Ultra-high-efficiency 2200-watt six-pole three-phase asynchronous motor

A three-phase asynchronous, ultra-high-efficiency technology, applied in the field of motors, can solve problems such as unsatisfactory energy-saving effects, and achieve the effects of improving energy conversion efficiency, saving energy, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

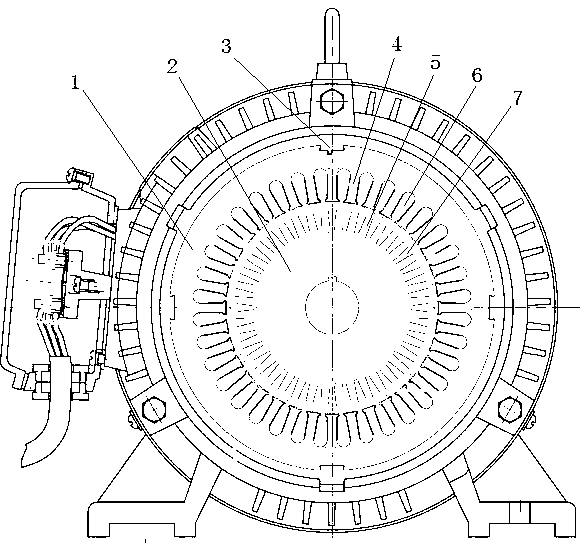

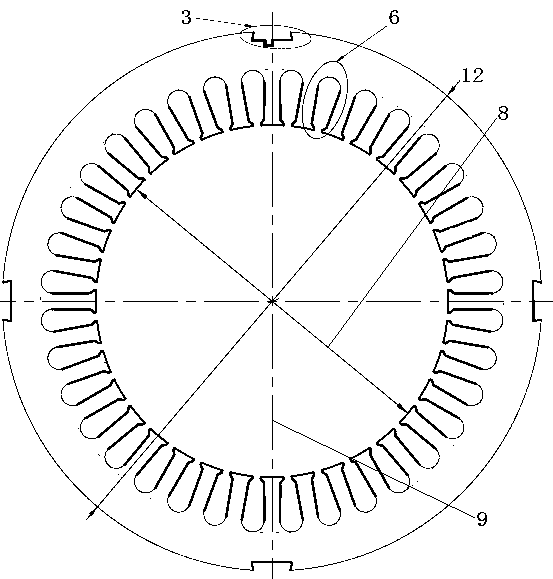

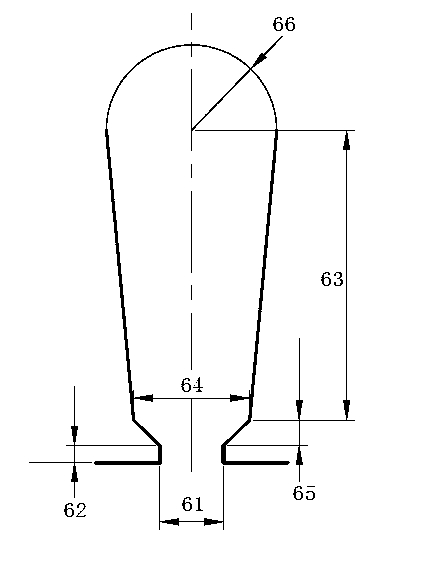

[0015] Such as figure 1 As shown, the present invention includes two main parts of the stator 1 and the rotor 2, the basic material, structure and manufacturing method are the same as the common 2200 watt 6-pole three-phase asynchronous motor, the difference is that the outer diameter of the stator 12 is made 19.00cm, the stator The inner diameter 8 is made into 12.40cm, and the number of stator punching slots 6 is made into 36 and evenly distributed in a ring shape. The groove shape of the stator punching slots 6 is made into a round-bottomed groove with oblique shoulders, and the slot width 61 is made into 3.00 mm, slot height 62 is made 0.80mm, slot upper depth 63 is made 13.60mm, slot shoulder width 64 is made 5.45mm, slot shoulder height 65 is made 1.20mm, slot bottom radius 66 is made 4.00mm, and the stator buckle The center line 9 of the slot passes through the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com