Combined hot melt adhesive net film and preparing technology thereof

A preparation process, a technology of glued omentum, applied in adhesives, melt spinning, spinneret assemblies, etc., can solve problems such as poor adhesion of non-polar materials, achieve high bonding strength, high production efficiency, reduce The effect of production failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A composite hot-melt adhesive omentum, which is composed of polyamide hot-melt adhesive omentum and polyolefin hot-melt adhesive omentum. The DSC final melting point of the polyamide hot-melt adhesive used is 122°C, and the melt flow rate is 30g / 10min / 160°C; the composition and mass percentage of the polyolefin hot melt adhesive used are:

[0030] Maleic anhydride grafted high-density polyethylene (graft rate 1%) 8%;

[0031] High-density polyethylene (melt flow rate 0.9g / 10min / 190℃) 50%;

[0032] Ethylene-octene copolymer (melt flow rate 1.6g / 10min / 190℃) 10%;

[0033] Benzoyl Peroxide 0.2%;

[0034] Vinyltrimethoxysilane 1%;

[0035] Rosin 145 20%;

[0037] Antioxidant 1010 0.8%.

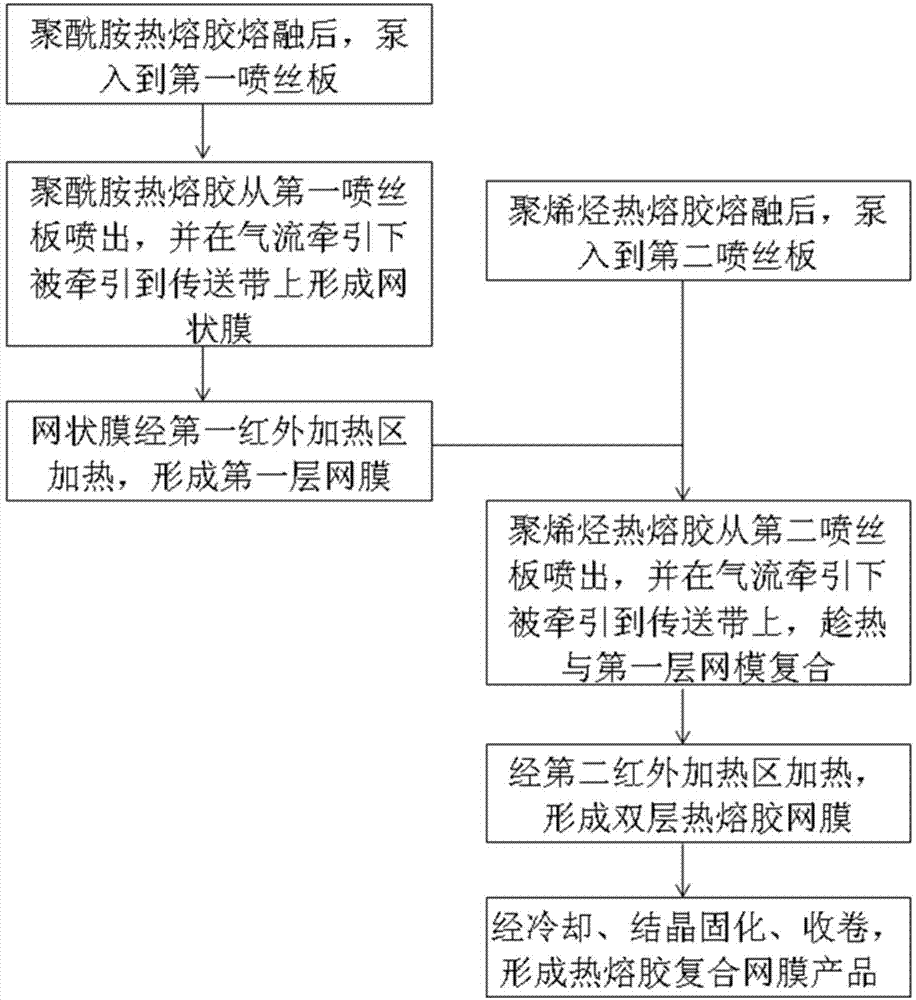

[0038] A preparation process of a composite hot-melt adhesive film, which melts the above-mentioned polyamide and polyolefin hot-melt adhesives and pumps them into the independent first spinneret and second spinneret; the distance between the two spinnerets i...

Embodiment 2

[0041] A composite hot-melt adhesive film, which is composed of polyamide hot-melt adhesive film and polyolefin hot-melt adhesive film. The DSC final melting point of the polyamide hot-melt adhesive used is 116°C, and the melt flow rate is 50g / 10min / 160°C; the composition and mass percentage of the polyolefin hot melt adhesive used are:

[0042] Maleic anhydride grafted low density polyethylene (graft rate 1.2%) 15%;

[0043] Linear low density polyethylene (melt flow rate 2g / 10min / 190℃) 60%;

[0044] Ethylene-octene copolymer (melt flow rate 3g / 10min / 190℃) 5%;

[0045]Di-tert-butyl peroxide 0.4%;

[0046] γ-Aminopropyltrimethoxysilane 1.3%;

[0047] Hydrogenated carbon five resin 10%;

[0048] Nano calcium carbonate 7.7%;

[0049] Antioxidant 1010 0.6%.

[0050] A preparation process of a composite hot-melt adhesive film, which melts the above-mentioned polyamide and polyolefin hot-melt adhesives and pumps them into the independent first spinneret and second spinneret;...

Embodiment 3

[0053] A composite hot-melt adhesive omentum, which is composed of polyamide hot-melt adhesive omentum and polyolefin hot-melt adhesive omentum. The DSC final melting point of the polyamide hot-melt adhesive used is 130°C, and the melt flow rate is 45g / 10min / 160°C; the composition and mass percentage of the polyolefin hot melt adhesive used are:

[0054] Maleic anhydride grafted linear low density polyethylene (graft rate 1%) 10%;

[0055] Low-density polyethylene (melt flow rate 7g / 10min / 190°C) 65%;

[0056] Polystyrene (melt flow rate 10g / 10min / 190°C) 3%;

[0057] Azobisisobutyronitrile 0.8%;

[0058] γ-Aminopropyltrimethoxysilane 0.7%;

[0059] Terpene resin 15%;

[0060] Kaolin 5%;

[0061] Antioxidant BHT 0.5%.

[0062] A preparation process of a composite hot-melt adhesive film, which melts the above-mentioned polyamide and polyolefin hot-melt adhesives and pumps them into the independent first spinneret and second spinneret; the distance between the two spinneret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com