Vortex compressor and refrigerator using ammonia-like as refrigrant

A scroll compressor, the technology of using ammonia, applied in the direction of compressors, electromechanical devices, components of pumping devices for elastic fluids, etc. The problem of the motor part, etc., can improve the efficiency of the molding operation, suppress the temperature rise, and reduce the torque fluctuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

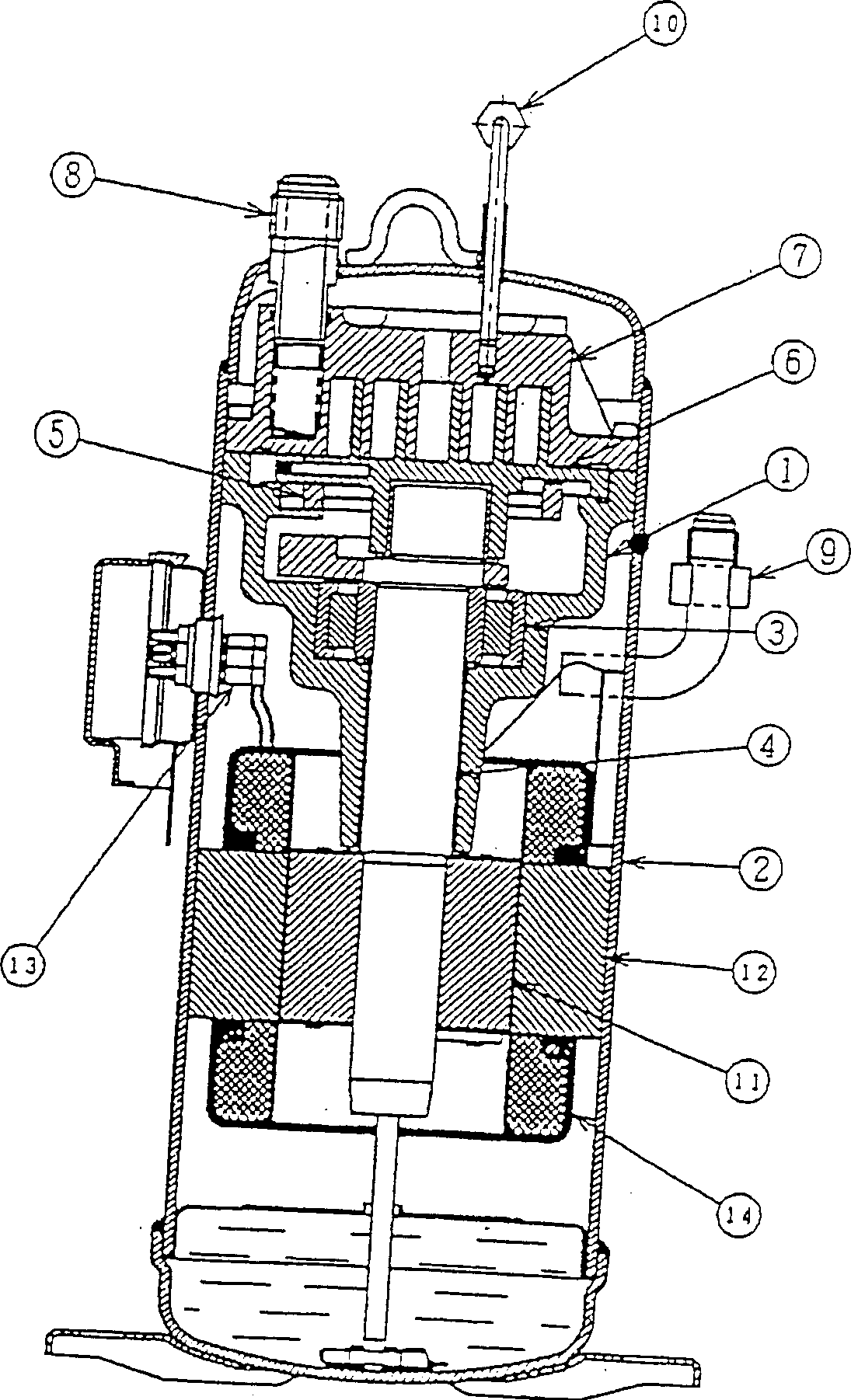

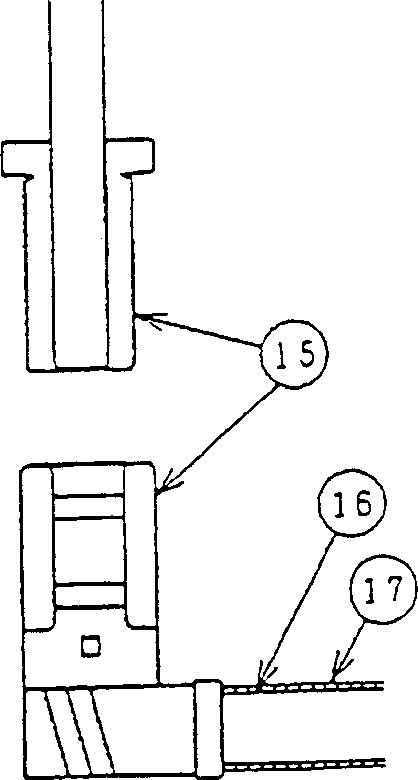

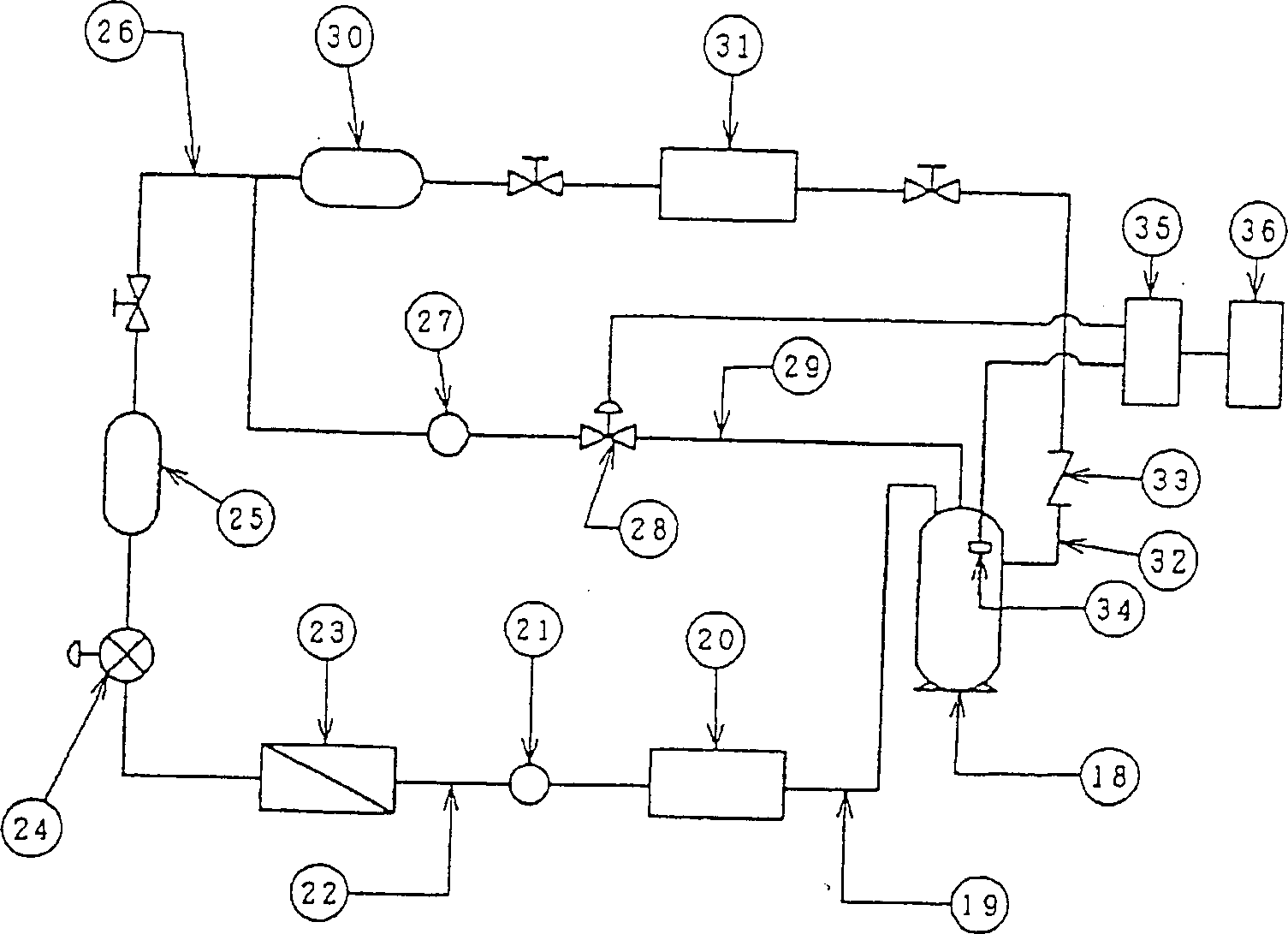

[0021] figure 1 A scroll compressor using an ammonia-based refrigerant used in this embodiment is shown. The scroll compressor is composed of a compression mechanism part, a bracket 1, an Oldham ring (Oldamring) 5, a rotating shaft 4, a motor part, etc., and the compression mechanism part is formed by engaging an orbiting scroll 6 and a fixed scroll 7, The bracket 1 supports the compression mechanism part, the Oldham ring 5 is used to prevent the rotation of the above-mentioned orbiting scroll, the above-mentioned rotating shaft 4 is installed on the above-mentioned orbiting scroll, and the above-mentioned motor part is installed on the rotating shaft 4 and is used to drive the The scroll compressor is housed in a pressure-resistant container 2 in a hermetically sealed manner. On the mirror plate portion of the above-mentioned fixed scroll 7, a liquid ejection circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com