Friction no-spark aluminium casting alloy for mine fanparts

A technology for casting aluminum alloy and ventilator, applied in the field of casting aluminum alloy material, can solve the problems of inability to realize, high cost, difficult smelting operation, etc., and achieve the effects of stable performance, low density, and good friction spark safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

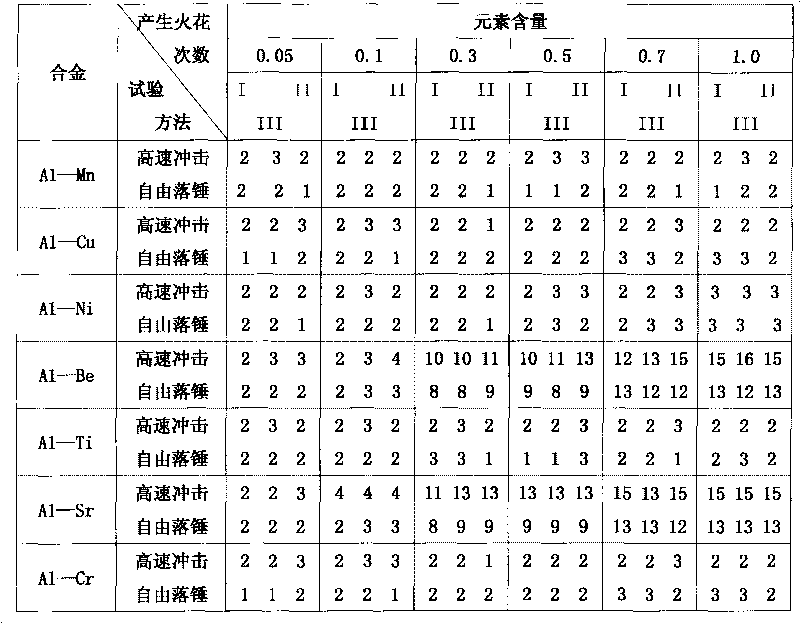

Method used

Image

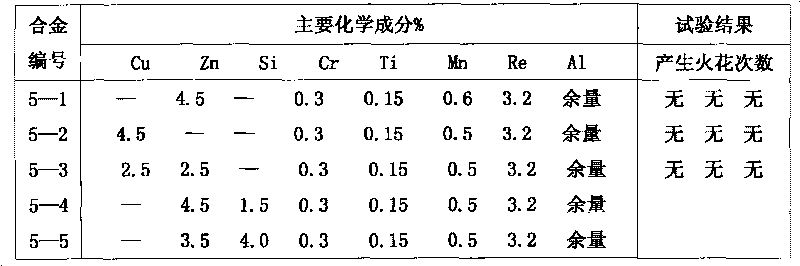

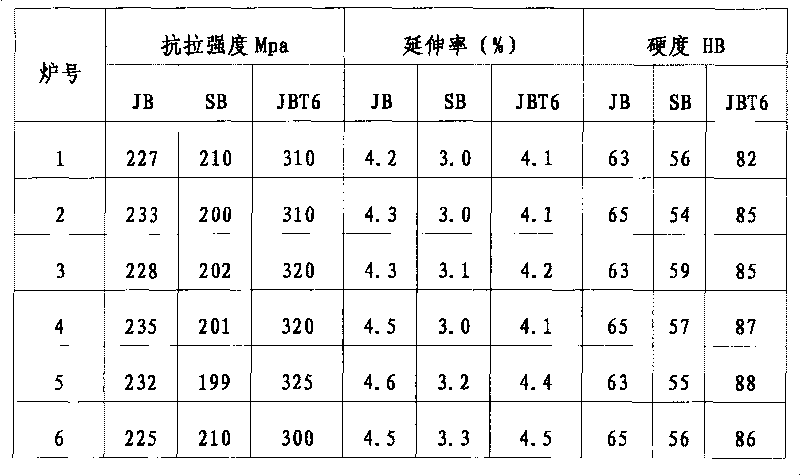

Examples

Embodiment 1

[0048] A friction-free spark-free cast aluminum alloy for mine ventilator parts, the composition and ratio of the aluminum alloy material are as follows: Zn 2.5%, Cu 3%, Cr 0.1%, Ti 0.1%, Mn 0.3 %, Re 2.5%, Si≤1.5%, Mg≤0.5%, Fe≤0.5%, balance Al.

Embodiment 2

[0050] A friction-free spark-free cast aluminum alloy for mine ventilator parts, the composition and ratio of the aluminum alloy material are as follows: Zn 1.0%, Cu 6.0%, Cr 0.3%, Ti 0.15%, Mn 0.8 %, Re 4.5%, Si≤1.5%, Mg≤0.5%, Fe≤0.5%, balance Al.

Embodiment 3

[0052] A friction-free spark-free cast aluminum alloy for mine ventilator parts, the composition and ratio of the aluminum alloy material are: Zn 2.0%, Cu 3.5%, Cr 0.2%, Ti 0.15%, Mn 0.5% by weight %, Re 3.5%, Si≤1.5%, Mg≤0.5%, Fe≤0.5%, balance Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com