Universal three-cut and four-cut hollow guide pipe device

A catheter device and four-segmentation technology, which is applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient production and difficult handling of finished steel bars, and achieve cost savings, increased convenience of replacement, and overall structural design ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding and knowledge of the present invention, the present invention will be further described and introduced in conjunction with the accompanying drawings.

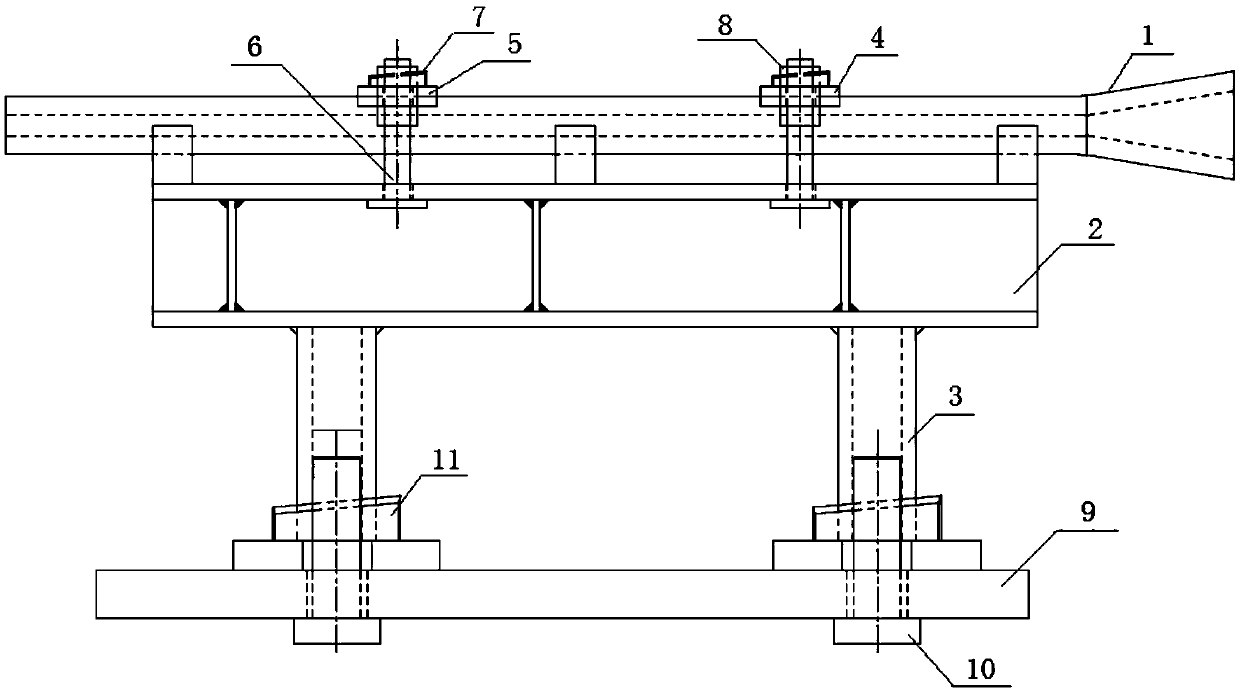

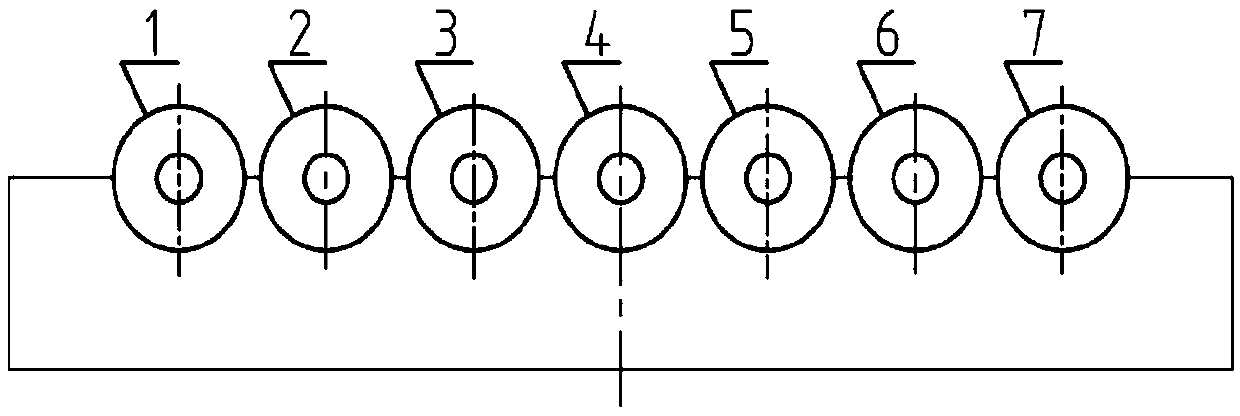

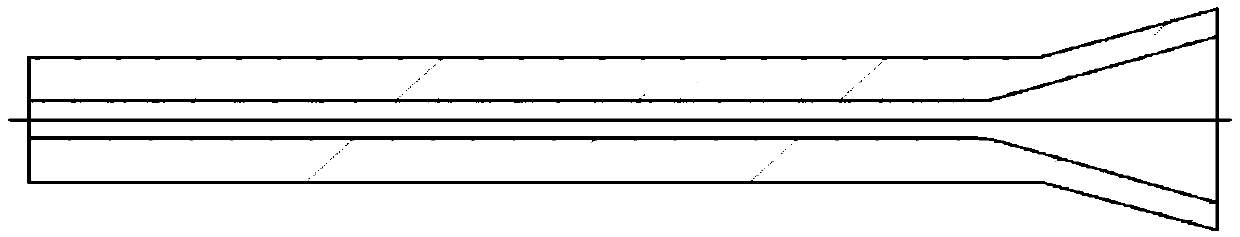

[0020] Such as Figure 1-4 As shown, a three-segment, four-segment universal empty passage catheter device specifically includes an empty passage pipe 1, a three-segment guide groove, a four-segment guide groove, a mounting base 2, a base support frame 3, and a pressing device 4. The three-segment guide grooves and the four-segment guide grooves are arranged in rows on the mounting base 2, the pressing device 4 is fixedly installed on the mounting base 2, and the empty pipe 1 is fixedly clamped in the third through the pressing device 4 The slit guide groove and the four slit guide groove can be quickly replaced by the pressing device 4 at the same time. The installation base 2 is welded to the base support frame 3, and the base support frame 3 is fixedly installed on the ground. The nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com