Roll ring steel for aluminium casting rolling mill and heat treatment method thereof

A technology of final heat treatment and roller sleeves, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as fatigue cracks, bursts, economic losses, etc., to improve the ability to resist thermal fatigue cracks, increase service life, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Steel is made in a 26-ton electric arc furnace, and two 13.2-ton octagonal steel ingots (steel ingots for free forging) are poured. The steel-making raw materials are mainly selected scrap steel, steel-making pig iron, and corresponding ferroalloys. The total weight of raw materials for each furnace is 33 tons. The deoxidation of molten steel uses Si-Ca iron instead of aluminum deoxidation. The molten steel also needs to be refined in a 30-ton ladle refining furnace. During the refining process, fine-tuning of components and vacuum refining and degassing are carried out. The vacuum degree is <133Pa, and the degassing time is 12 minutes. The final chemical composition (weight percent) of molten steel is: C 0.43, Mn 0.76, Si 0.39, P 0.012, S 0.008, Cr 2.80, Ni 0.90, Mo 1.10, V 0.18, Al 0.01, and the rest are iron and other impurities.

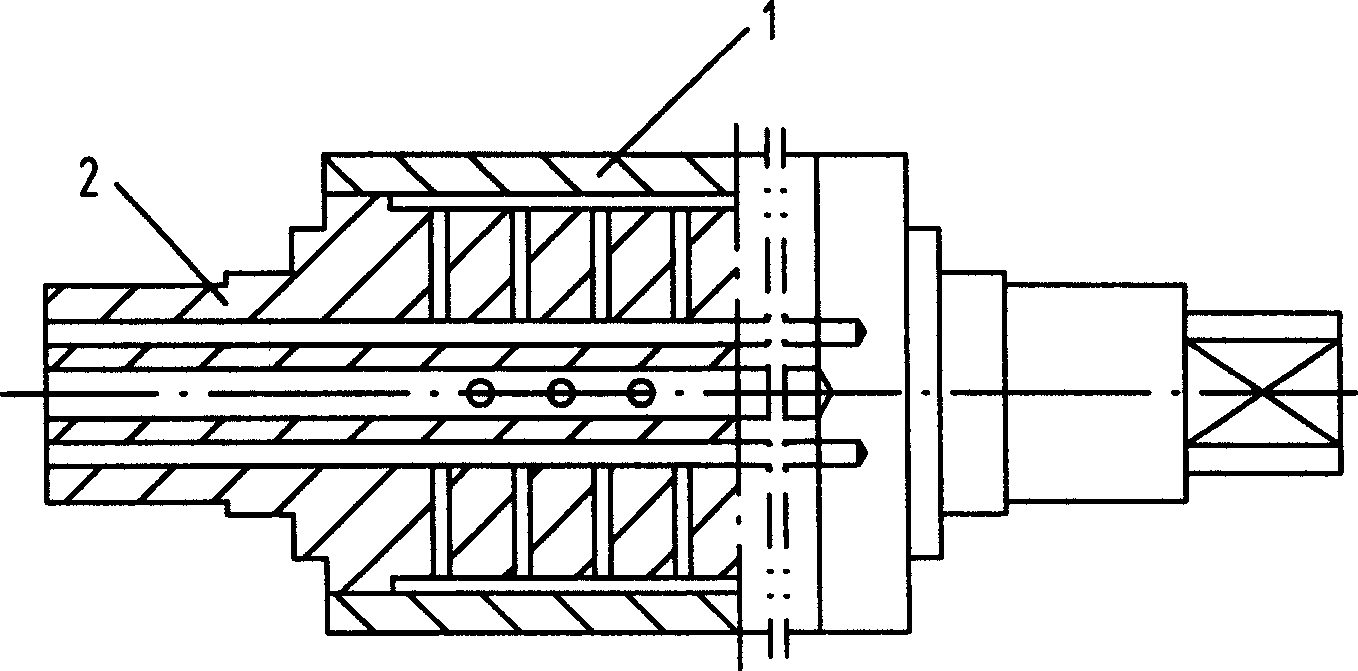

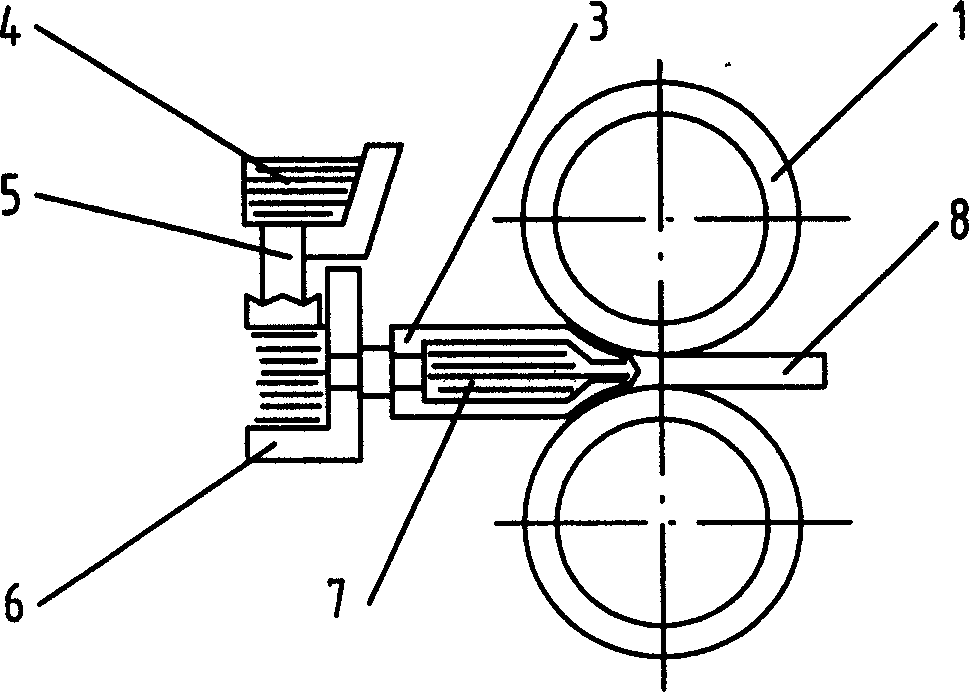

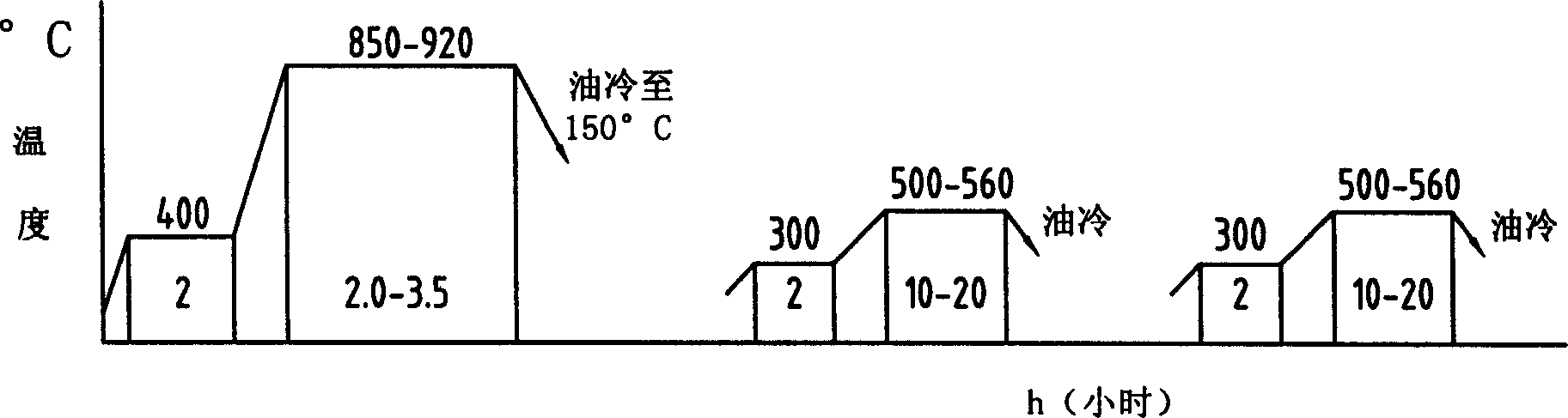

[0015] The steel ingot is forged on a 2,500-ton hydraulic press to form two cylindrical forging blanks with an outer diameter of 1,000m...

Embodiment 2

[0020] Steel is made in a 26-ton electric arc furnace, and two 13.2-ton octagonal steel ingots (steel ingots for free forging) are poured. The steel-making raw materials are mainly selected scrap steel, steel-making pig iron, and corresponding ferroalloys. The total weight of raw materials for each furnace is 33 tons. The deoxidation of molten steel uses Si-Ca iron instead of aluminum deoxidation. The molten steel also needs to be refined in a 30-ton ladle refining furnace. During the refining process, fine-tuning of components and vacuum refining and degassing are carried out. The vacuum degree is <133Pa, and the degassing time is 12 minutes. The final chemical composition (weight percent) of molten steel is: C 0.38, Mn 0.70, Si 0.35, P 0.011, S 0.008, Cr 2.40, Ni 0.70, Mo 0.95, V 0.15, Al 0.01, and the rest are iron and other impurities.

[0021] Each steel ingot is forged on a 2,500-ton hydraulic press to form two cylindrical forging billets with an outer diameter of 730m...

Embodiment 3

[0025] Steel is made in a 26-ton electric arc furnace, and two 13.2-ton octagonal steel ingots (steel ingots for free forging) are poured. The steel-making raw materials are mainly selected scrap steel, steel-making pig iron, and corresponding ferroalloys. The total weight of raw materials for each furnace is 33 tons. The deoxidation of molten steel uses Si-Ca iron instead of aluminum deoxidation. The molten steel also needs to be refined in a 30-ton ladle refining furnace. During the refining process, fine-tuning of components and vacuum refining and degassing are carried out. The vacuum degree is <133Pa, and the degassing time is 12 minutes. The final chemical composition (weight percent) of molten steel is: C 0.32, Mn 0.62, Si 0.30, P 0.012, S 0.009, Cr 2.20, Ni 0.65, Mo 0.83, V 0.16, Al 0.01, and the rest are iron and other impurities.

[0026] Each steel ingot is forged on a 2,500-ton hydraulic press to form three cylindrical forging blanks with an outer diameter of 690...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com