Patents

Literature

37results about How to "Reduce production failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

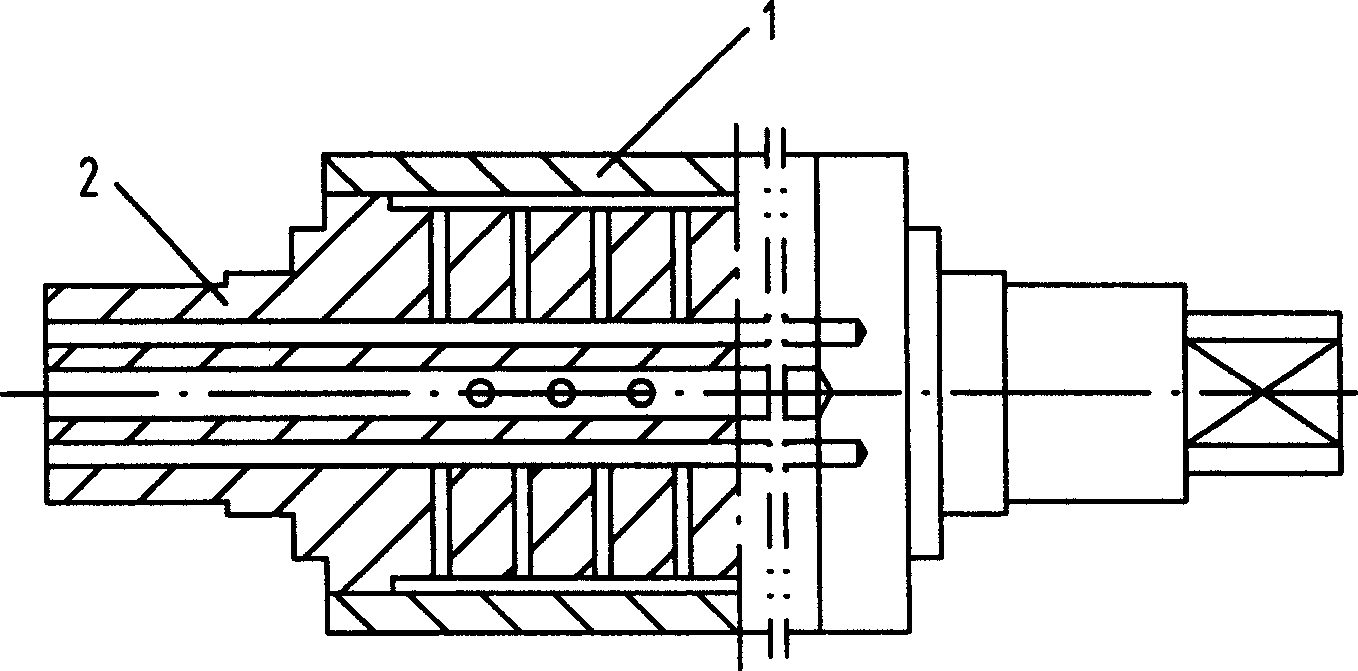

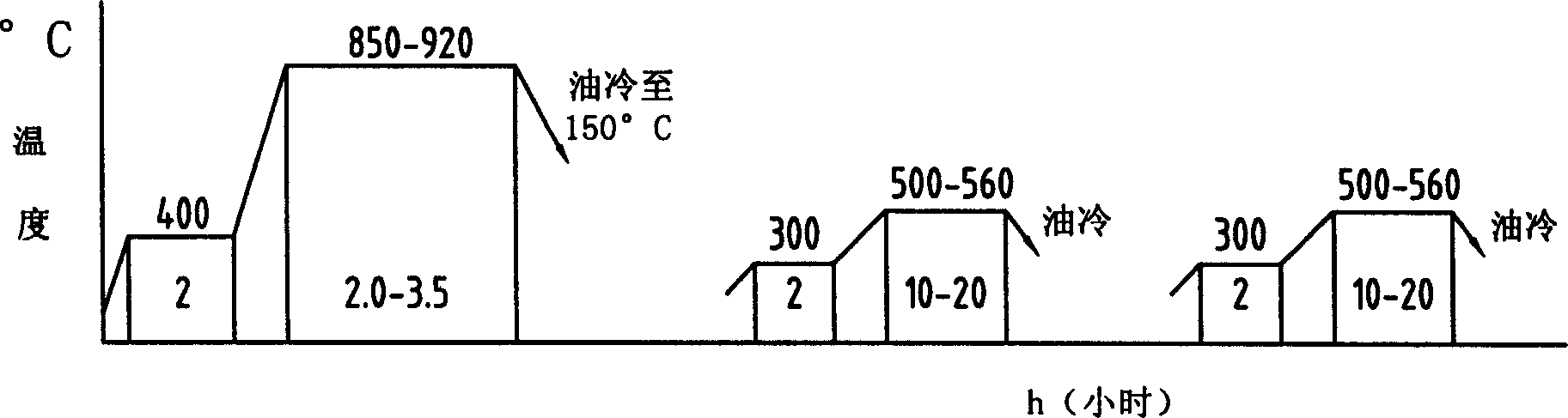

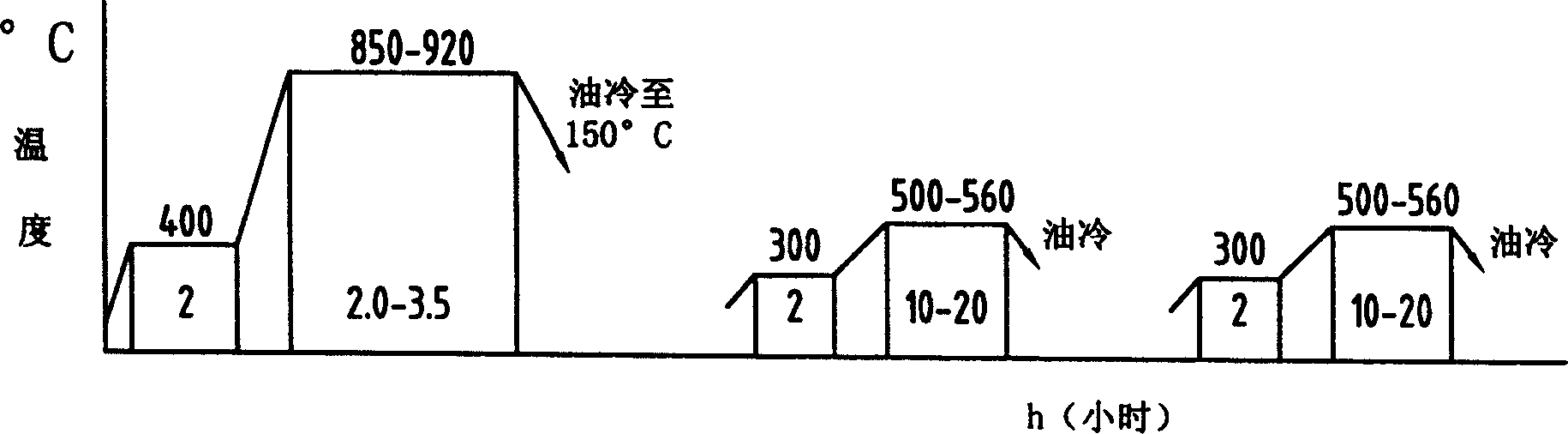

Roll ring steel for aluminium casting rolling mill and heat treatment method thereof

InactiveCN1594636AImproved resistance to thermal fatigue cracksExtended service lifeFurnace typesHeat treatment furnacesStrip millAluminium casting

The invention relates to a roll ring steel for aluminum casting rolling mill and its heat treatment method. Chemical ingredient weight percentage of roll ring steel for aluminum casting rolling mill are : C 0.30-0.45, Mn 0.60-0.80, Si 0.20-0.40, P <=0.025, S <=0.025, Cr 2.00-3.00, Ni 0.50-1.00, Mo 0.80-1.20, V 0.10-0.20, Al <=0.012, surplus being ferrum and other impurity. The final heat treatment method of roll ring steel adopt second tempering after quenching. Quenching temperature is 850-920 DEG C , and proceeding in engine oil after heat preservation. In first tempering, roll ring is heated to 500-560 DEG C , insulated 10-20 hours, cooled in engine oil. The second tempering parameters are same with that of first tempering. The invention promotes anti heat fatigue crack capability of roll ring, so promotes the life of roll ring.

Owner:李春治

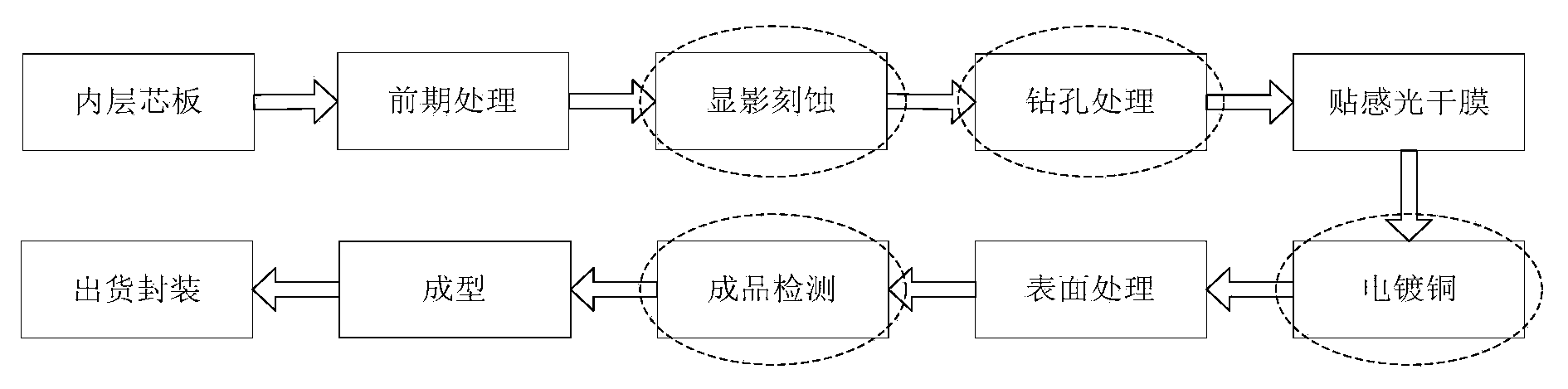

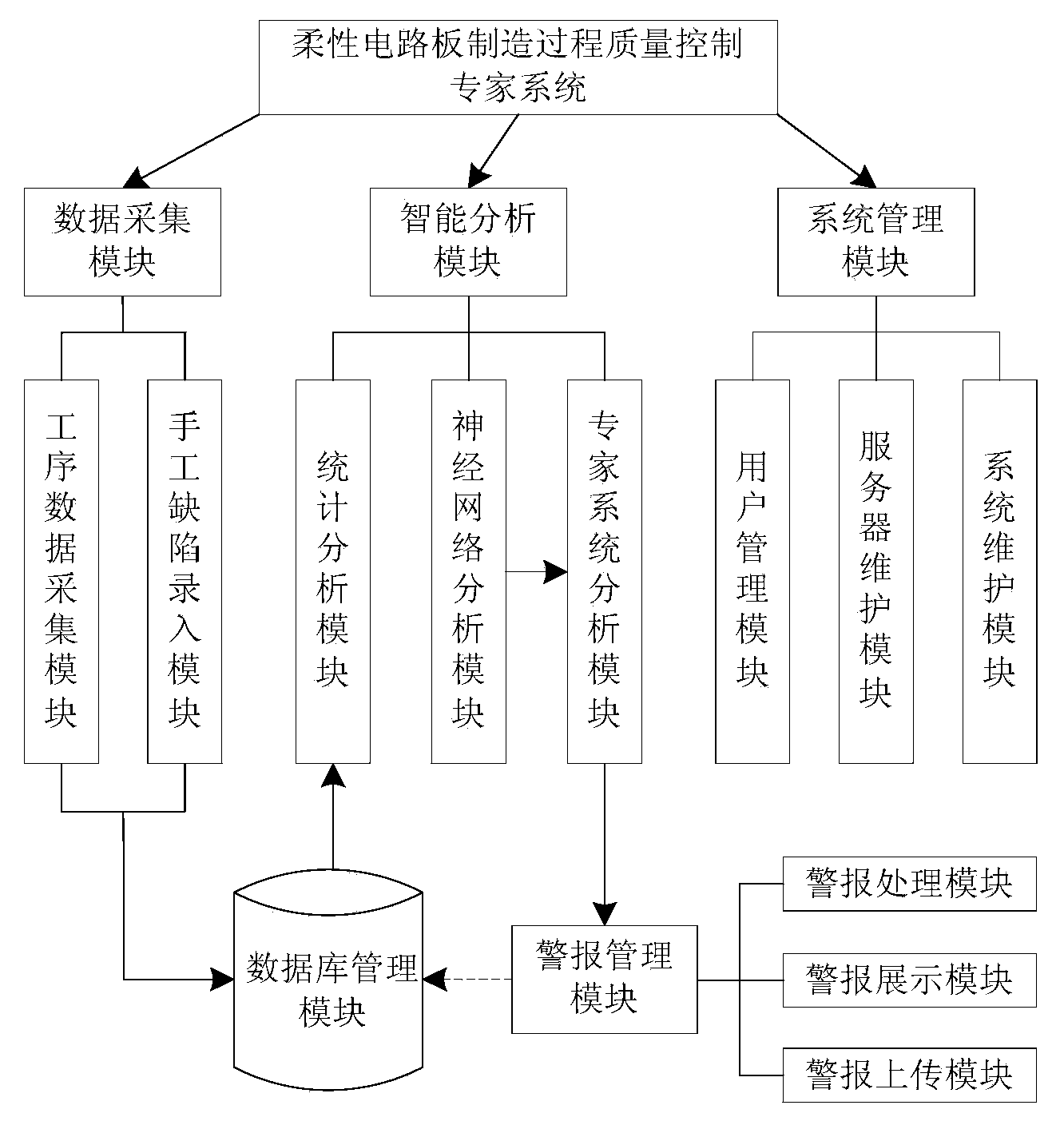

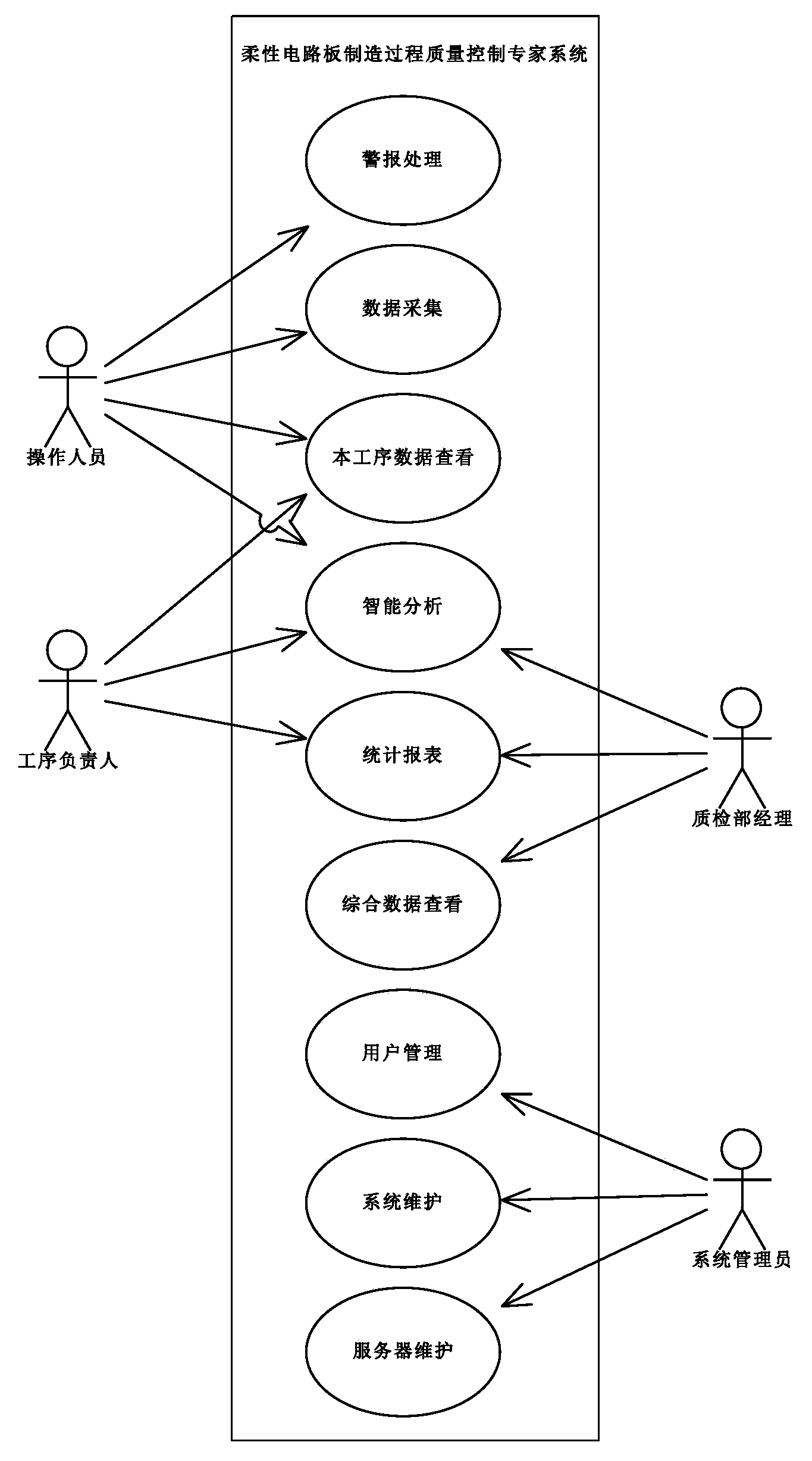

Quality control expert system and method for FPC manufacturing process

InactiveCN104238505AHigh degree of automationIncrease productivityTotal factory controlProgramme total factory controlQuality controlComputer module

The invention discloses a quality control expert system and method for an FPC manufacturing process. The system comprises a data collection module, an intelligent analysis module, a warning management module and a database management module. Key physical parameters and FPC defect data of FPC manufacturing procedures are collected through the data collection module; afterwards, the physical conditions of the procedures are evaluated through a neural network; finally, defects generated in the procedures are automatically diagnosed and analyzed through an expert system, and early warning and warning are performed according to the diagnosis results and analysis results of the defects. The expert system diagnoses and analyzes the corresponding defects on the basis of the neural network, so that the bottleneck problem of knowledge acquisition for the expert system and the problems of misdiagnosis and rule conflicts in the diagnosis process are solved. According to the quality control expert system and method, the problems existing in quality control and defect analysis of the key working procedures in the FPC manufacturing process at present can be effectively solved, increase of the automation degree of the whole FPC manufacturing process and improvement on the production efficiency in the whole FPC manufacturing process are facilitated, and production failures are reduced.

Owner:SOUTH CHINA UNIV OF TECH

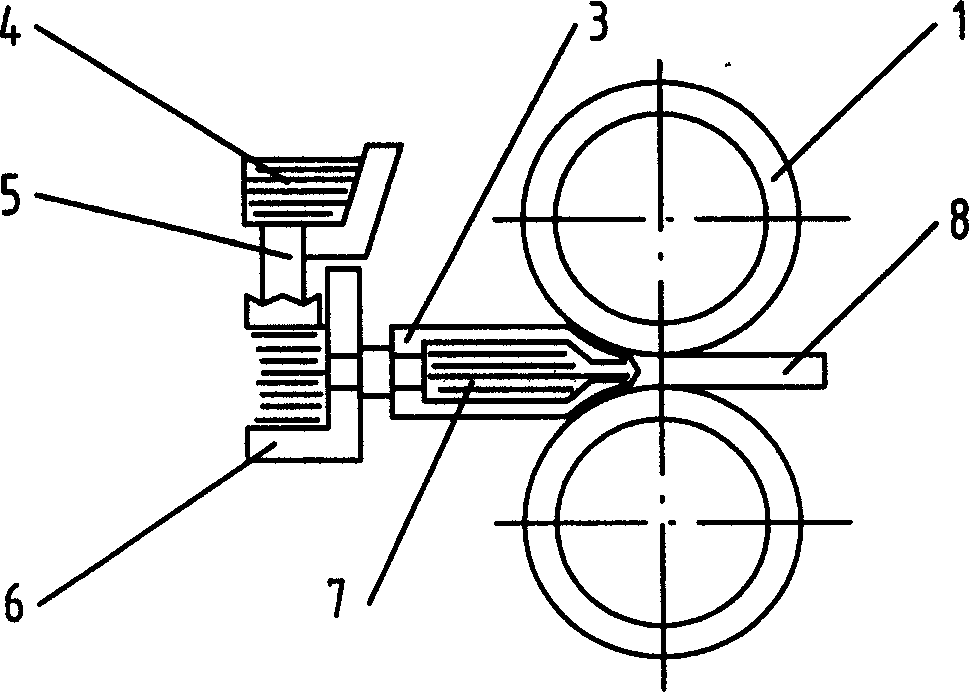

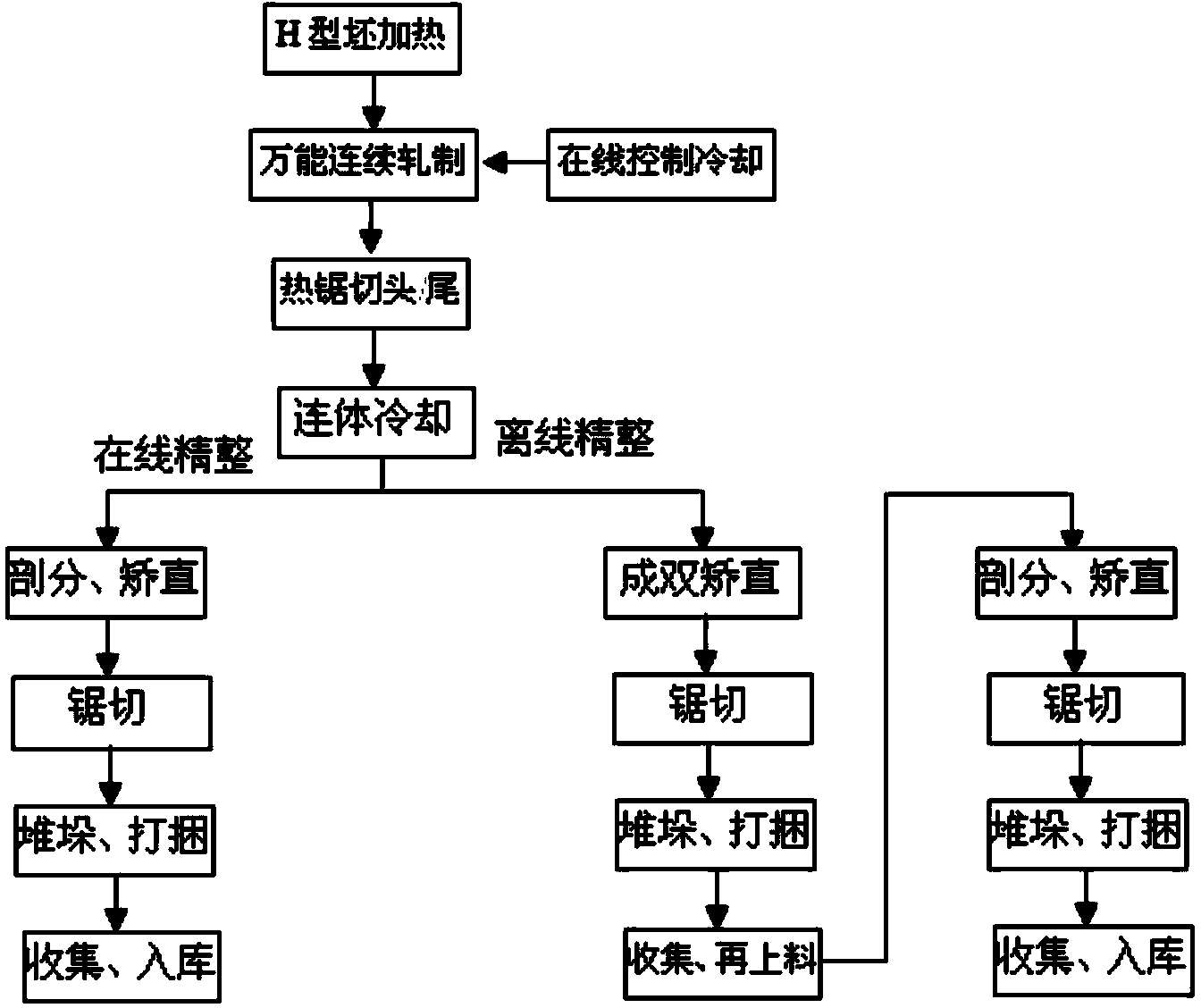

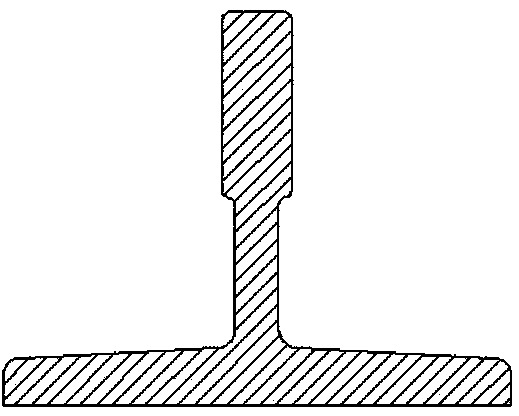

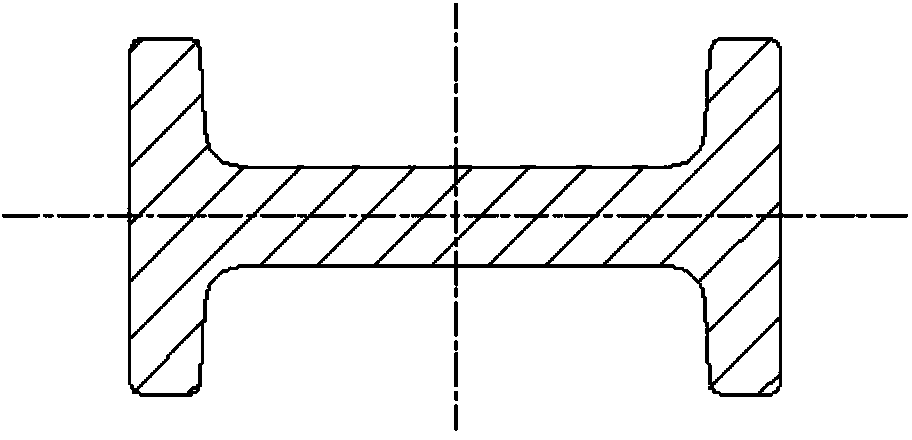

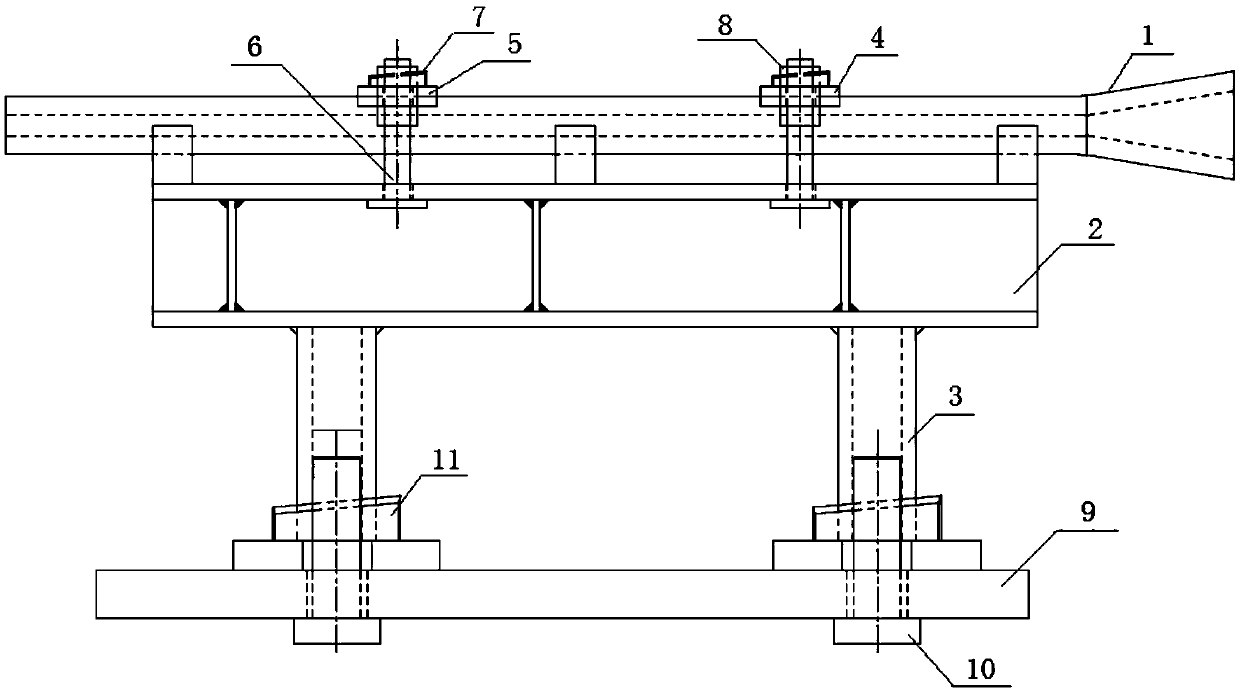

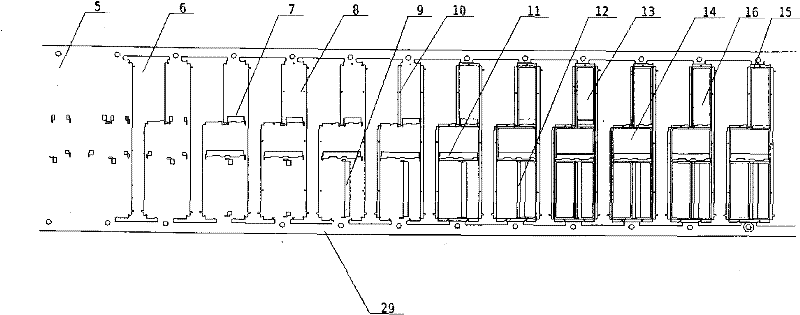

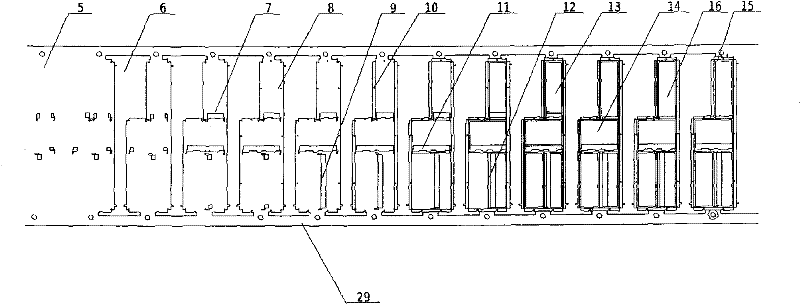

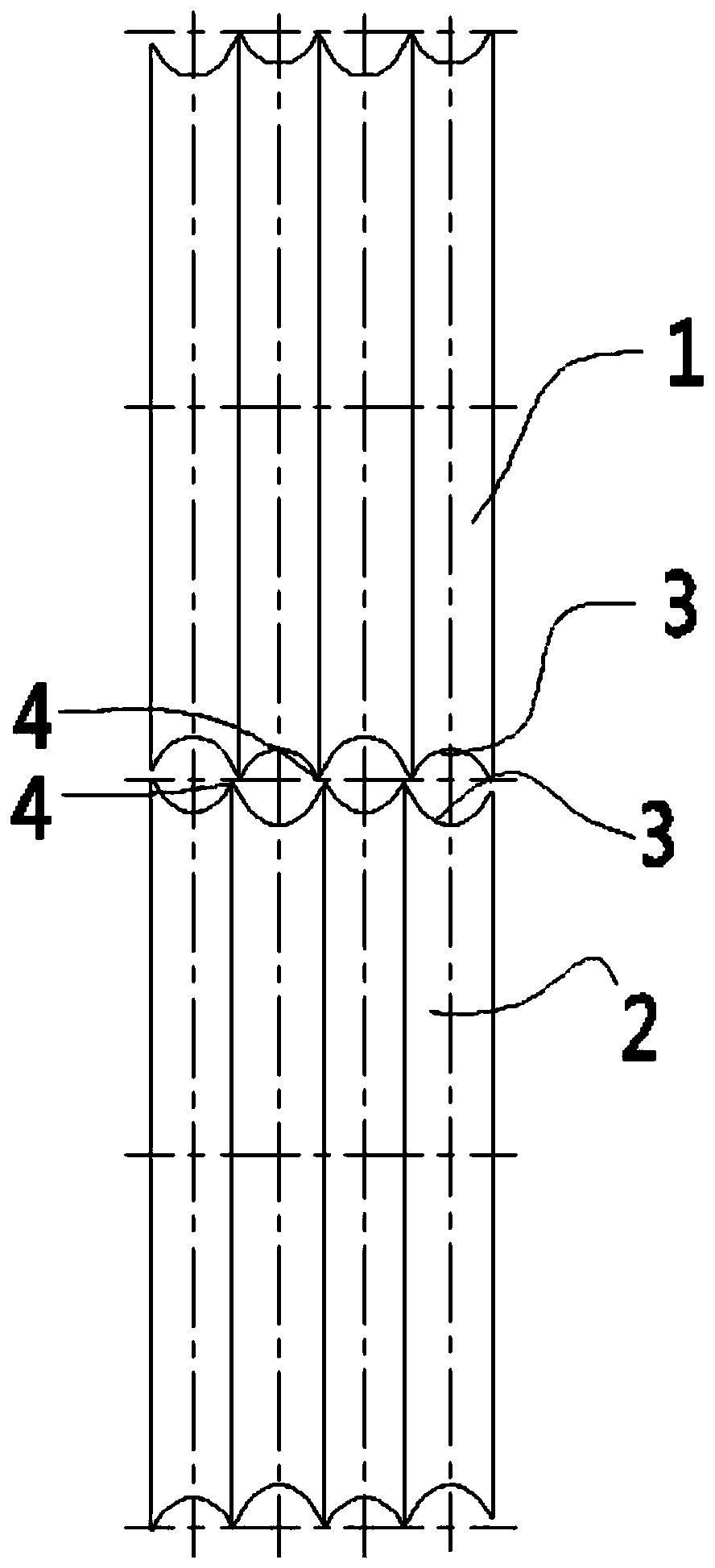

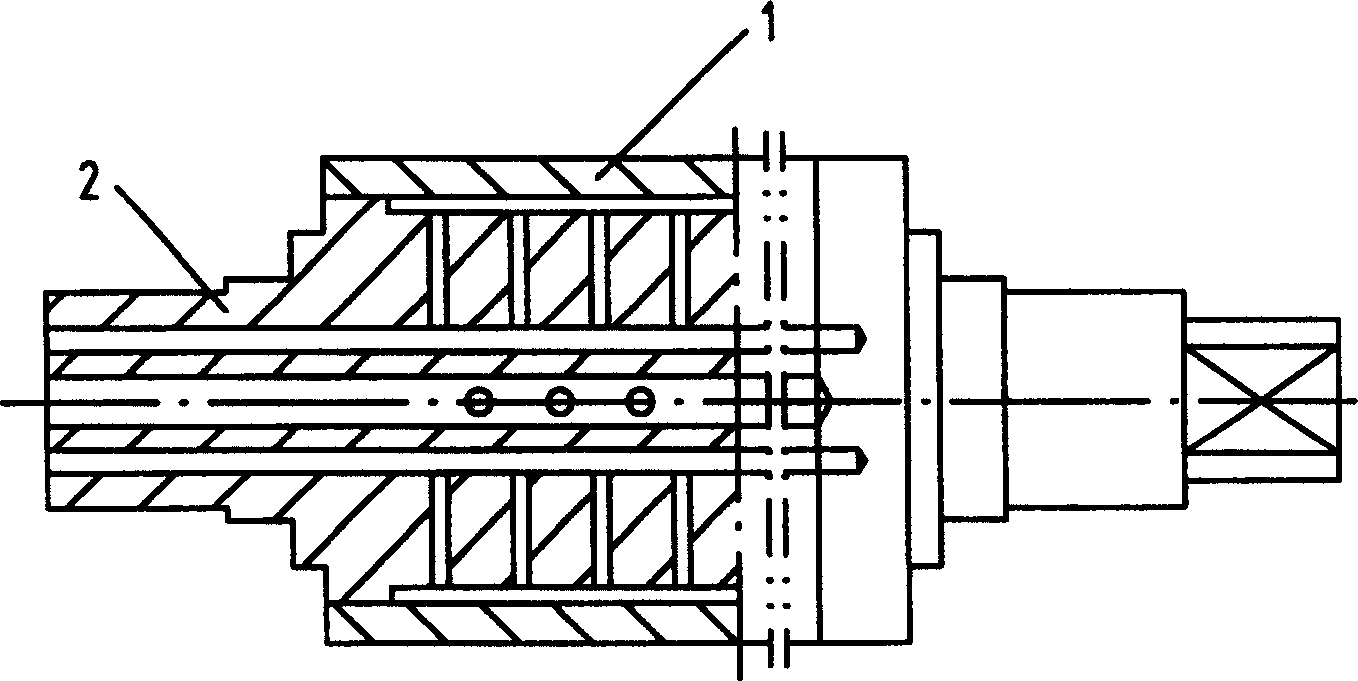

Long-length rolling method and production line of T-shaped elevator guide rails

InactiveCN104014587ASolve the problem of bending on coolingRealization of free specification high precision rollingMetal rolling arrangementsProduction lineEngineering

The invention discloses a long-length rolling method and a production line of T-shaped elevator guide rails. The method mainly comprises the steps of firstly, taking an H-shaped continuously cast bloom as an original blank; secondly, feeding the H-shaped continuously cast bloom to the universal paired one-piece rolling procedure to obtain a pair of symmetrical T-shaped guide rails; thirdly, feeding the one-piece T-shaped guide rails into a cooling device to be cooled, and conducting subdivision and straightening on the one-piece T-shaped guide rails to obtain two independent finished T-shaped rolled pieces; finally, conducting fixed-length sawing and other follow-up processing procedures on the subdivided finished T-shaped rolled pieces to obtain a final finished product. According to the long-length rolling method and the production line of the T-shaped elevator guide rails, cooling bending of a single elevator guide rail caused by limitation of the cooling condition after universal rolling can be avoided, the surface quality of the elevator guide rails can be improved after rolling, post-rolling internal stress can be improved, the size precision and using performance of the elevator guide rails are improved, and the long-length elevator guide rail production technology featured in long-length rolling, long-length cooling and long-length straightening is realized.

Owner:CISDI ENG CO LTD

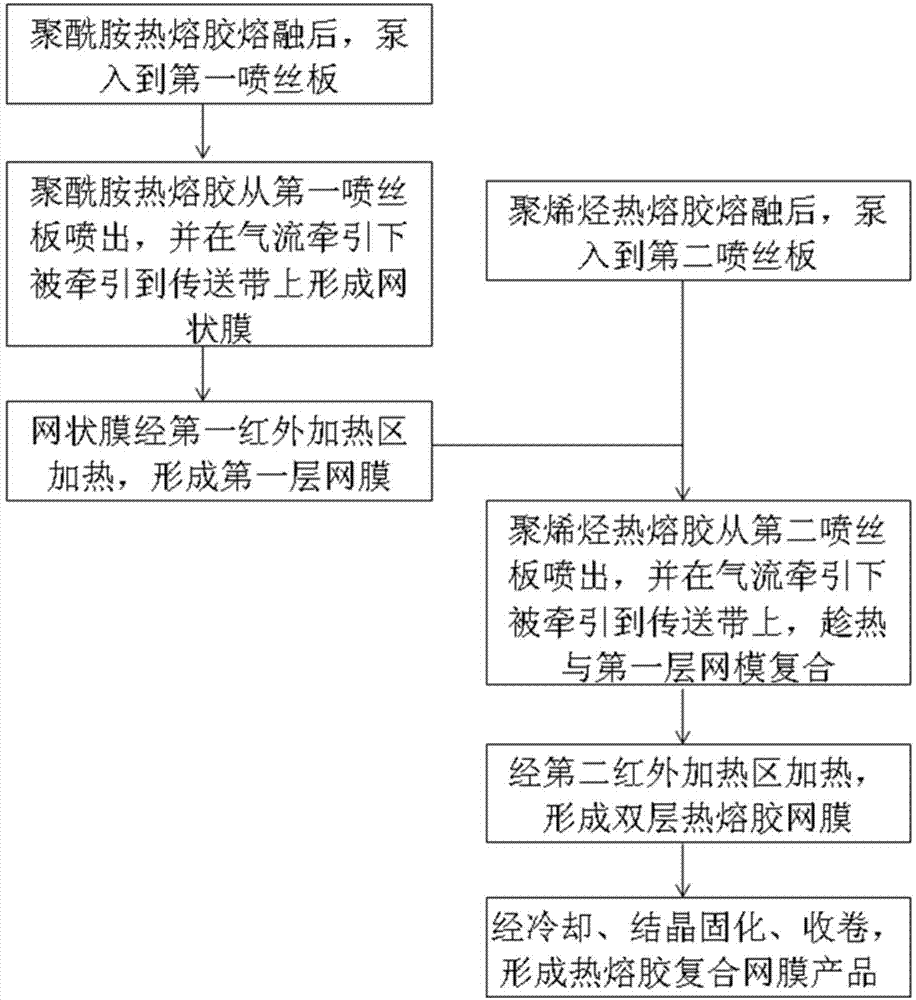

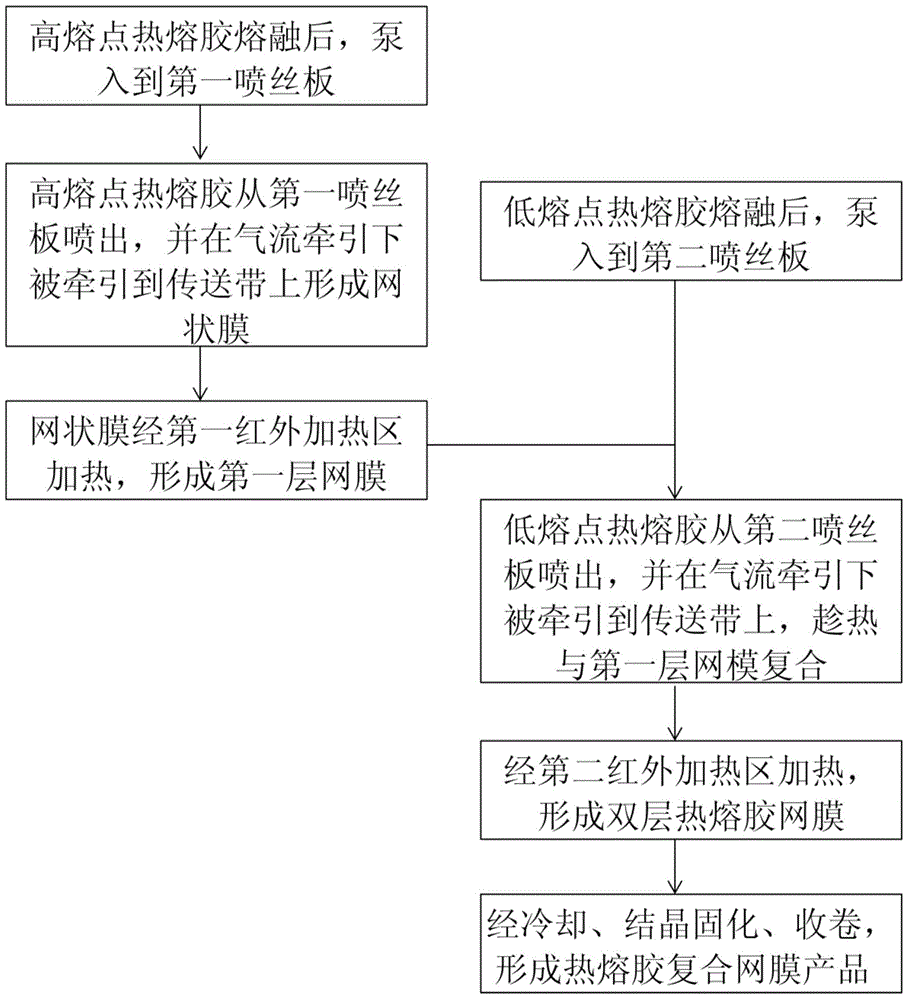

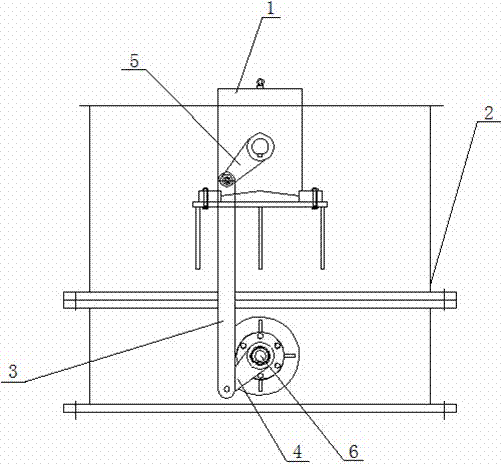

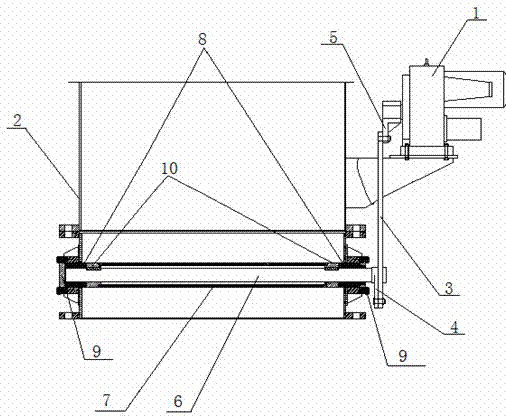

Combined hot melt adhesive net film and preparing technology thereof

ActiveCN104711772AHigh bonding strengthBonding is durable and stableNon-macromolecular adhesive additivesSpinnerette packsPolymer sciencePolyolefin

The invention discloses a combined hot melt adhesive net film and a preparing technology thereof, and particularly relates to a combined hot melt adhesive net film used for bonding metal and nonpolar materials and a preparing technology of the combined hot melt adhesive net film. Due to the fact that the specific formula is adopted, the polar polyamide hot melt adhesive and the nonpolar polyolefin including a bulking agent are effectively fused. According to the combined hot melt adhesive net film prepared through the technology, the bonding strength of the combined hot melt adhesive net film is high, bonding is durable and stable, and the combined hot melt adhesive net film is particularly suitable for bonding and combining of stainless steel, aluminum, copper and other metal materials with polyethylene, polypropylene and other nonpolar polymers. Meanwhile, according to the preparing technology, the process from raw material preprocessing to final finished combined hot melt adhesive net film preparing is finished in one set of production procedures, the production fault can be greatly reduced, the production efficiency is high, and cost is low.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

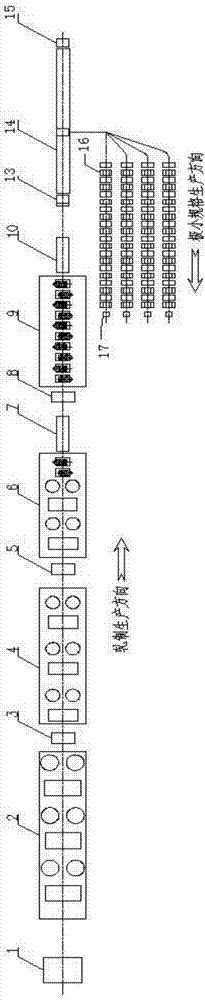

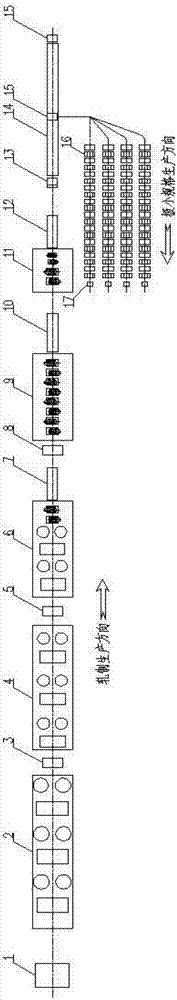

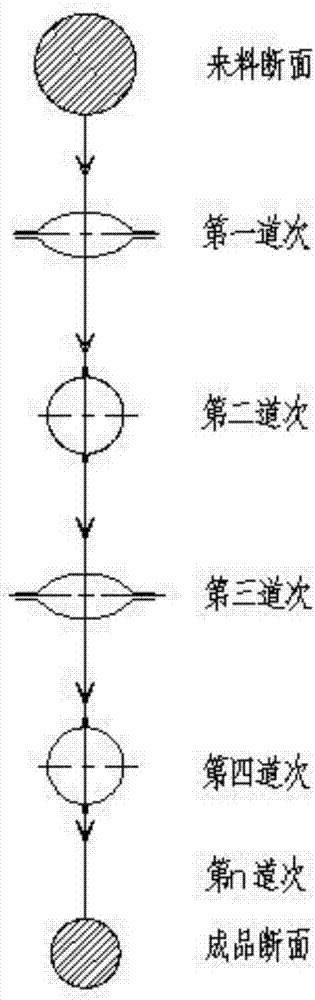

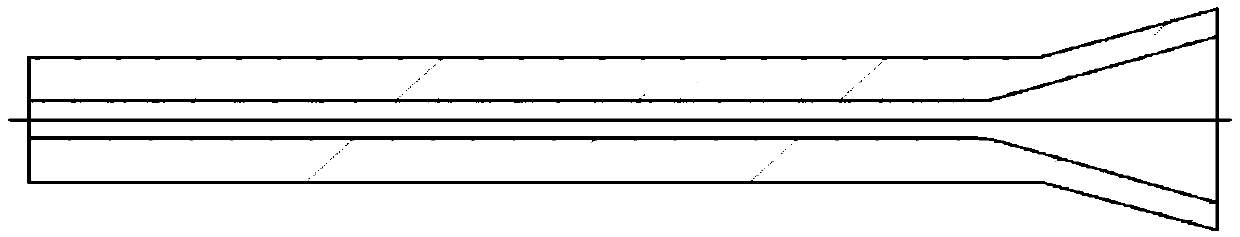

Technological arrangement and preparation method of minimal-specification tire cord steel wire rods

InactiveCN107138524AHigh precisionReduce production failureWork treatment devicesMetal rolling arrangementsWire rodProduction line

The invention relates to a technological arrangement and preparation method of minimal-specification tire cord steel wire rods. The technological arrangement of the minimal-specification tire cord steel wire rods comprises a high-speed wire rod production line and further comprises a minimal-specification rolling production line arranged behind the high-speed wire rod production line. The minimal-specification rolling production line comprises a cluster mill unit. After a gathered roll is collected, the temperature of tire cord steel is kept at 400-600 DEG C, then minimal-specification continuous rolling is conducted, and rolling is conducted for 10-20 passes. By the adoption of the technological arrangement and preparation method of the minimal-specification tire cord steel wire rods, the minimal-specification tire cord steel at the dimension of phi4.5 mm-phi1.6 mm can be produced, the fault rate is effectively reduced in the wire rod production process, the labor consumption, the machine consumption, the equipment consumption and the like of the follow-up drawing step are greatly reduced, and the production cost is reduced.

Owner:CISDI ENG CO LTD +1

Vehicle carpet using unfigured island non-woven open-edge waste material

ActiveCN105401336AAppropriate wayReduce wasteVehicle arrangementsRoad vehiclesLow-density polyethylenePolyester

The invention relates to a vehicle carpet using unfigured island non-woven open-edge waste material; the preparation method comprises the following steps: 1, opening and mixing: opening polyester fiber 60-95% and unfigured sea island fiber open-edge waste material 5-40% by two rough openers, sending the material into a large chamber cotton blender for mixing, and opening the material by a fine opener; 2, carding and netting: feeding the finely opened mixture fibers into a carding machine, carding the fibers so as to form uniform single layer cotton web, and using a lapping machine to lap the single layer cotton web into thick cotton web, and outputting the thick cotton web; 3, needling: using a feeder to feed the thick cotton web, outputted by the lapping machine, into a pre-needle machine for pre-winding reinforcement, using a main needle machine to process the material so as to obtain semi-finished product, and forming the coiled material of needed gram weight by processing the semi-finished product on a coiler; 4, baking: baking the needled coiled material at the temperature of 120-200 DEG C for 2-8 minutes, thus melting the low density polyethylene on the outer layer of the unfigured sea island fiber. The unfigured island non-woven open-edge waste material can be used in the non-decrement field, thus reducing resource waste.

Owner:怡星(沧州)汽车内饰件有限公司

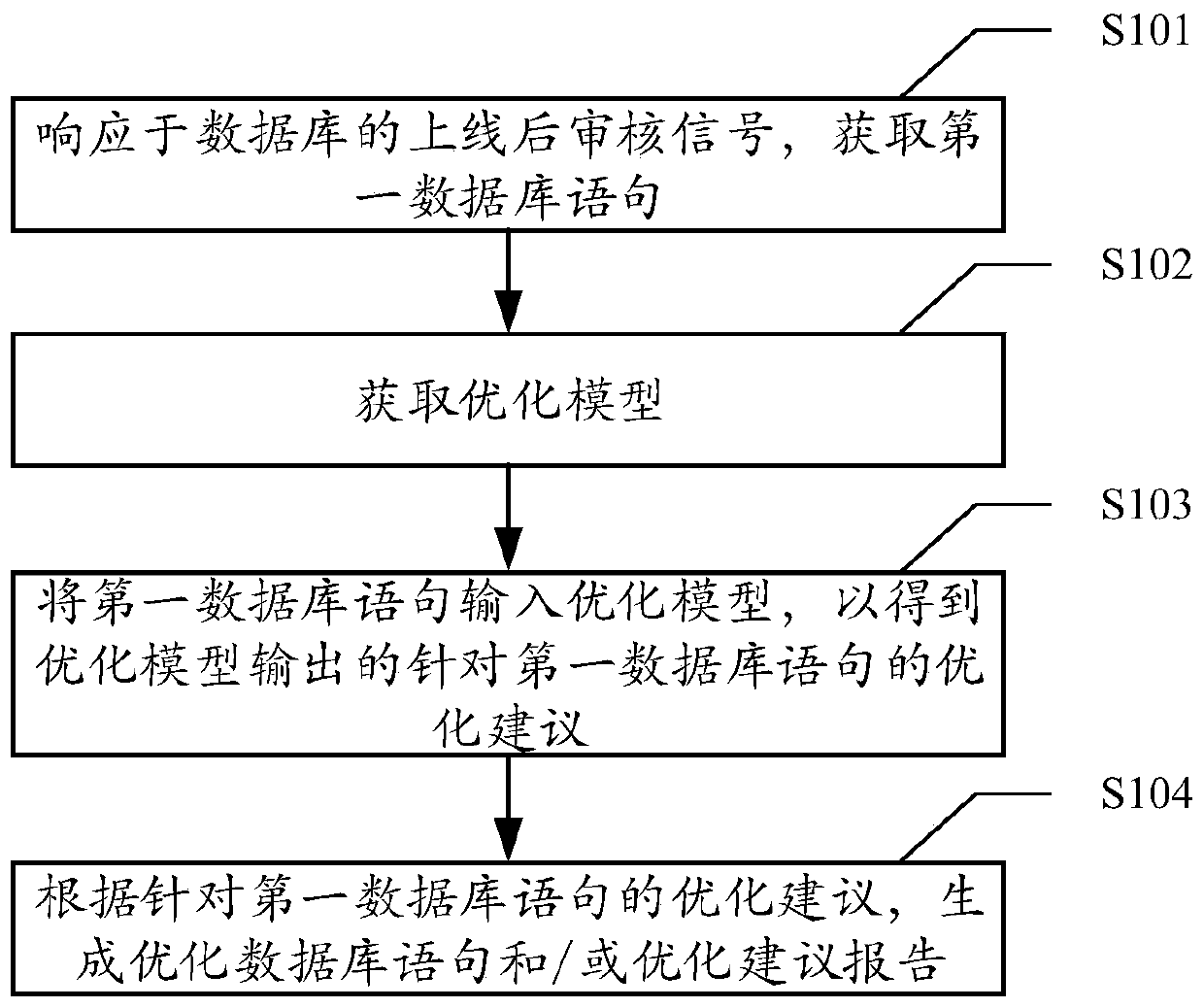

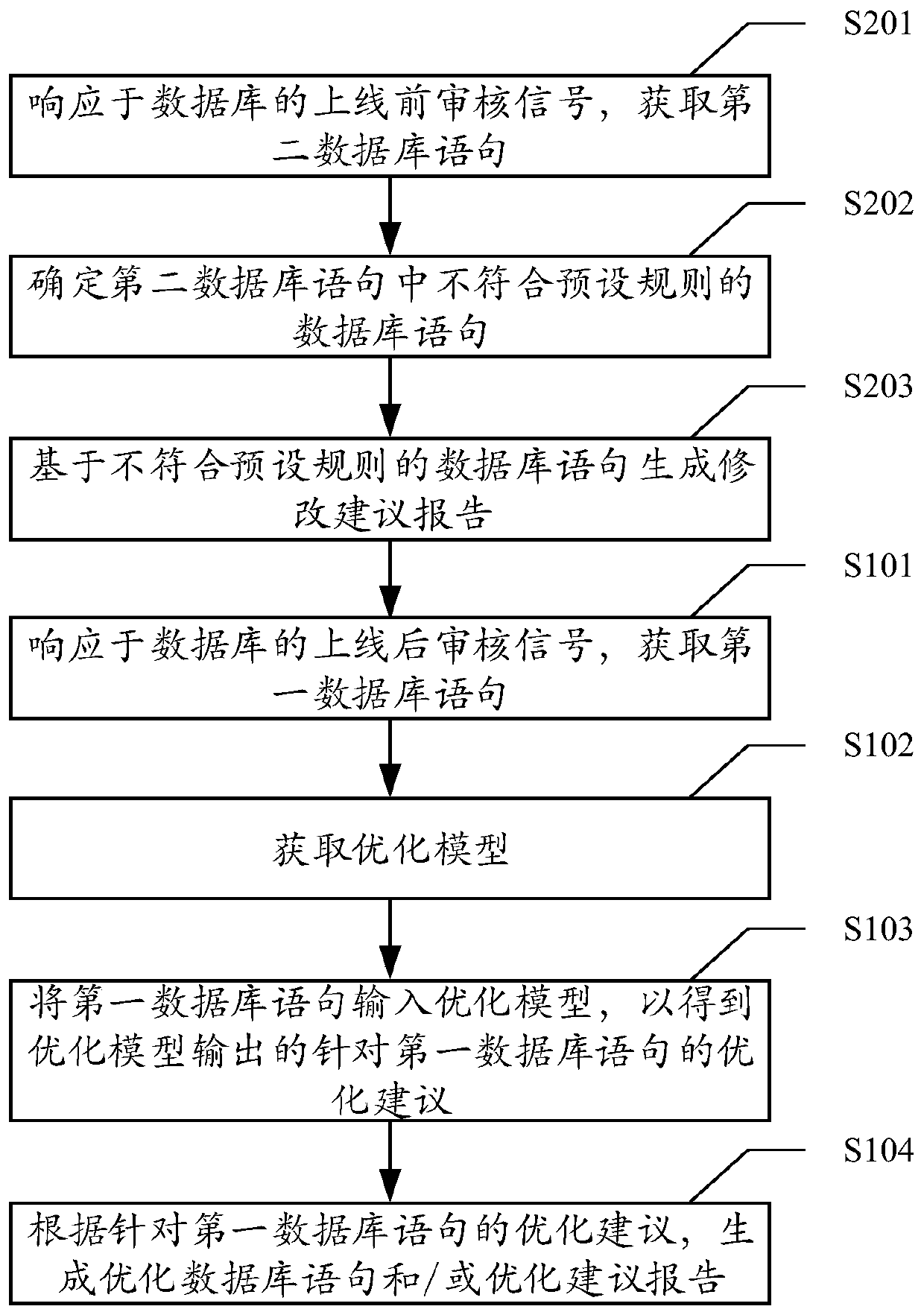

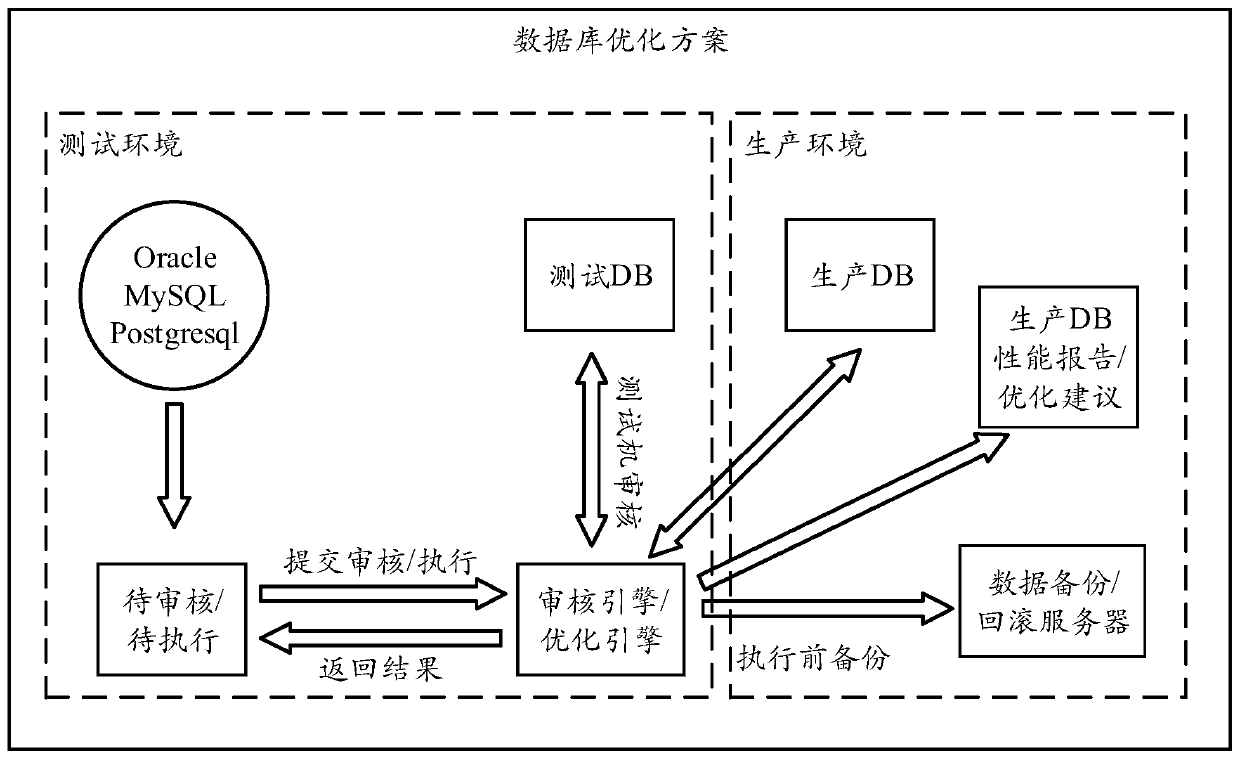

Database optimization method, system and equipment based on vulnerability repair, and medium

PendingCN109753490AReduce production failureExtended availabilityDatabase design/maintainanceDatabase optimizationVulnerability

The invention provides a database optimization method based on vulnerability repair. The method is characterized by comprising: obtaining a first database statement in response to an online post-auditing signal of a database; obtaining an optimization model, and the optimization model is used for outputting corresponding optimization suggestions for database statements input into the optimizationmodel; inputting the first database statement into an optimization model to obtain an optimization suggestion which is output by the optimization model and aims at the first database statement; and generating an optimized database statement and / or an optimized suggestion report according to the optimized suggestion for the first database statement. The invention further provides a database optimization system based on vulnerability restoration, computer equipment and a computer readable storage medium.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

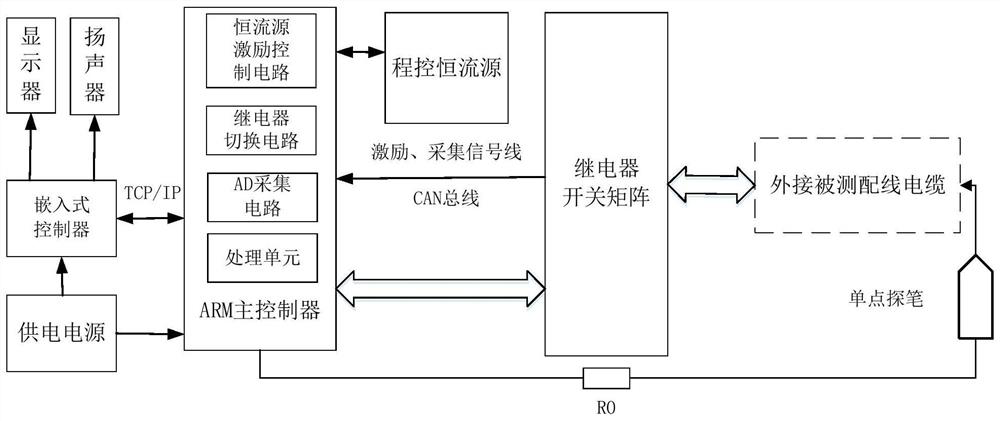

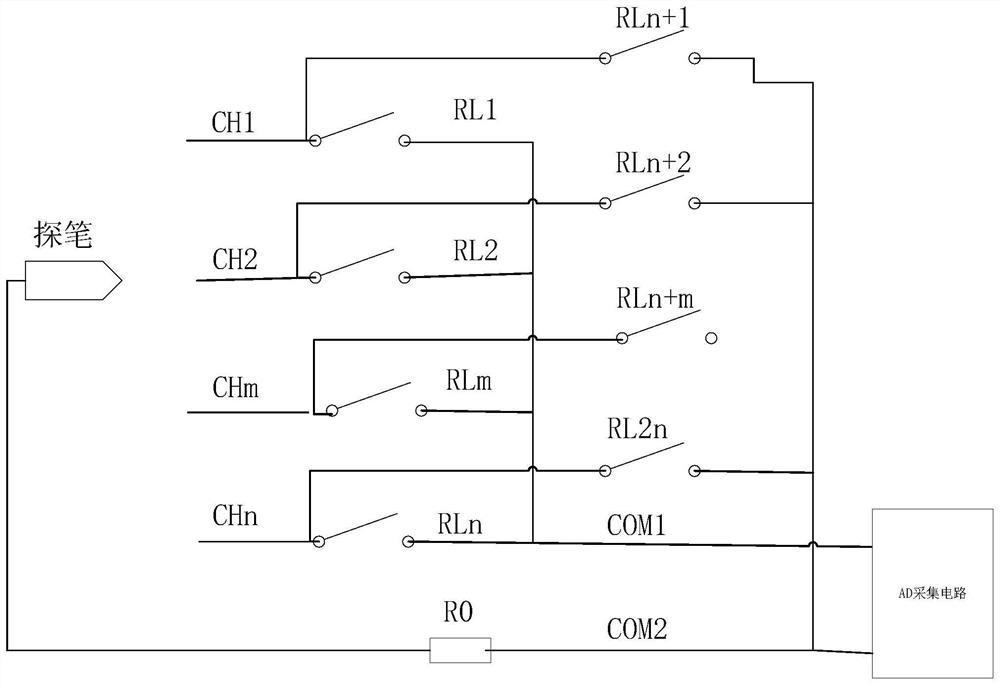

Automatic cable wiring detection system

PendingCN111830428AImplement automatic detection and matchingReduce work intensityShort-circuit testingMeasurement instrument housingElectrical resistance and conductanceComputer science

The invention provides an automatic cable wiring detection system. A relay switch matrix is connected with one end of a tested cable; an AD acquisition circuit is used for acquiring the on resistanceof a loop where the tested cable core is located in real time; a connection point at the other end of the tested cable core is automatically searched according to whether the on resistance is the sameas the resistance of the standard resistor, and automatic detection and matching of cable wiring are realized, so that the working intensity of detection personnel is reduced, wiring errors caused bymanual detection of the detection personnel are effectively avoided, and the wiring detection accuracy and the detection efficiency are improved; and the system is a wiring detection system which canavoid production faults, reduce the production cost and improve labor efficiency.

Owner:BEIJING AEROSPACE MEASUREMENT & CONTROL TECH

Method of purifying sorbic acid

InactiveCN105198727ASimple processGood choiceCarboxylic compound separation/purificationSorbic acidImpurity

The invention discloses a production process for preparing high-purity sorbic acid by utilizing melt crystallization. The production process comprises the following steps: first introducing chilled brine into the bottom of a melt crystallizer outer jacket, facilitating the chilled brine to uniformly flow on the outer wall of the crystallizer in a falling film manner, then putting a crude sorbic acid solution into a melt crystallizer, gradually cooling the sorbic acid solution to be crystallized under the condition that the sorbic acid solution flows down in a falling-film manner on the inner wall of the crystallizer, gradually growing a uniform crystal layer on a heat exchanging surface, wherein the concentration of the crystal layer is higher than that of a mixture solution, and gradually gathering impurities into the mixture solution; partially melting the crystal layer by adjusting the temperature of hot water via a heat exchanger, melting and eliminating partial low-melting-point substances mingled in the crystal layer, and further purifying crystal. The method is simple in process, equipment is compact in structure, a falling film form is adopted, the energy is reduced, and meanwhile the cost and equipment investment are reduced; the purity of a product produced by utilizing the melt crystallizer is high.

Owner:张勇

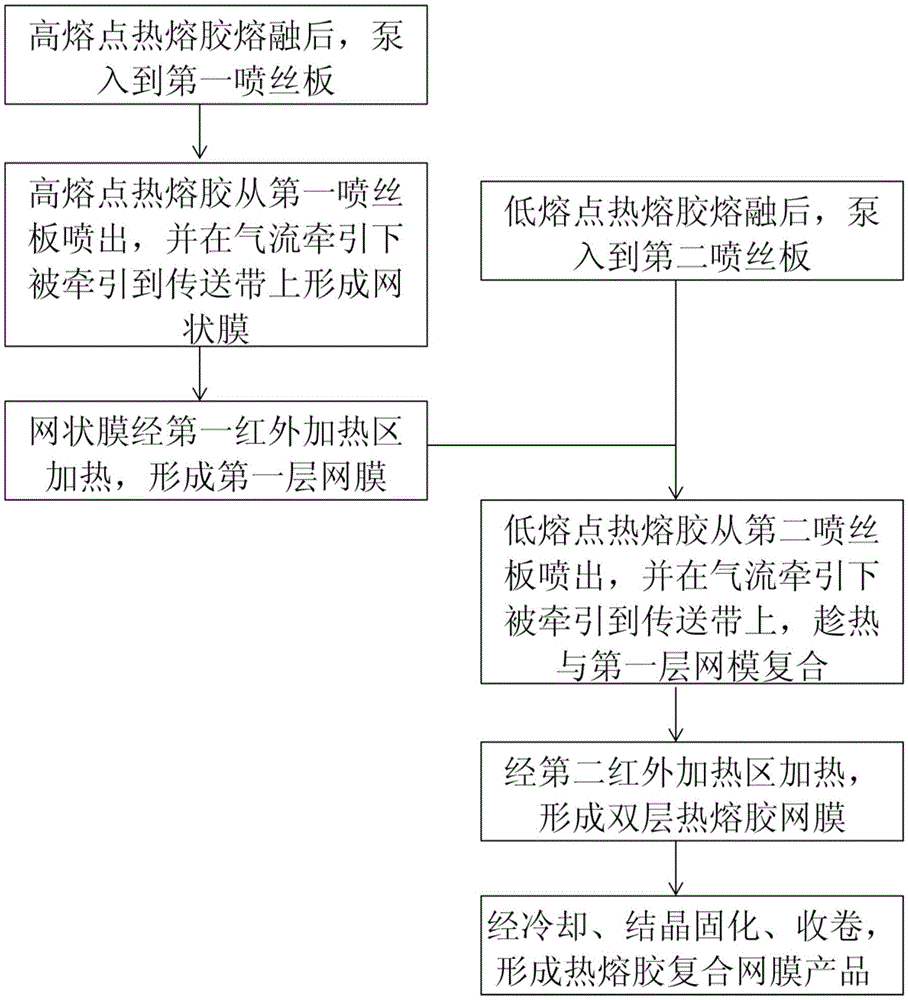

Process for making hot melt adhesive net film

ActiveCN104480637AImprove initial tensile strengthImprove efficiencyNon-woven fabricsHot-melt adhesiveMelting point

The invention provides a process for making a hot melt adhesive net film. The process is characterized in that the hot melt adhesive net film is of a bilayer structure, and two kinds of hot melt adhesive resin different in melting point and performance are melt-blown respectively and stacked sequentially to form the net film through online melt-blow composite technology. The process has the advantages that performance of the hot melt adhesive net film can be adjusted conveniently and flexibly, and limitation, on net film production, of melting point of the hot melt adhesive resin is improved.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

Method for purifying aluminum oxide

InactiveCN108622923AAchieve separationAchieve purificationChemical industryAluminates/aluminium-oxide/aluminium-hydroxide purificationThermal waterWater temperature

The invention discloses a production process for preparing high-purity aluminum oxide by utilizing melt crystallization, and the production process comprises the following steps: introducing frozen saline water into the bottom of an outer jacket of a melting crystallizer, enabling the frozen saline water to uniformly flow on the outer wall of the crystallizer in the form of a falling film; addinga rough aluminum oxide solution into the melting crystallizer, flowing down the aluminum oxide solution on the inner wall of the crystallizer in the form of the falling film, cooling step by step to crystallize, growing out a uniform crystal layer on a heat exchange surface step by step, enabling concentration of the crystal layer to be higher than that of a mixture solution, enriching impuritiesinto the mixture solution step by step; regulating the hot water temperature through a heat exchanger for performing partial melting operation on the crystal layer, enabling low-melting-point impurities in the crystal layer to partly melt and remove, thereby further purifying the crystal. According to the method disclosed by the invention, the process is simple, the equipment structure is compact,the falling film form is adopted, energy is reduced, cost and equipment investment are reduced; and a product produced by the melting crystallizer is high in purity.

Owner:NANTONG DISONG TEXTILE CO LTD

Method for purifying sorbic acid

InactiveCN105949050ASimple processGood choiceCarboxylic compound separation/purificationSaline waterImpurity

The invention discloses a production technology for preparing high-purity sorbic acid by utilizing melt crystallization. The production technology comprises the following steps: firstly, filling frozen saline water into the bottom of an outer jacket of a melt crystallizer, wherein the frozen saline water evenly flows in a falling film manner on the outer wall of the crystallizer; after that, putting a coarse sorbic acid solution into the melt crystallizer, wherein the sorbic acid solution flows down in a falling film manner on the inner wall of the crystallizer so as to be gradually cooled and further crystallized; enabling a uniform crystal layer to gradually grow on the heat exchange surface, wherein the concentration of the crystal layer is higher than that of a mixture solution, and gradually enabling impurities to be enriched in the mixture solution; then, adjusting the temperature of hot water by using a heat exchanger, carrying out partial melting operation on the crystal layer so as to melt and remove low-melting-point impurities mixed in the crystal layer, and further purifying crystal. The method is simple in technology and compact in equipment structure, adopts a falling film form so as to reduce energy, and can reduce cost and equipment investment; the product produced by using the melt crystallizer is high in purity.

Owner:南通中兴多元复合钢管有限公司

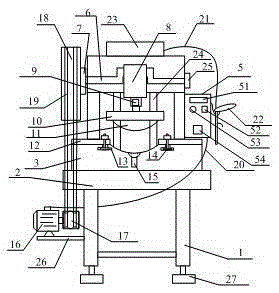

Intelligent special-shaped forming machine for air conditioner mesh enclosure production

The invention discloses an intelligent special-shaped forming machine for air conditioner mesh enclosure production. The intelligent special-shaped forming machine is characterized by comprising a base, a bed body, a workbench, damping padding iron, an intelligent control device, a crankshaft, a clutch, a connection rod, a pneumatic tightening switch, a hammer body, a special-shaped hammer head, a special-shaped die, a T-shaped groove, a fixing bolt, a drawing device, a motor, a motor belt wheel, a big belt wheel, a V-shaped belt, a cable, a pneumatic pipe, a pneumatic blow gun, an air pump, a guide rail, a brake and a motor support; and the bed body is arranged on the base, the damping padding iron is arranged below the base, and the workbench is arranged in front of the bed body. According to the intelligent special-shaped forming machine, through arrangement of the intelligent control device, the clutch, the brake, the special-shaped die, the special-shaped hammer head and the damping padding iron, the machining efficiency and the machining quality of an air conditioner mesh enclosure are facilitated, the intelligent degree is increased, the production cost is lowered, damping and noise reduction are achieved, the service life is prolonged, multiple purposes are achieved through one machine, and application and popularization are facilitated.

Owner:TIANJIN MALIGAISHA TECH

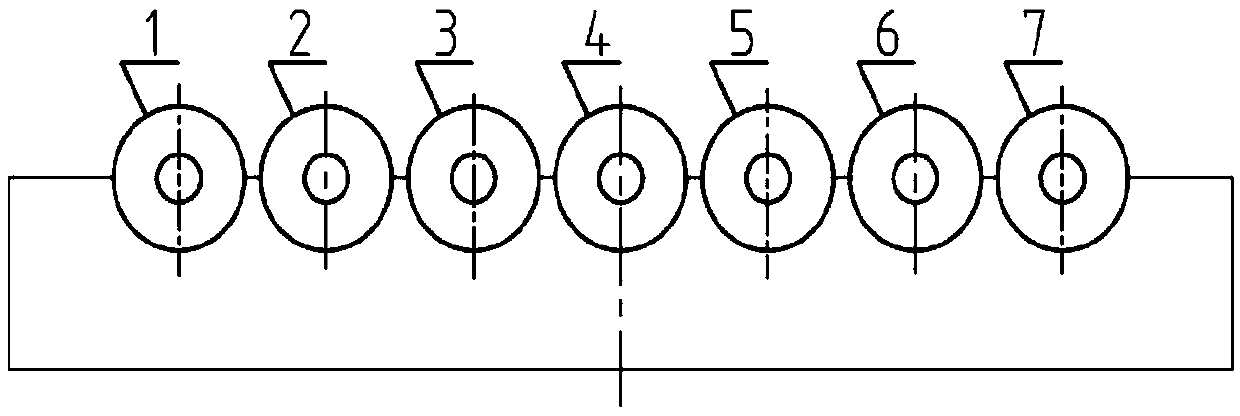

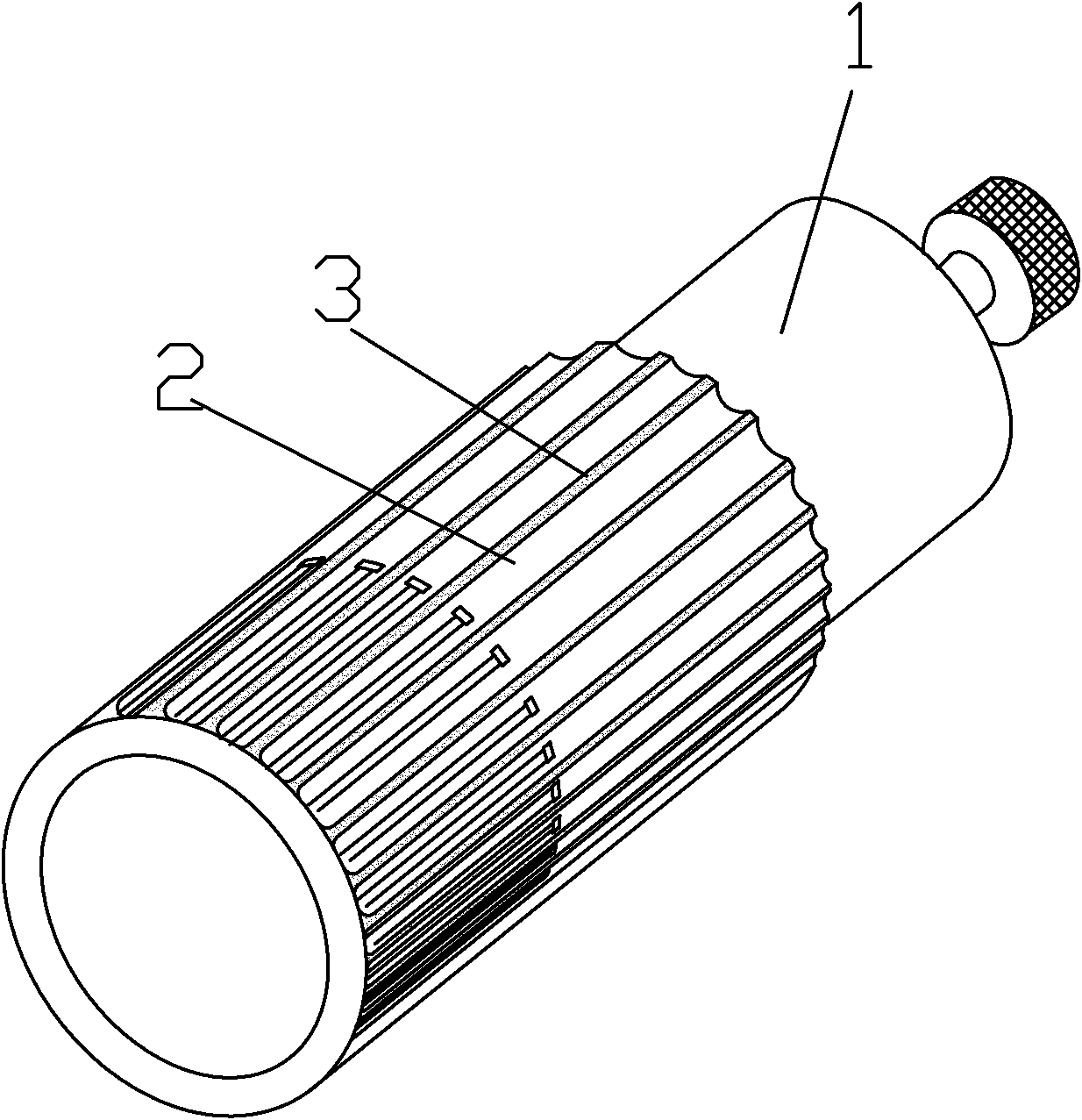

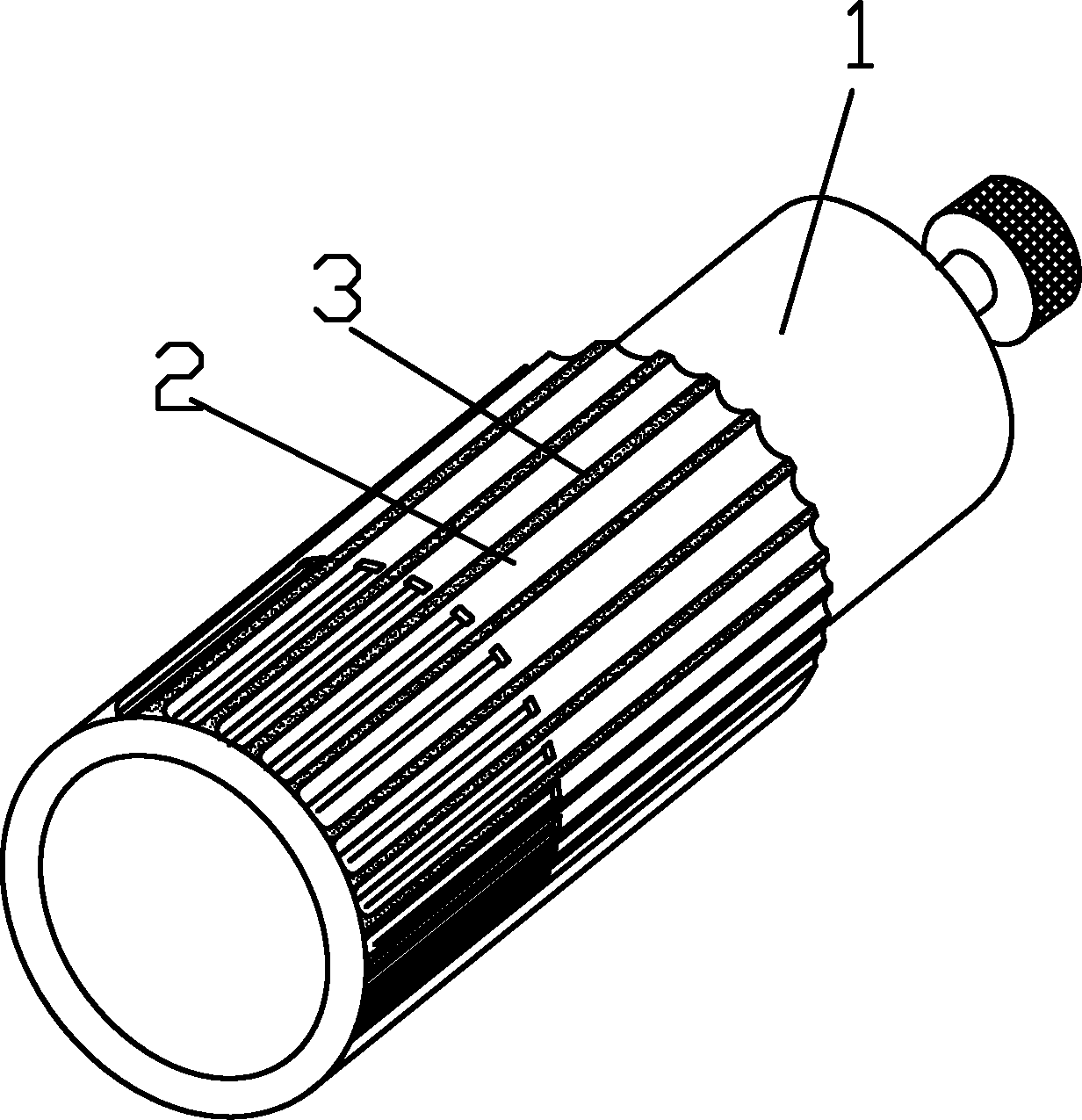

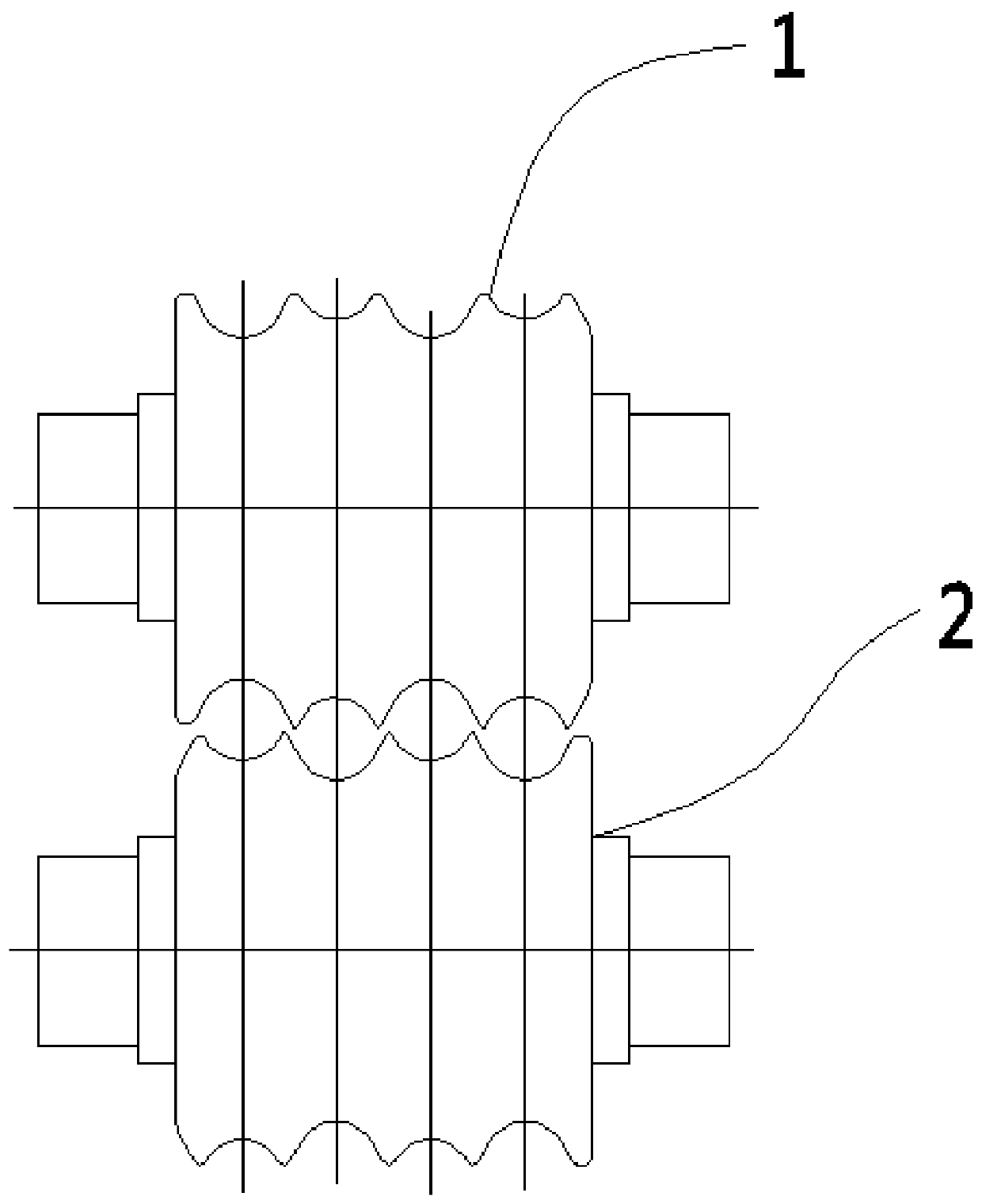

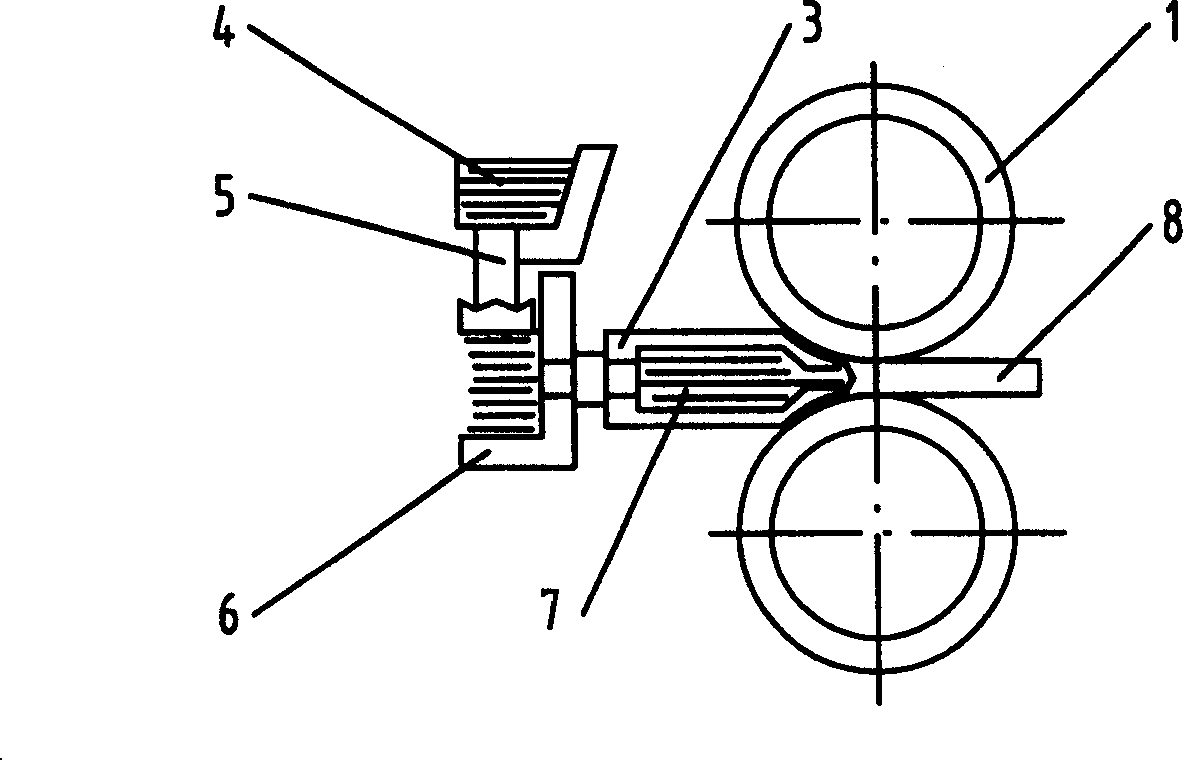

Universal three-cut and four-cut hollow guide pipe device

PendingCN109550785AReduce weightImprove the convenience of replacementMetal rolling arrangementsCompression deviceEngineering

The invention relates to a universal three-cut and four-cut hollow guide pipe device, which includes a hollow guide pipe, three three-cut guide grooves, four four-cut guide grooves, an installation base, a base supporting frame and a compression device, the three-cut guide grooves and the four-cut guide grooves are formed in the installation base, the compression device is fixedly installed on theinstallation base, the hollow guide pipe is fixedly clamped in the three-cut guide grooves and the four-cut guide grooves through the compression device, the installation base is connected with the base supporting frame by welding, the base supporting frame is fixedly installed on the ground, and each three-cut guide groove is arranged between every two adjacent four-cut guide grooves. Accordingto the universal three-cut and four-cut hollow guide pipe device, the structure is simple, the manufacturing cost is low, the requirements of three-cut and four-cut rolling can be met at the same time, and quick replacement of the hollow guide pipe can be realized.

Owner:张家港联峰钢铁研究所有限公司

Double twisting machine

The invention relates to a double twisting machine which comprises a frame, an upper mounting platform, a middle mounting platform and a lower mounting platform and a transition device. The upper mounting platform, the middle mounting platform and the lower mounting platform are arranged on the frame from top to bottom. The transition device is used for effectively preventing the single yarn from being broken by the middle mounting platform. The double twisting machine ensures the strength of the plied yarn, reduces the probability of occurrence of the production failure and improves the work efficiency.

Owner:江苏华宇机械有限公司

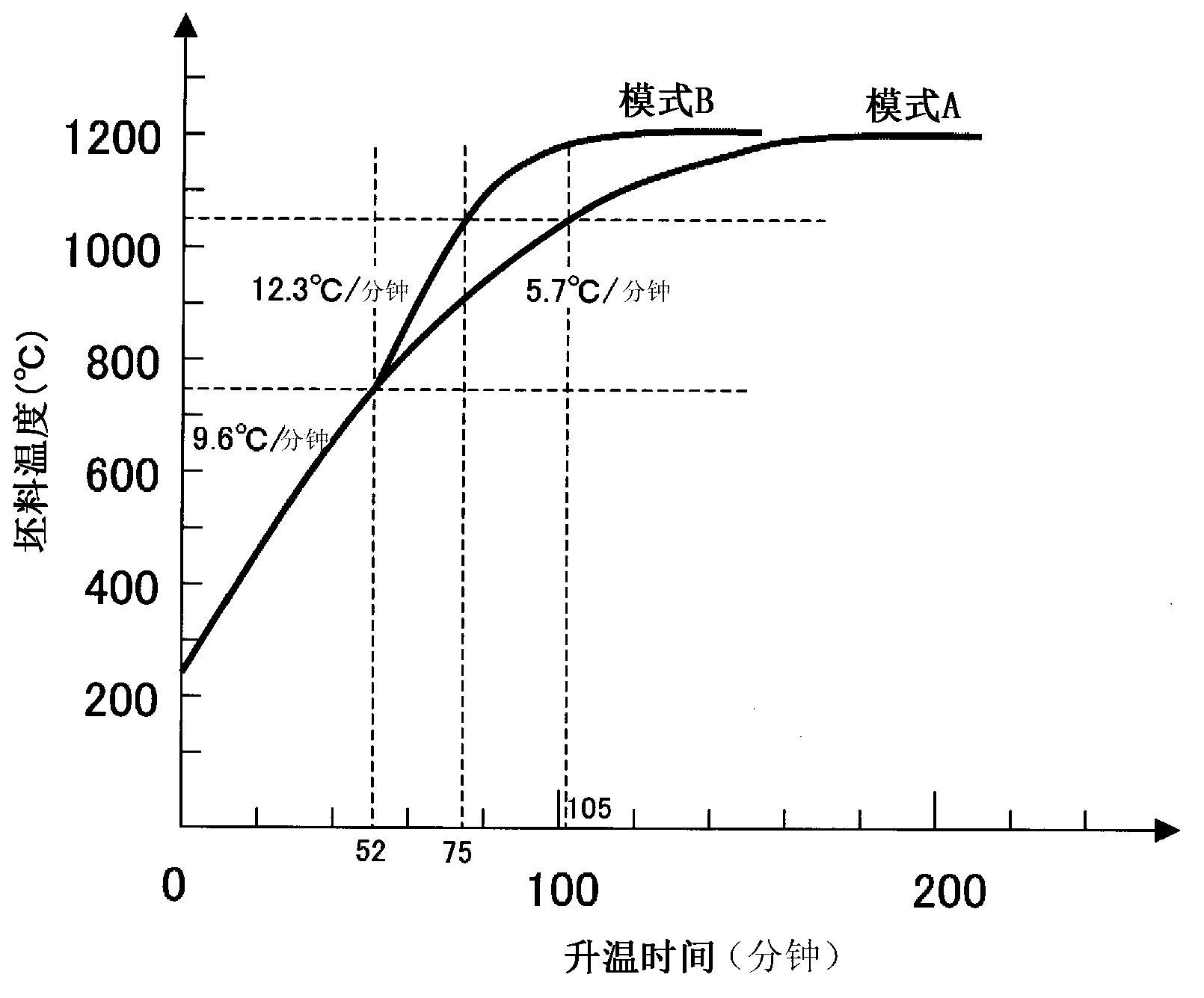

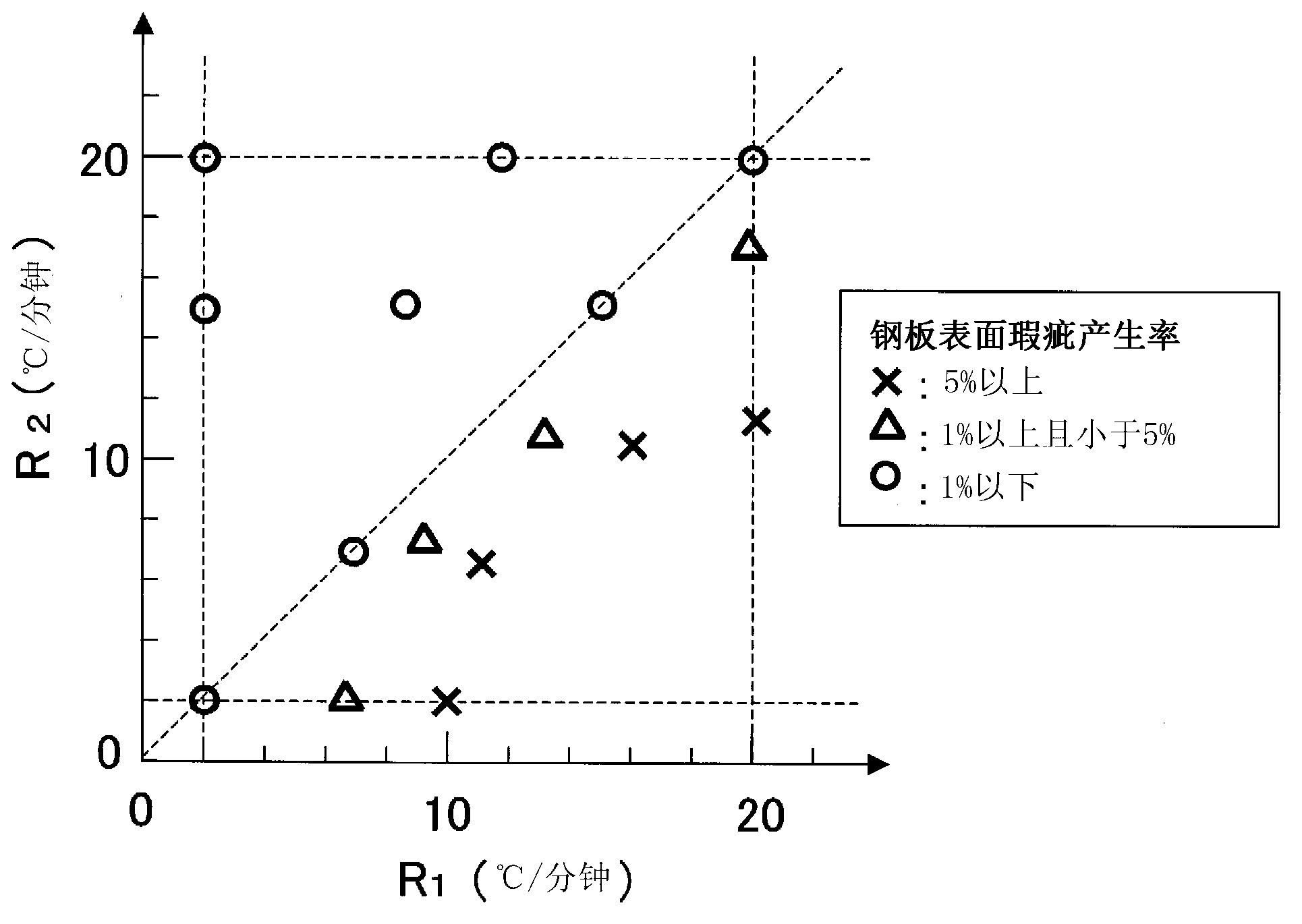

Hot rolling method for silicon-ontaining steel slab

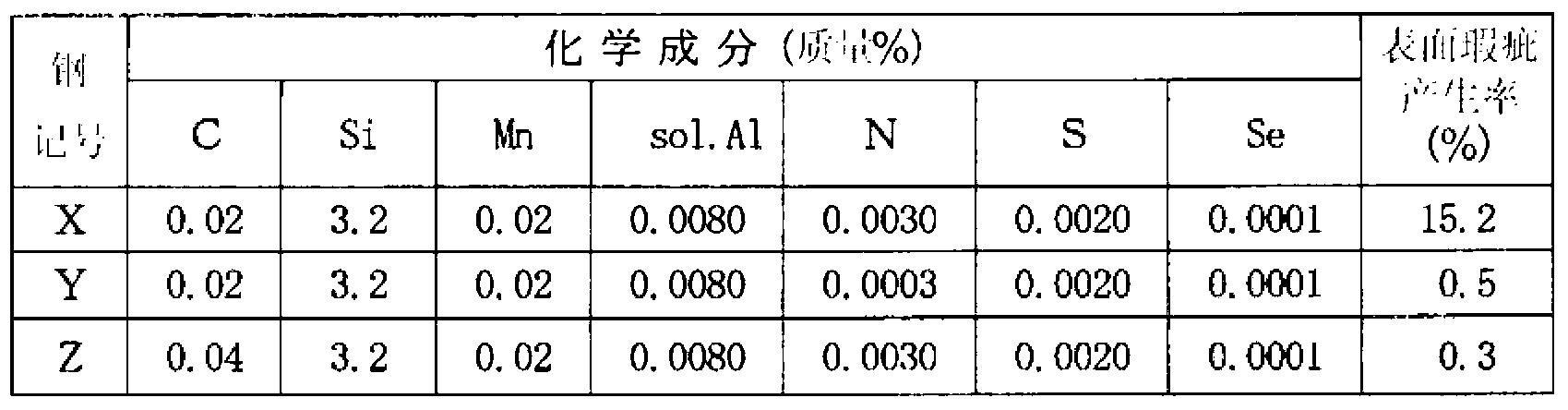

ActiveCN103237907AReduce surface blemishesReduce production failureFurnace typesMetal rolling arrangementsHot rolledImpurity

When a steel slab, which has a component composition containing 0.03 mass% or less of C, 2.0-5.0 mass% of Si, 0.005-1.0 mass% of Mn, 0.040 mass% or less of sol. Al, 0.0005-0.0150 mass% of N and 0.030 mass% or less of S + Se with the balance made up of Fe and unavoidable impurities, is re-heated and hot rolled, the steel slab is re-heated so that heating rates R1 and R2 of the steel slab during the re-heating satisfy the following relation of 20 DEG C / min >= R2 >= R1 >= 2 DEG C / min when the heating rate for the range from the beginning of the re-heating to 750 DEG C is represented by R1 ( DEG C / min) and the heating rate for the range from 750 DEG C to 1,050 DEG C is represented by R2 ( DEG C / min) and then hot rolled, thereby reducing surface marks formed on the hot-rolled sheet.

Owner:JFE STEEL CORP

Parallel drum wheel for PASSIM cigarette making machine

InactiveCN102640988AExtended service lifeReduce manufacturing costCigarette manufactureEngineeringSmoke

The invention discloses a parallel drum wheel for a PASSIM cigarette making machine. The parallel drum wheel comprises a drum wheel body, wherein a plurality of air suction grooves are uniformly distributed in the outer peripheral surface of the drum wheel body, the surfaces of the air suction grooves are smooth, separation plates are formed between the two adjacent air suction grooves, and wear-resistance material layers are sprayed and coated on the upper surfaces of the separation plates. The parallel drum wheel is characterized in that the wear resistance material layers are sprayed and coated on the upper surfaces of the separation plates between the two air suction grooves, so when the parallel drum wheel is in contact with a plastic guide sheet, the plastic guide sheet can only generate the friction with the wear resistance material layers. The intensity of the wear resistance material layers is high, so the abrasion to the parallel drum wheel caused by the plastic guide sheet is relatively small, the service life of the parallel drum wheel can be prolonged, the production cost of the enterprises is reduced, in addition, the long-time normal operation of the equipment can be ensured through the adoption of the parallel drum wheel, the production fault occurrence frequency of smoke blockage and washboard blockage can be reduced, the production efficiency is improved, and the quality of cigarettes is improved.

Owner:CHINA TOBACCO GUIZHOU IND

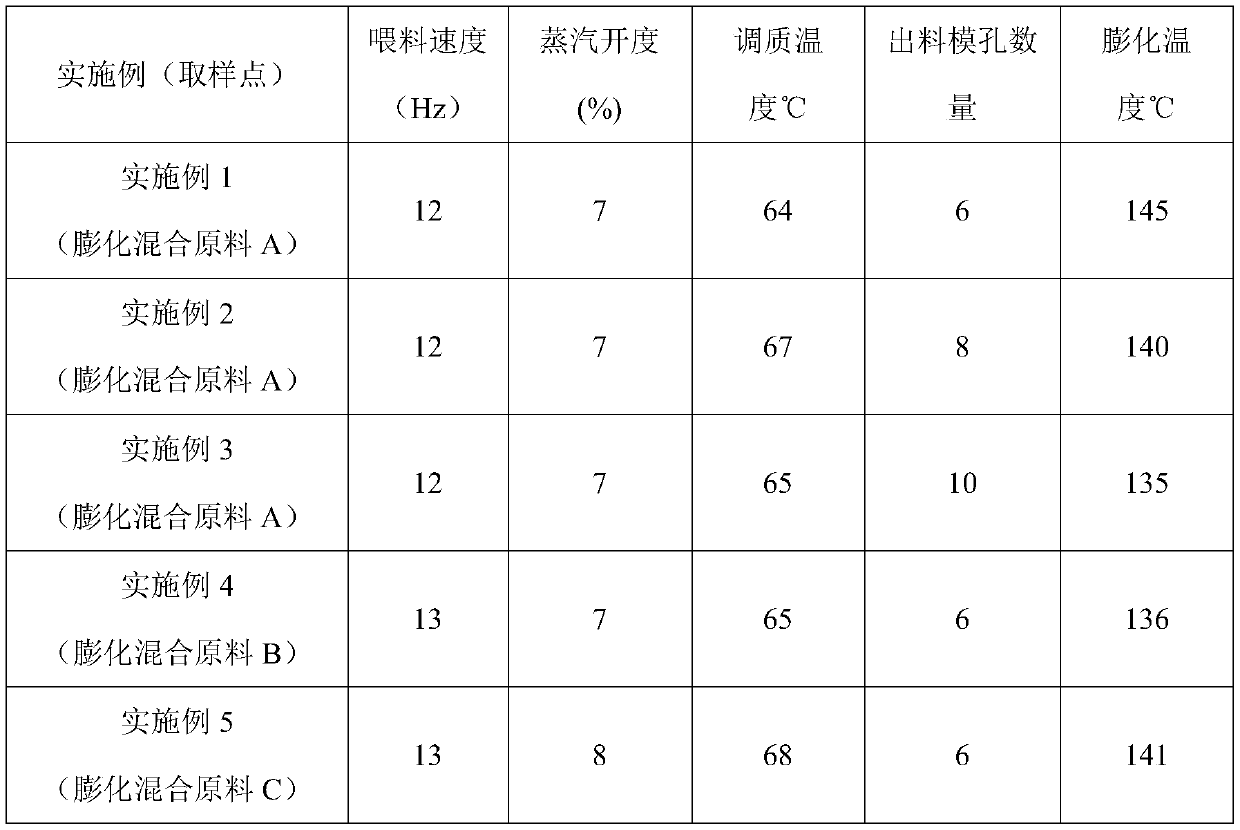

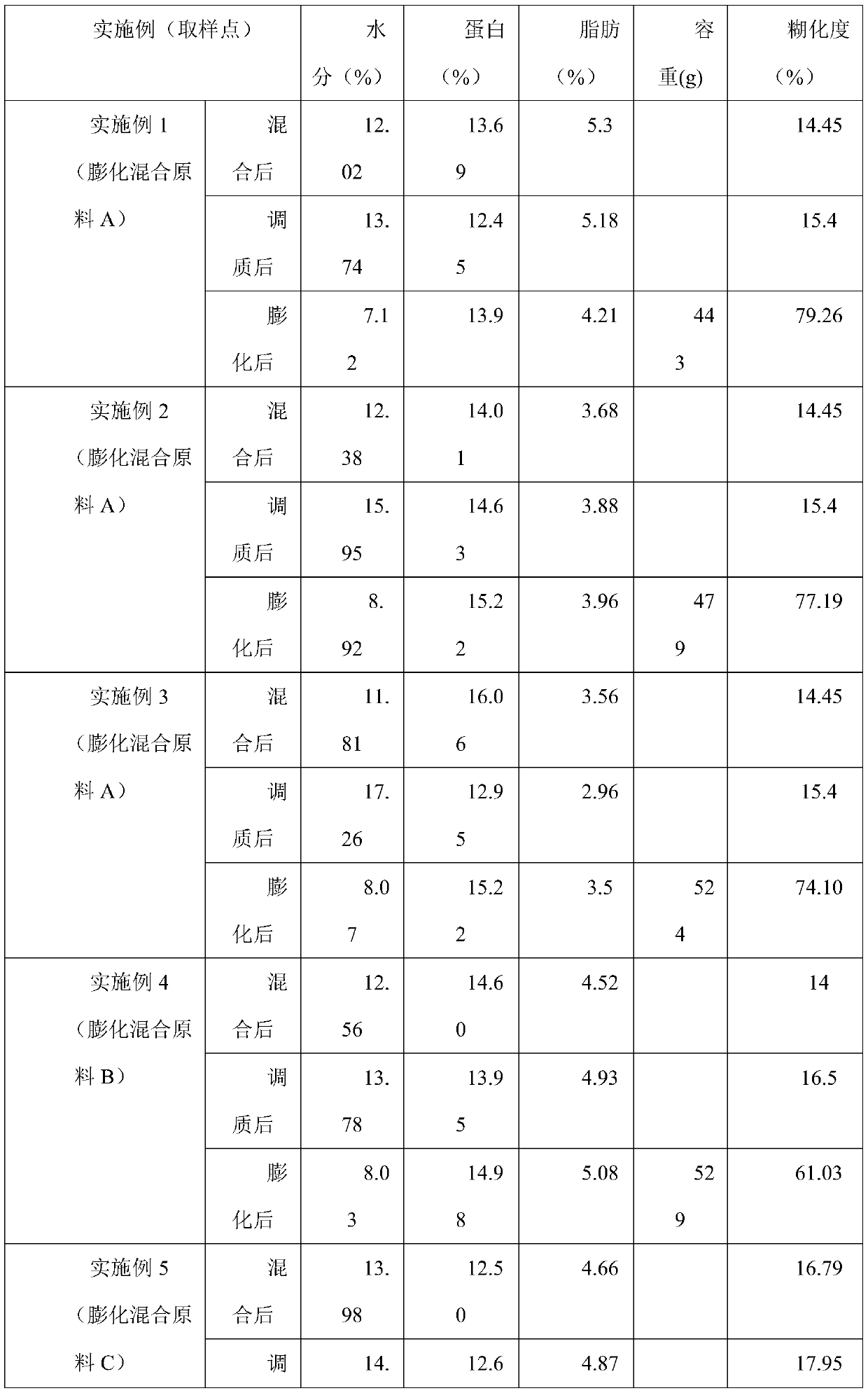

Puffed mixed raw material, processing method thereof and compound feed prepared by using same

InactiveCN109757618AEliminate anti-nutritional factorsGreat tasteFood processingAnimal feeding stuffVegetable oilBroken rice

The invention discloses a puffed mixed raw material, a processing method thereof and a compound feed prepared by using the same. The puffed mixed raw material is prepared by mixing pretreated corn, broken rice and soybean meal with vegetable oil according to the mass ratio of 20-28:15-27:9-11:1, controlling the soybean meal content in the mixed raw material to be below 20% and the vegetable oil content to be below 2%, then expanding at a high temperature of 135-145 DEG C, and then conducting cooling and pulverizing. According to the puffed mixed raw material and the processing method, the high-temperature puffing technology is utilized to eliminate anti-nutritional factors in the mixed raw material, the sterilization effect is remarkable, and the puffed material is good in taste. After thepuffed mixed raw material is added, the compound feed creep feed is good in palatability and high in processing quality and can reduce the diarrhea rate of piglets and improve the growth performanceof the piglets.

Owner:SHANGHAI XINNONG FEED

Method for purifying sorbic acid

InactiveCN106699547ASimple processGood choiceCarboxylic compound separation/purificationSalt waterSorbic acid

The invention discloses a production technology for preparing high-purity sorbic acid by melt crystallization. The production technology comprises the following steps of firstly, sending freezing salt water into the bottom part of an outer jacket of a melt crystallization device, enabling the freezing salt water to uniformly flow along the outer wall of the crystallization device in a falling film way, feeding a crude sorbic acid solution into the melt crystallization device, enabling the sorbic acid solution to flow down along the inner wall of the crystallization device in the falling film way, gradually cooling and crystallizing, gradually growing a uniform crystal layer on the heat exchange surface, enabling the concentration of the crystal layer to be higher than the concentration of mixture solution, and enabling impurities to gradually enrich into the mixture solution; then, melting one part of crystal layer by adjusting the hot water temperature through a heat exchanger, and melting and removing the impurities with low melting point in the crystal layer, so as to further purify crystals. The production technology has the advantages that the method and technology are simple, the equipment structure is compact, the falling film type is adopted, the energy is decreased, and the cost and equipment investment are reduced at same time; the purity of a product produced by the melt crystallization device is high.

Owner:于银强

Method for purifying sorbic acid

InactiveCN106946695ASimple processGood choiceCarboxylic compound separation/purificationImpuritySorbic acid

The invention discloses a production method for preparing highly pure sorbic acid by using melt crystallization. The method comprises the following steps: introducing frozen brine to the bottom of the outer jacket of a melting crystallizer, allowing the frozen brine to uniformly flow on the outer wall of the crystallizer in a falling film manner, adding a crude sorbic acid solution into the melting crystallizer, allowing the sorbic acid solution to flow on the inner wall of the crystallizer in a falling film manner to carry out gradual cooling for crystallization, gradually growing a uniform crystal layer on a heat exchange surface, and gradually enriching impurities in a mixture solution, wherein the concentration of the crystal layer is higher than the concentration of the mixture solution; and partially melting the crystal layer by adjusting the temperature of hot water through a heat exchanger to partially melt and eliminate low-melting point impurities included in the crystal layer in order to further purify crystals. The method has the advantages of simple process, compact device structure, reduction of the energy through adopting a falling film form, reduction of the cost and the device investment, and realization of high purity of the product produced by using the melting crystallizer.

Owner:于银强

Method for purifying dehydroacetic acid

The invention discloses a production process for preparing high purity dehydroacetic acid by virtue of melt crystallization. The process comprises the following steps of: firstly introducing frozen saline water into the bottom of an outer jacket of a melting crystallizer, wherein the frozen saline water uniformly flows in a falling film manner on the outer wall of the crystallizer; then inputting a concentrated dehydroacetic acid solution into the melting crystallizer, wherein the dehydroacetic acid solution flows in a falling film manner on the inner wall of the crystallizer and is gradually cooled to be crystallized; gradually growing a uniform crystal layer on a heat exchange face, wherein the concentration of the crystal layer is higher than that of a mixed solution, and impurities are gradually enriched in the mixture solution; and then adjusting the temperature of hot water by virtue of a heat exchanger to partly melt the crystal layer, namely a sweating operation, wherein low-melting-point impurities mingled in the crystal layer are partly melted and removed, so that the crystal is further purified. The process disclosed by the invention is simple, the equipment is compact in structure, and the energy is reduced in form of the falling film, and meanwhile, the cost and equipment investment are lowered; a product produced by the melting crystallizer is high in purity.

Owner:张勇

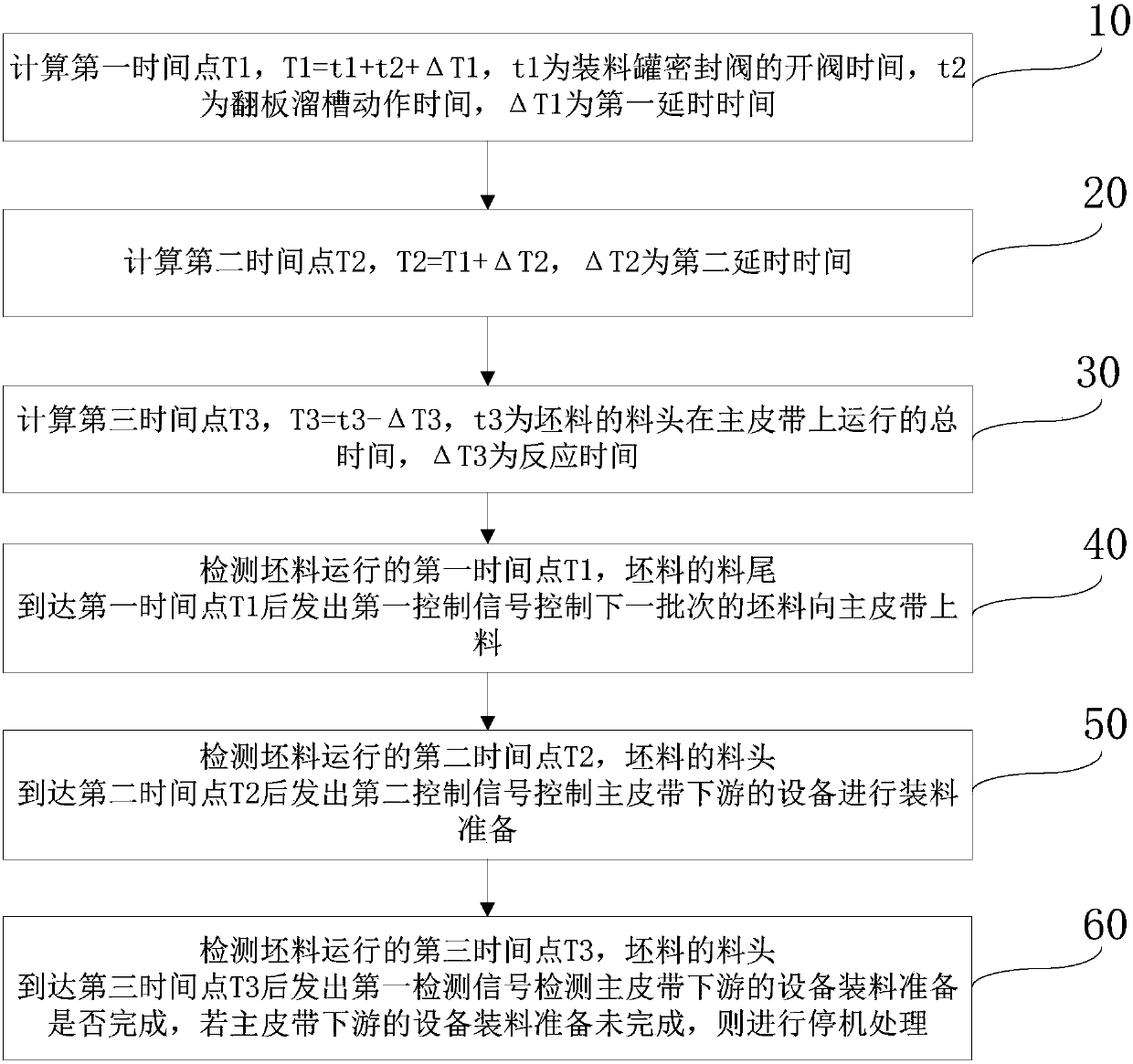

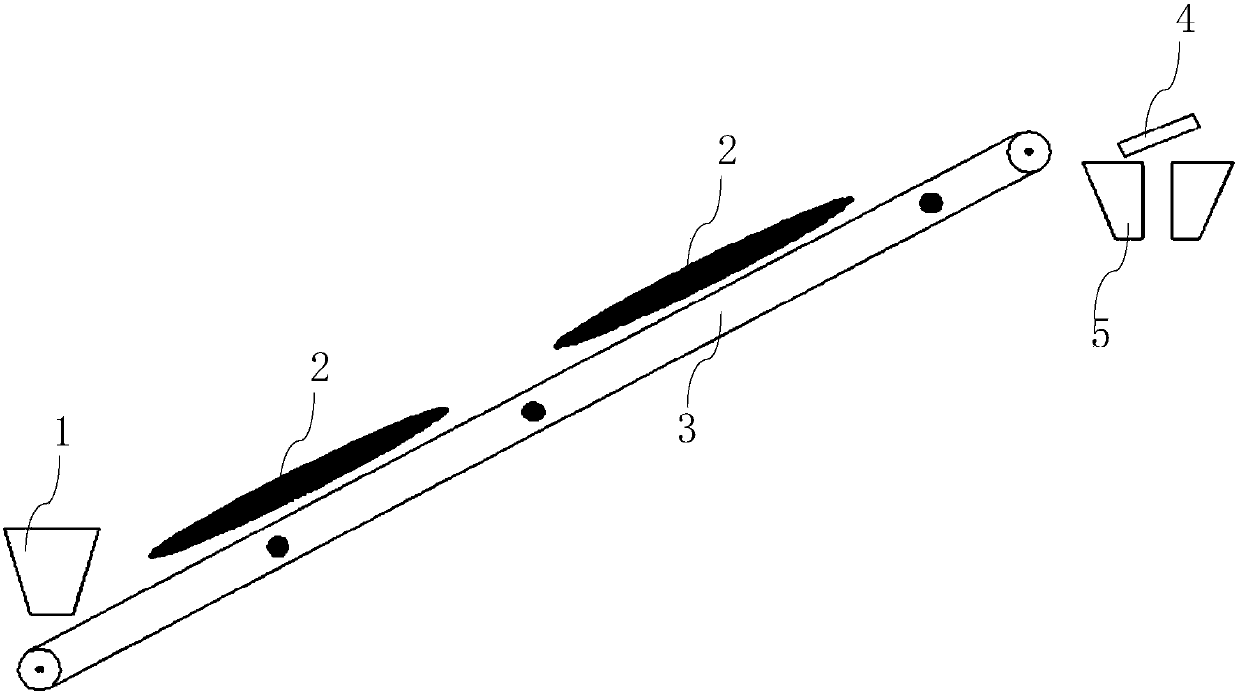

A blast furnace main belt material flow tracking control method and device

ActiveCN105907907BStable controlAvoiding Technical Problems of MisoperationBlast furnace detailsTreatment unitBlast furnace

The invention relates to a blast furnace main belt material flow tracking control method and a device. The method comprises the following steps: a first time point, a second time point and a third time point are calculated; after a material tail reaches the first time point, a next batch of blanks is controlled to be loaded on a main belt; after a material head reaches the second time point, equipment downstream of the main belt is controlled to prepare for loading; after the material head reaches the third time point, whether preparation for loading by the equipment downstream of the main belt is completed is detected; and if the loading preparation by the equipment downstream of the main belt is not completed, shutdown treatment is performed. The device consists of a first calculating unit, a second calculating unit, a third calculating unit, a first processing unit, a second processing unit, a third processing unit, first material flow detecting equipment, second material flow detecting equipment and third material flow detecting equipment. The blast furnace main belt material flow tracking control method and device provided by the invention can prevent the technical problem of misoperation of the equipment caused by damage of the material flow detectors, and reduces production faults caused by the faults of the material flow detectors.

Owner:武汉钢铁有限公司

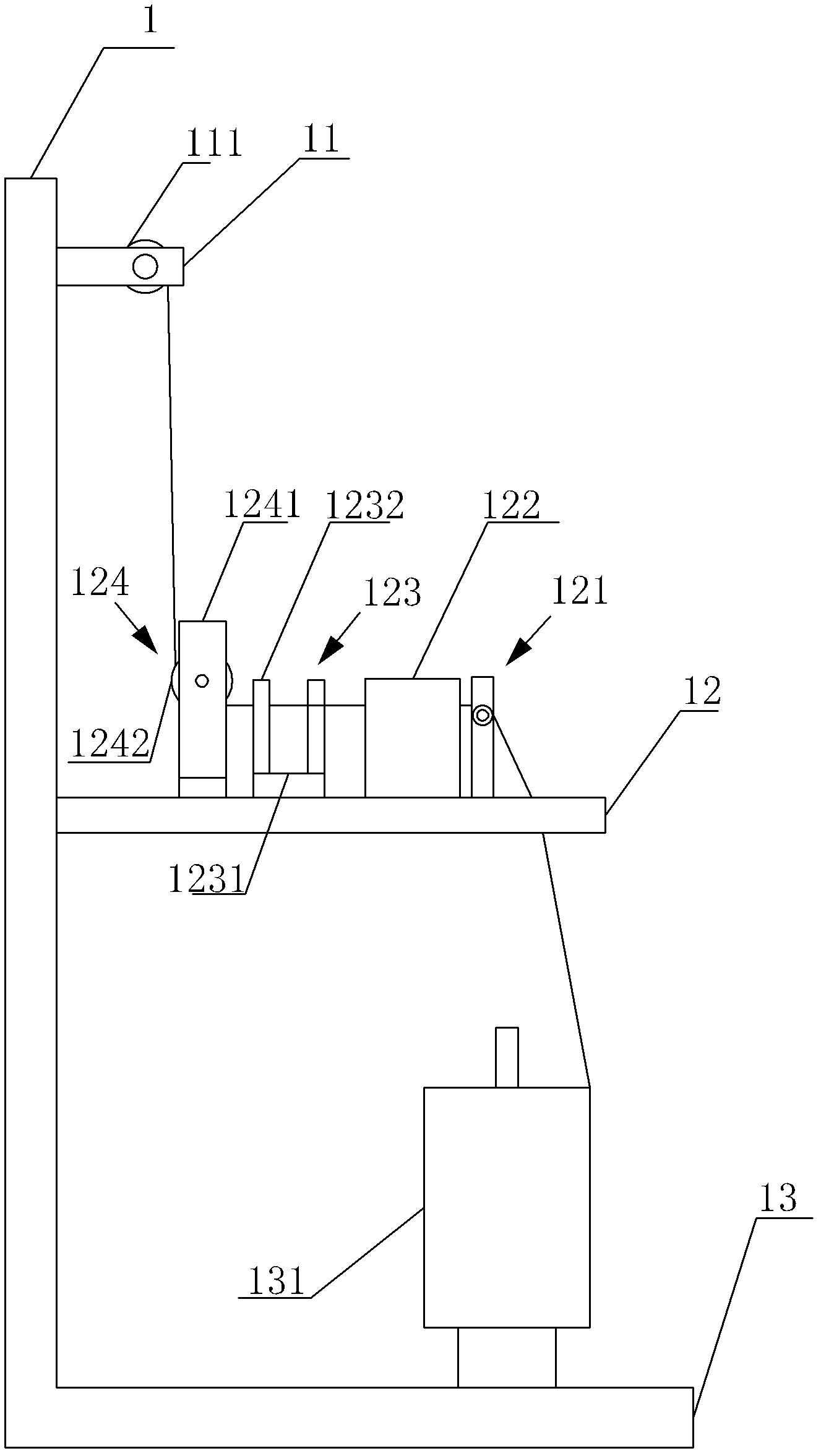

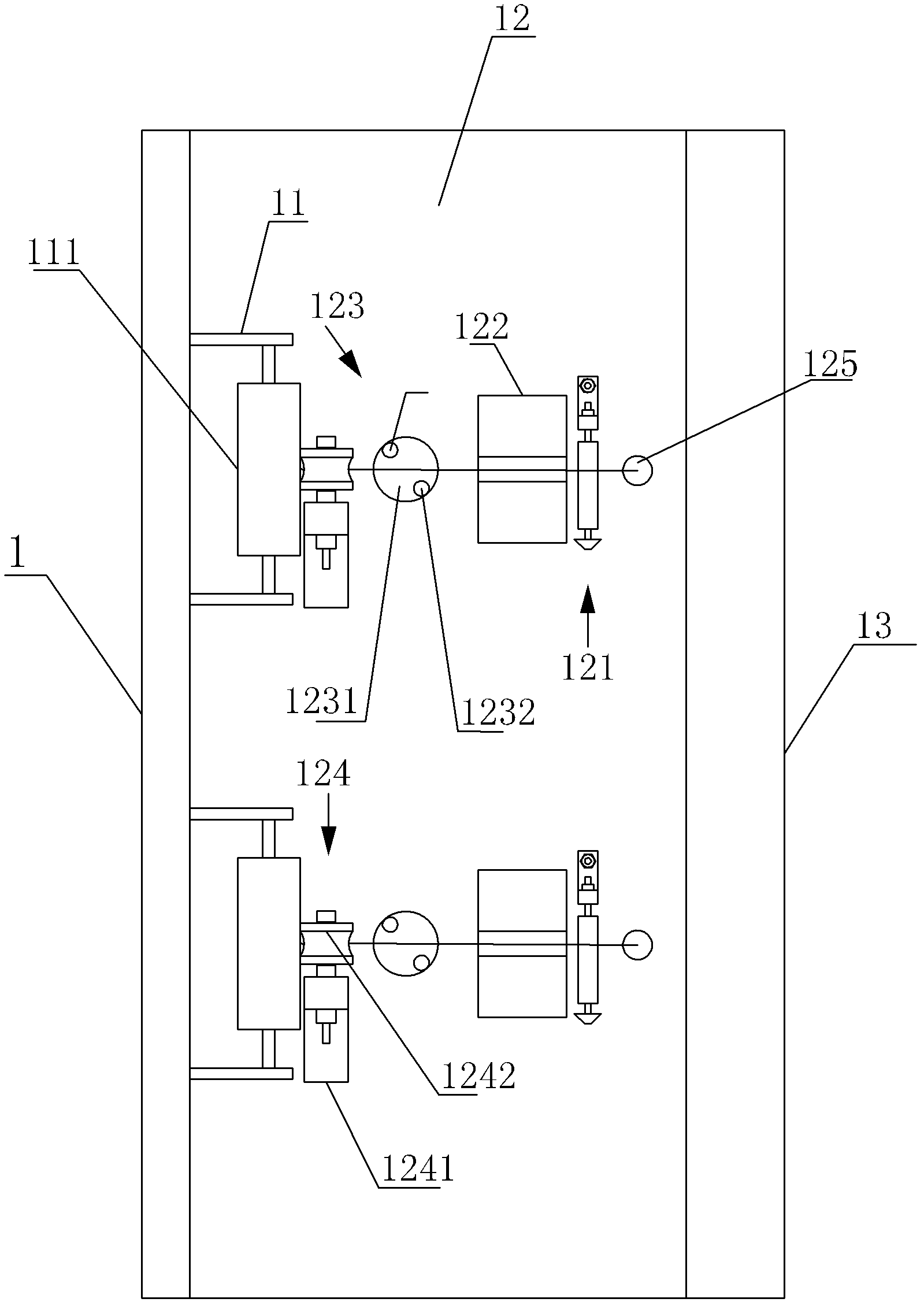

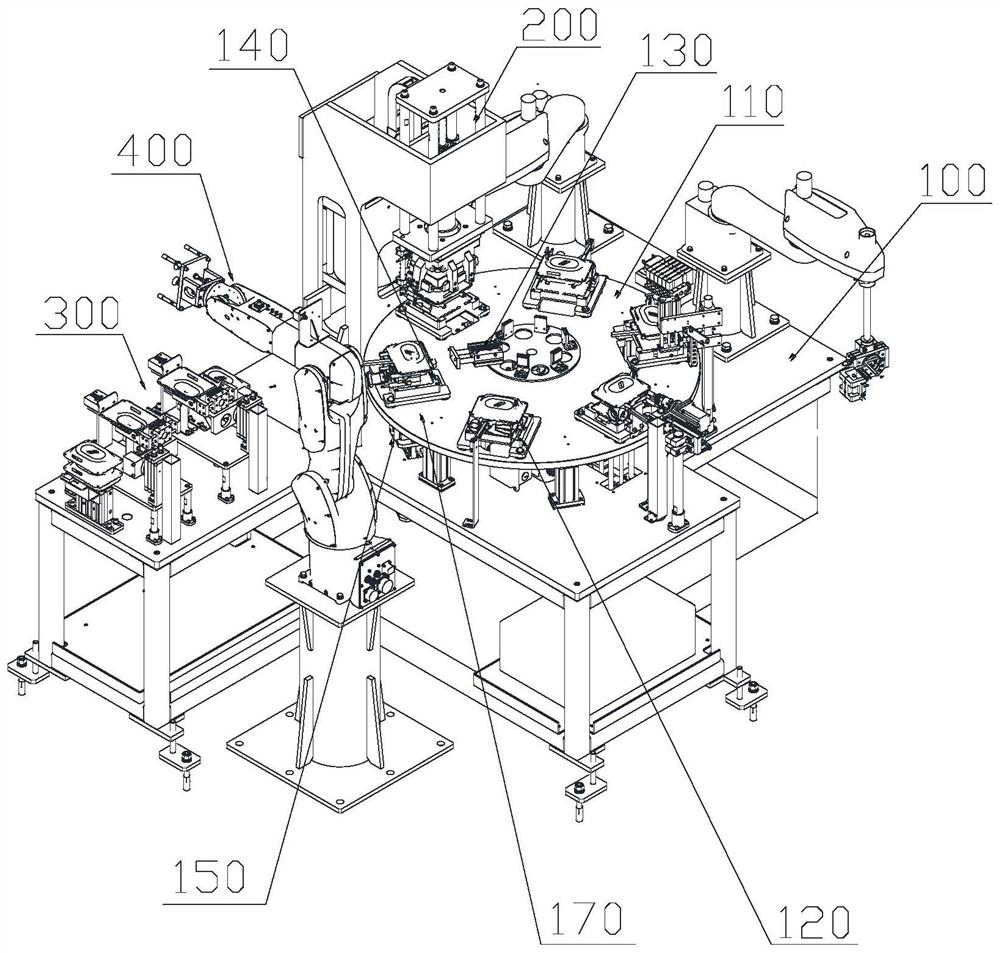

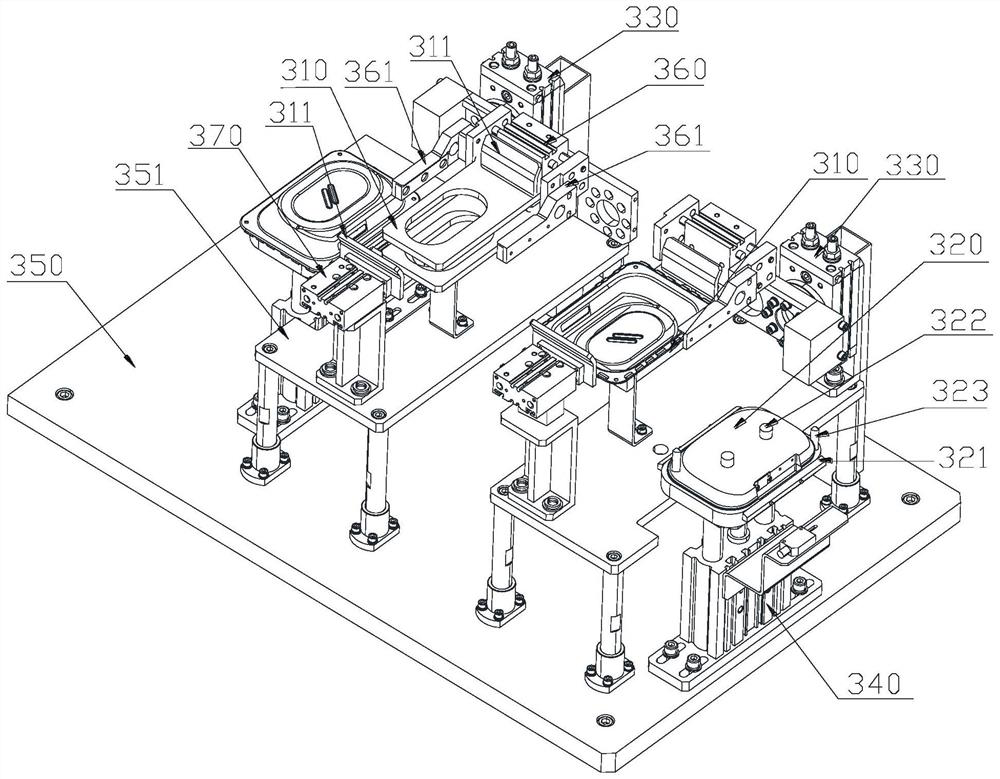

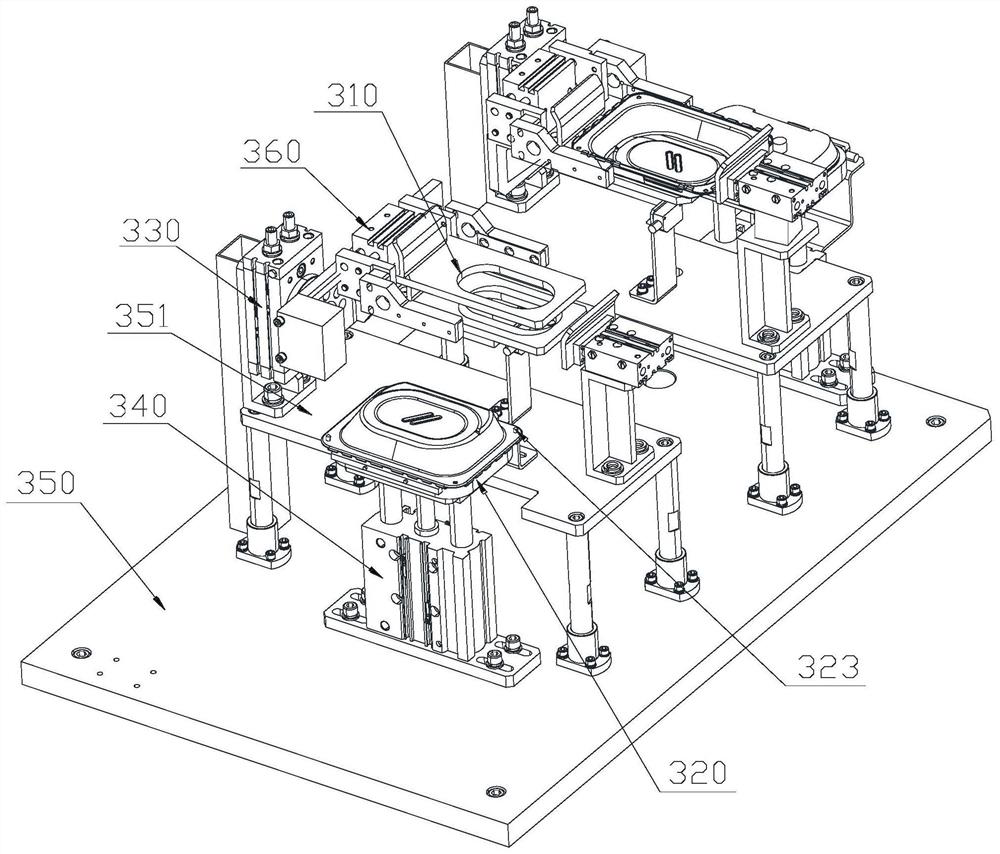

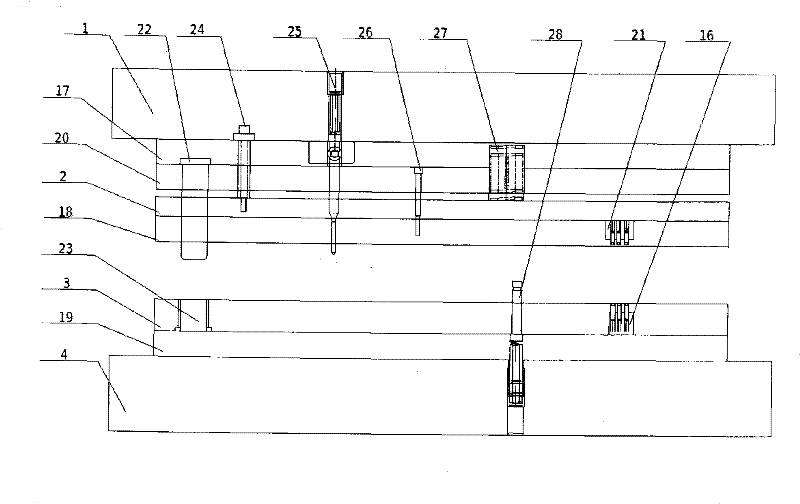

Metering shell press sealing system of diaphragm gas meter

PendingCN113927277AImprove the efficiency of fastening and even riveting pressure sealingReduce production failureMetal working apparatusRobot handControl engineering

The invention belongs to the field of gas meter production equipment, and discloses a metering shell press sealing system of a diaphragm gas meter. The metering shell press sealing system of the diaphragm gas meter comprises a rack, a rotary index plate and a press sealing machine, wherein the rotary index plate and the press sealing machine are arranged on the rack. The rotary index plate is provided with movement body positioning seats evenly distributed in the circumferential direction of the rotary index plate. A secondary positioning mechanism and a metering shell mechanical arm are arranged on one side of the rotary index plate. The secondary positioning mechanism comprises an overturning plate and a profiling tool which are arranged in a one-to-one correspondence manner. The overturning plate is provided with an overturning air cylinder and used for receiving a metering shell with an upward opening, the profiling tool is located on one side of the overturning plate, the shape of the profiling tool is matched with that of the metering shell, and the profiling tool is used for receiving the metering shell with a downward rotating opening of the overturning plate. The movement body positioning seats are used for containing movement bodies, and the metering shell mechanical arm is used for transferring the metering shell on the profiling tool and buckling the metering shell to the movement bodies. Press sealing is finished in the manners of shaping, expanding and pre-tightening, the buckling and even riveting press sealing efficiency of the metering shell and the movement bodies is effectively improved, and production faults and the like are reduced.

Owner:QIANWEI KROMSCHRODER METERS CHONGQING

Shielding case progressive die

ActiveCN101869945BPrecision structureImprove shielding effectShaping toolsMagnetic/electric field screeningProduction ratePunching

Owner:KUNSHAN ZHENHE MOLD HARDWARE MACHINERY

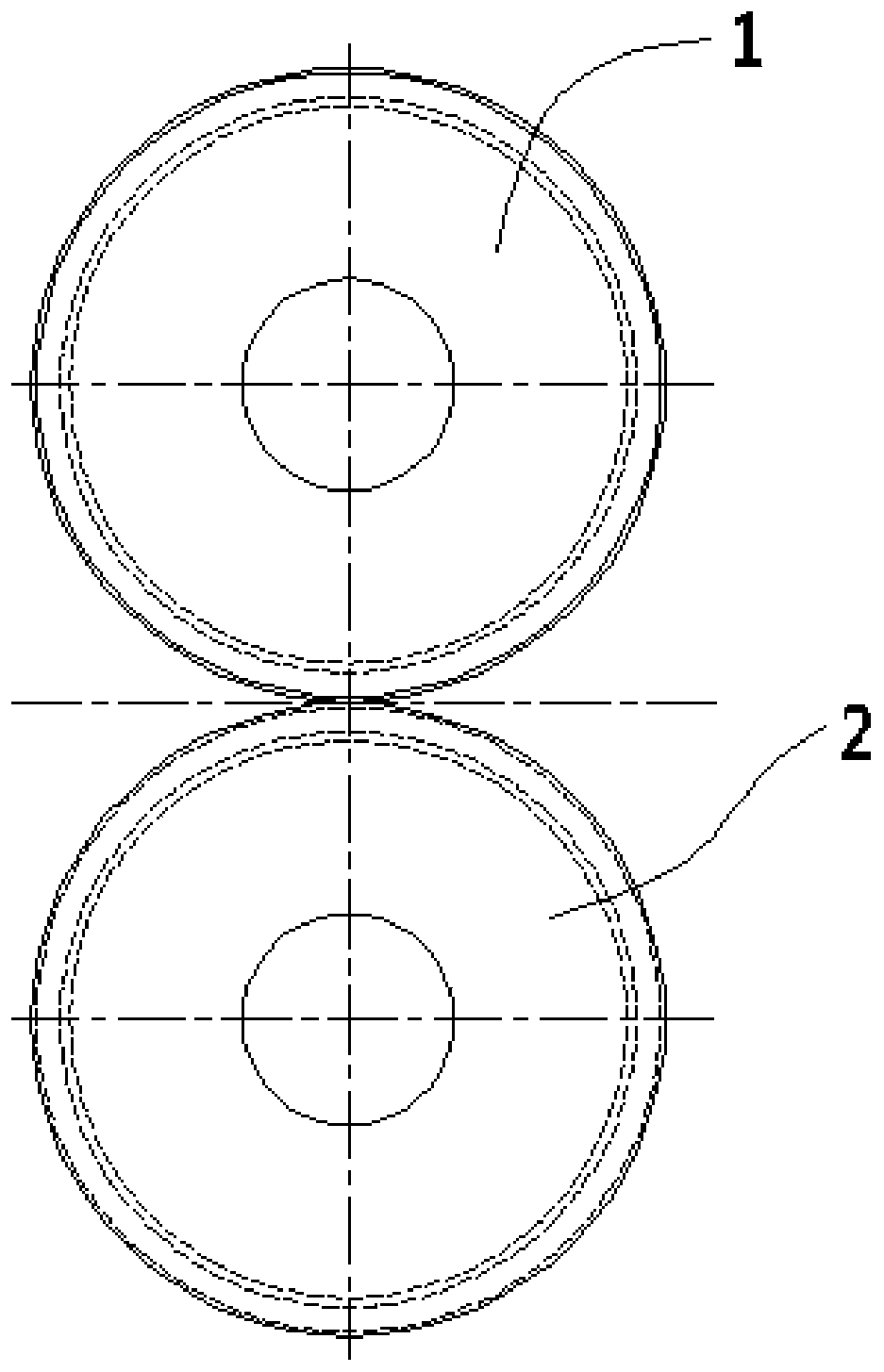

Slitting wheel for rolling production of thread steel

PendingCN110421006AFacilitate subsequent processingImprove wear resistanceMetal rolling arrangementsConvex structureEngineering

The invention provides a slitting wheel for the rolling production of thread steel, and belongs to the field of processing devices. The slitting wheel comprises an upper slitting wheel and a lower slitting wheel, which are arranged up and down; a slitting cavity used for slitting a rolled piece is formed between the slitting wheels arranged up and down; a slitting groove is formed in the outer circumferential surface of each slitting wheel; two sides of the section of each slitting groove are in of a protruded angular structure; and vertexes of the angular structures between the slitting grooves in the upper slitting wheel and the lower slitting wheel are arranged in a staggered manner. The slitting wheel for the rolled production of the thread steel can be used for slitting the rolled piece, the slit rolled pieces are separated up and down, and subsequent processing is facilitated. The design of the grooves with a concave structure is adopted, and compared with a slitting cutter witha convex structure, the abrasion of a slitting part is reduced; and a group of slitting wheels are omitted, and the production failure is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

Car carpets with indeterminate nonwovens

ActiveCN105401336BAppropriate wayReduce wasteVehicle arrangementsRoad vehiclesPolyesterLow-density polyethylene

The invention relates to a vehicle carpet using unfigured island non-woven open-edge waste material; the preparation method comprises the following steps: 1, opening and mixing: opening polyester fiber 60-95% and unfigured sea island fiber open-edge waste material 5-40% by two rough openers, sending the material into a large chamber cotton blender for mixing, and opening the material by a fine opener; 2, carding and netting: feeding the finely opened mixture fibers into a carding machine, carding the fibers so as to form uniform single layer cotton web, and using a lapping machine to lap the single layer cotton web into thick cotton web, and outputting the thick cotton web; 3, needling: using a feeder to feed the thick cotton web, outputted by the lapping machine, into a pre-needle machine for pre-winding reinforcement, using a main needle machine to process the material so as to obtain semi-finished product, and forming the coiled material of needed gram weight by processing the semi-finished product on a coiler; 4, baking: baking the needled coiled material at the temperature of 120-200 DEG C for 2-8 minutes, thus melting the low density polyethylene on the outer layer of the unfigured sea island fiber. The unfigured island non-woven open-edge waste material can be used in the non-decrement field, thus reducing resource waste.

Owner:怡星(沧州)汽车内饰件有限公司

Roll ring steel for aluminium casting rolling mill and heat treatment method thereof

InactiveCN1285749CImproved resistance to thermal fatigue cracksExtended service lifeFurnace typesHeat treatment furnacesManganeseQuenching

The invention relates to a roll sleeve steel for aluminum casting and rolling mills and a heat treatment method thereof. A roll sleeve steel for aluminum casting and rolling mills, the chemical composition weight percent (%) is: carbon (C) 0.30-0.45, manganese (Mn) 0.60-0.80, silicon (Si) 0.20-0.40, phosphorus (P) ≤ 0.025 , sulfur (S) ≤ 0.025, chromium (Cr) 2.00 ~ 3.00, nickel (Ni) 0.50 ~ 1.00, molybdenum (Mo) 0.80 ~ 1.20, vanadium (V) 0.10 ~ 0.20, aluminum (Al) ≤ 0.012, the rest is iron and other impurities. The final heat treatment method of the roller sleeve steel is secondary tempering after quenching, the quenching heating temperature is 850-920°C, and quenching in engine oil after heat preservation; the first tempering roller sleeve is heated to 500-560°C, and the heat preservation is 10-20 hours. Cool in oil; the second tempering parameters are the same as the first tempering parameters. The invention improves the ability of the roller sleeve to resist thermal fatigue cracks, thereby increasing the service life of the roller sleeve, reducing production failures and reducing production costs.

Owner:李春治

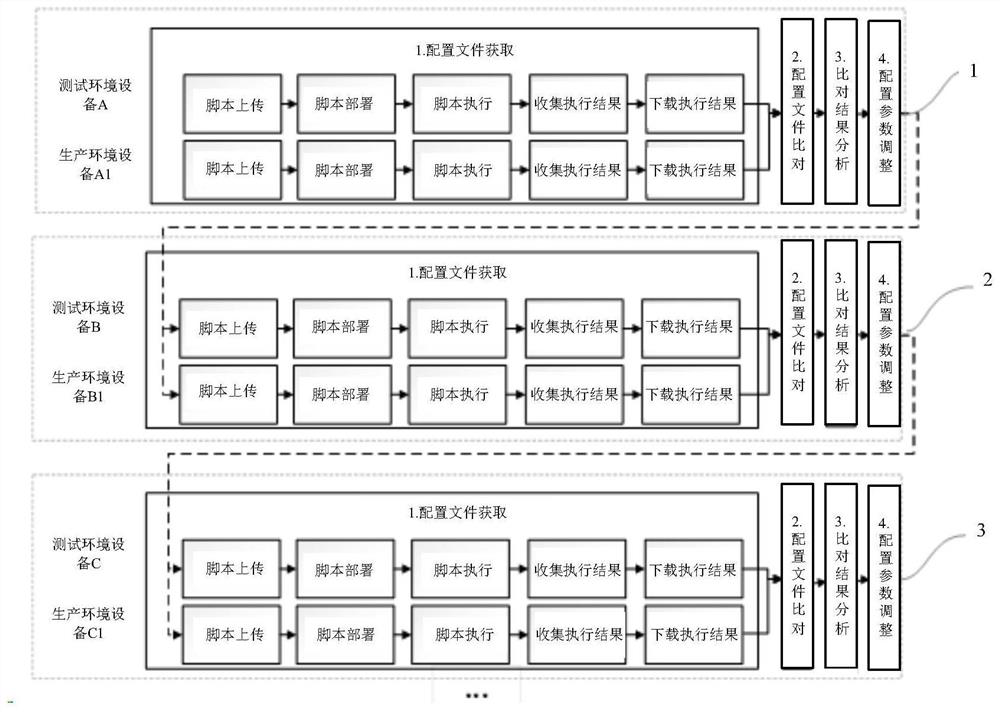

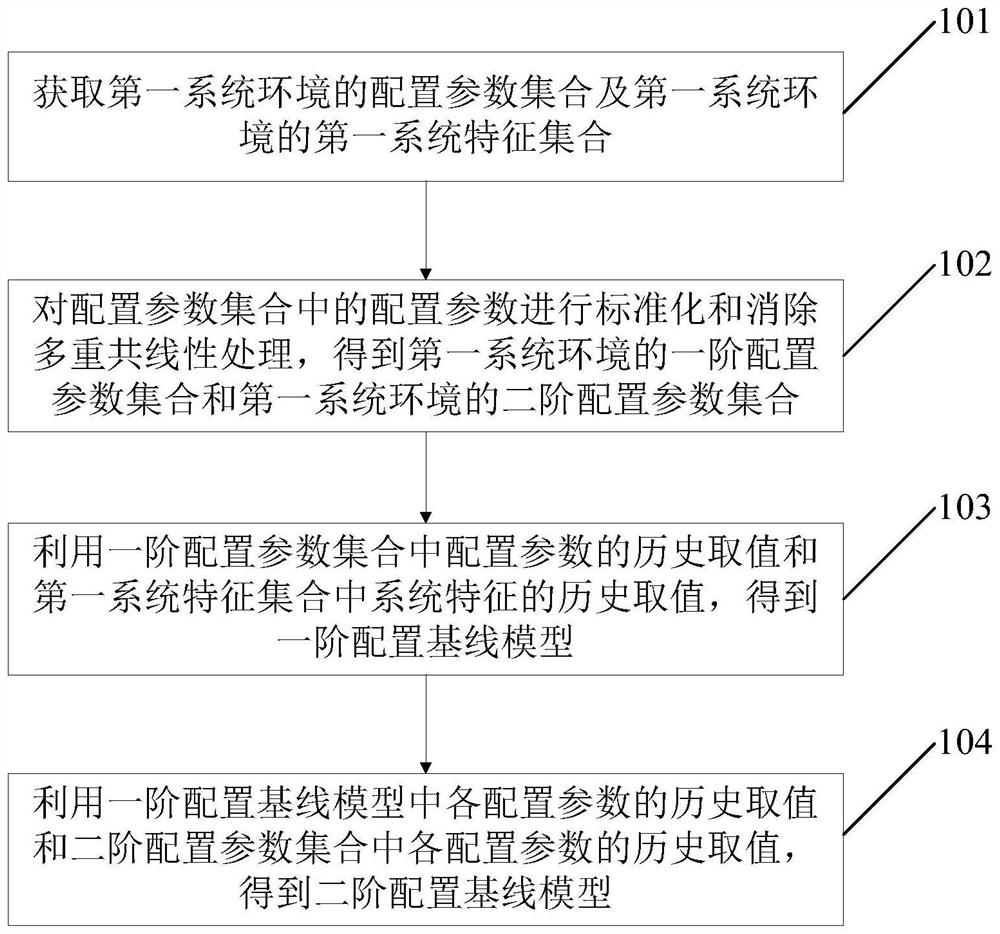

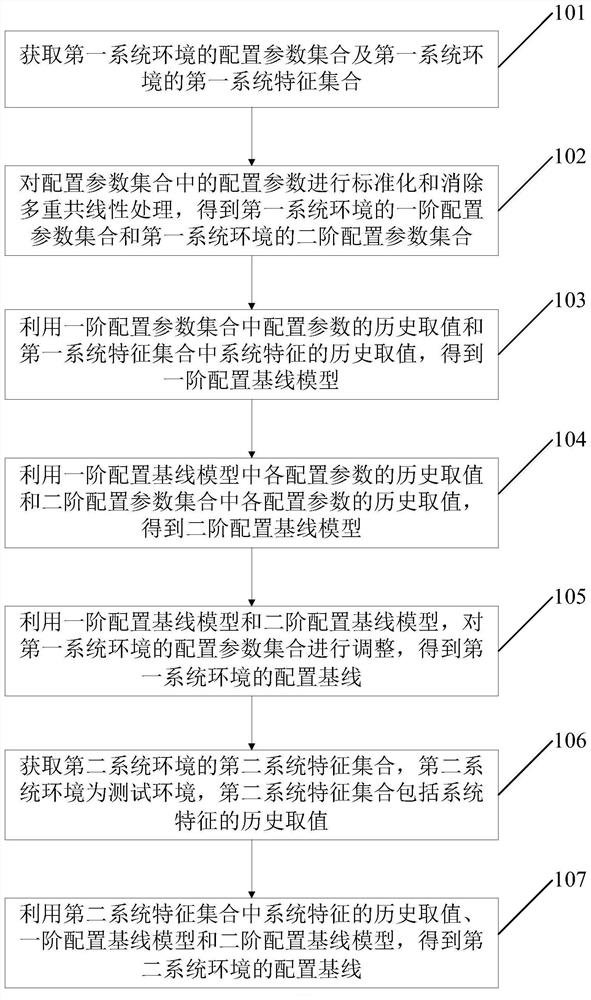

A configuration parameter calibration method and device

The present application provides a configuration parameter calibration method and device for acquiring characteristic data of a device to be processed, where the characteristic data is a numerical value that affects the value of a configuration parameter of the device to be processed when the device to be processed is in a target environment; according to the characteristics of the device to be processed The data and the preset configuration baseline model are used to determine the configuration parameters to be calibrated when the device to be processed is in the target environment; a calibration instruction is sent to the device to be processed, and the calibration instruction is used to instruct the device to be processed to calibrate the configuration parameters to be calibrated; wherein, The pre-built configuration baseline models include a first-order configuration baseline model and a second-order configuration baseline model. The first-order configuration baseline model is used to indicate the quantifiable relationship between configuration parameters and system characteristics, and the second-order configuration baseline model is used to indicate the configuration that has an associated relationship. A quantifiable relationship between parameters to improve the accuracy of calibration, thereby reducing the chance of production failures.

Owner:CHINA CONSTRUCTION BANK

Safety valve applicable to controlling high temperature flue gas

InactiveCN104776231AGuaranteed safety and reliabilityPlay a protective effectOperating means/releasing devices for valvesEqualizing valvesFlue gasFlap valve

The invention provides a safety valve applicable to controlling high temperature flue gas. The safety valve comprises an executing mechanism and a flap valve body, wherein the executing mechanism is arranged outside the flap valve body; the flap valve body comprises a flap rotator protecting sleeve, a flap rotator and a sealing ring arranged on the inner wall of the flap valve body; the flap rotator comprises a rotating shaft and valve plates welded on both sides of the rotating shaft; a plurality of reinforcing ribs are arranged on each valve plate; the rotating shaft is fixed on the flap valve body through a cast iron sleeve and an end plate; the rotating shaft is connected with the executing mechanism through a connecting rod mechanism. By the additional arrangement of the reinforcing ribs, the safety valve is high in structural stability, low in equipment cost, high in equipment applicability, fewer in production faults and low in manufacturing cost, and resources are saved. According to the safety valve provided by the invention, opening and closing of a traditional manual control valve are changed, opening and closing of an electric control valve are increased, and thus a production system is capable of operating stably.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

A kind of preparation technology of hot melt adhesive omentum

ActiveCN104480637BImprove initial tensile strengthImprove efficiencyNon-woven fabricsHot meltHot-melt adhesive

The invention provides a process for making a hot melt adhesive net film. The process is characterized in that the hot melt adhesive net film is of a bilayer structure, and two kinds of hot melt adhesive resin different in melting point and performance are melt-blown respectively and stacked sequentially to form the net film through online melt-blow composite technology. The process has the advantages that performance of the hot melt adhesive net film can be adjusted conveniently and flexibly, and limitation, on net film production, of melting point of the hot melt adhesive resin is improved.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com