Aluminium casting air tightness detector

A technology for air tightness detection and aluminum casting, which is used in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the acceleration and deceleration rate of fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

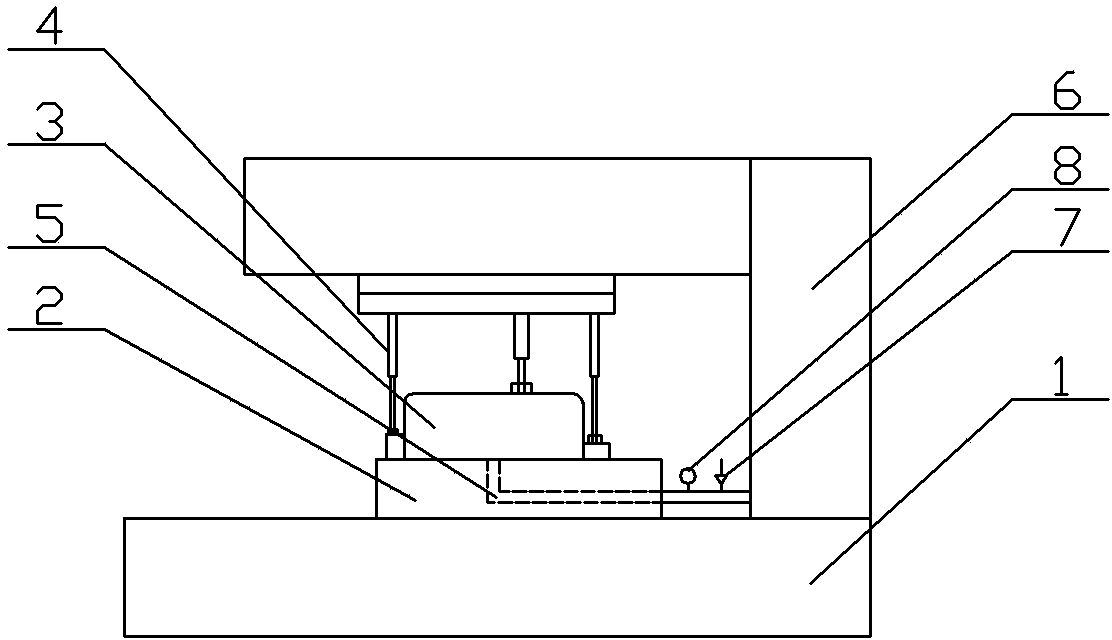

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0013] like figure 1 As shown, the present invention provides an aluminum casting air tightness detection device, including a detection platform 1, and a base 2 arranged on the detection platform 1, the upper surface of the base 2 is provided with a sealing surface matching the aluminum casting 3 On the mating surface, the base 2 is provided with an extruded aluminum casting 3 and a hydraulic ejector rod 4 connecting the screw holes. The base 2 is provided with a vent hole corresponding to the cavity of the aluminum casting 3, and the vent hole is connected to the On the compressor 6, an electromagnetic valve 7 and a barometer 8 are connected in series on the vent pipe 5. In order to ensure the strength of the vent pipe 5 and prolong its service life, the vent pipe 5 adopts a metal pipe.

[0014] In use, the aluminum casting 3 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com