Hydro-generator set air gap measuring method and measuring device

A technology of air gap and measuring device, which is applied in the direction of mechanical gap measurement, etc., can solve the problems of generator stator transverse difference current and split phase difference rheological change, asymmetric and uniform magnetic flux density, and the unit cannot be put into operation, etc., to achieve reduction The effects of transverse differential current and split phase differential current, improved stability, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

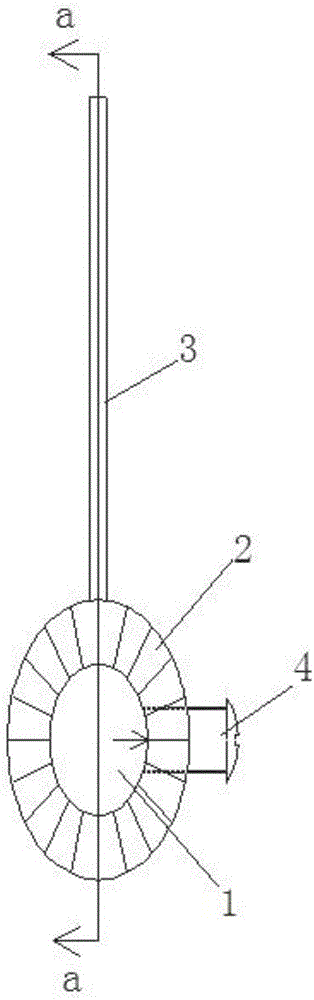

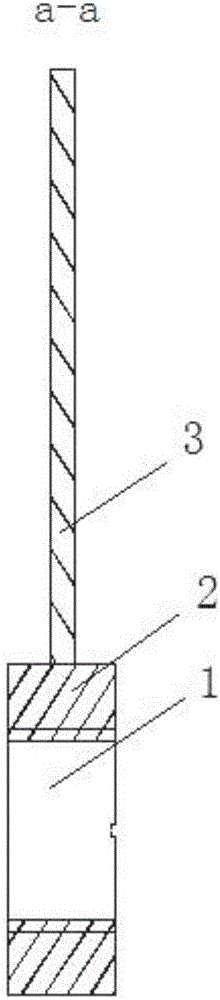

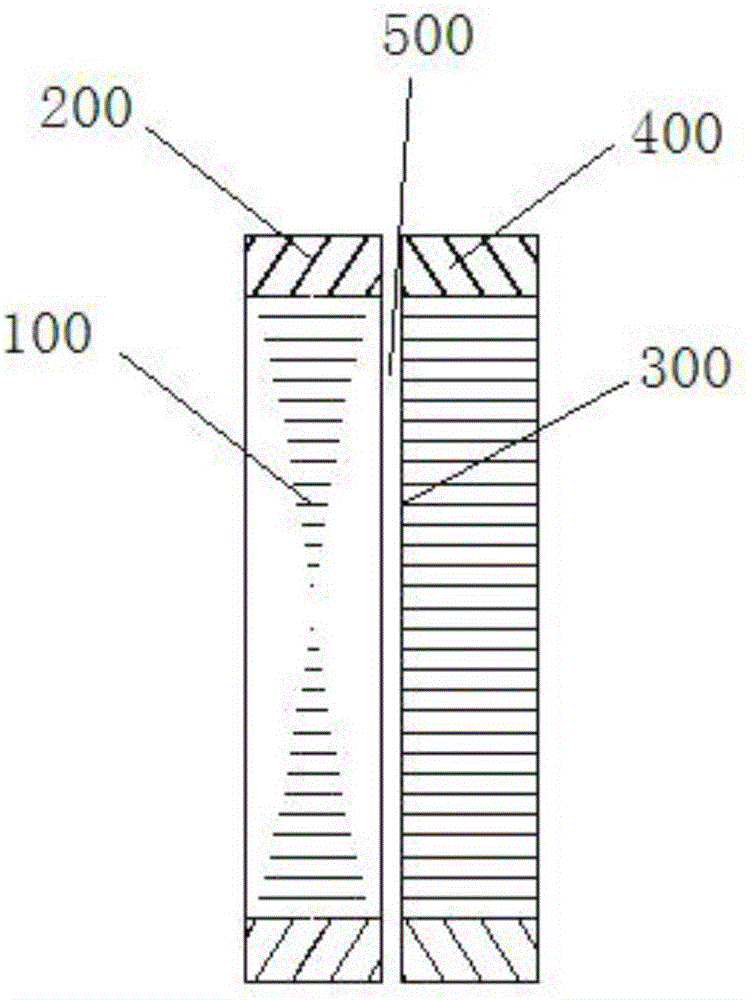

[0018] refer to figure 1 with figure 2 , the air gap measuring device of the hydroelectric generator set includes a stud 1, a round nut 2, a handle 3 and a bolt 4, wherein the stud 1 and the round nut 2 are screwed together to form a screw pair; the outer surface of the handle 3 and the round nut 2 They are fixedly connected to each other; the bolt 4 is screwed in from the outer surface of the round nut 2 and abuts against the stud 1.

[0019] Both the above-mentioned stud 1 and the round nut 2 are made of copper material, which is difficult to be magnetized. One end face of the round nut 2 is divided into 20 equal divisions and an indicator line is drawn across the center of the circle. In this embodiment, the specification of the stud 1 is M16, the length is 13 millimeters, the specification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com