High-temperature-resistant aluminium casting alloy and cast part for internal combustion engines cast from such an alloy

A technology for casting aluminum alloys and internal combustion engines, which is applied in the field of casting aluminum alloys, can solve problems such as increased thermal cracking tendency and limited casting performance, and achieves the effects of improving tolerance, good casting performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

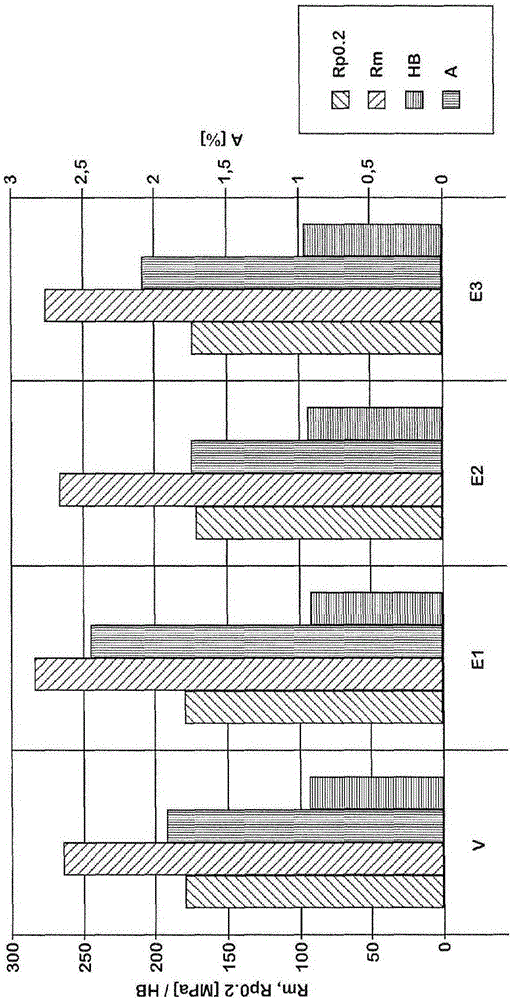

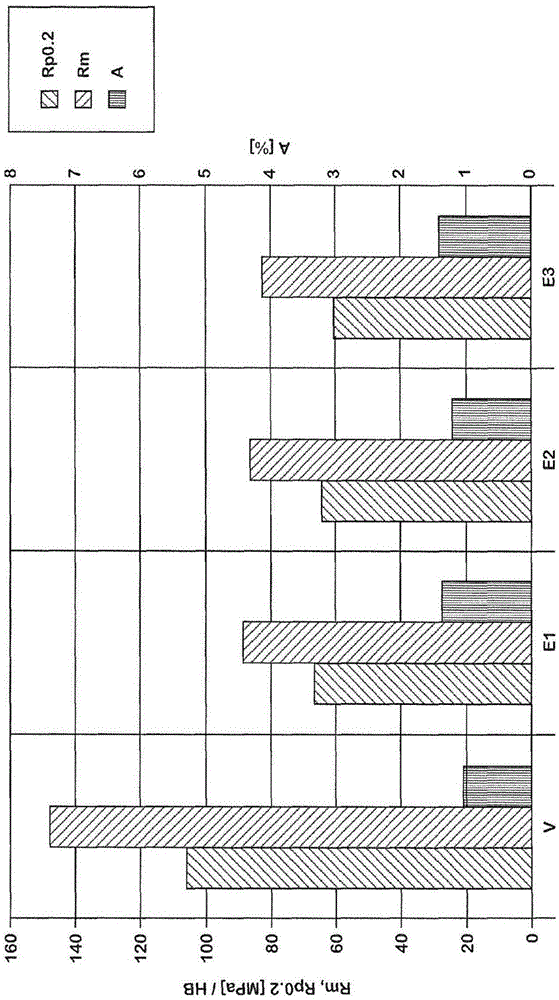

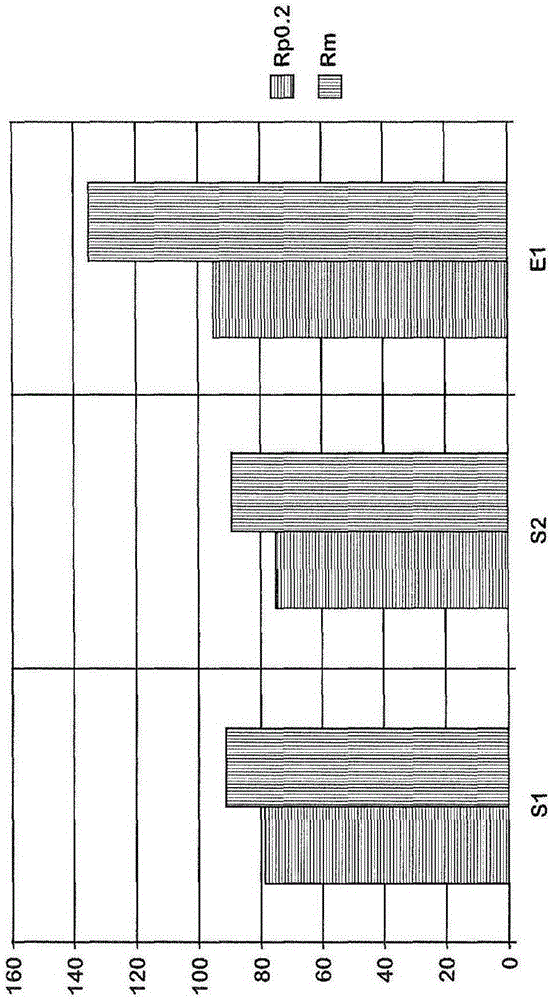

[0030] Three cast aluminum alloys E1, E2, E3 according to the invention were melted, the compositions of which are indicated in Table 1. Comparative alloy V was melted for comparison, the composition of which is likewise listed in Table 1 corresponding to the usual cast aluminum alloy "AlCu7MnZr".

[0031] Cylinder heads were cast from cast aluminum alloys E1, E2, E3, V, which were subjected to T6W treatment after solidification. Here, the cylinder heads were solution annealed at 480-500° C. for seven and a half hours each, then quenched with water and then thermally aged at 240° C. for over four hours. The mechanical properties were subsequently measured on the thus treated cylinder head in the area of the combustion chamber: tensile strength Rm, yield point Rp0.2, Brinell hardness HB and elongation at break A. Forty casting samples each made of cast aluminum alloys E1 and E2 and fifteen casting samples each made of cast aluminum alloy E3 and comparative alloy V were exami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com