DC propulsion motor

A technology of electric motor and armature iron core, applied in the field of electric motor, can solve the problems such as the higher requirements of vibration and noise of quiet DC propulsion motor, the phase difference in the direction of radial electromagnetic force, large electromagnetic vibration and noise that cannot be well satisfied , to ensure the performance of single pivot operation, electromagnetic vibration suppression, low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

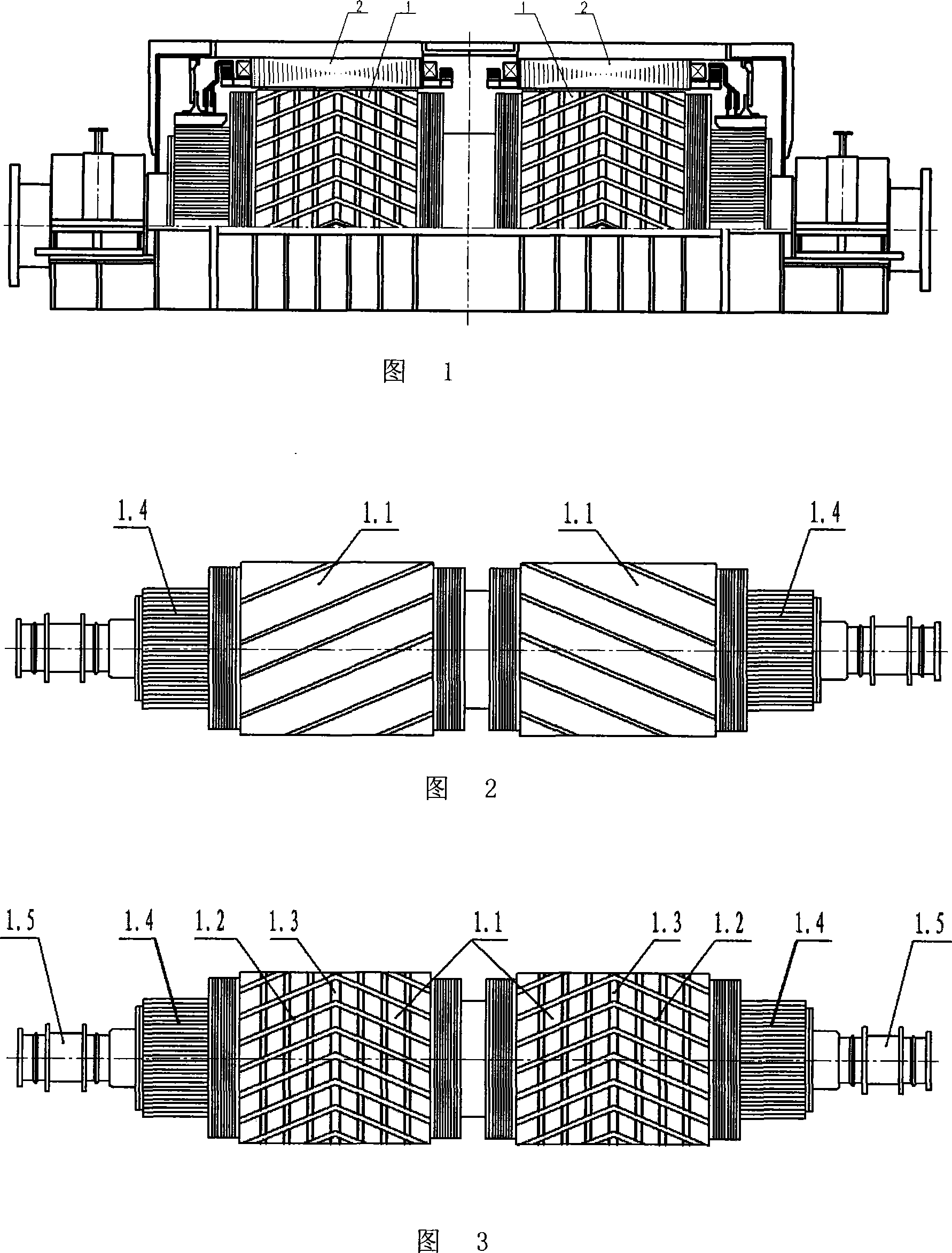

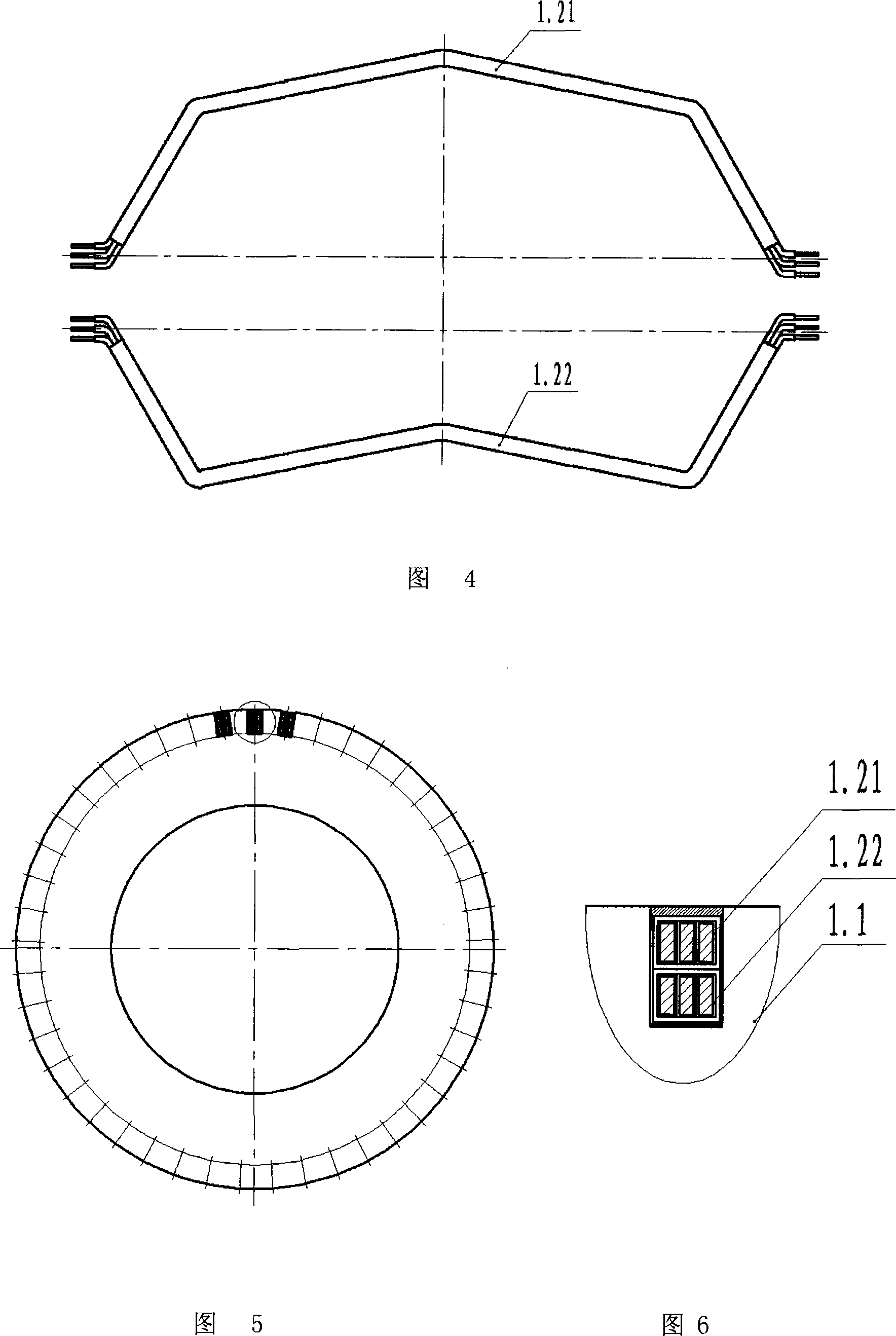

[0025] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

[0026] As shown in Figures 1, 3, 4, 5, and 6, it is a DC propulsion motor, which has a rotor 1 and a stator 2; the rotor 1 has an armature core 1.1, an armature winding 1.2, and a radial ventilation ditch 1.3, commutator 1.4, rotating shaft 1.5; the armature winding 1.2 distributed on the outer circumference of the armature core 1.1 is a "herringbone"-shaped winding; the "herringbone"-shaped armature winding 1.2 is insulated by a coil The "herringbone"-shaped upper coil 1.21 and the package-insulated "herringbone"-shaped lower coil 1.22 are divided into half structures, embedded in the "herringbone"-shaped chute of the armature core 1.1 (as shown in Figure 4, Figure 5, As shown in Figure 6), the size of the chute near the turning point is slightly larger than the size of the chute at the straight line; the "herringbone" shape of the armature winding 1.2, its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com