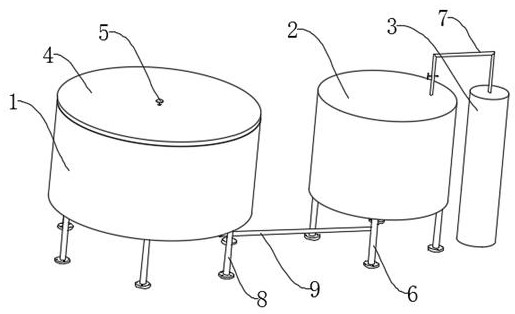

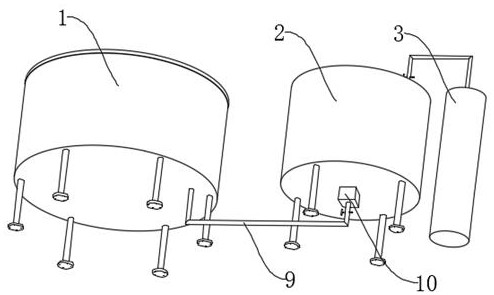

Air tightness detection equipment for precise aluminum casting

A technology of air tightness detection and aluminum casting, applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leak point, etc., to achieve the effect of improving detection and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

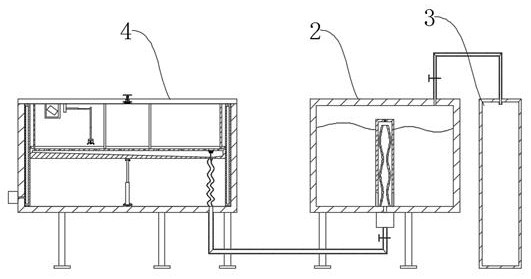

[0049] like Figure 8 As shown, the upper inner wall of the inner chamber 20 is fixedly welded with a vertically distributed vertical rod 44, and a sealing plug 43 is slidably arranged on the vertical rod 44. The diameter of the sealing plug 43 is consistent with the diameter of the connecting hole 45, and the vertical rod 44 is The bottom of 44 penetrates to the below of connecting hole 45, and the limit nut 46 that is blocked in the bottom of sealing plug 43 is connected with screw thread on the vertical rod 44, and the upper end outer ring of sealing plug 43 is integrally provided with upper limit ring 42.

[0050] Further, when the sealing plug 43 descends, the lower end of the sealing plug 43 is blocked in the connecting hole 45, and the upper limit ring 42 at the upper end of the sealing plug 43 is restricted on the surface of the inclined plane 48, thereby avoiding the downward leakage of the sealing plug 43.

[0051] like Figure 6 As shown in , the upper cover 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com