Built-in permanent magnet driving motor of electric automobile and electromagnetic vibration weakening method thereof

An electric vehicle, permanent magnet drive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

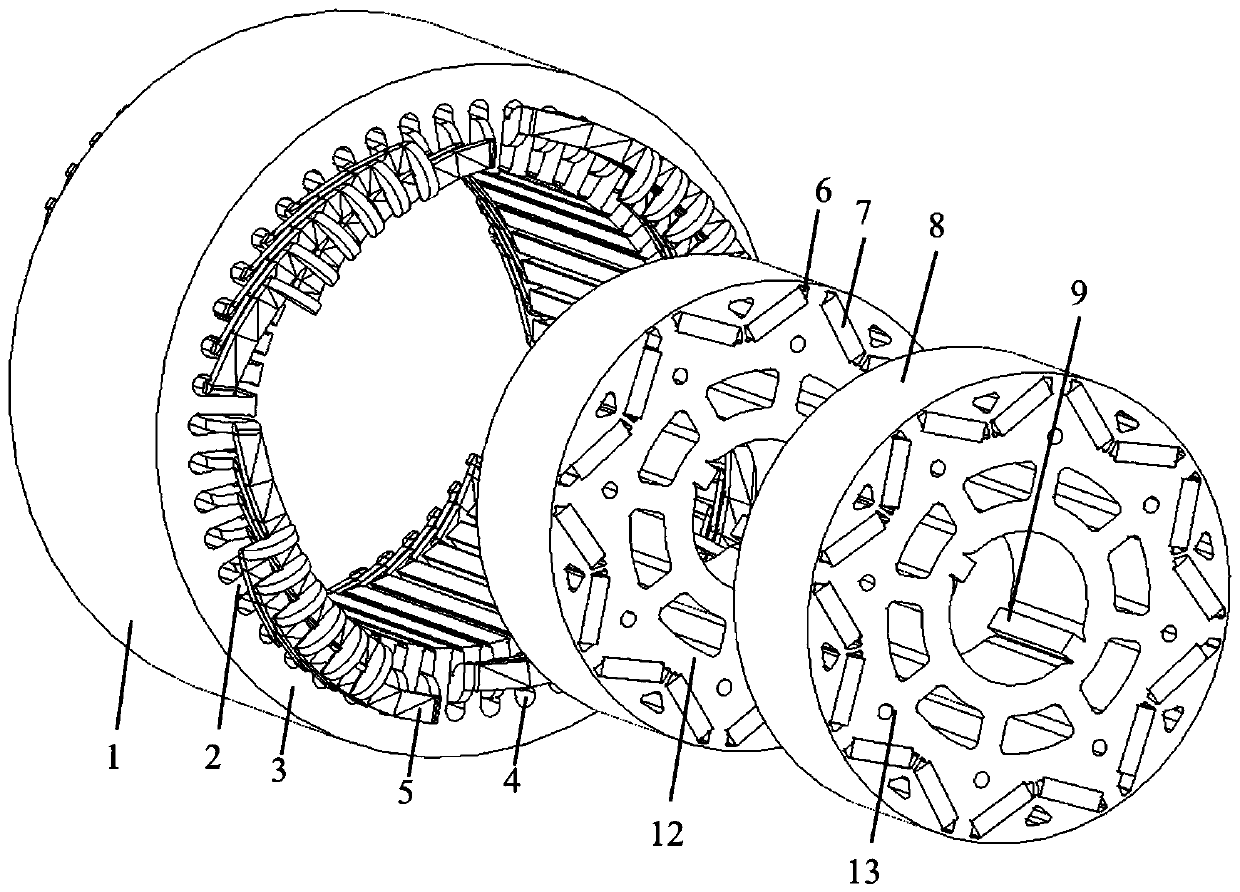

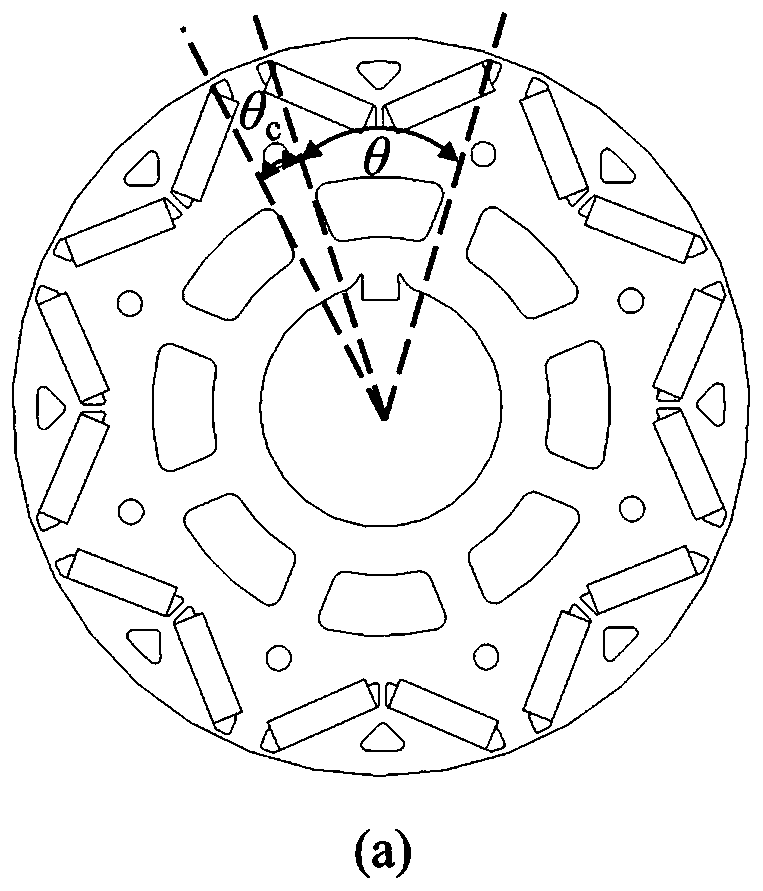

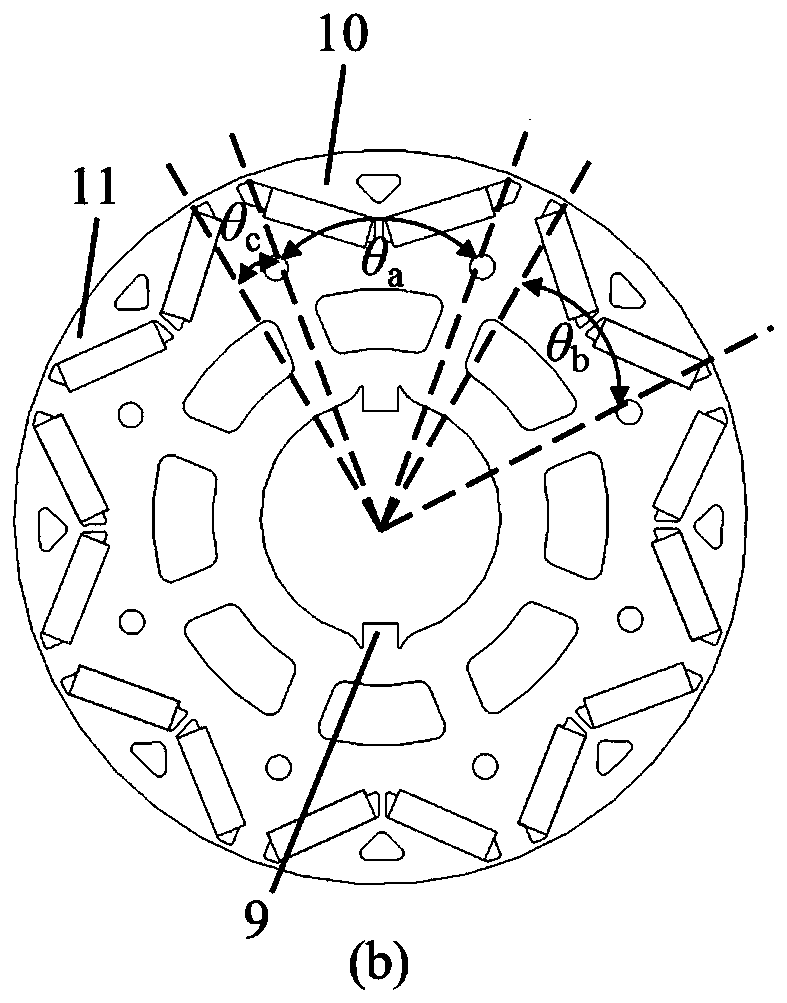

[0090] Such as Figure 1-Figure 8 As shown, the number of motor poles in this embodiment is 8, and the number of stator slots is 48. This embodiment includes a stator 1, permanent magnet rotors 12 and 13 and armature windings 5, and the permanent magnet rotors 12 and 13 include rotor cores 8 And the permanent magnet 7, the rotor core 8 is provided with a rotor slot 6, and the permanent magnet 7 is placed in the rotor slot 6, and the permanent magnet 7 acts on the rotor core 6 to form 8 rotor poles. Wherein, the permanent magnet rotors 12 and 13 are set inside the stator 1 and arranged coaxially with the stator 1 , and the stator 1 is provided with an armature winding 5 . The permanent magnet rotor is divided into two sections along the axial direction. The two sections of permanent magnet rotors 12 and 13 have the same structure, and both have 8 rotor poles. Among the rotor poles, the pole arc width corresponding to one rotor pole 10 is equal to The pole arc widths correspond...

Embodiment 2

[0099] Such as Figure 9-Figure 16 As shown, the number of motor poles in this embodiment is 8, and the number of stator slots is 48. This embodiment includes a stator 1, permanent magnet rotors 12 and 13 and armature windings 5, and the permanent magnet rotors 12 and 13 include rotor cores 8 And the permanent magnet 7, the rotor core 8 is provided with a rotor slot 6, and the permanent magnet 7 is placed in the rotor slot 6, and the permanent magnet 7 acts on the rotor core 6 to form 8 rotor poles.

[0100] Wherein, the permanent magnet rotors 12 and 13 are set inside the stator 1 and arranged coaxially with the stator 1 , and the stator 1 is provided with an armature winding 5 .

[0101] The permanent magnet rotor is divided into two sections along the axial direction. The two sections of permanent magnet rotors 12 and 13 have the same structure, and both have 8 rotor poles. Among the rotor poles, the pole arc width corresponding to one rotor pole 10 is equal to The pole ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com