group refrigerant is used in the scroll compressor. Further, a refrigerating system using the above-mentioned scroll compressor, is incorporated therein with a circuit for injecting ammonia group refrigerant into a compression room in the compression mechanism portion.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

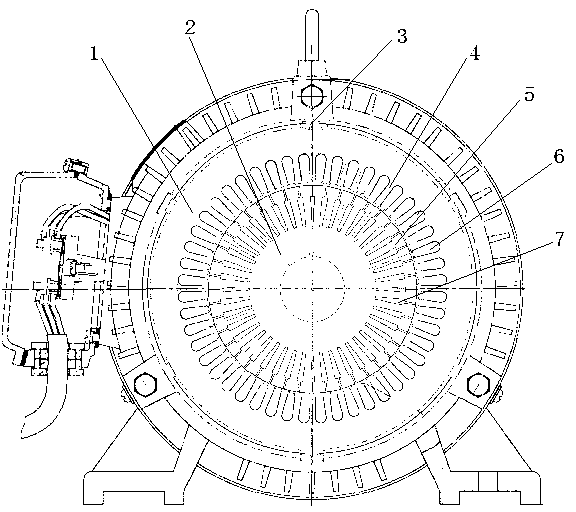

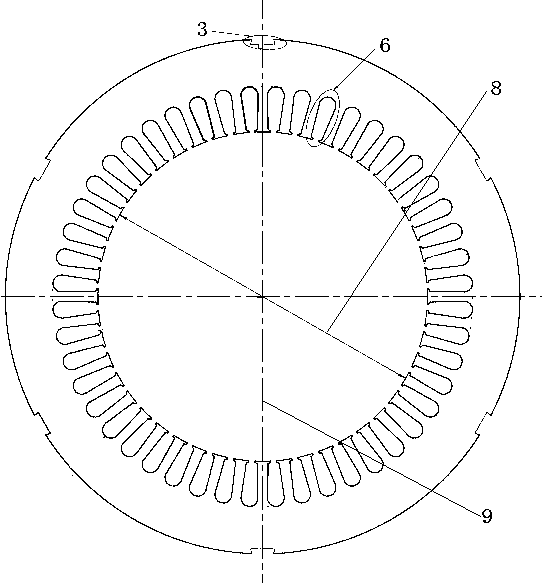

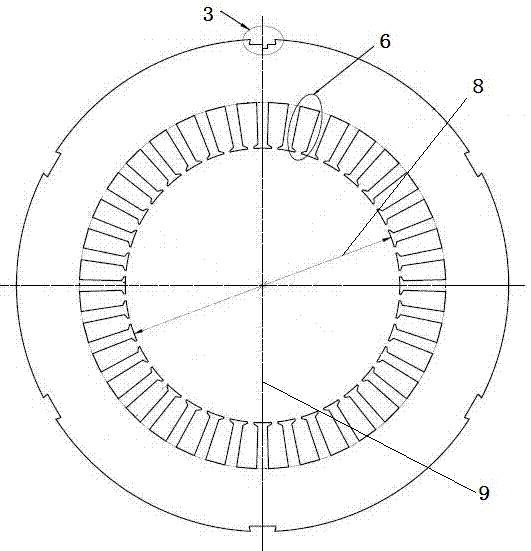

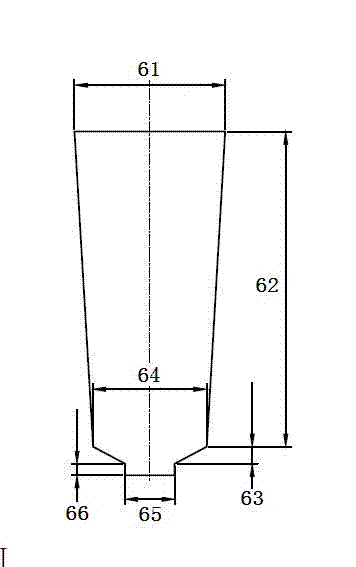

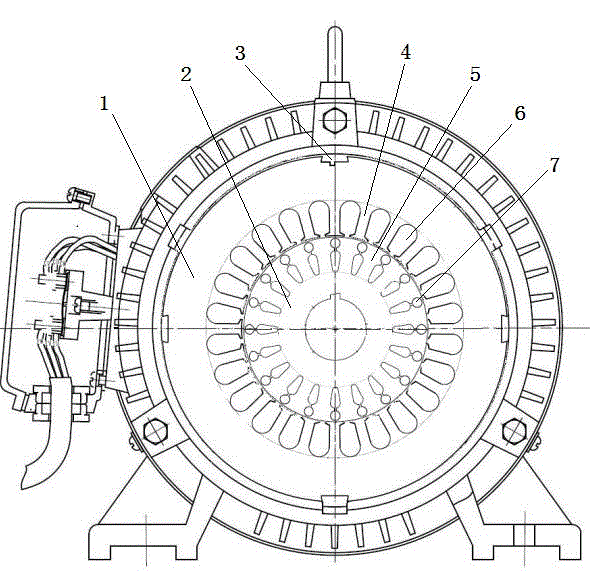

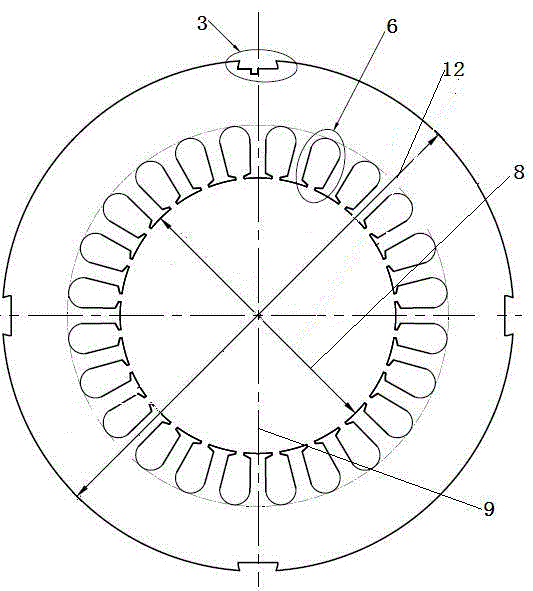

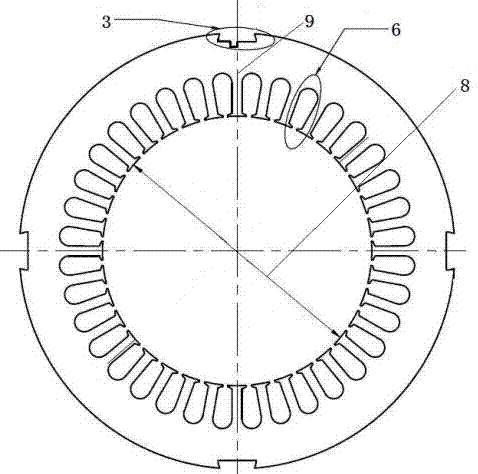

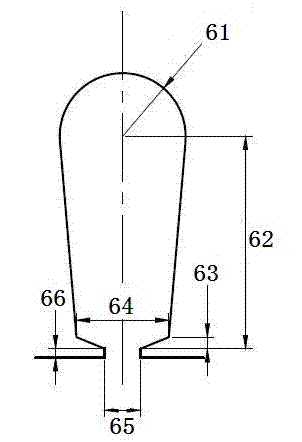

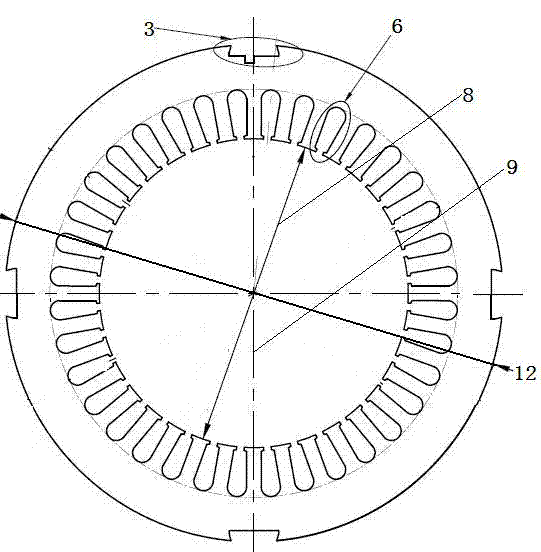

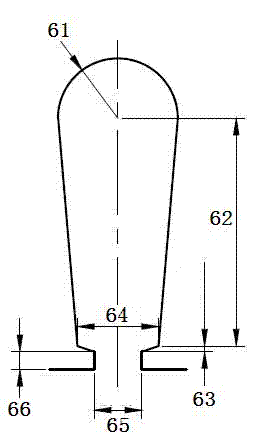

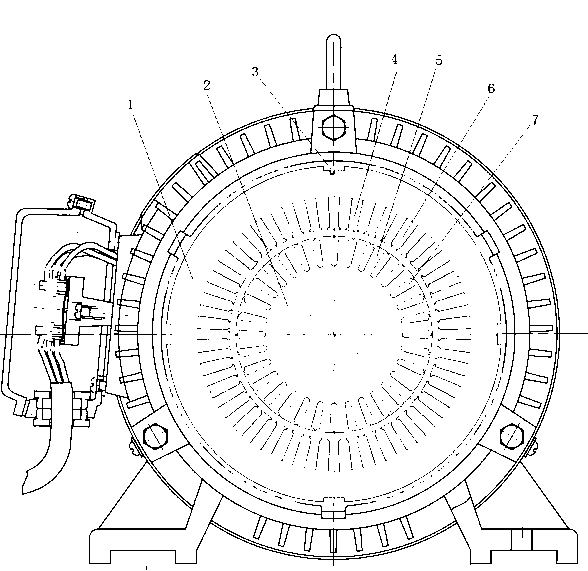

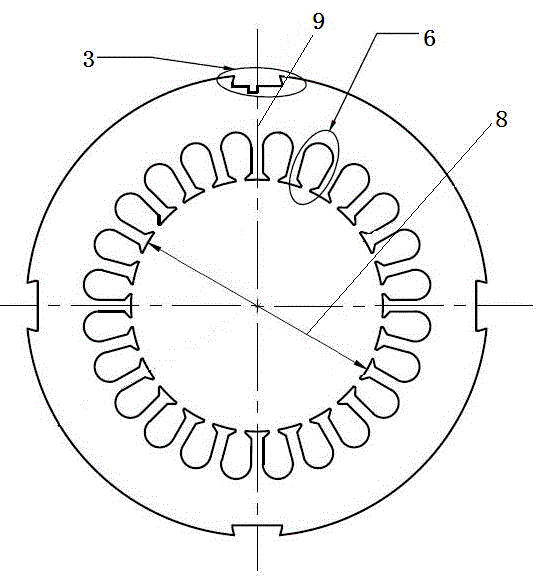

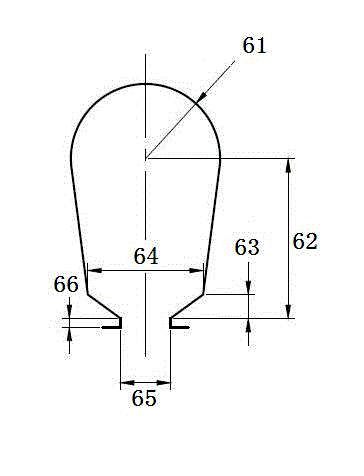

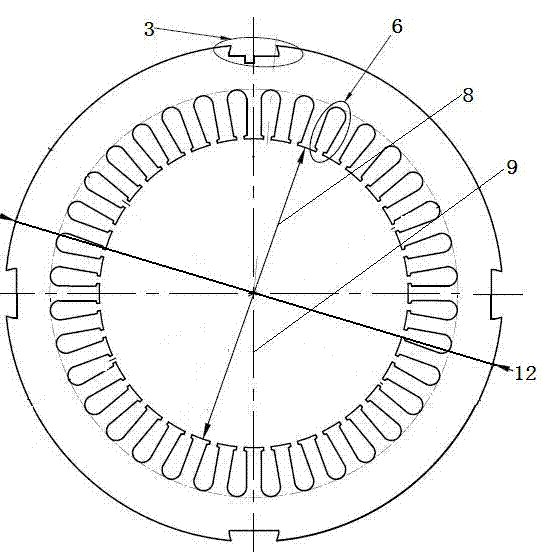

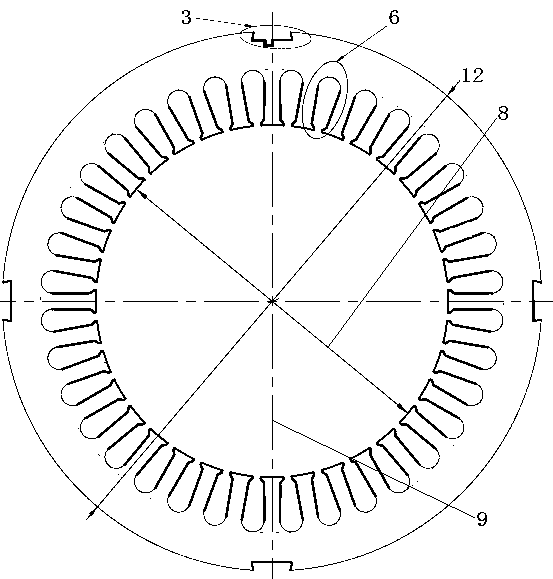

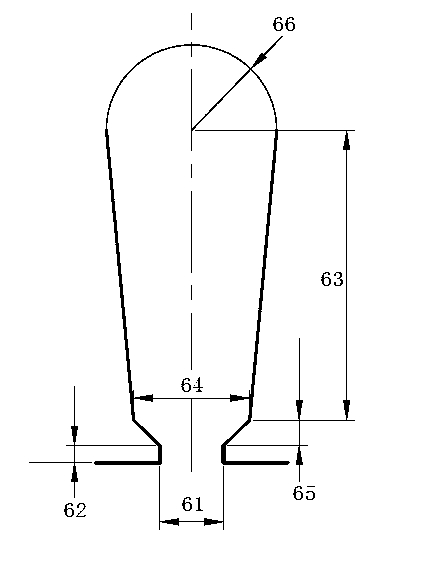

Ultra-energy-saving 18500W four-pole three-phase asynchronous electric motor

InactiveCN102780345AImprove conversion efficiencyWeaken Radial Electromagnetic Force WavesMagnetic circuit rotating partsMagnetic circuit stationary partsThree phase asynchronous motorEngineering

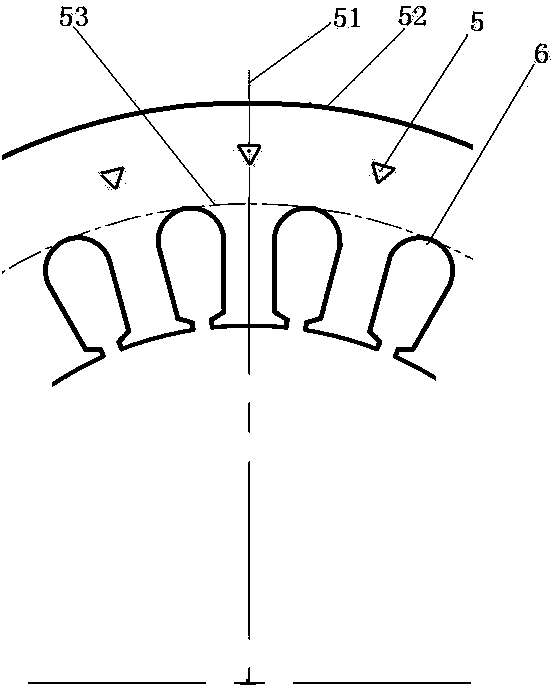

The invention relates to an ultra-energy-saving 18500W four-pole three-phase asynchronous electric motor, which comprises a stator and a rotor. The inner diameter and the iron core length of the stator, the groove shape and the size of a stator punching sheet groove, the inner diameter, the outer diameter and the iron core length of the rotor, and the groove shape and the size of a rotor punching sheet groove are optimized and reasonably designed, so the stator winding loss, the rotor winding loss and the iron core loss are greatly reduced, on the premise that the output power is identically 18.5kW, the total loss quantity of the existing similar product is 2126.7W, the total loss quantity of the ultra-energy-saving 18500W four-pole three-phase asynchronous electric motor is only 1402.1W and is reduced by 34.07 percent, and energy sources are greatly saved. Compared with the energy source conversion efficiency of the existing similar product being 89.7 percent, the energy source conversion efficiency of the ultra-energy-saving 18500W four-pole three-phase asynchronous electric motor is 93.0 percent and is improved by 3.3 percent. Meanwhile, because the center line of a stator buckle sheet groove is designed to penetrate through the a position between two grooves of the stator punching sheet groove, the radial electromagnetic force wave in an air gap is weakened, the electromagnetic vibration is reduced, and the electromagnetic noise is lowered.

Owner:CHONGQING LEERJIA MACHINERY

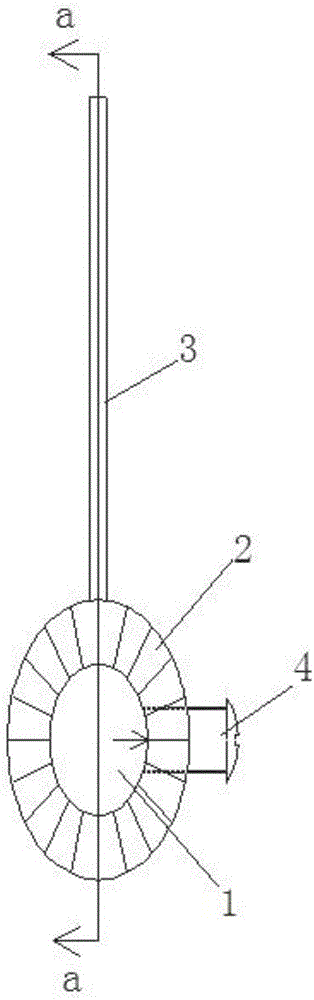

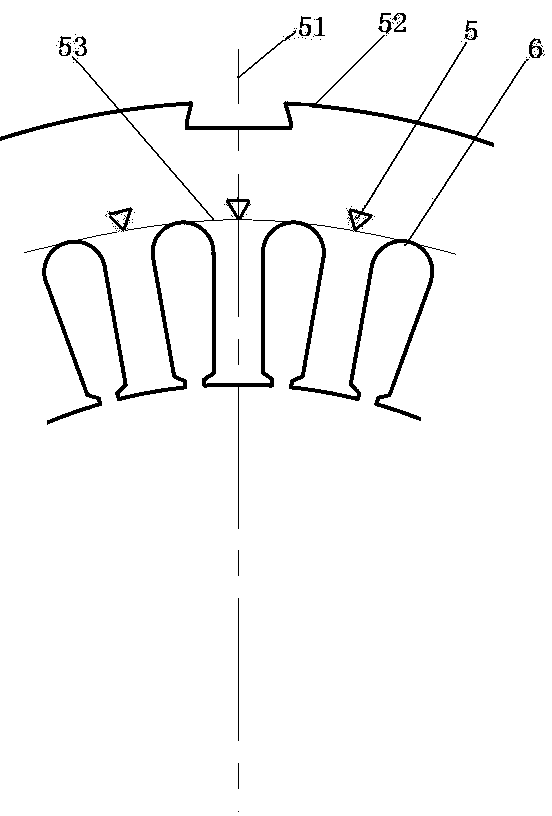

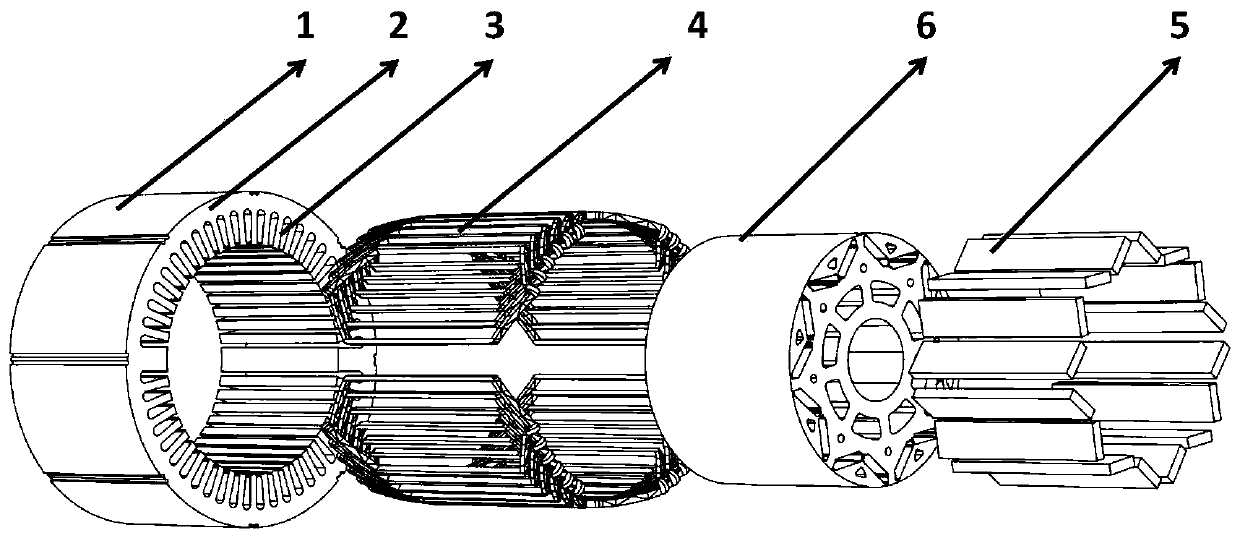

Structure of rotor of three-phase permanent-magnet synchronous motor

InactiveCN102882298AEasy to processImprove efficiencyMagnetic circuit rotating partsSynchronous motorLoop control

The invention discloses a structure of the rotor of a three-phase permanent-magnet synchronous motor. The rotor is formed by casting aluminium on a silicon steel sheet axially slantwise in an overlaying way, wherein an aluminium casting slot is punched on the outer circumference of the silicon steel sheet, and an arc-shaped magnetic steel slot is punched in the silicon steel sheet; rotor slantwise slots and an arc-shaped slantwise slots are formed on the rotor; the magnetic steel is arranged in each arc-shaped slantwise slot of the rotor; and the magnetic steel is made of the adhesive rare-earth permanent-magnet material and is in the shape of an inclined tile. Because the rotor slantwise slots are adopted, the magnetic vibration and the noise are reduced greatly, the loss is reduced, and the efficiency is improved. When the magnetic steel in the shape of the inclined tile is arranged in the rotor slantwise slots, the fit clearance of the magnetic steel in the circumferential direction isolates magnetism naturally, thus the strength of the punched sheet is improved effectively, and the rotor can be processed conveniently by adopting the mature asynchronous motor rotor aluminum casting process. The three-phase permanent-magnet synchronous motor is simple in structure, can operate stably and reliably, has high efficiency and a wide range of speed regulation and outputs at constant torque. A simple and effective open-loop control system with constant rotation speed requirements can be formed, and the cost spent constructing a control system is saved.

Owner:WUXI XISHAN SPECIAL FAN

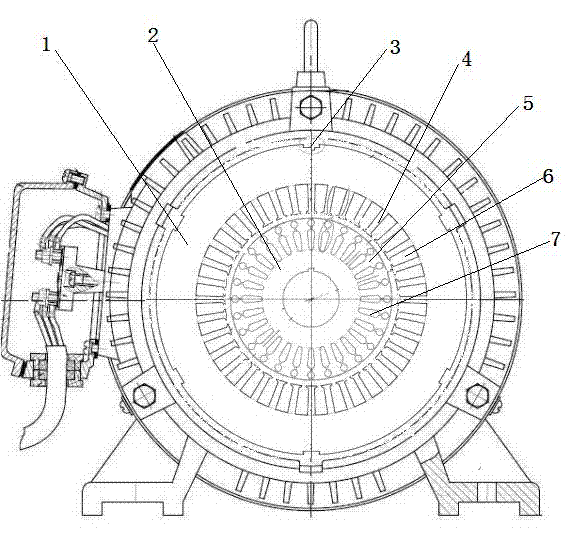

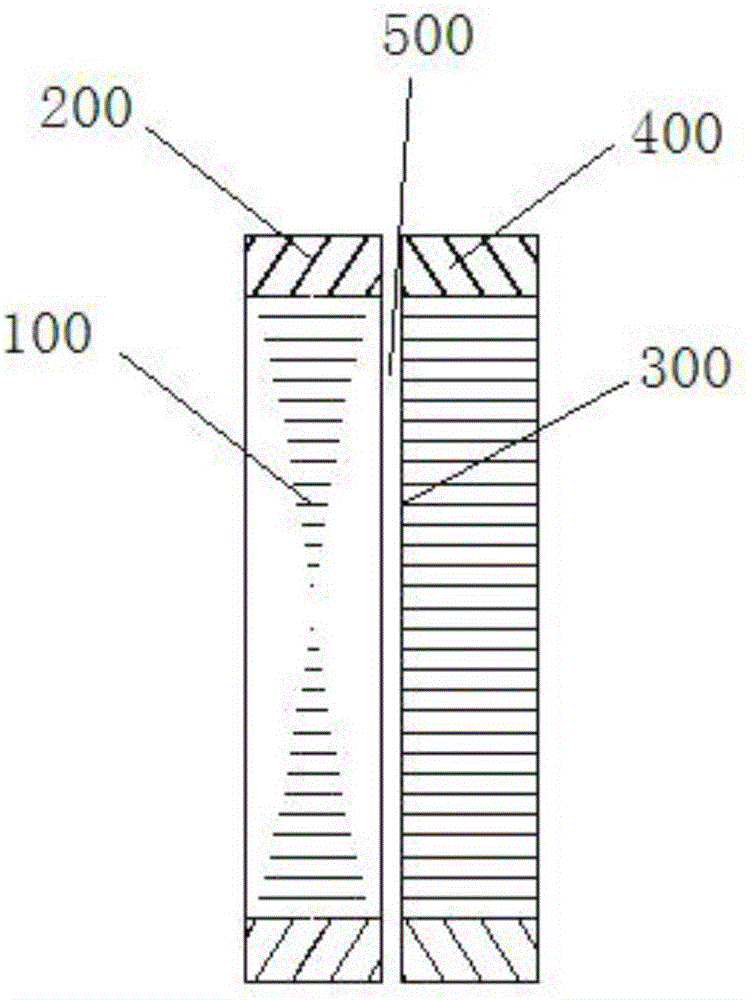

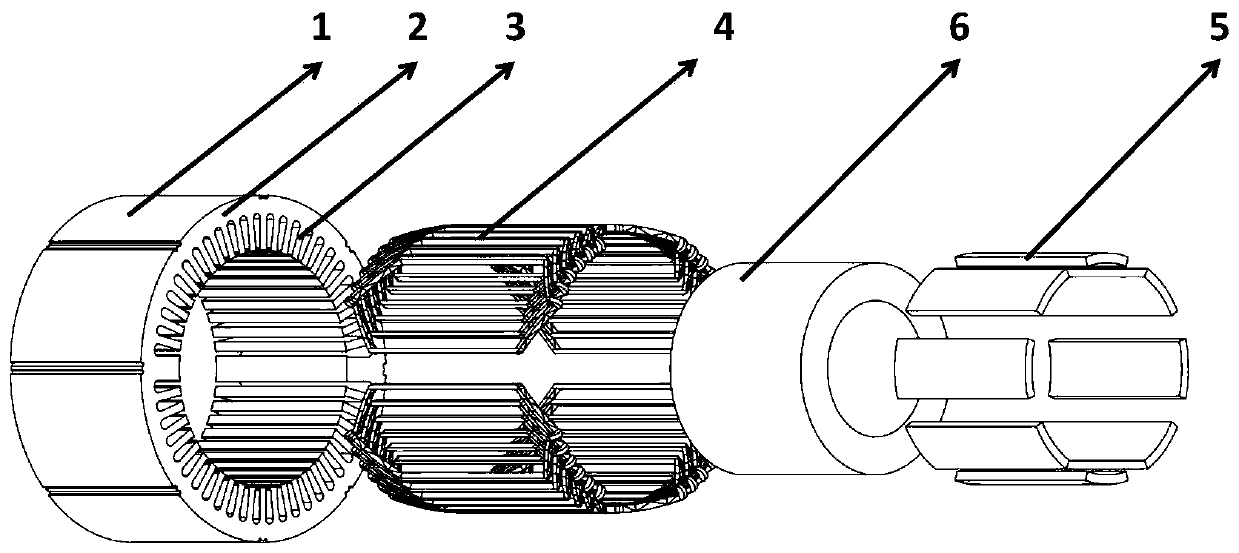

Induction motor

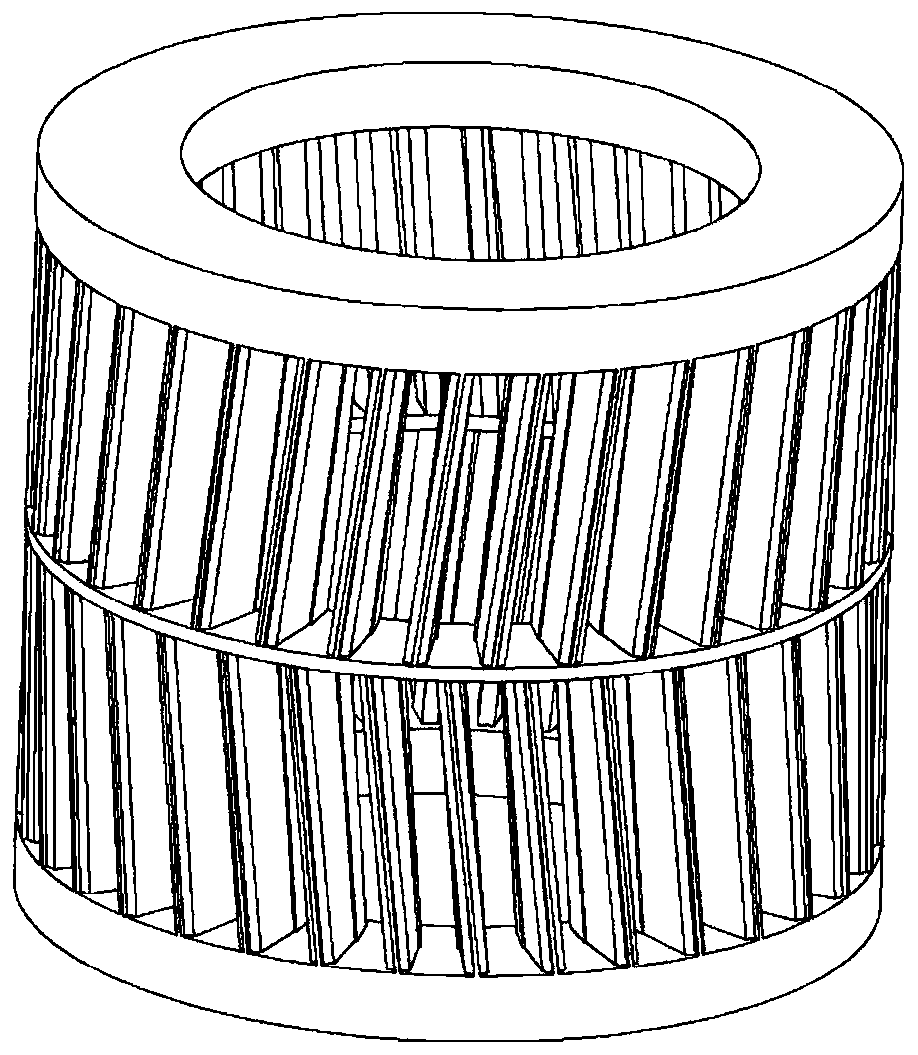

InactiveCN105515236AReduce electromagnetic vibrationEasy to fixMagnetic circuit rotating partsInduction motorWorking environment

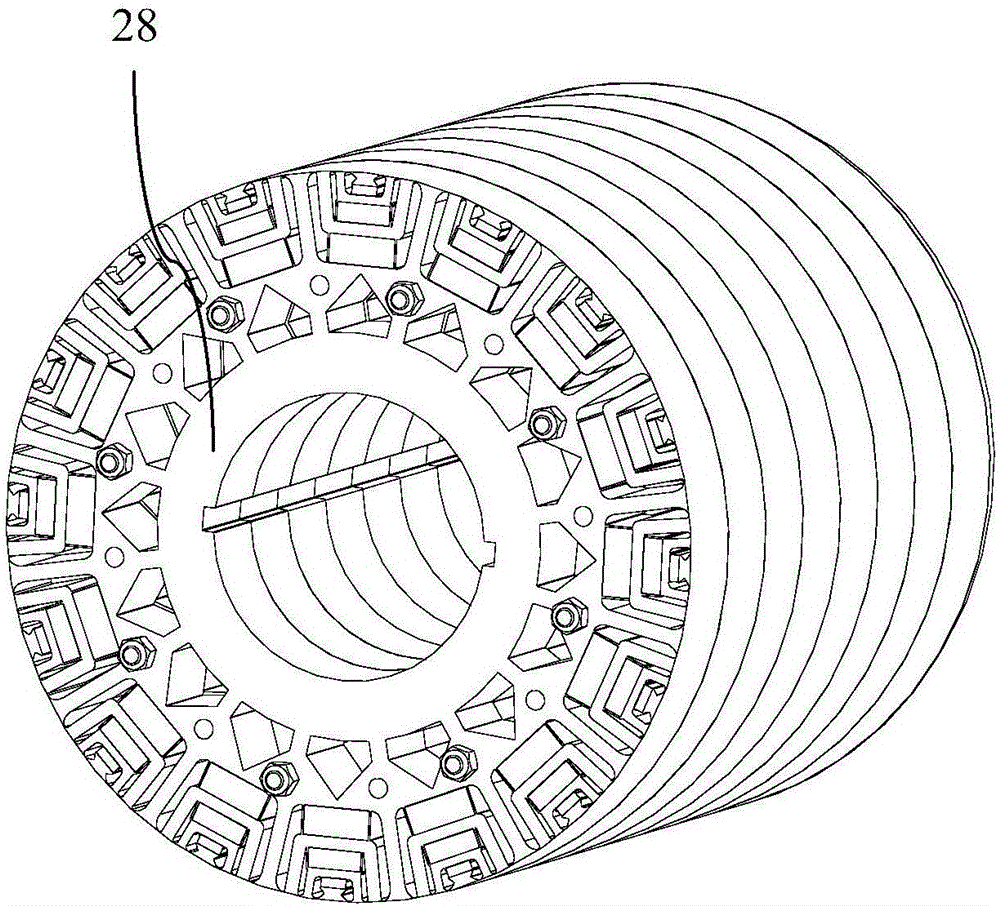

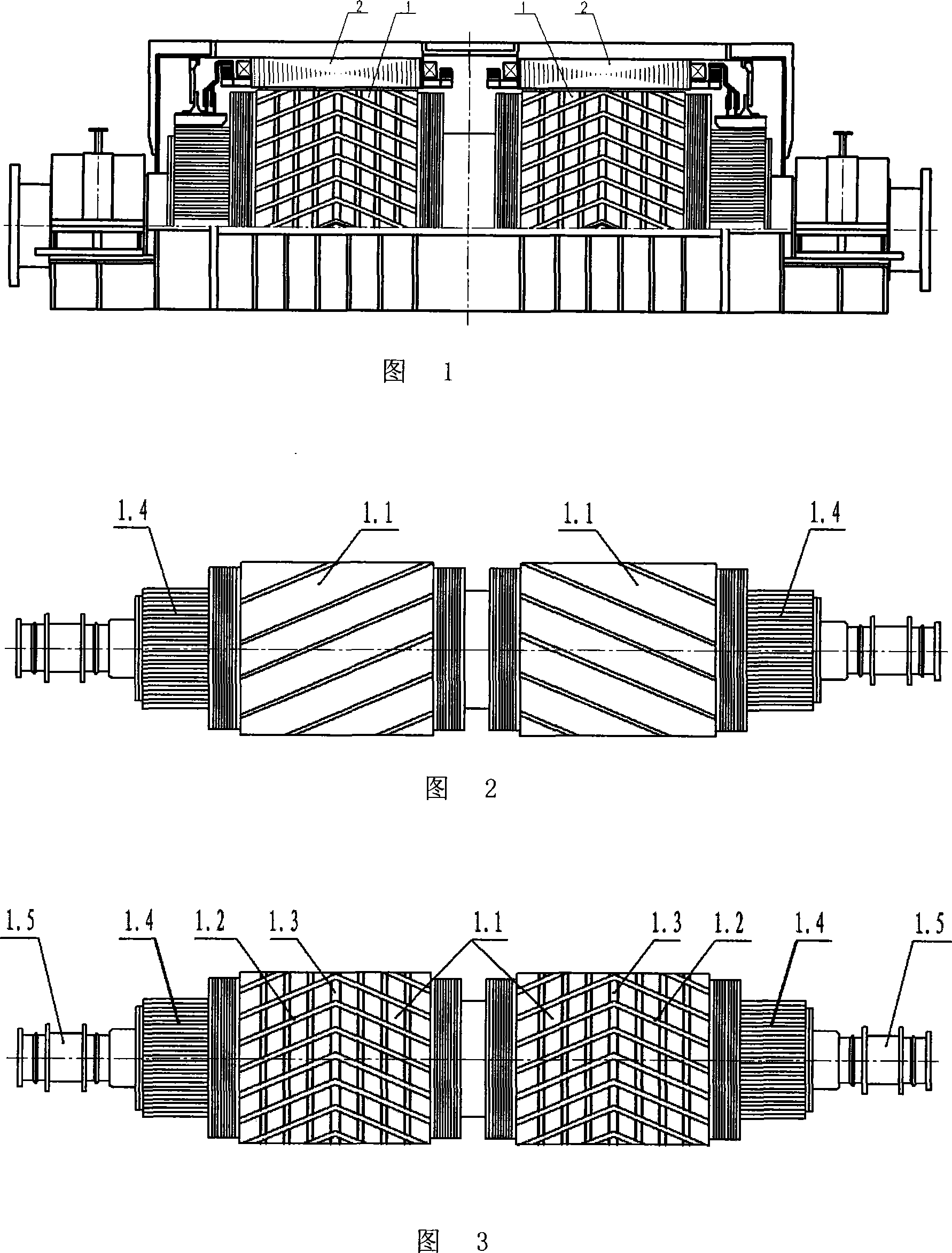

The invention discloses an induction motor which comprises a rotor and a stator. The rotor comprises a rotating shaft, two end rings, multiple rotor ventilating groove plates, multiple rotor iron cores, multiple V-shaped guide bars mutually independent, wherein the two end rings are installed on the rotating shaft in a spaced mode, the rotor ventilating groove plates and the rotor iron cores are located between two end rings, installed on the rotating shaft and arranged alternately, the V-shaped guide bars are sequentially installed on the rotor iron cores in the circumferential direction, the two ends of any guide bar are connected with the two end rings in a one-to-one corresponding mode, a plurality of V-shaped installing grooves are uniformly formed in the rotor iron cores in the axial direction, and the guide bars are installed in the multiple installing grooves in a one-to-one corresponding mode. According to the induction motor, the V-shaped installing grooves on the rotor iron cores are symmetrical inclined grooves, radial force can be reduced, amplitude and noise are reduced, working environment is improved, it is ensured that electromagnetic vibration of the motor in the forward and reverse operation process is restrained to the maximum degree, and the operation effect is better.

Owner:CHINA NAT OFFSHORE OIL CORP +1

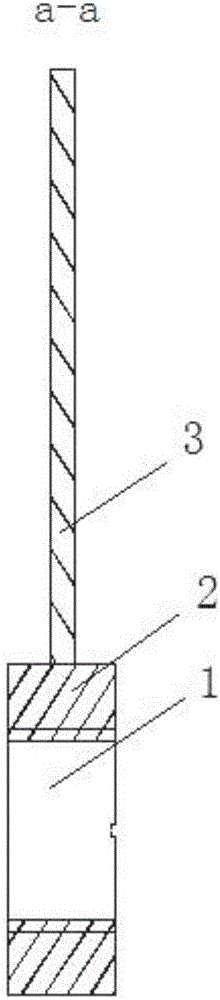

Ultra-energy-saving 18500W two-pole three-phase asynchronous electric motor

InactiveCN102780346AImprove conversion efficiencyWeaken Radial Electromagnetic Force WavesMagnetic circuit rotating partsMagnetic circuit stationary partsThree phase asynchronous motorControl theory

The invention relates to an ultra-energy-saving 18500W two-pole three-phase asynchronous electric motor, which comprises a stator and a rotor. The inner diameter and the iron core length of the stator, the groove shape and the size of a stator punching sheet groove, the inner diameter, the outer diameter and the iron core length of the rotor, and the groove shape and the size of a rotor punching sheet groove are optimized and reasonably designed, so the stator winding loss, the rotor winding loss and the iron core loss are greatly reduced, on the premise that the output power is identically 18.5kW, the total loss quantity of the exiting similar product is 2523.1W, the total loss quantity of the ultra-energy-saving 18500W two-pole three-phase asynchronous electric motor is only 1481.9 W and is reduced by 41.26 percent, and energy sources are greatly saved. Compared with the energy source conversion efficiency of the existing similar product being 88.0 percent, the energy source conversion efficiency of the ultra-energy-saving 18500W two-pole three-phase asynchronous electric motor is 92.7 percent and is improved by 4.7 percent. Meanwhile, because the center line of a stator buckle sheet groove is designed to penetrate through a position between two grooves of the stator punching sheet groove, the radial electromagnetic force wave in an air gap is weakened, the electromagnetic vibration is reduced, and the electromagnetic noise is lowered.

Owner:CHONGQING LEERJIA MACHINERY

Ultra-high-efficiency 3000-watt dipolar three-phase asynchronous motor

InactiveCN102751830AReduced power lossEnergy savingMagnetic circuit rotating partsAsynchronous induction motorsPhysicsElectric energy

An ultra-high-efficiency 3000-watt dipolar three-phase asynchronous motor comprises a stator and a rotor. The external diameter and the internal diameter of each of the stator and the rotor, the core length and the number, the shape and the size of punching sheet slots are optimized and reasonably designed to enable loss of a stator winding, a rotor winding and a core to be greatly reduced, and with the 3000-watt output power, compared with the existing like products, the ultra-high-efficiency 3000-watt dipolar three-phase asynchronous motor has the advantages that rotational speed is increased from 2868r / min to 2920r / min; total electric energy loss is decreased from 619.2w to 384.1w, and energy is saved by 37.97%; energy conversion efficiency is greatly increased from 82.9% to 88.7%, is increased by 5.8% and is 1.6% higher than the highest international grade standard of 87.1%; and since a central line of a stator cramp slot is designed to penetrate through the middles of two of the stator punching sheet slots, radial electromagnetic force waves in air gaps are weakened, electromagnetic vibration is reduced, and electromagnetic noise is reduced.

Owner:CHONGQING LEERJIA MACHINERY

Ultra-energy-saving 5500W six-pole three-phase asynchronous electric motor

InactiveCN102684434AImprove conversion efficiencyWeaken Radial Electromagnetic Force WavesMagnetic circuit rotating partsAsynchronous induction motorsThree phase asynchronous motorControl theory

The invention relates to an ultra-energy-saving 5500wW six-pole three-phase asynchronous electric motor, which comprises a stator and a rotor. The inner diameter of the stator, the length of an iron core, the groove shape and the dimension of a stator punching sheet groove, the inner diameter and the outer diameter of the rotor, the length of the iron core and the groove shape and the dimension of a rotor punching sheet groove are optimized and reasonably designed, the consumption of a stator winding is only 277.4W, the consumption of a rotor winding is only 173.4W, and the consumption of the iron core is only 34.2W. On the premise that the output power is 5500W, the input power required by the existing similar products is 34.2kW, the energy conversion efficiency is 86.3 percent, while the input power required by the ultra-energy-saving 5500W six-pole three-phase asynchronous electric motor is only 6.087kW, the energy conversion efficiency is 90.4 percent, so the energy sources are greatly saved, the rotating speed is improved from 967r / min to 1164r / min, the speed acceleration is increased by 20.4 percent, meanwhile, the stator buckle sheet groove center line is designed to penetrate through a position between the two grooves of the stator punching sheet groove, the radial electromagnetic force waves in the air gap are weakened, the electromagnetic vibration is reduced, and the electromagnetic noise is reduced.

Owner:CHONGQING LEERJIA MACHINERY

Ultra energy efficient 1500-w six-pole three-phase asynchronous motor

InactiveCN102780361AImprove conversion efficiencyWeaken Radial Electromagnetic Force WavesMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingThree phase asynchronous motor

The invention provides an ultra energy efficient 1500-w six-pole three-phase asynchronous motor comprises a stator and a rotor. The inner diameter and core length of the stator, the shape and size of a stator punching groove, the inner diameter, outer diameter and core length of the rotor, and the shape and size of a rotor punching groove are optimally and rationally designed, so that the winding loss of the stator is only 159.9 w, while the winding loss of the rotor is only 94.5 w and the core loss is only 10.2 w; in case of the same output power of 1500 w, the input power needed by the existing same product is 2.016 kw and the energy conversion efficiency is 75.4%; however, the input power needed by the ultra energy efficient 1500-w six-pole three-phase asynchronous motor provided by the invention is only 1.794 kw and the energy conversion efficiency is 83.5%; therefore, the energy source is greatly saved; and simultaneously, as the center line of a stator locking groove is designed to penetrate through the middle parts of the two grooves of the stator punching groove, the radial electromagnetic wave in an air gap is weakened, the electromagnetic vibration is reduced, and consequently, the electromagnetic noise is reduced.

Owner:CHONGQING LEERJIA MACHINERY

Super-efficient 2200-watt 4-pole three-phase asynchronous motor

InactiveCN102780360AReduced energy consumptionEnergy savingMagnetic circuit rotating partsMagnetic circuit stationary partsElectric energyElectromagnetic vibration

The invention provides a super-efficient 2200-watt 4-pole three-phase asynchronous motor which comprises a stator and a rotor. Due to the fact that inner diameter, outer diameter of the stator and the rotor, iron core length and quantity, groove shapes and sizes of punching grooves are optimized and designed reasonably, and stator winding loss, rotor winding loss and iron core loss are reduced greatly. Under the condition that output power is at 2200 watts, compared with existing similar products, the rotating speed is promoted from 1415 r / min to 1443 r / min and accelerated by 28 r / min, total power loss is reduced from 505.5 W to 293.7 W, energy conservation reaches 41.90%, energy conversion efficiency is improved from 81.3% to 88.2% and improved by 6.9%, the energy conversion efficiency is 1.5% higher than the highest international grade standard 86.7%, and the energy conversion efficiency is improved greatly. Simultaneously, due to the fact that a central line of a stator cramping groove penetrates between two grooves of the stator punching grooves, radial electromagnetic force wave in air gaps is weakened, electromagnetic vibration is reduced, and electromagnetic noise is lowered.

Owner:CHONGQING LEERJIA MACHINERY

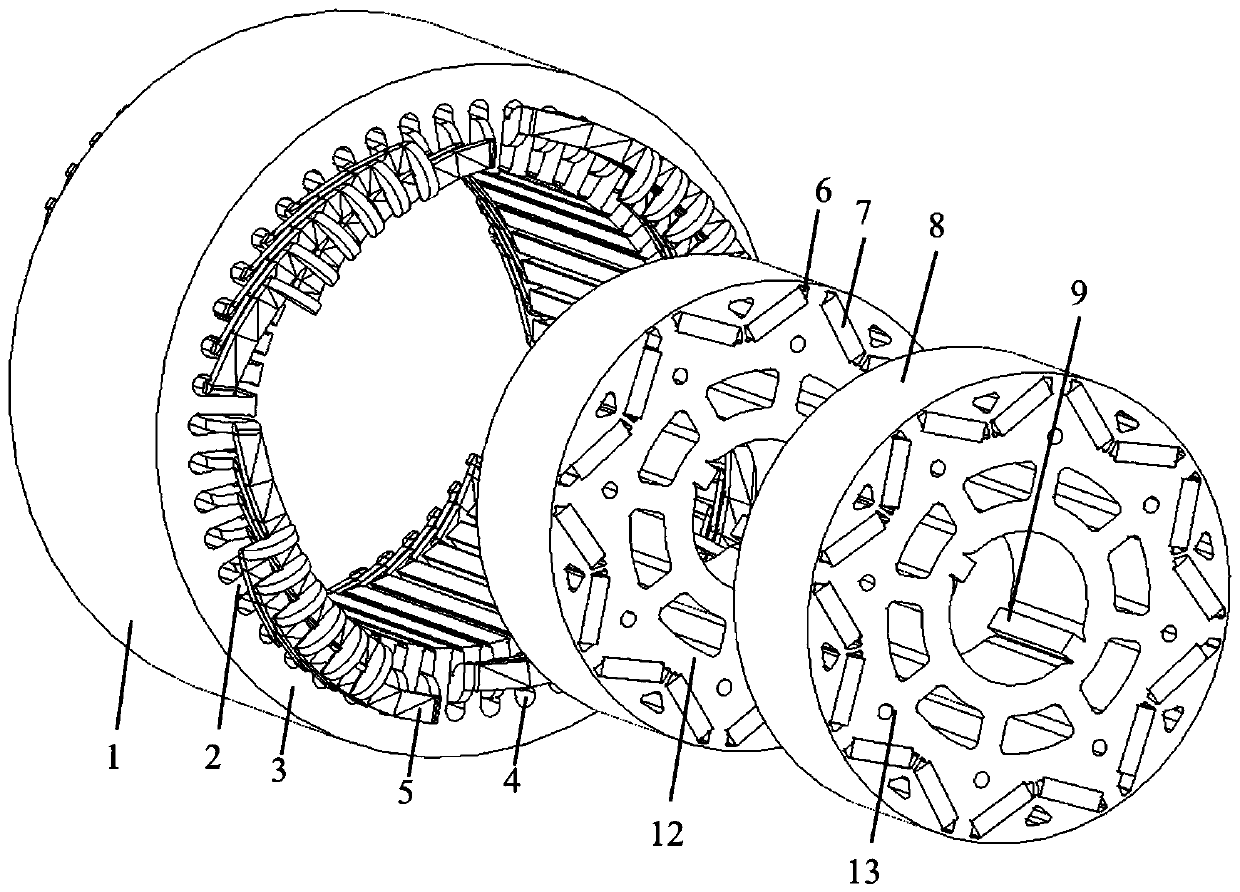

Built-in permanent magnet driving motor of electric automobile and electromagnetic vibration weakening method thereof

ActiveCN111193337ALow costImprove production efficiencyMagnetic circuit rotating partsElectric machinesPermanent magnet rotorElectric machine

The invention provides a built-in permanent magnet driving motor of an electric automobile and an electromagnetic vibration weakening method thereof. The built-in permanent magnet driving motor comprises a permanent magnet rotor which is disposed in a stator in a sleeving manner and is coaxially arranged with the stator, and an armature winding is arranged on the stator; the permanent magnet rotorcomprises a rotor core and permanent magnets, a rotor groove is formed in the rotor iron core, a permanent magnet is placed in the rotor groove, 2p rotor magnetic poles are formed on the rotor iron core by the permanent magnet, the pole arc width corresponding to one rotor magnetic pole in the rotor magnetic poles is different from the pole arc widths corresponding to other 2p-1 rotor magnetic poles, and the pole arc widths of the other 2p-1 rotor magnetic poles are the same; and magnetic flux on the permanent magnet rotor enters the stator along an air gap between the stator and the permanent magnet rotor, formed main magnetic flux acts with a magnetic field generated by an armature winding on the stator, and the motor generates torque. Through the novel rotor magnetic pole segmentationmethod, the cogging torque, the tooth harmonic electromotive force and the torque pulsation of the built-in permanent magnet motor can be greatly weakened, so that the electromagnetic vibration of thebuilt-in permanent magnet motor is effectively weakened.

Owner:SHANDONG UNIV

Ultra-high-efficiency 7500-watt four-pole three-phase asynchronous motor

InactiveCN102780357AReduce lossImprove conversion efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsThree phase asynchronous motorEnergy conversion efficiency

An ultra-high-efficiency 7500-watt four-pole three-phase asynchronous motor comprises a stator and a rotor. The external diameter and the internal diameter of each of the stator and the rotor, the core length and the number, the shape and the size of punching sheet slots are optimized and reasonably designed systematically to enable loss of a stator winding, a rotor winding and a core to be greatly reduced. With the 7500-watt output power, compared with existing like products, the ultra-high-efficiency 7500-watt four-pole three-phase asynchronous motor has the advantages that rotational speed is increased from 1451r / min to 1466r / min; total electric energy loss is decreased from 1088.8w to 665.6w, and energy is saved by 38.87%; energy conversion efficiency is greatly increased from 87.3% to 91.8%, is increased by 4.5% and is 1.4% higher than the highest international grade standard of 90.4%; and since a central line of a stator cramp slot is designed to penetrate through the middles of two of the stator punching sheet slots, radial electromagnetic force waves in air gaps are weakened, electromagnetic vibration is reduced, and electromagnetic noise is reduced.

Owner:CHONGQING LEERJIA MACHINERY

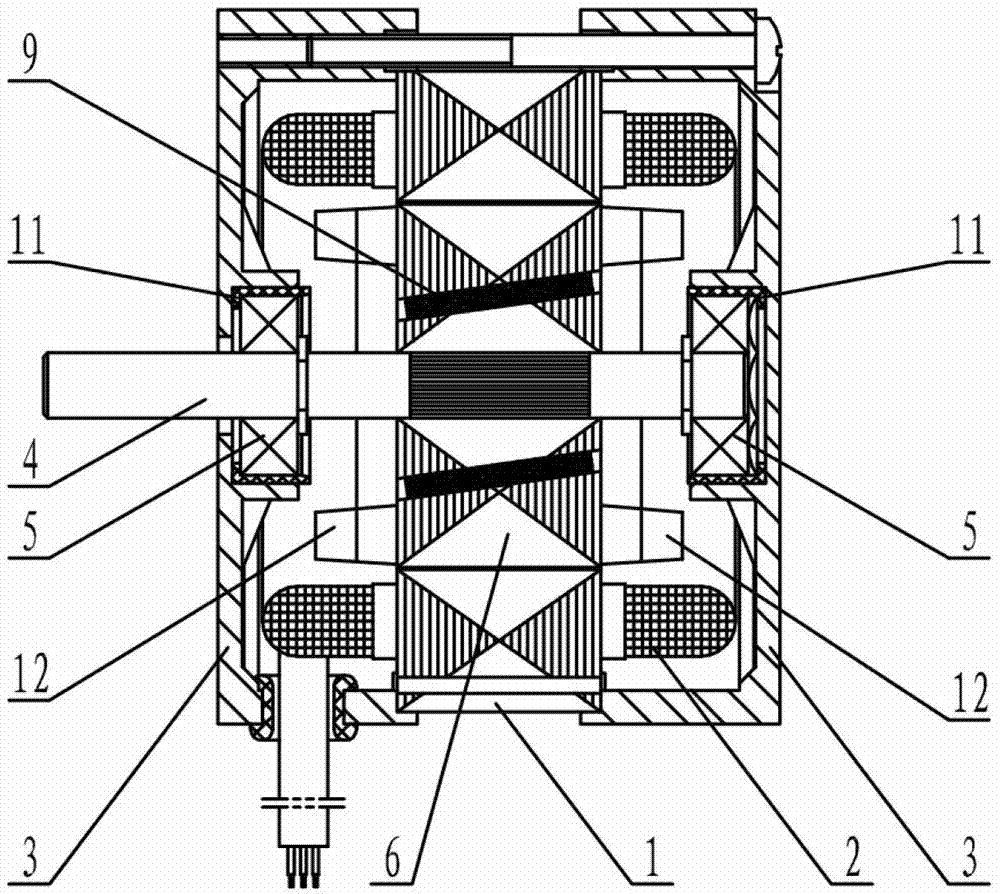

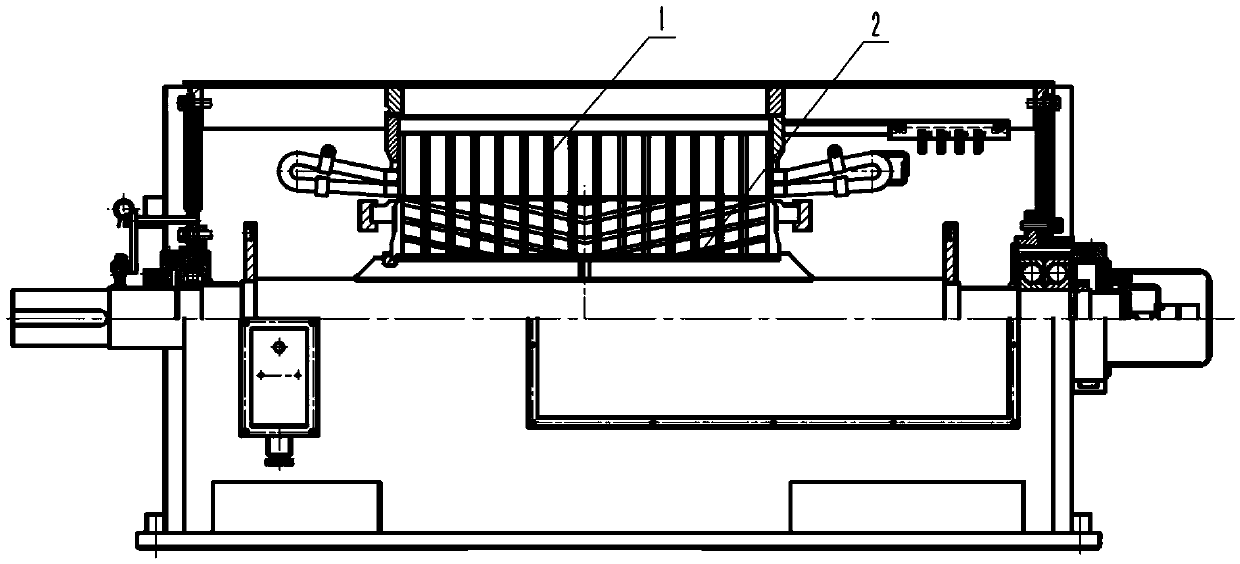

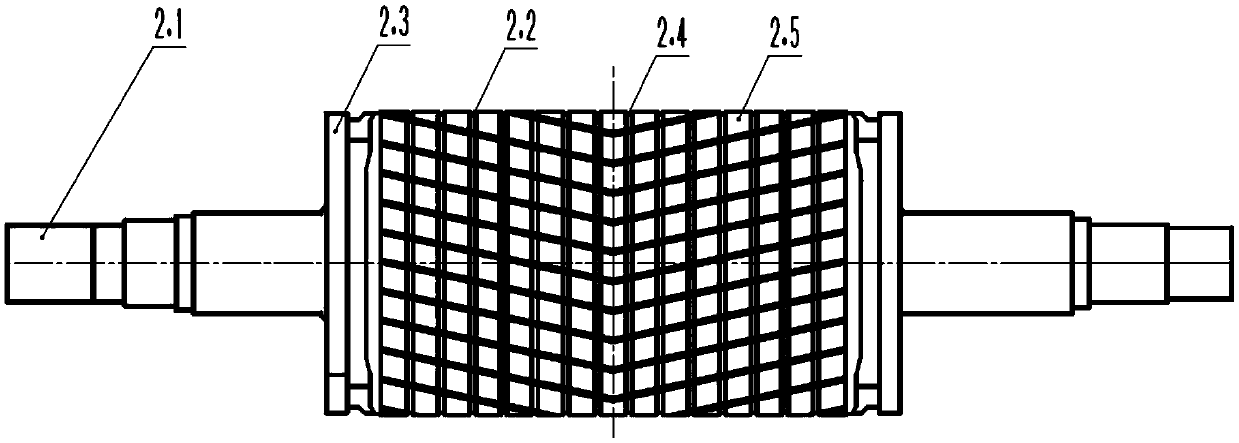

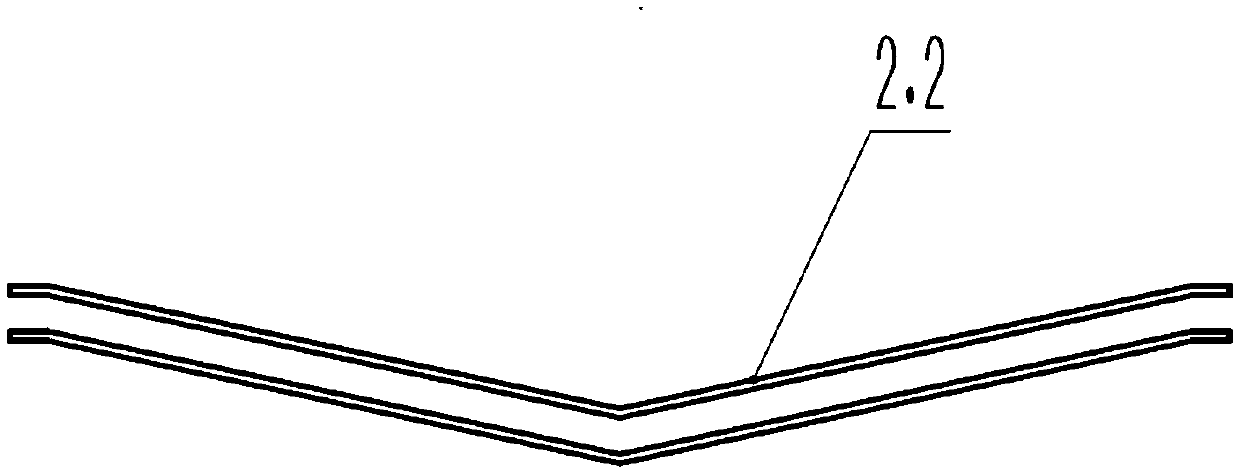

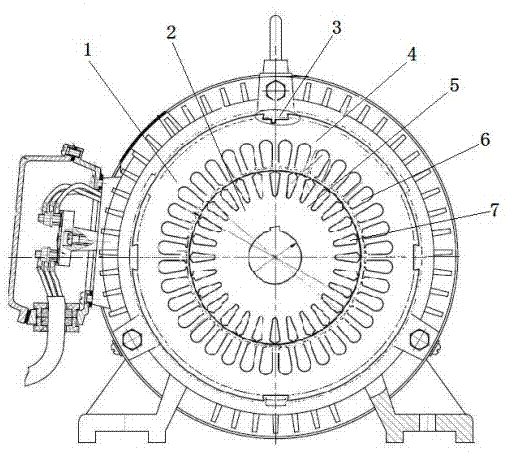

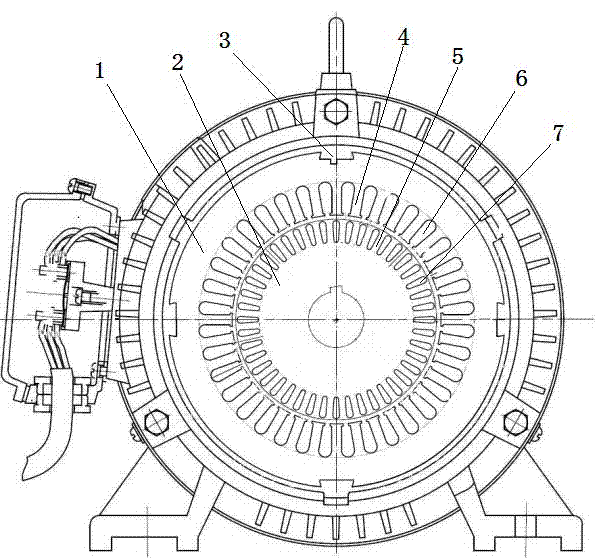

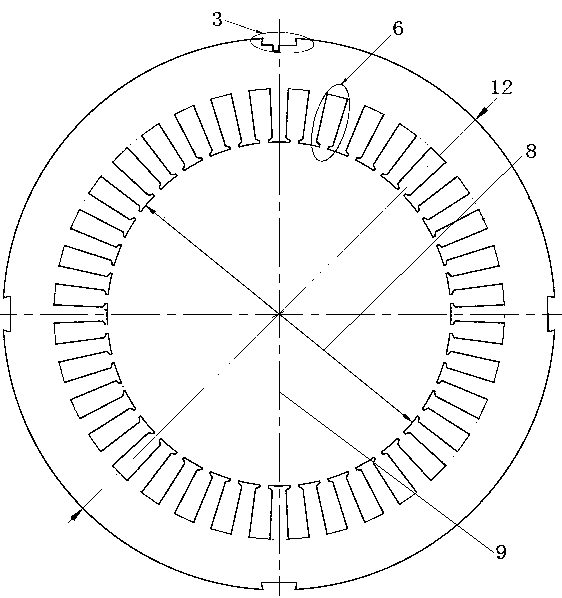

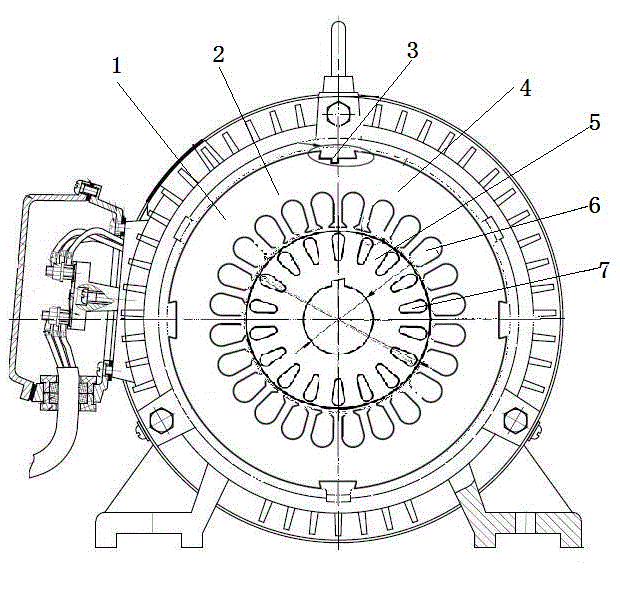

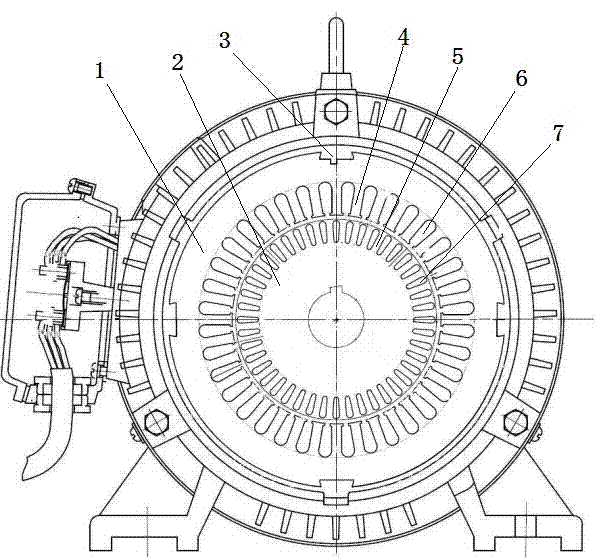

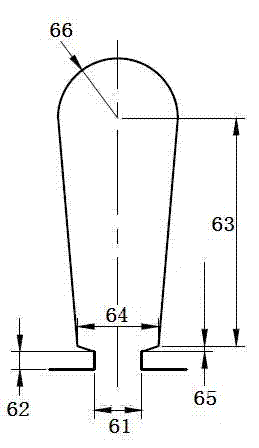

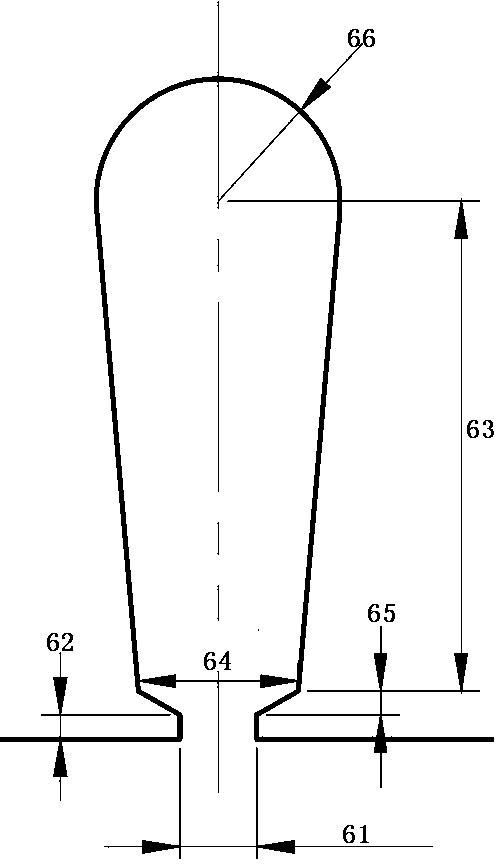

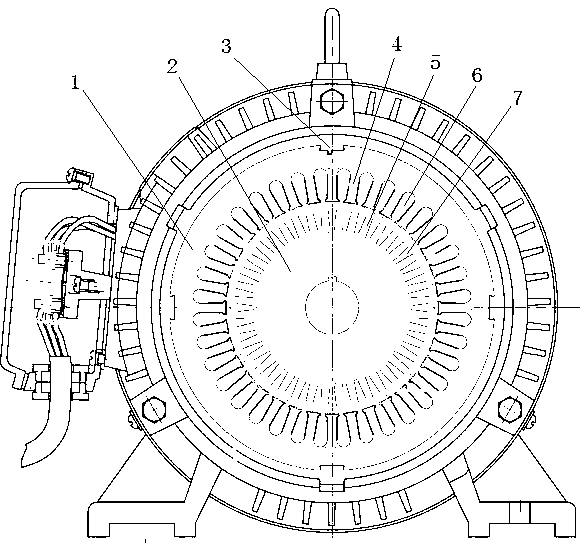

DC propulsion motor

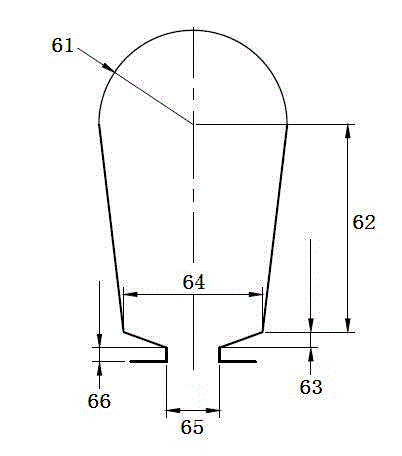

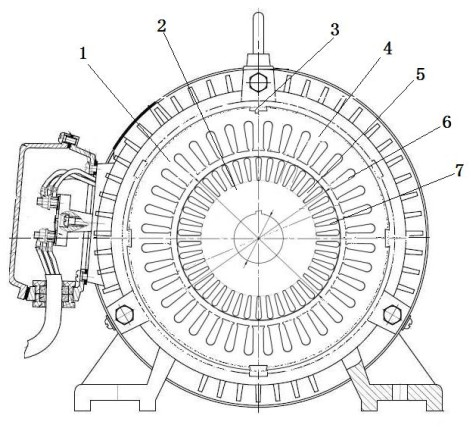

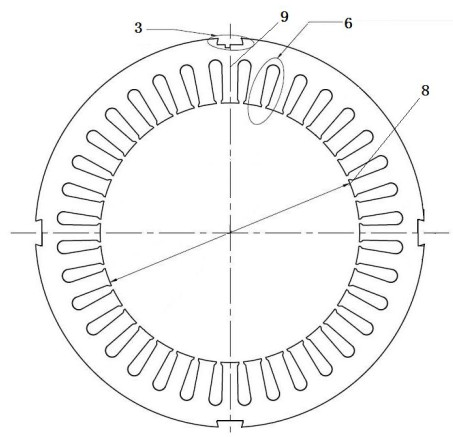

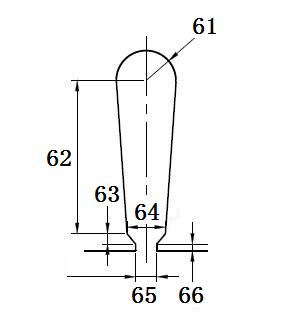

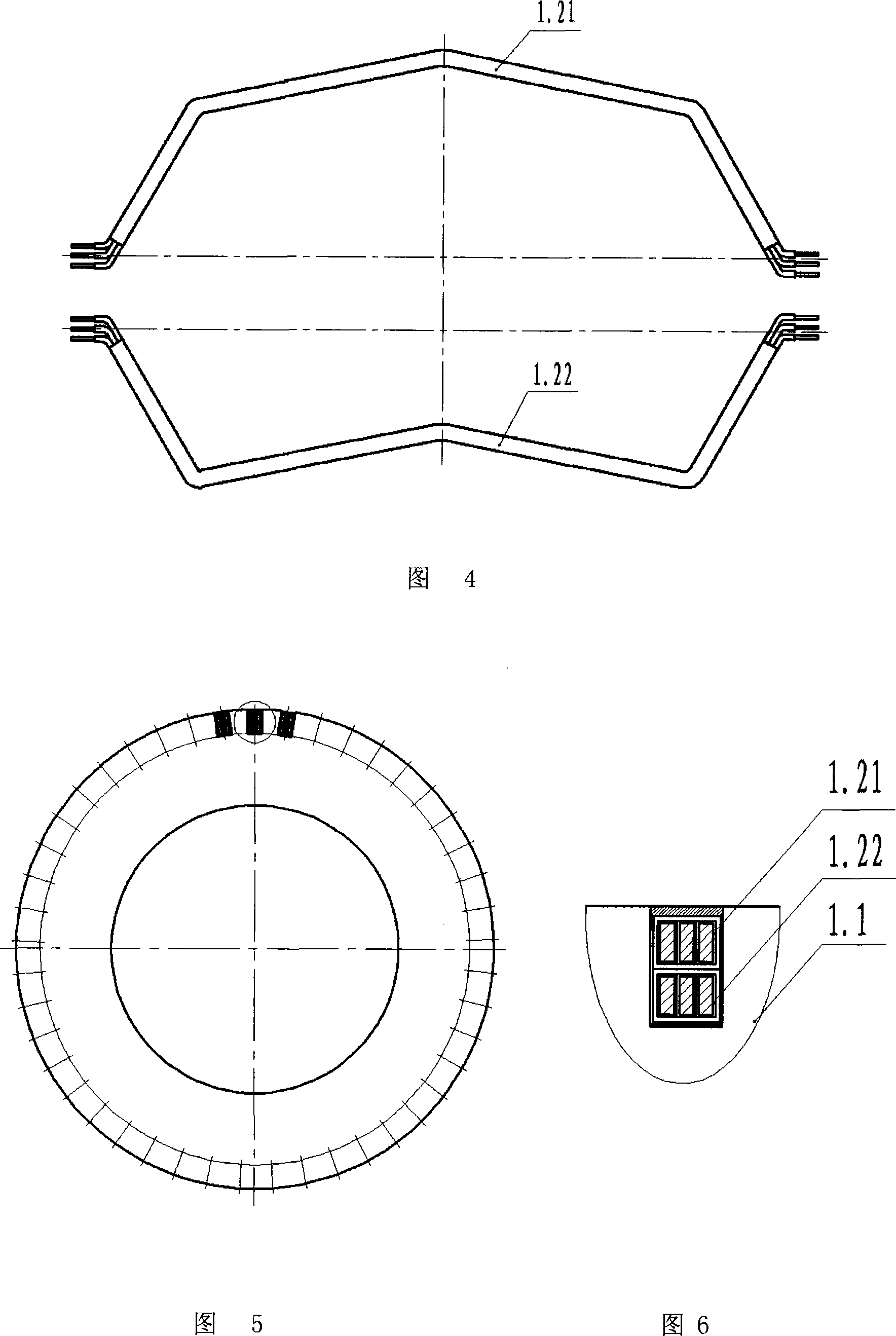

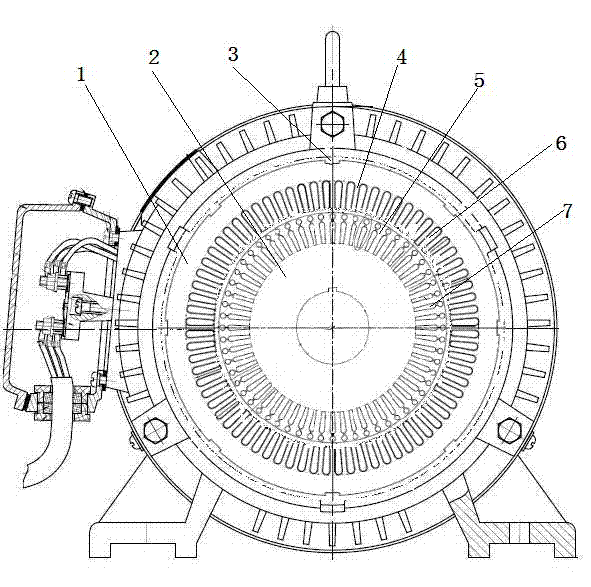

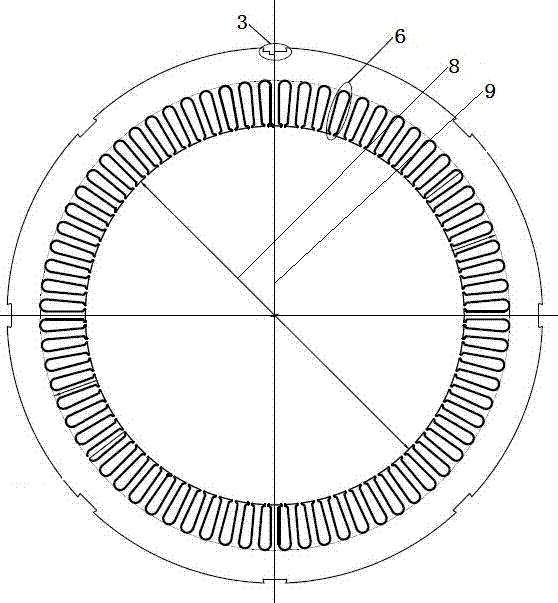

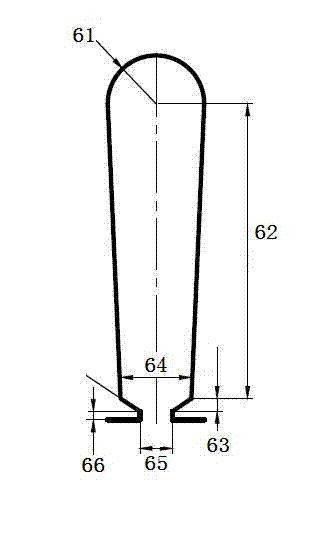

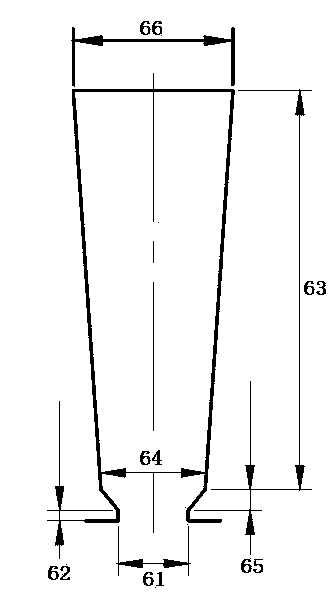

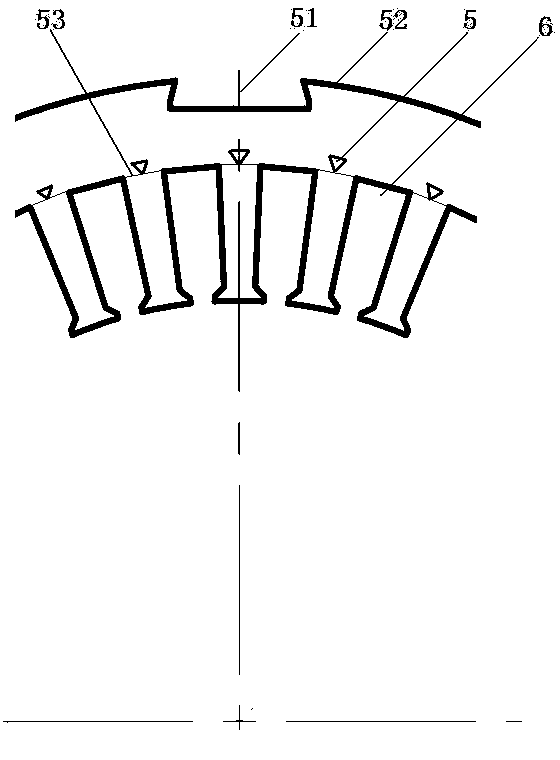

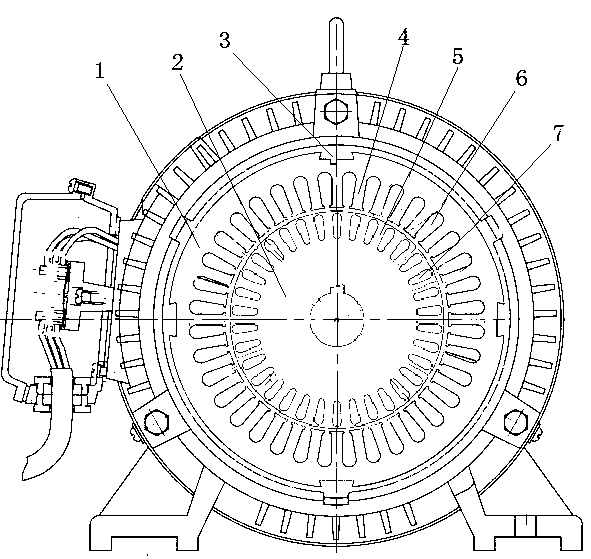

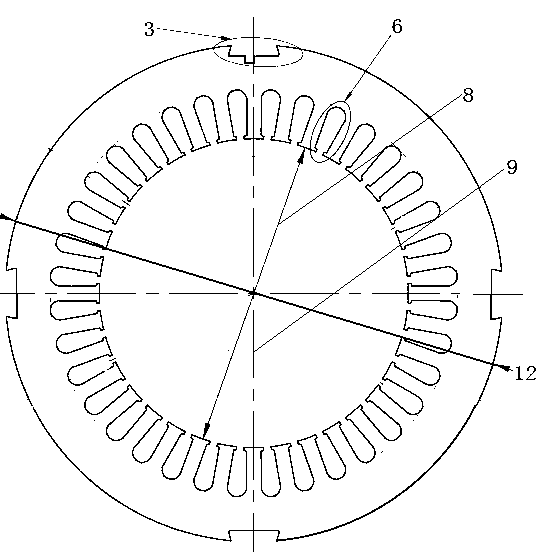

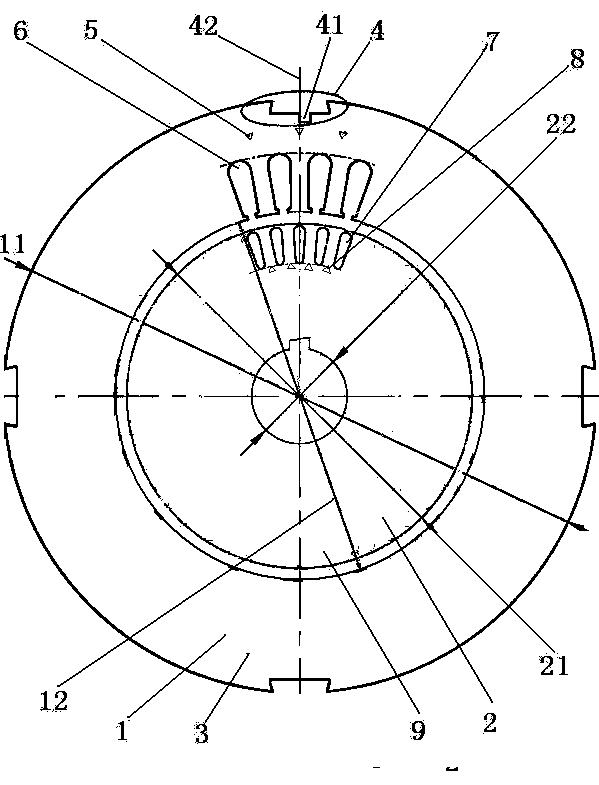

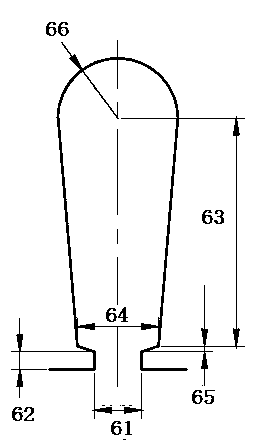

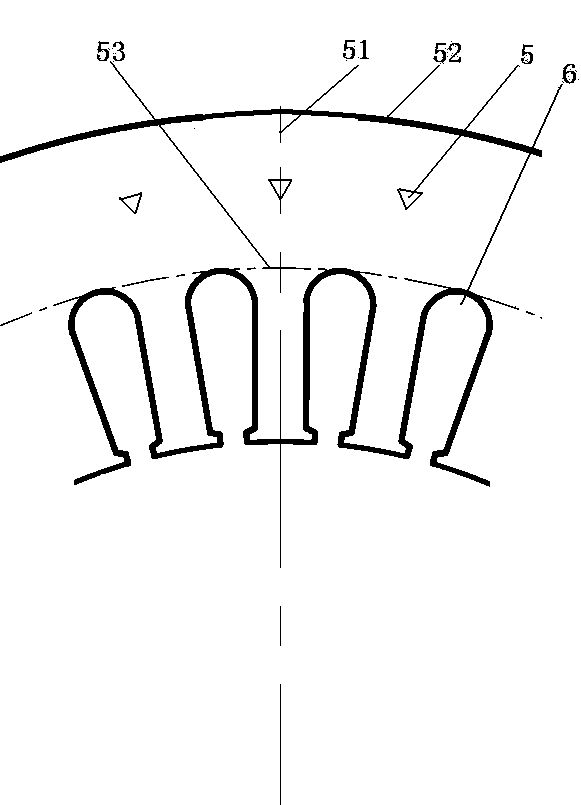

InactiveCN101114790AGood technical effectNormal functioningDC commutatorWorking environmentEngineering

The invention relates to a direct current propulsion motor which belongs to the field of motor technology, which is particularly suitable for the direct current propulsion motor which is used for medium vessel and large vessel. The invention comprises a rotor and a stator, wherein the rotor comprises an armature core, an armature winding, a radical ventilation duct, a commutator and a rotating shaft; the armature winding which is distributed on the external circumference surface of the armature core is inverted 'V'-shaped; the inverted 'V'-shaped armature winding consists of an inverted 'V'-shaped upper coil of winding insulation and an inverted 'V'-shaped lower coil of winding insulation which are both of half-style structure and are embedded into an inverted 'V'-shaped skewed slot of the armature core. The invention has the advantages that: the radial electromagnetic force of the motor is reduced; the amplitude and the vibration noise are reduced; the working environment is improved; the electromagnetic vibration of a whole motor base is reduced; the electromagnetic vibration in the whole speed range of the motor is assuredly promoted to be restricted to the greatest degree; the operation effect is better; and the function is much better exerted.

Owner:中国船舶重工集团公司第七一二研究所

Ultrahigh-efficiency and energy-saving 1500W six-pole three-phase asynchronous motor

InactiveCN103647409AImprove cooling effectReduce lossAsynchronous induction motorsElectric machineThree phase asynchronous motor

Provided is an ultrahigh-efficiency and energy-saving 1500W six-pole three-phase asynchronous motor which comprises a stator and a rotor. Design of external diameters, internal diameters, length of iron cores, number of punching sheet grooves and shape and size of the grooves of the stator and the rotor is systematically optimized so that stator winding loss, rotor winding loss and iron core loss are substantially reduced. Compared with existing similar products, total energy loss amount is reduced from 515.9W to 292.7W, and reduction is 43.3% under the premise of the same output power of 1500W. The required input power is reduced from original 2.016kW to 1.793kW, energy conversion efficiency is increased from 74.4% to 83.7%. Compared with 1500W six-pole three-phase asynchronous motor efficiency standard requirement of 82.5% which is specified in the highest grade of IE3 of international motor energy efficiency grade standard, energy conversion efficiency is enhanced for 1.2% so that energy conversion efficiency is substantially enhanced.

Owner:CHONGQING LEERJIA MACHINERY

Ultra-efficient 37 kW 6-pole three-phase asynchronous motor

InactiveCN102790491AImprove conversion efficiencyWeaken Radial Electromagnetic Force WavesMagnetic circuit rotating partsAsynchronous induction motorsThree phase asynchronous motorElectric machine

The invention provides an ultra-efficient 37 kW 6-pole three-phase asynchronous motor, which comprises a stator and a rotor; as the internal diameter of the stator, an iron core length and the slot shape and size of a stator punching sheet slot, and the internal diameter and external diameter and the iron core length of the rotor, and the slot shape and size of a rotor punching sheet slot are efficiently designed, the stator winding loss, rotor winding loss and iron core loss are greatly reduced; when the output power is 37 kW, the domestic existing similar products require an input power of 40.558 kW, the power loss amount is 3557.7 W, while the input power required by the ultra-efficient 37 kW 6-pole three-phase asynchronous motor is only 39.158 kW, the power loss amount is only 2158.0 W, thus, the power loss amount is reduced by 39.34 percent; the energy conversion efficiency exceeds 3.3 percent of that of the domestic similar products, and 1.2 percent of the highest level standard of the international motor energy efficiency is exceeded. The center line of the stator cleat slot penetrates from the middle of the two slots of the stator punching sheet slots, thus, the radial electromagnetic wave in an air gap is weakened, the electromagnetic vibration is reduced and the electromagnetic noise is reduced.

Owner:CHONGQING LEERJIA MACHINERY

Super-energy-saving 2200w dipolar three-phase asynchronous motor

InactiveCN102723829AImprove conversion efficiencyWeaken Radial Electromagnetic Force WavesMagnetic circuit rotating partsMagnetic circuit stationary partsThree phase asynchronous motorEngineering

A super-energy-saving 2200w dipolar three-phase asynchronous motor comprises a stator and a rotor. Since the inner diameter and the iron core length of the stator, the shape and size of stator punching plate grooves, the inner diameter, the outer diameter and the iron core length of the rotor and the shape and size of stator punching plate grooves are optimized and designed reasonably to enable the stator winding loss to be only 122.3w, the rotor winding loss to be only 111.0w and the iron core loss to be only 19.0w. On the premise that the output power is 2200w, existing like products require input power of 2.655kw and the energy conversion efficiency is 82.9%, while the super-energy-saving 2200w dipolar three-phase asynchronous motor only requires the input efficiency of 2.536kw and the energy conversion efficiency is 86.7%, so that energy resources are greatly saved, and energy conversion efficiency is improved. The rotation speed is increased from 2849r / min to 2860r / min. Further, since the center line of each stator cramp groove is designed to penetrate between each two stator punching plate grooves, radial electromagnetic waves in air gaps are weakened, electromagnetic vibration is reduced, and electromagnetic noise is lowered.

Owner:CHONGQING LEERJIA MACHINERY

Superhigh-energy-efficiency 4-kW four-pole three-phase asynchronous motor

InactiveCN103595208AImprove cooling effectReduce lossMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingThree phase asynchronous motor

A superhigh-energy-efficiency 4-kW four-pole three-phase asynchronous motor comprises a stator and a rotor. Due to the fact that the outer diameters and the inner diameters of the stator and the rotor, the length of an iron core, and the number, the groove shape and the size of punching grooves are optimized systematically, the loss of a stator winding, the loss of a rotor winding and the loss of the iron core are largely lowered; on the premise that the output power is 4kW, compared with same-class products, the total energy loss amount of the superhigh-energy-efficiency 4-kW four-pole three-phase asynchronous motor is decreased to 481.2W from 599.2W and is decreased by 19.7%, the needed input power is decreased to 4.481kW from original 4.599kW, and the energy conversion efficiency is improved to 89.2% from 87.0% and is improved by 2.2%; compared with the latest national standard 'GB18613-2012' of 88.6% enforced in September, 2016, the energy conversion exceeds by 0.6% and is largely improved. The superhigh-energy-efficiency 4-kW four-pole three-phase asynchronous motor will provide powerful support for the work of energy conservation and emission reduction in China when being applied and popularized.

Owner:CHONGQING LEERJIA MACHINERY

Ultra-high-efficiency 250-watt six-pole three-phase asynchronous motor

InactiveCN102780355AReduce lossImprove conversion efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsThree phase asynchronous motorEngineering

An ultra-high-efficiency 250-watt six-pole three-phase asynchronous motor comprises a stator and a rotor. The external diameter and the internal diameter of each of the stator and the rotor, the core length and the number, the shape and the size of punching sheet slots are optimized and reasonably designed systematically to enable loss of a stator winding, a rotor winding and a core to be greatly reduced. With the 250-watt output power, compared with existing like products, the ultra-high-efficiency 250-watt six-pole three-phase asynchronous motor has the advantages that rotational speed is increased from 757r / min to 932r / min; total electric energy loss is decreased from 500.5w to 75.6w, and energy is saved by 84.90%; energy conversion efficiency is greatly increased from 33.3% to 76.8%, is increased by 43.5% and is 1.8% higher than the highest international grade standard of 75.0%; and since a central line of a stator cramp slot is designed to penetrate through the middles of two of the stator punching sheet slots, radial electromagnetic force waves in air gaps are weakened, electromagnetic vibration is reduced, and electromagnetic noise is reduced.

Owner:CHONGQING LEERJIA MACHINERY

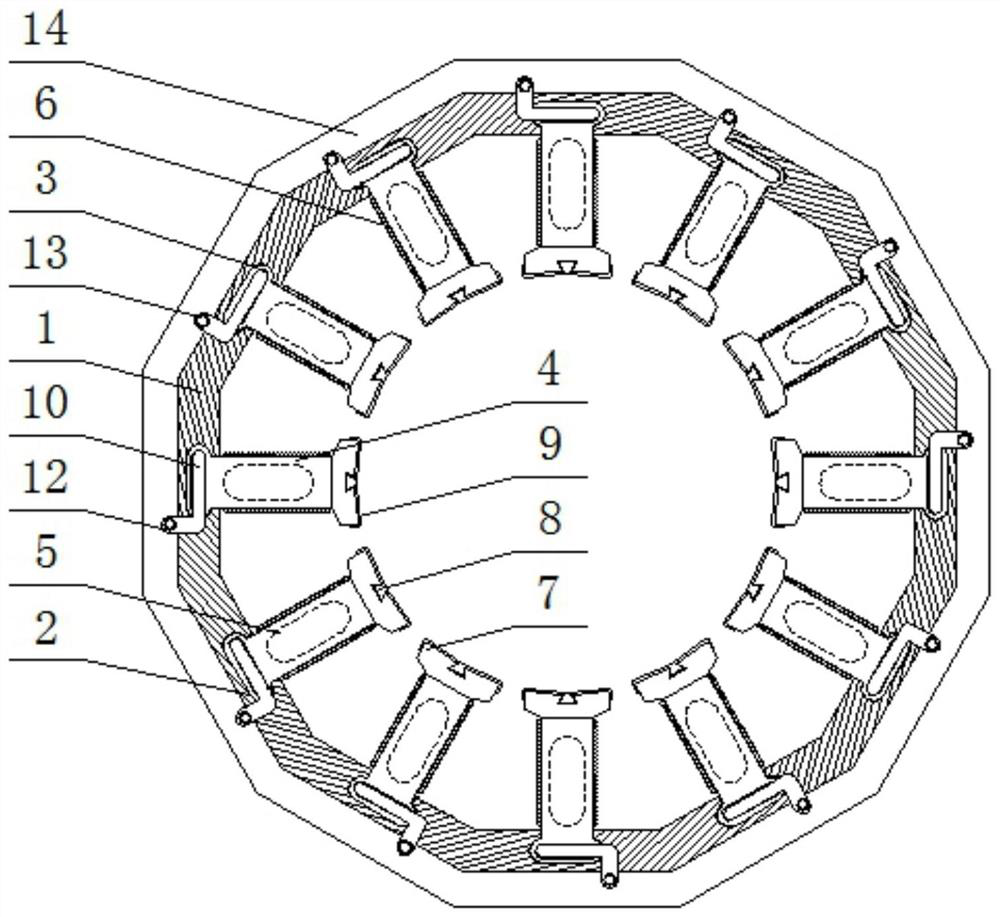

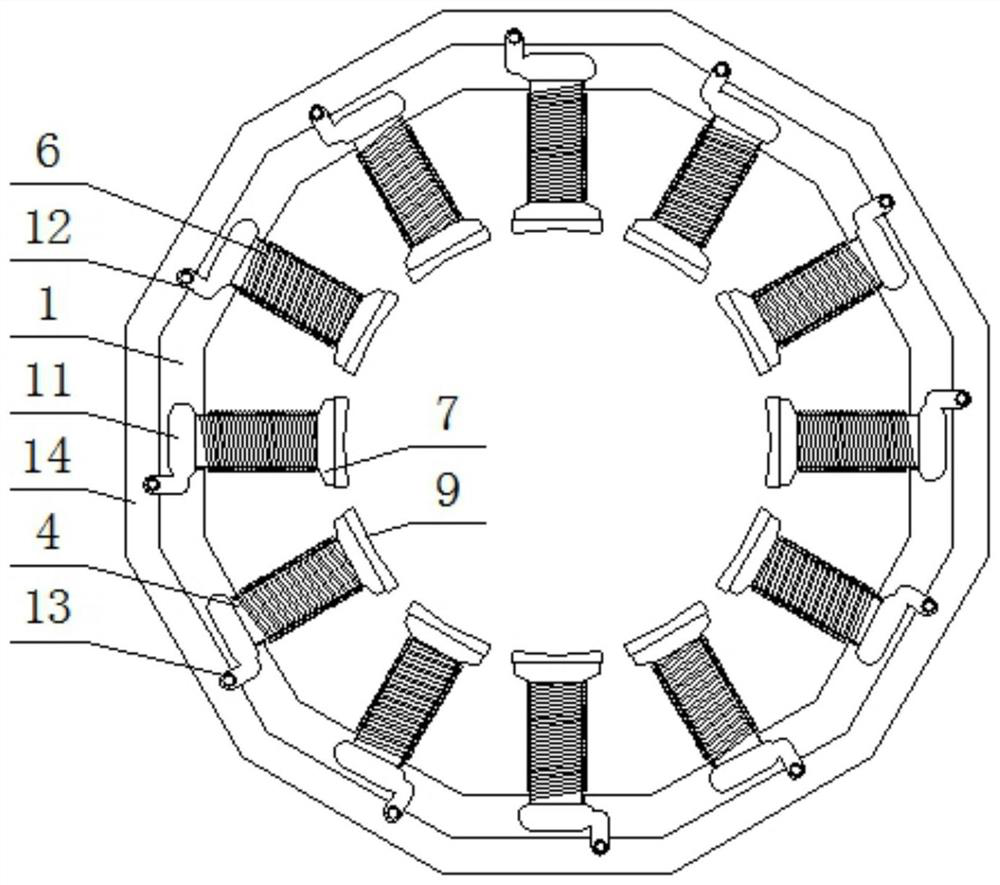

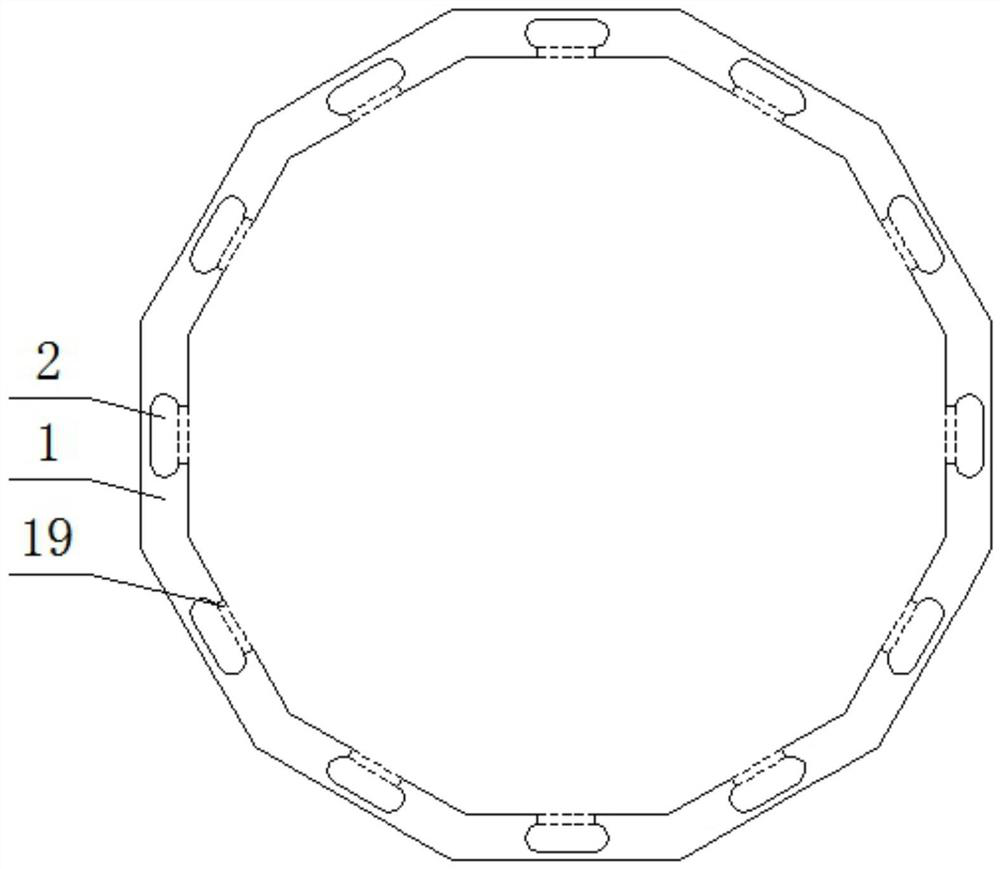

Stator structure for solving motor resonance

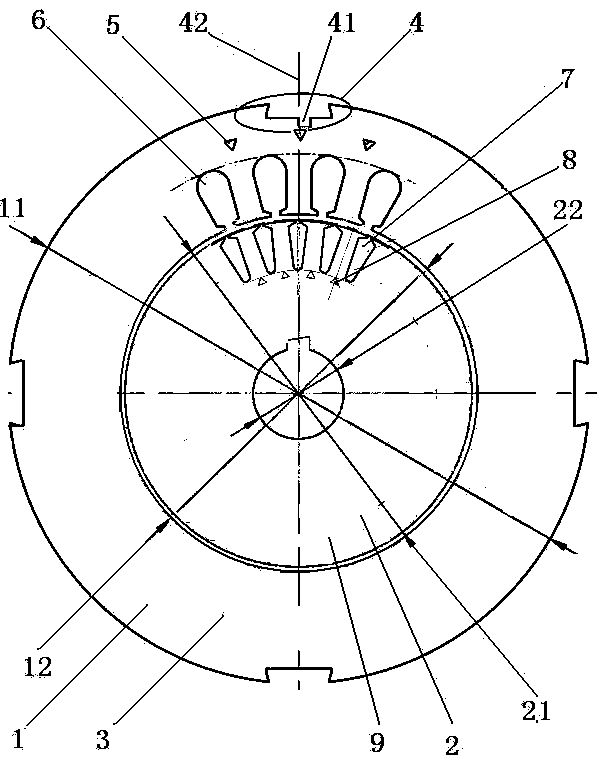

PendingCN113162259AIncreased Yoke ThicknessRaise the natural frequencyMagnetic circuit stationary partsElectric machineStructural engineering

The invention discloses a stator structure for solving motor resonance. The stator structure comprises a stator yoke, wherein an outer wall of the stator yoke is of twelve-tangent-edge design, the outer wall of the stator yoke is sleeved with an insulating framework, an outer wall of the insulating framework is sleeved with a motor shell, a middle part of a front surface of the stator yoke is uniformly provided with a plurality of elliptical grooves, an inner wall of the stator yoke is uniformly provided with a plurality of connecting grooves, each connecting groove is communicated with the corresponding elliptical groove, an elliptical ring is clamped in each elliptical groove, one side of each elliptical ring is fixedly provided with a stator iron core, each stator iron core is located in the corresponding connecting groove and connected with the connecting groove in a clamped mode, and a connecting assembly is arranged between each elliptical ring and the insulating framework. The stator core is convenient to disassemble and assemble, and meanwhile, the stator yoke part is designed to be twelve tangent edges, and the outer wall of the stator yoke is sleeved with the insulating framework, so yoke thickness is increased, and electromagnetic vibration and noise caused by resonance are effectively reduced.

Owner:安徽美孚智控科技有限公司

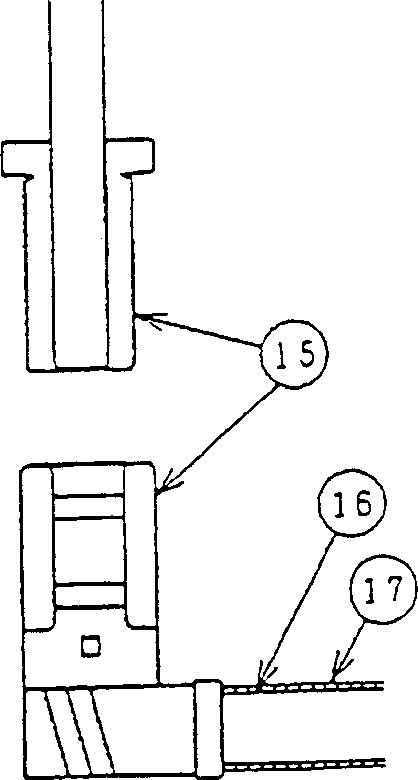

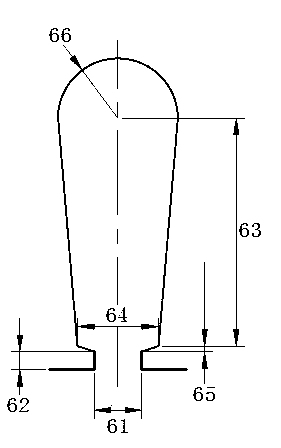

Hydro-generator set air gap measuring method and measuring device

ActiveCN105823397ASimple and fast operationAccurate dataMechanical clearance measurementsVernier scaleMeasurement device

The invention discloses a hydro-generator set air gap measuring method. The measuring method includes the following steps: 1) a measuring device is prepared, which includes a round nut, a stud in mutual threaded connection with the round nut, and a handle fixedly connected on an outer side face of the round nut, wherein the round nut and the stud form a screw pair; 2) a wooden wedge is utilized to predict a gap value; 3) the total length of the screw pair is adjusted according to the predicted gap value; and 4) the screw pair is inserted between a magnetic pole and an iron core from a side face of a magnetic pole surface vertical center line, then the screw pair is moved transversely to pass through a gap between the magnetic pole and the iron core, the length of the screw pair is adjusted again according to the degree of tightness of the screw pair between the magnetic pole and the iron core, when the degree of tightness is appropriate, a vernier caliper is utilized to measure the length of the screw pair, and a measured value is an air gap value of a certain measuring point. The measuring method is easy and convenient to operate, data are accurate when air gap measurement is performed, and the measuring device that is used is simple in structure and low in manufacturing cost.

Owner:GUANGXI GUIGUAN ELECTRIC POWER CO LTD

Super-efficient 1500-watt 6-pole three-phase asynchronous motor

InactiveCN102780367AReduce lossImprove conversion efficiencyMagnetic circuit rotating partsAsynchronous induction motorsThree phase asynchronous motorEngineering

The invention provides a super-efficient 1500-watt 6-pole three-phase asynchronous motor which comprises a stator and a rotor. Due to the fact that inner diameter, outer diameter of the stator and the rotor, iron core length and quantity, groove shapes and sizes of punching grooves are optimized and designed systematically and reasonably, and stator winding loss, rotor winding loss and iron core loss are reduced greatly. Under the condition that output power is at 1500 watts, compared with existing similar products, the rotating speed is promoted from 911 r / min to 946 r / min, total power loss is reduced from 515.9 W to 259.1 W, energy conservation reaches 49.78%, energy conversion efficiency is improved from 74.4% to 85.3% and improved by 10.9%, the energy conversion efficiency is 2.8% higher than the highest international grade standard 82.5%, and the energy conversion efficiency is improved greatly. Simultaneously, due to the fact that a central line of a stator cramping groove penetrates between two grooves of the stator punching grooves, radial electromagnetic force wave in air gaps is weakened, electromagnetic vibration is reduced, and electromagnetic noise is lowered.

Owner:CHONGQING LEERJIA MACHINERY

Ultrahigh-efficiency and energy-saving 2200W six-pole three-phase asynchronous motor

InactiveCN103647411AImprove cooling effectReduce lossMagnetic circuit rotating partsAsynchronous induction motorsThree phase asynchronous motorNational standard

Provided is an ultrahigh-efficiency and energy-saving 2200W six-pole three-phase asynchronous motor which comprises a stator and a rotor. Design of external diameters, internal diameters, length of iron cores, number of punching sheet grooves and shape and size of the grooves of the stator and the rotor is systematically optimized so that stator winding loss, rotor winding loss and iron core loss are substantially reduced. Compared with existing similar products, total energy loss amount is reduced from 622.9W to 361.5W, and reduction is 42.0% under the premise of the same output power of 2200W. The required input power is reduced from original 2.823kW to 2.562kW, energy conversion efficiency is increased from 77.9% to 85.9%, and increment is 8.0%. Compared with standard of 84.3% which is specified in the latest national standard "GB18613-2012" and enforced in September, 2016, energy conversion efficiency surpasses for 1.6% so that energy conversion efficiency is substantially enhanced. Application and popularization of the ultrahigh-efficiency and energy-saving 2200W six-pole three-phase asynchronous motor provide powerful support for national energy conservation and emission reduction work.

Owner:CHONGQING LEERJIA MACHINERY

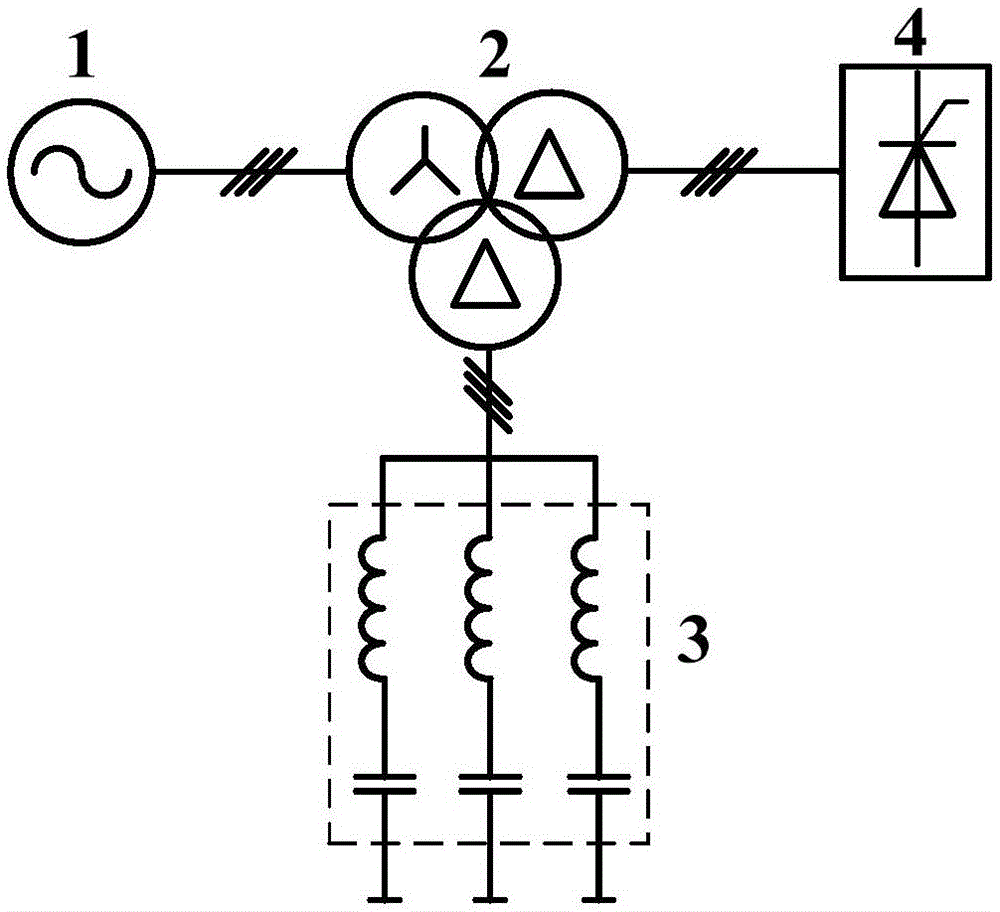

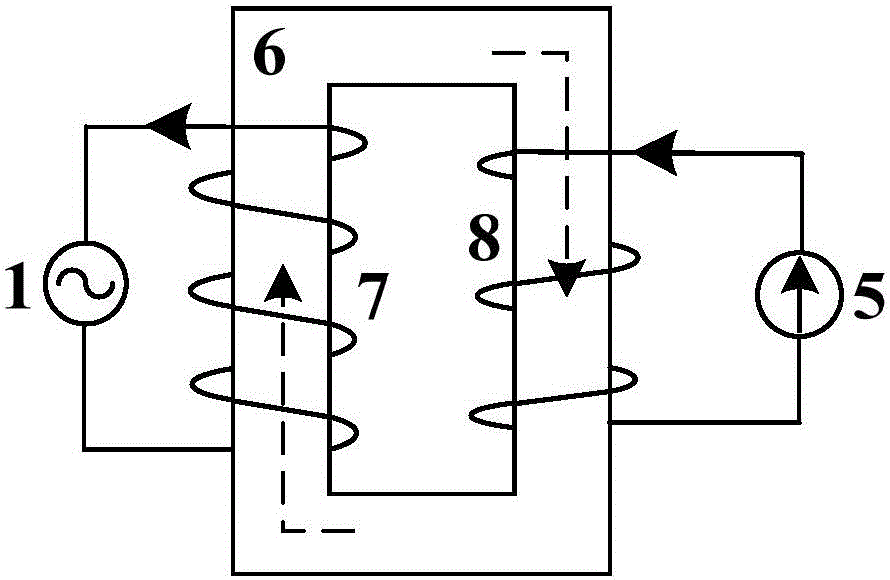

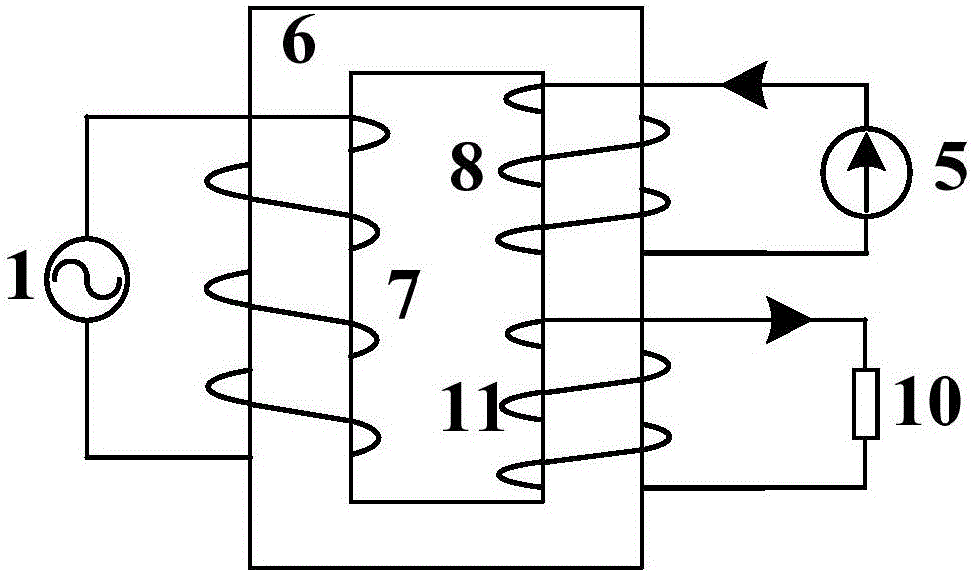

Method and device for suppressing electromagnetic vibration of inductive filtering converter transformer

InactiveCN106300388AElectromagnetic vibration suppressionReduce electromagnetic vibrationPower oscillations reduction/preventionUnwanted magnetic/electric effect reduction/preventionTransformerFiltration

The invention discloses a method and device for suppressing electromagnetic vibration of an inductive filtering converter transformer. According to the method, a zero impedance path is provided for second harmonic current, fifth harmonic current, seventh harmonic current, eleventh harmonic current and thirteenth harmonic current through a filter winding and a matched all-tunable filter for drainage and filtration. Harmonic waves are filtered off nearby, the path that the harmonic current escapes to a network side from a valve side is cut off and the harmonic current and the harmonic electromagnetic force of a network side winding of the converter transformer and circulating harmonic flux and magnetostriction level in an iron core are effectively reduced in a manner of effectively suppressing the harmonic flux of the iron core of the transformer, thereby achieving the target of suppressing the electromagnetic vibration of a converter transformer body.

Owner:STATE GRID CORP OF CHINA +3

Ultra-high-efficiency 2200-watt six-pole three-phase asynchronous motor

InactiveCN102780356AReduce lossImprove conversion efficiencyMagnetic circuit rotating partsAsynchronous induction motorsThree phase asynchronous motorEngineering

An ultra-high-efficiency 2200-watt six-pole three-phase asynchronous motor comprises a stator and a rotor. The external diameter and the internal diameter of each of the stator and the rotor, the core length and the number, the shape and the size of punching sheet slots are optimized and reasonably designed systematically to enable loss of a stator winding, a rotor winding and a core to be greatly reduced. With the 2200-watt output power, compared with existing like products, the ultra-high-efficiency 2200-watt six-pole three-phase asynchronous motor has the advantages that rotational speed is increased from 930r / min to 959r / min; total electric energy loss is decreased from 622.9w to 340.3w, and energy is saved by 50.49%; energy conversion efficiency is greatly increased from 77.9% to 87.7%, is increased by 9.8% and is 3.4% higher than the highest international grade standard of 84.3%; and since a central line of a stator cramp slot is designed to penetrate through the middles of two of the stator punching sheet slots, radial electromagnetic force waves in air gaps are weakened, electromagnetic vibration is reduced, and electromagnetic noise is reduced.

Owner:CHONGQING LEERJIA MACHINERY

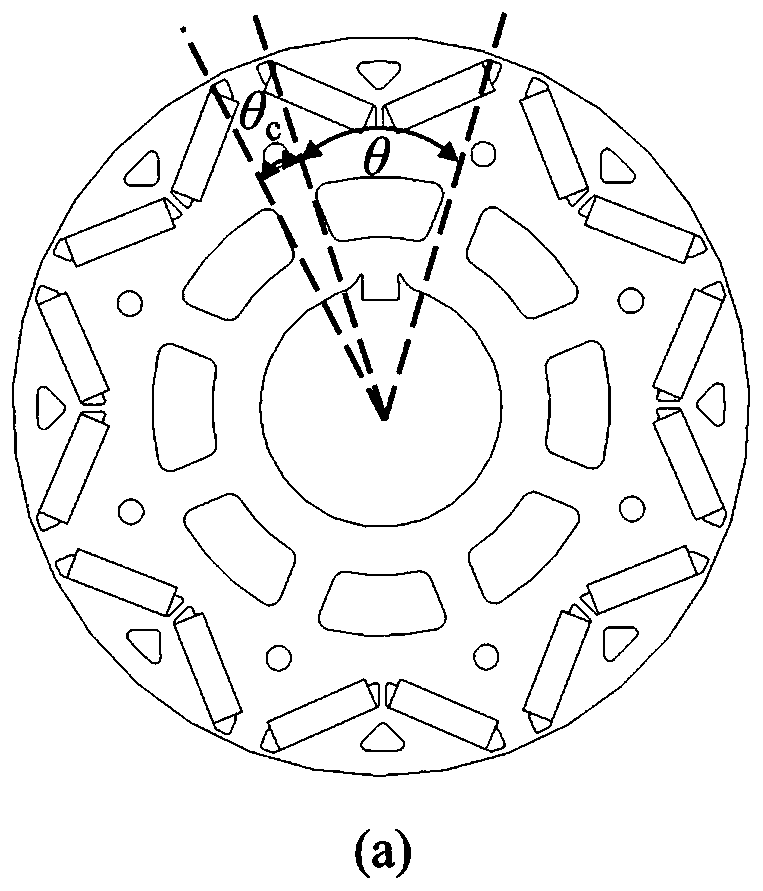

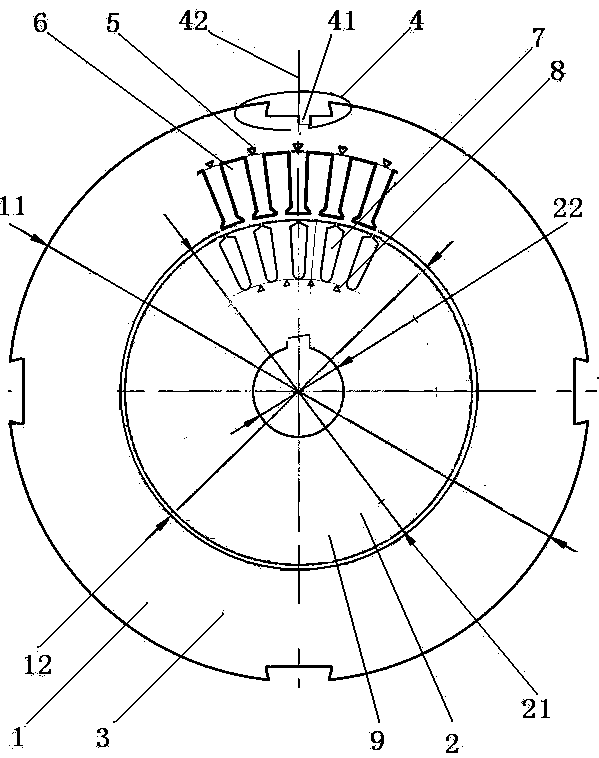

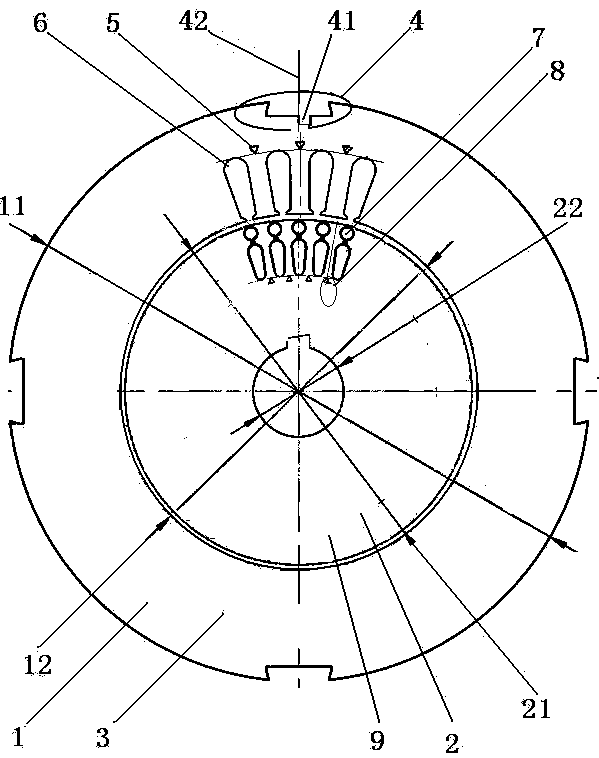

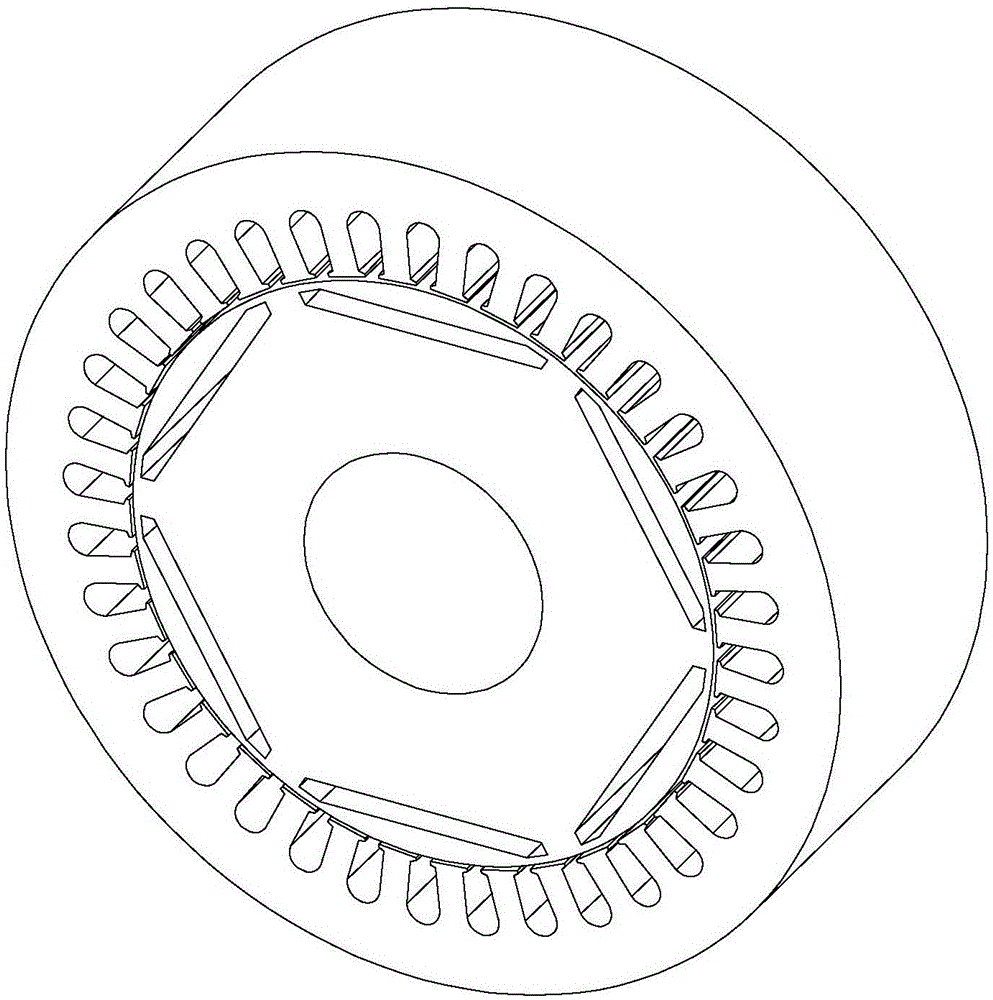

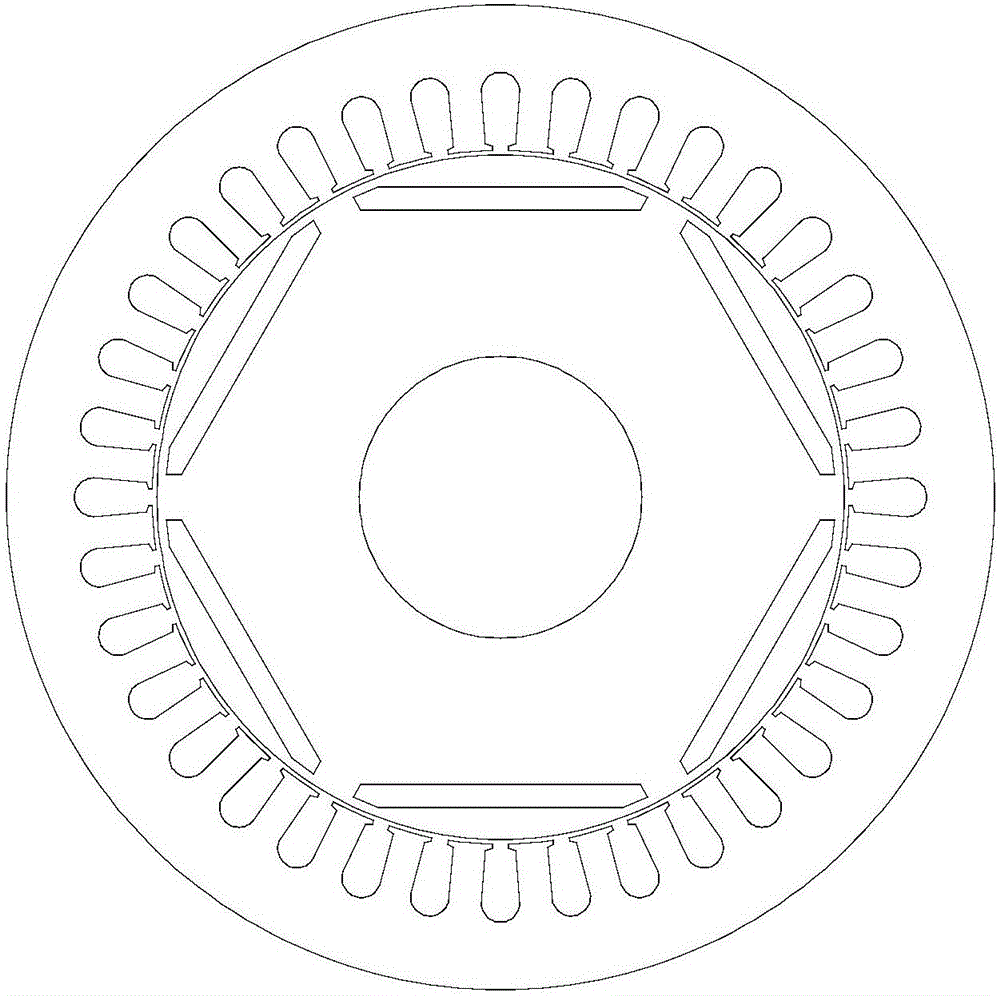

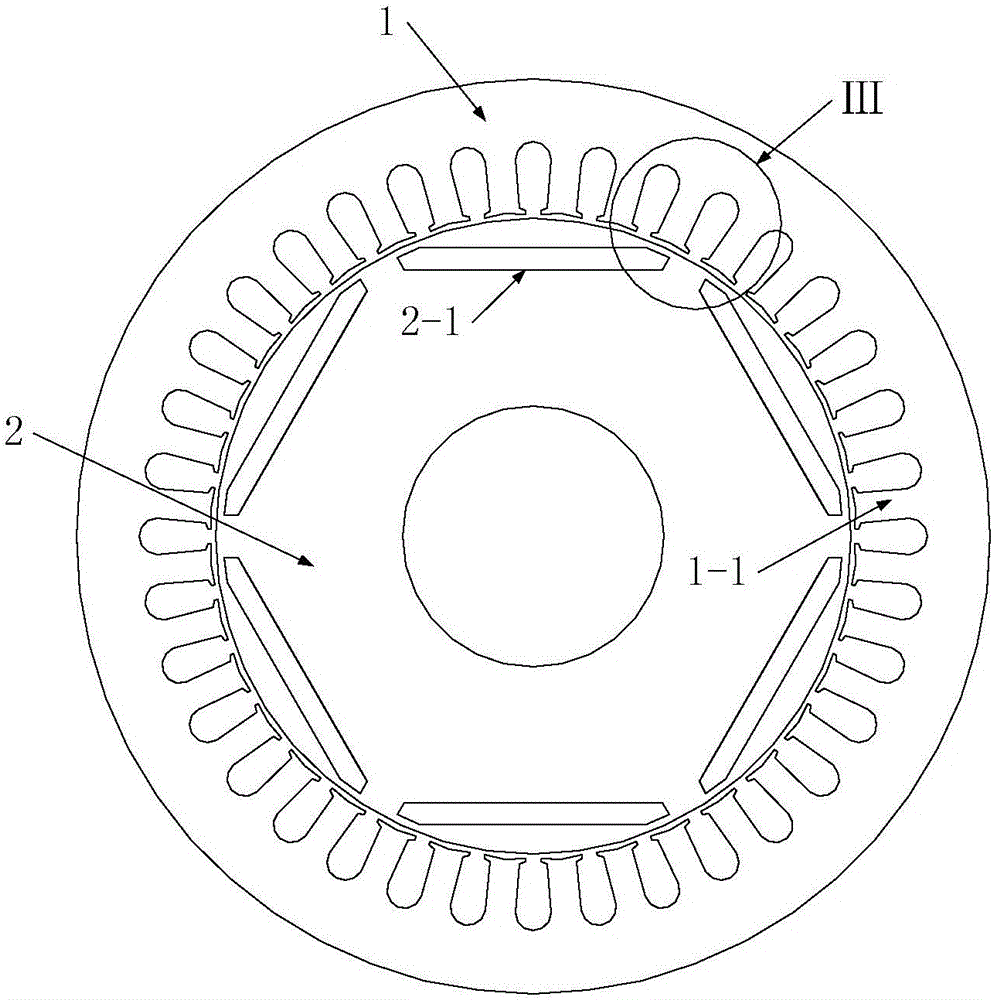

Unequal tooth width combined permanent magnet synchronous motor and electromagnetic vibration weakening method thereof

ActiveCN111245118ALow costImprove production efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorElectric machine

The invention discloses an unequal tooth width combined permanent magnet synchronous motor and an electromagnetic vibration weakening method thereof. The unequal tooth width combined permanent magnetsynchronous motor comprises a stator, a permanent magnet rotor and armature windings, the stator sleeves the permanent magnet rotor, and the permanent magnet rotor is coaxially arranged with the stator. The stator comprises stator slots, stator teeth and a stator yoke part, the stator yoke part is annular, the stator teeth are uniformly distributed along the circumference of the stator yoke part.The stator slots are arranged between the stator teeth, and the armature windings are arranged in the stator slots. The width of at least one stator tooth in the stator teeth is different from the widths of other stator teeth, and the widths of other stator teeth are the same. According to the invention, the cogging torque and the tooth harmonic electromotive force of the permanent magnet motor are greatly reduced by adopting the stator with the unequal tooth width combined structure, so that the motor can have smaller torque pulsation; the torque ripple weakening effect equivalent to that ofa stator skewed slot can be achieved by changing the width of the motor stator tooth, and the torque ripple is weakened by replacing a stator skewed slot or rotor skewed pole method in the industry.

Owner:SHANDONG UNIV

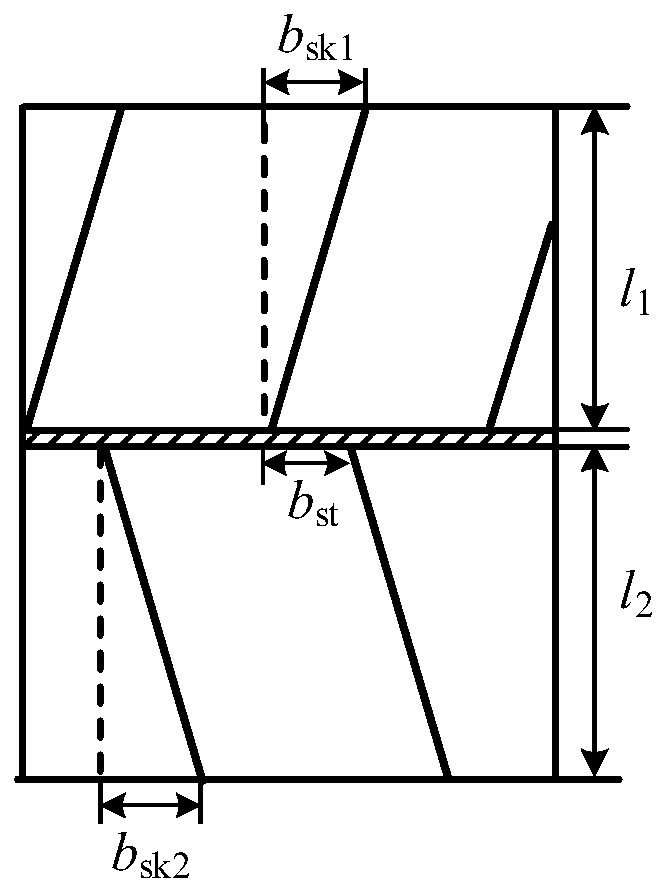

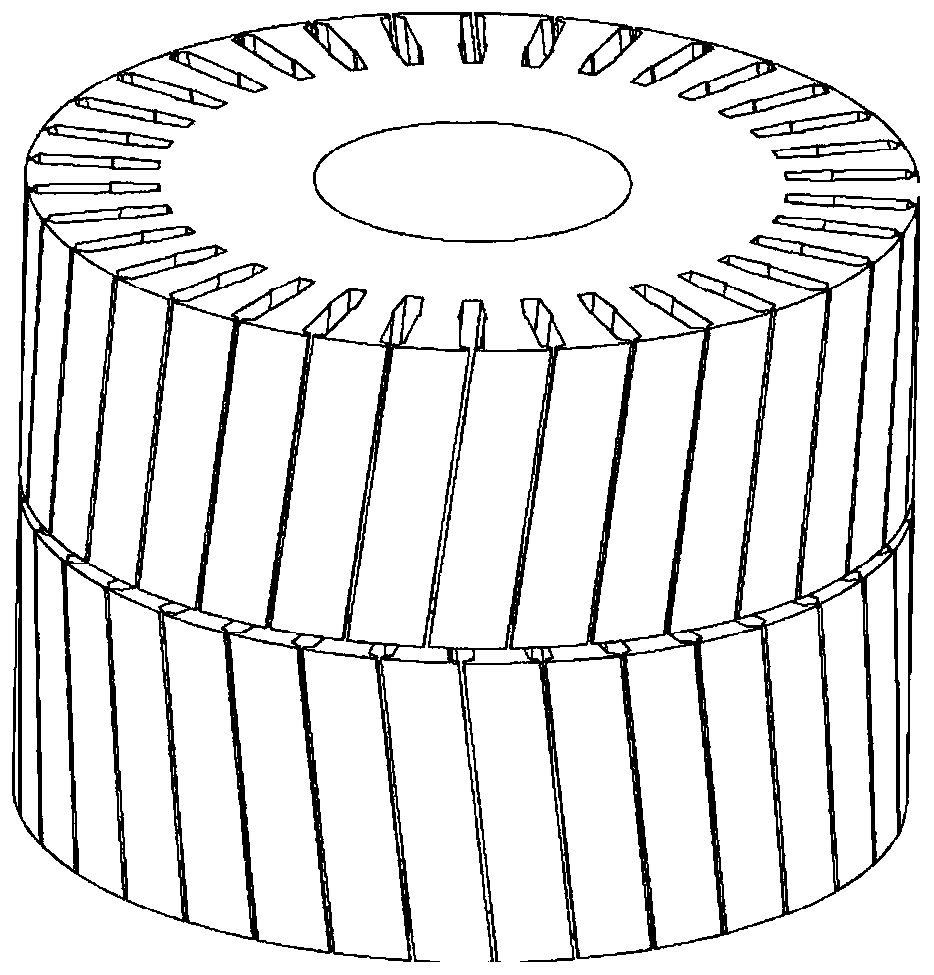

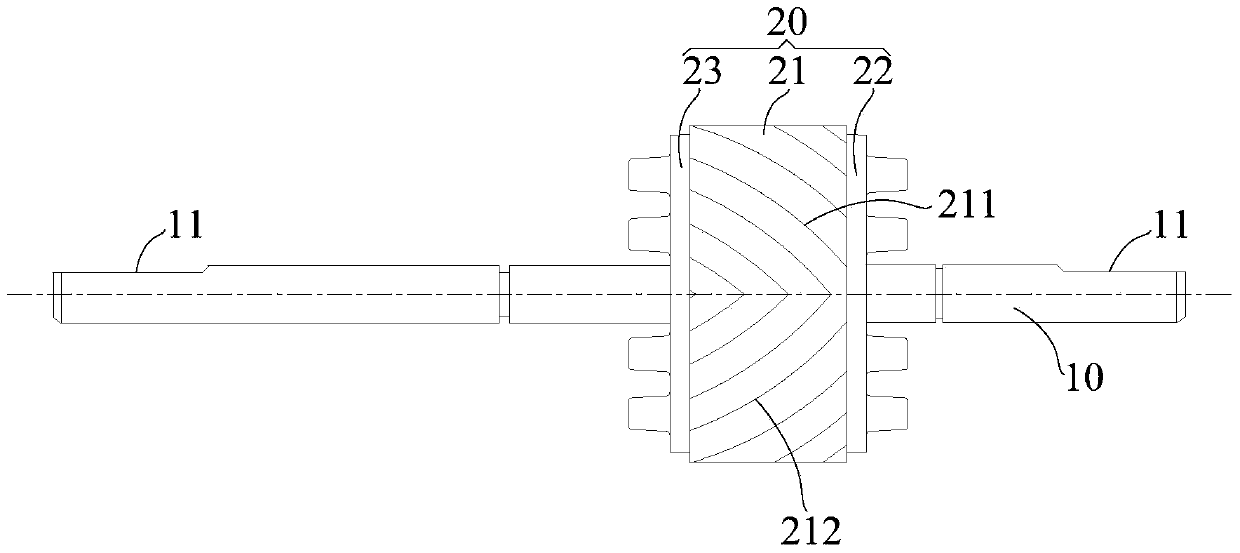

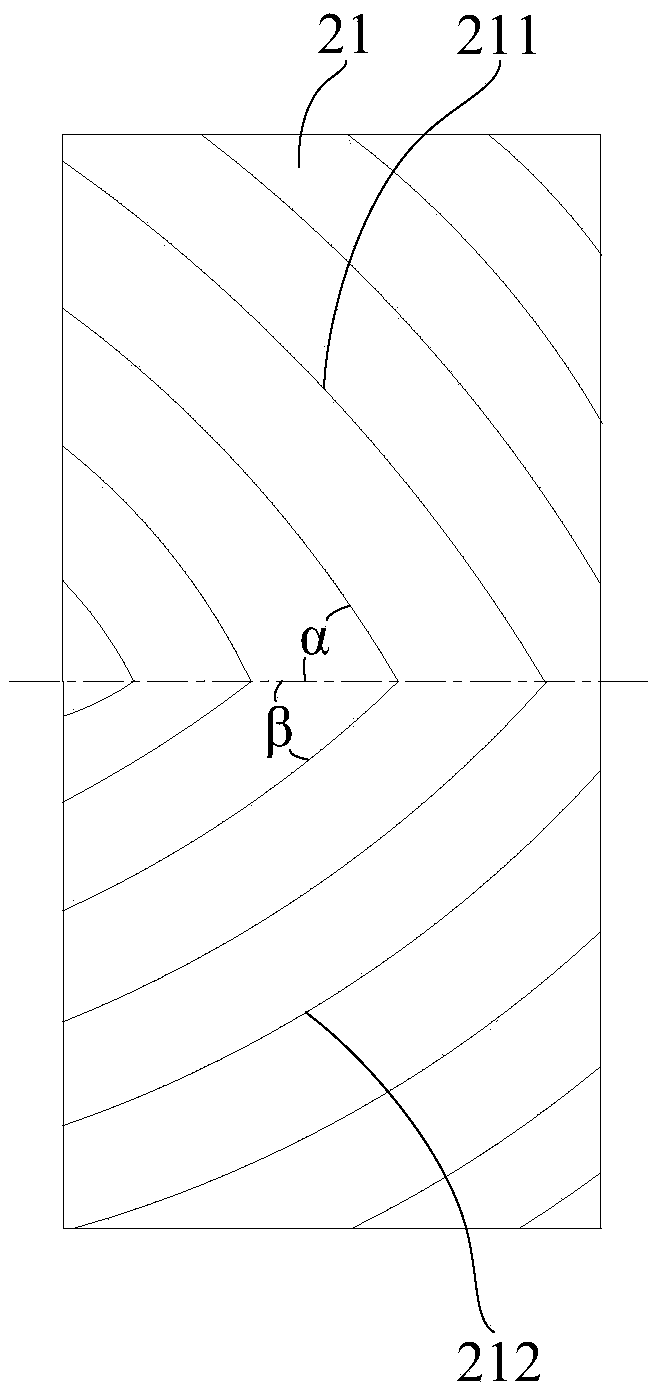

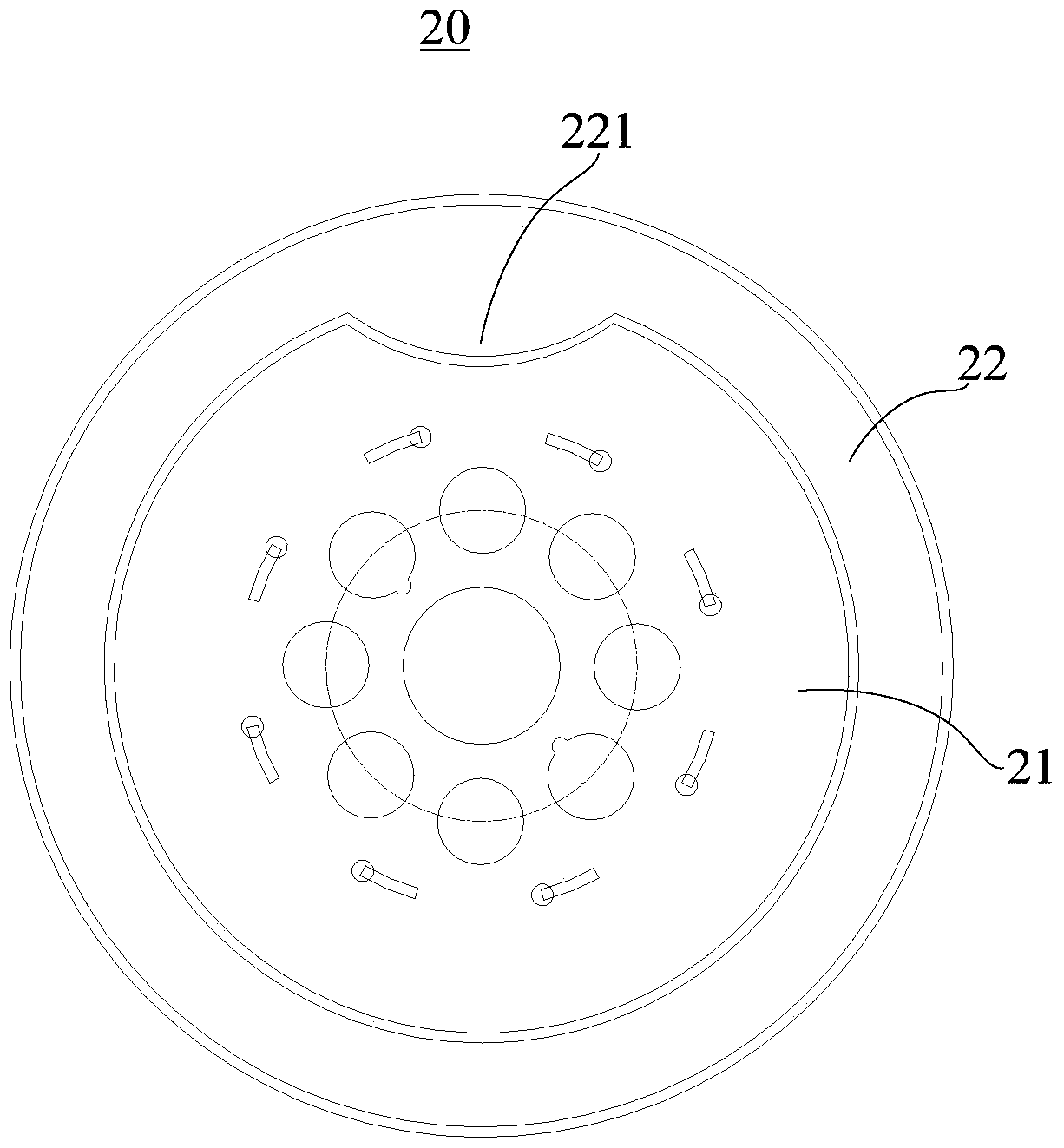

Design method for double-skewed-slot rotor structure in few-slot near-slot fit

ActiveCN110808644AReduce electromagnetic vibrationReduce noiseMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringHarmonics

The invention discloses a design method for a double-skewed-slot rotor structure in few-slot near-slot fit. The method comprises the following steps of: 1, listing a low-order radial force wave ordertable corresponding to slot fit, and determining a harmonic magnetic field component for generating a low-order radial force and a corresponding stress wave order, 2, calculating a radial force wave expression generated by a stator and rotor harmonic magnetic field by utilizing a Maxwell law, and obtaining an average radial force formula of the whole length of the rotor through basic mathematicaloperation, and 3, calculating a double-skewed-slot coefficient of the harmonic magnetic field near a default parameter, and when the absolute value of the double-skewed-slot coefficient correspondingto the harmonic magnetic field generating the main low-order radial force is minimum, determining the design parameter of the double-skewed-slot rotor. The skewed-slot distance and the staggered distance are designed in a matched mode, electromagnetic vibration noise is reduced, the degree of weakening a harmonic magnetic field is further improved, and the amplitude of low-order radial electromagnetic force waves is effectively reduced.

Owner:HEFEI UNIV OF TECH

Ultrahigh energy efficiency 2200W six-pole three-phase asynchronous motor

InactiveCN103647391AImprove cooling effectReduce lossAsynchronous induction motorsThree phase asynchronous motorEngineering

Provided is an ultrahigh energy efficiency 2200W six-pole three-phase asynchronous motor which comprises a stator and a rotor. Design of external diameters, internal diameters, length of iron cores, number of punching sheet grooves and shape and size of the grooves of the stator and the rotor is systematically optimized so that stator winding loss, rotor winding loss and iron core loss are substantially reduced. Compared with existing similar products, total energy loss amount is reduced from 455.2W to 333.5W, and reduction is 26.7% under the premise of the same output power of 2200W. The required input power is reduced from original 2.655kW to 2.533kW, energy conversion efficiency is increased from 82.9% to 86.8%, and increment is 3.9%. Compared with standard of 85.9% which is specified in the latest national standard "GB18613-2012" and enforced in September, 2016, energy conversion efficiency surpasses for 0.9% so that energy conversion efficiency is substantially enhanced. Application and popularization of the ultrahigh energy efficiency 2200W six-pole three-phase asynchronous motor provide powerful support for national energy conservation and emission reduction work.

Owner:CHONGQING LEERJIA MACHINERY

Built-in permanent magnet vibration reduction and noise reduction synchronous motor

InactiveCN106329748AImproved Radial Electromagnetic ForceEven by forceMagnetic circuit rotating partsMagnetic circuit stationary partsMotor driveSynchronous motor

The invention discloses a built-in permanent magnet vibration reduction and noise reduction synchronous motor and relates to the field of motor vibration reduction and noise reduction. Vibration and noise of an existing built-in permanent magnet motor are effectively suppressed. Two schemes are provided and are both improvements in teeth of a stator. Each tooth is divided into a front half tooth and a rear half tooth. According to the first scheme, the tooth top arc of each front half tooth is different from the tooth top arc of each rear half tooth in radian. According to the second scheme, the radial height of the interface between each front half tooth and the corresponding rear half tooth changes step by step. The width of an air gap corresponding to the center of each tooth is larger than the width of an air gap corresponding to any one end of each tooth. The synchronous motor is mainly applied to the motor driving field.

Owner:HARBIN UNIV OF SCI & TECH

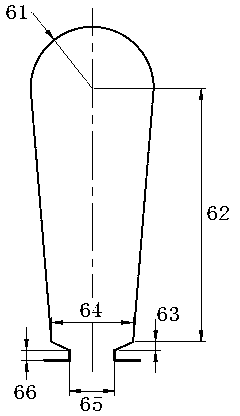

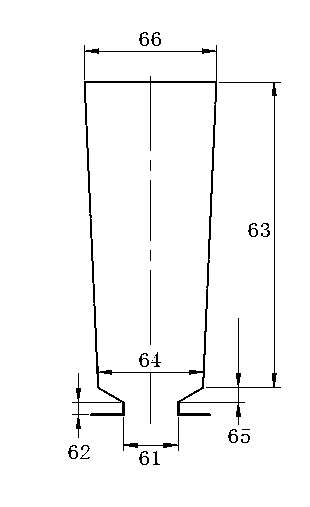

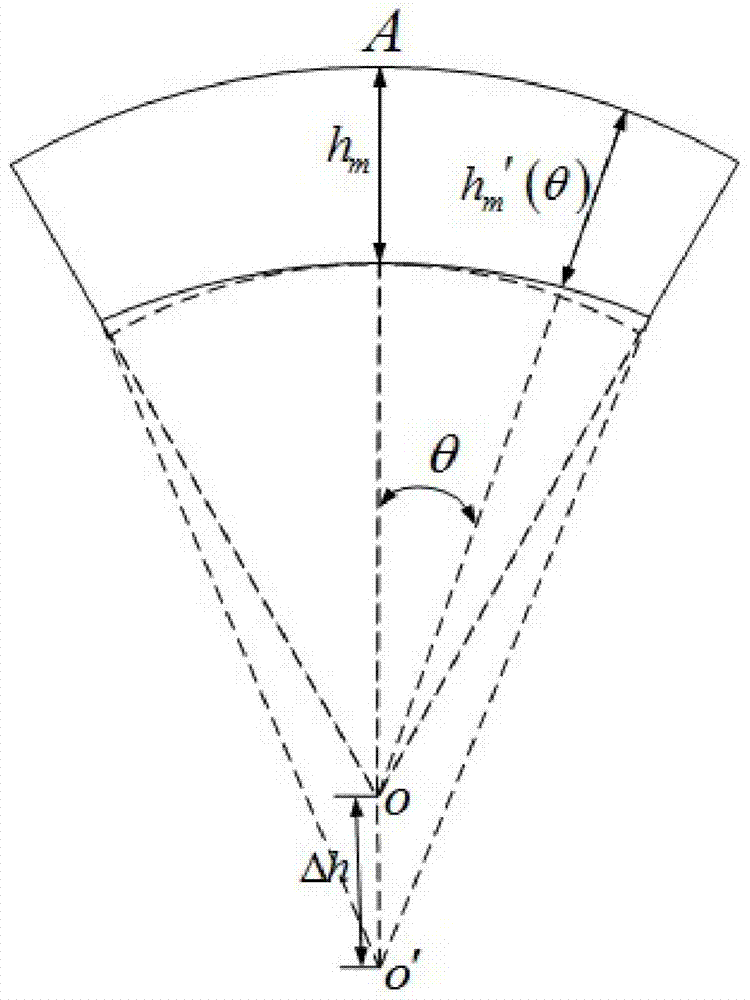

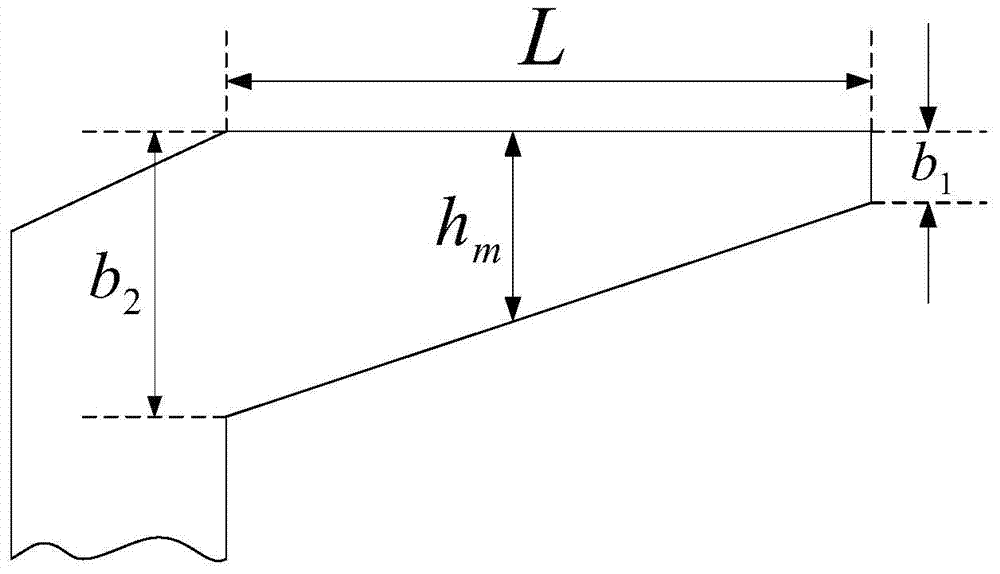

Method for reducing electromagnetic vibration noise of automobile claw-pole power generator and on the basis of magnetic pole eccentricity

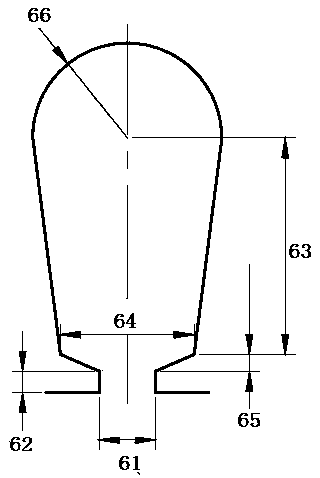

ActiveCN103490528AImprove air gap magnetic density distributionWeaken torque rippleSalient polesWave shapeElectromagnetic vibration

The invention discloses a method for reducing electromagnetic vibration noise of an automobile claw-pole power generator and on the basis of magnetic pole eccentricity. The method for reducing the electromagnetic vibration noise of the automobile claw-pole power generator and on the basis of the magnetic pole eccentricity is characterized in that the plane where the section, in the radial direction, of the extending end in the axial direction of each claw pole of the N pole and the S pole of the claw-pole power generator is located is set to be an S surface, and an outer circular arc line and an inner circular arc line of the extending end, in the axial direction, of each claw pole are formed on the S surface; the circle center of each outer circular arc line serves as an O point, the midpoint of each outer circular arc line serves as an A point, the circle center of each inner circular arc line serves as an O' point, the O' point is located on an extension line at one end, at the position of the O point, of a connection line between the O point and the A point, and the distance between the O' point and the O point is deltah. Compared with the arrangement that each outer circular arc line and each inner circular arc line are set to be concentric, the method for reducing the electromagnetic vibration noise of the automobile claw-pole power generator and on the basis of the magnetic pole eccentricity improves distribution of gap flux densities, waveforms of the gap flux densities corresponding to the claw poles trend to be sine-shaped, torque pulsation caused by air-gap field harmonic is reduced, and electromagnetic vibration and electromagnetic noise of the automobile claw-pole power generator are reduced.

Owner:HEFEI UNIV OF TECH

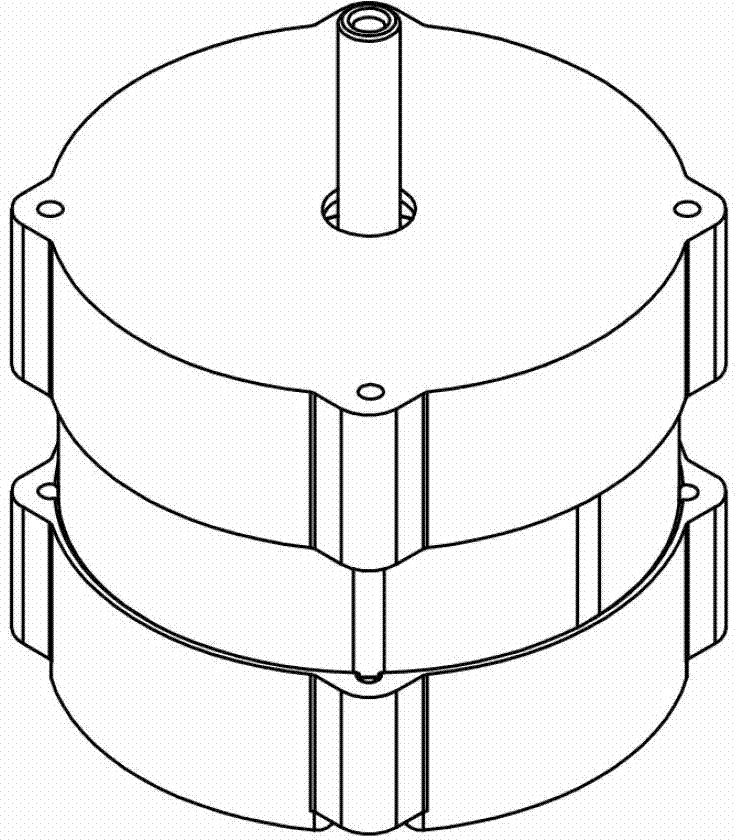

Motor rotors and motors

ActiveCN105429326BReduce electromagnetic vibrationReduce electromagnetic noiseMagnetic circuit rotating partsDistortionParallel arrangement

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com