Patents

Literature

50results about How to "Improve the convenience of replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tire cleaning device for new energy automobiles

InactiveCN108620354AImprove convenienceEfficiencyCleaning using toolsCleaning using gasesRear quarterABSORPTION BASE

The invention relates to the technical field of new energy automobile equipment, and discloses a tire cleaning device for new energy automobiles. The tire cleaning device comprises a fixed base, wherein side plates are fixedly arranged at the left side and right side of the top of the fixed base; a shock absorption base is fixedly arranged in the middle of the upper surface of the fixed base; themiddle of the upper surface of the shock absorption base is fixedly connected to the bottom of a fixed threaded rod; a fixed rod is arranged right above the fixed threaded rod; the exterior of the bottom of the fixed rod is fixedly in sleeve connection with a thread strip; and the top of the fixed rod is fixedly connected to the middle of the bottom of a hair brush. According to the tire cleaningdevice for the new energy automobiles, the left side of a new energy automobile tire is fixed by using a left fixation device, and meanwhile, the right side of the new energy automobile tire is fixedby using a right fixation device, so that the convenience and high efficiency of follow-up tire cleaning work is further improved while the stability of the fixation of the new energy automobile tireis improved.

Owner:胡金友

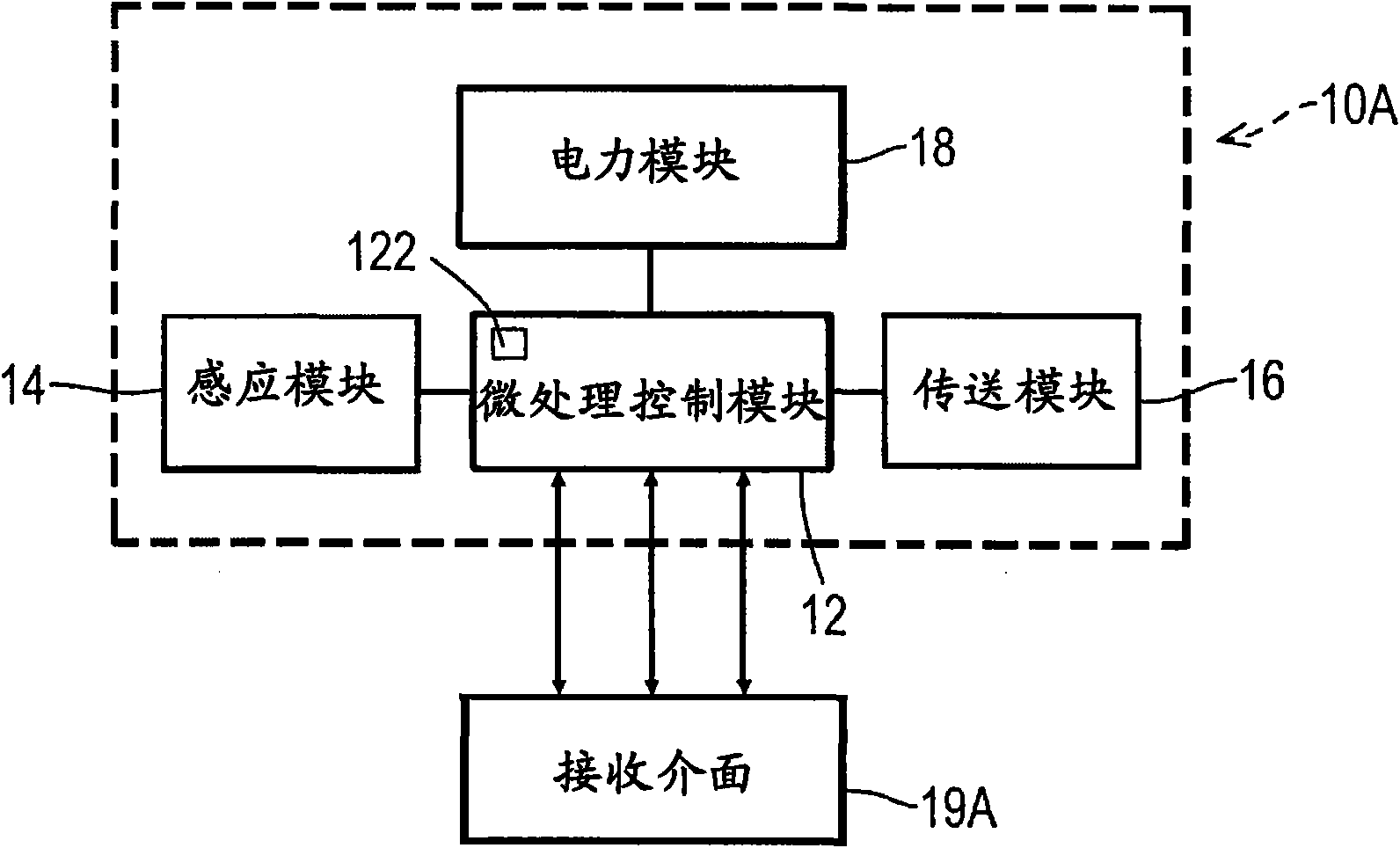

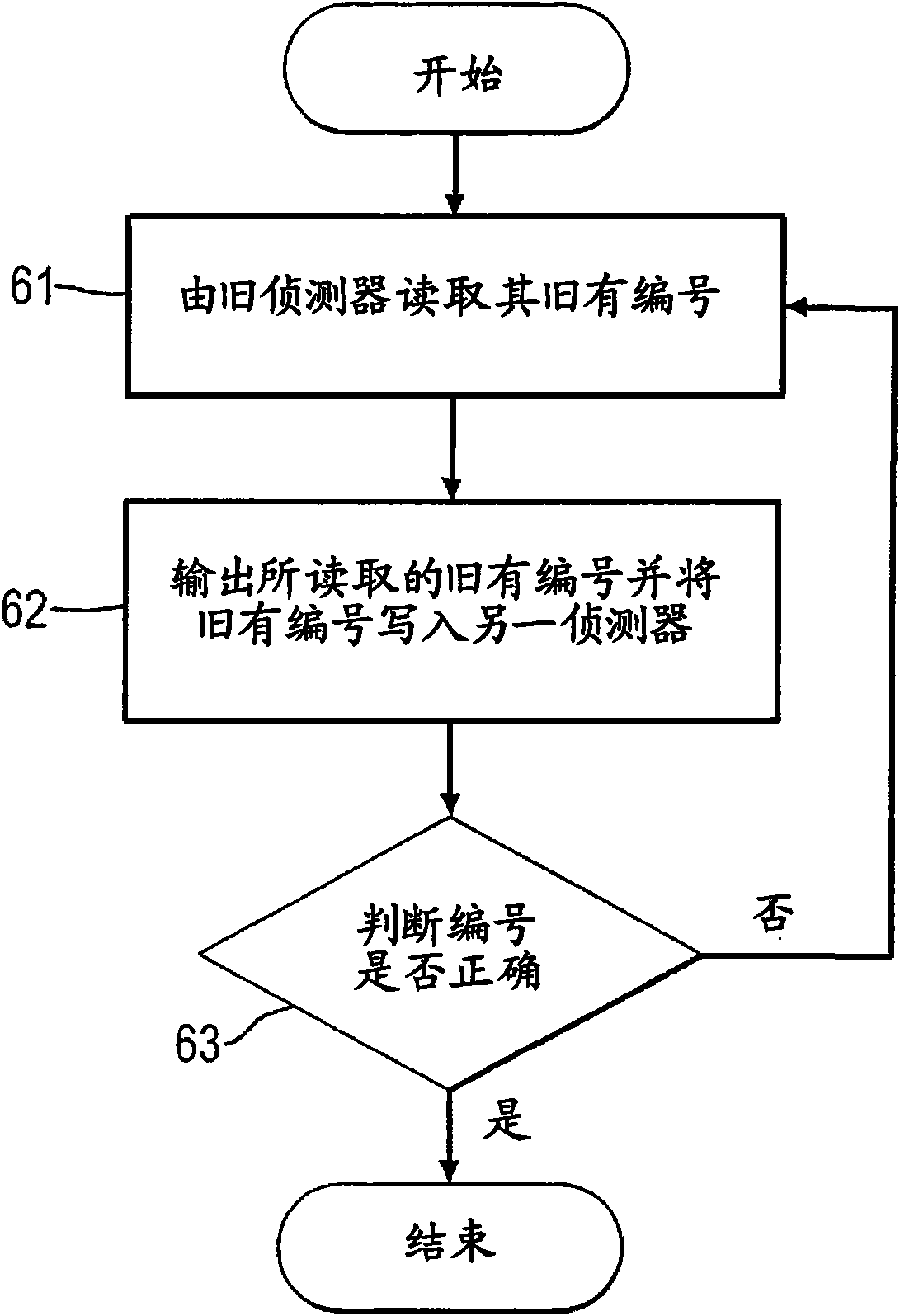

Tire pressure detection device with writable number and inputting method thereof

ActiveCN101881699AImprove work convenienceReduce maintenance costsVehicle tyre testingEngineeringTire pressure

The invention relates to a tire pressure detection device with a writable number and an inputting method thereof. The tire pressure detection device with the writable number comprises a tire condition detection device with a writable number and a setting device. When in use, the number of an old tire pressure detection device to be replaced is firstly read by the setting device; and then, the number is transmitted to the tire condition detection device with a writable number and is set as the number of the tire condition detection device with the writable number. Therefore, a user can directly use the tire condition detection device with the writable number after number write-in, thus dispensing with the repeated complex setting operation.

Owner:ORANGE ELECTRONICS

Rotary oil cylinder for lathe spindle box

PendingCN107695364AEasy to disassembleImprove the convenience of disassembly and assemblyLarge fixed membersPositioning apparatusCylinder blockHeadstock

The invention provides a rotary oil cylinder for a lathe spindle box and belongs to the technical field of machinery. By means of the rotary oil cylinder, the problem that existing rotary oil cylinders are inconvenient to dismount. The rotary oil cylinder for the lathe spindle box comprises a cylinder body. The cylinder body is provided with a fitting end and a mounting end, wherein the mounting end is used for being connected with a spindle of the lathe spindle box. The cylinder body is internally provided with a piston, wherein the piston can move. One end of the piston is provided with a protruding fitting portion. The fitting portion extends out of the fitting end of the cylinder body, and a mounting disc is detachably connected to the end of the fitting portion. A pull tube of the lathe spindle box can sequentially penetrate the fitting portion and the mounting disc, and detachable connection can be formed between the pull tube and the mounting disc. The rotary oil cylinder has the beneficial effects of being convenient to dismount, simple in structure and the like.

Owner:郭必龙

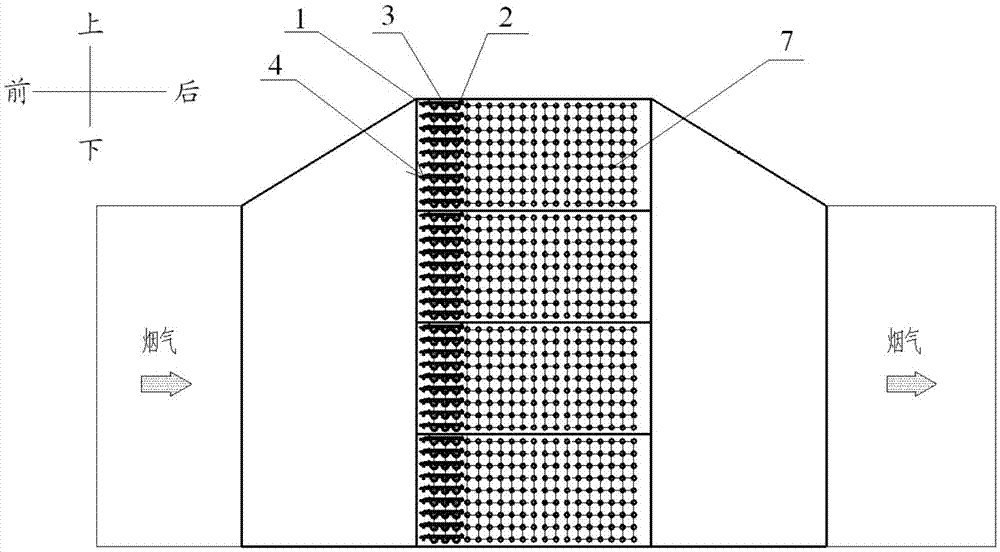

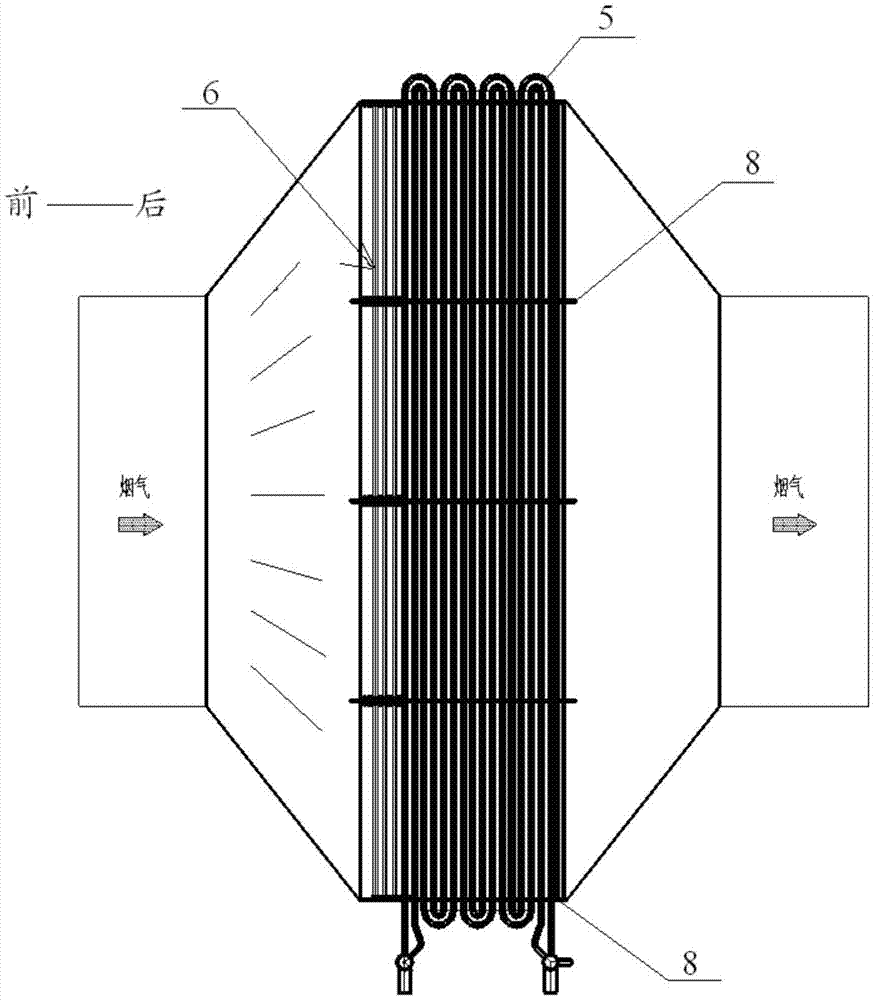

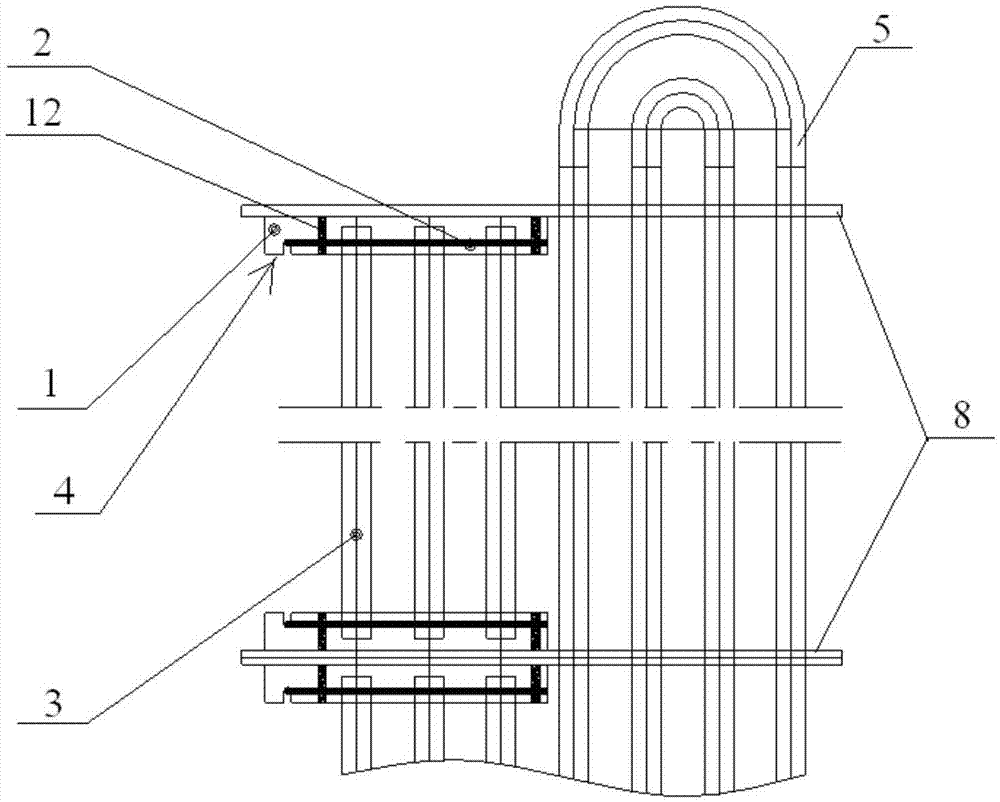

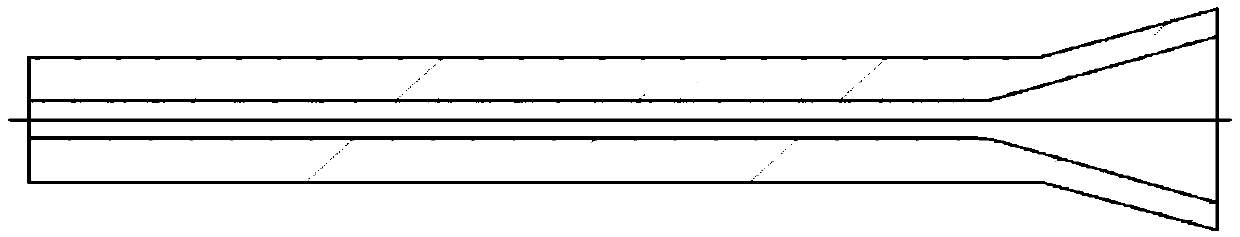

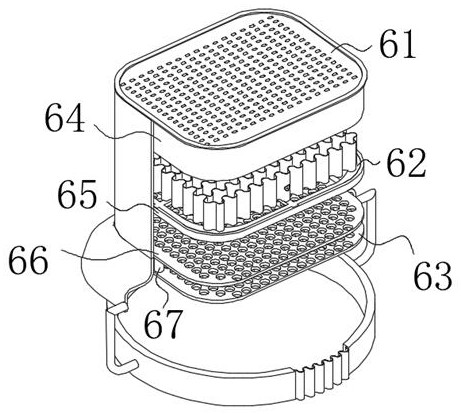

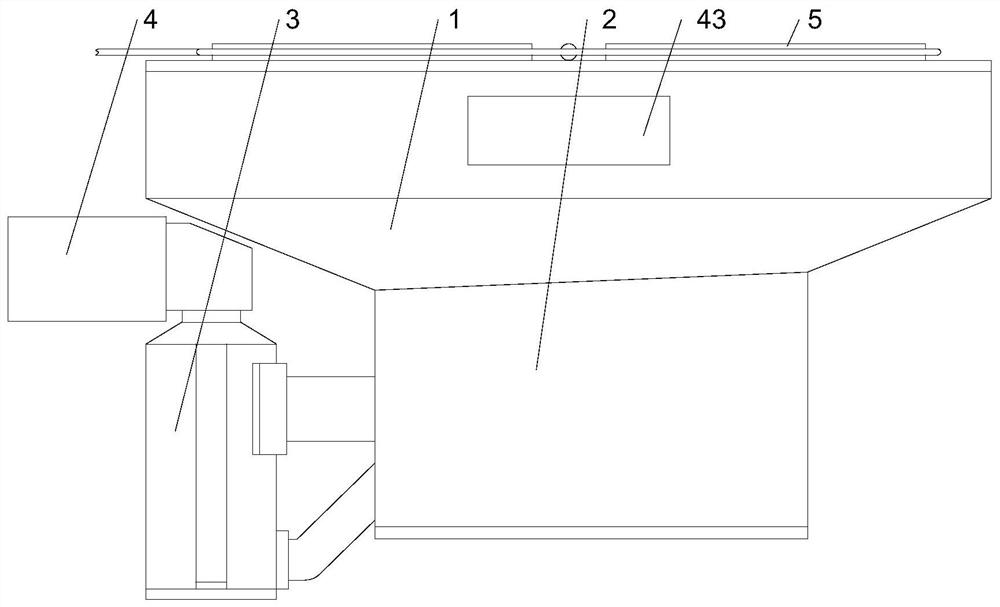

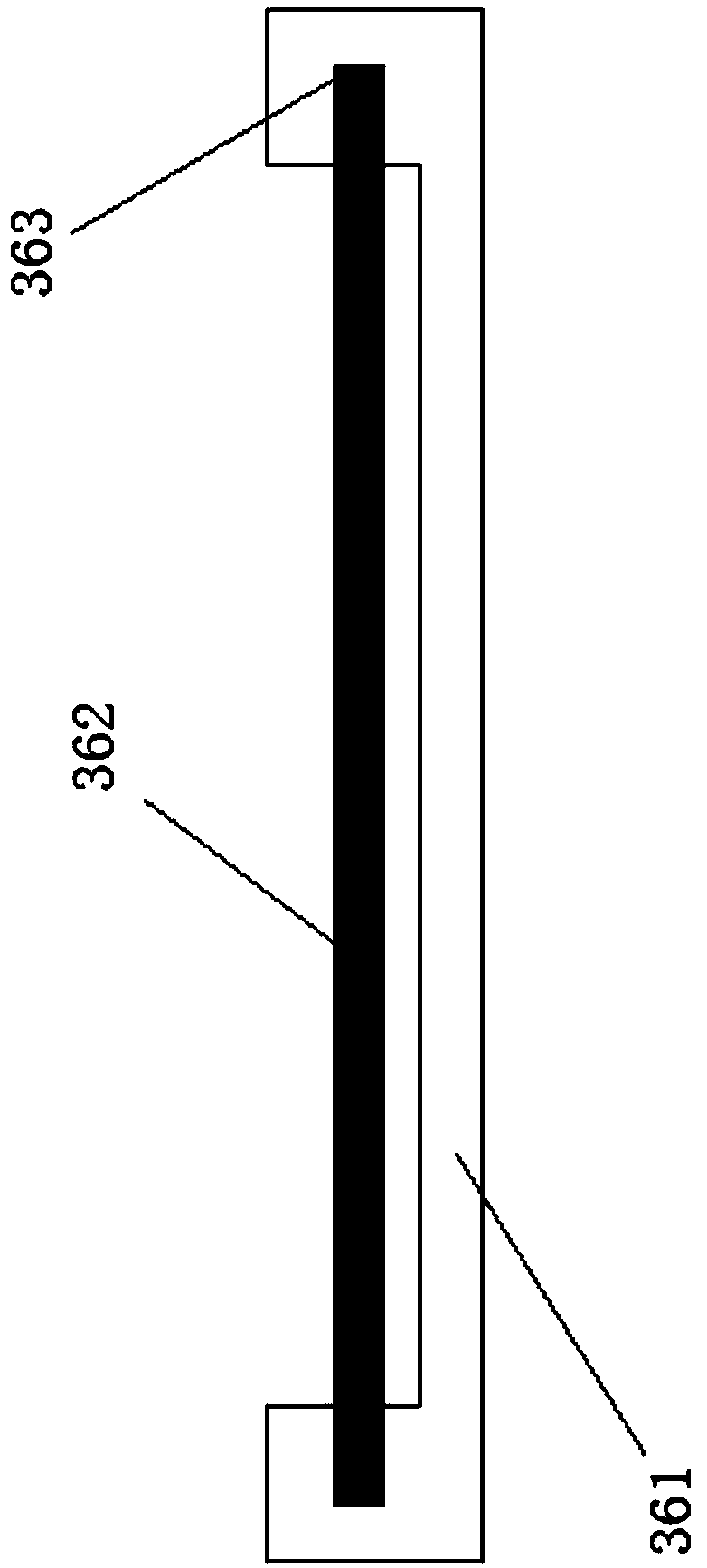

Abrasion-proof false pipe component, detachable assembly component and smoke heat exchanger

ActiveCN105444606APrevent prolapseRealize installation positioningSafety devices for heat exchange apparatusCombustion technology mitigationPlate heat exchangerMechanical engineering

The invention provides a smoke heat exchanger, an abrasion-proof false pipe component and a detachable assembly component of abrasion-proof false pipes. Detachable assembly of the abrasion-proof false pipes can be realized, so that changing of the abrasion-proof false pipes after abrasion is more rapid and convenient, and meanwhile, the performance of the smoke heat exchanger is prevented from being affected by changing. The detachable assembly component comprises a support plate and an insertion rod, wherein the top surface of the support plate is provided with a plurality of assembly positions; the assembly positions are distributed at intervals along the extension direction of the support plate, are in one-to-one correspondence with the abrasion-proof false pipes, and are used for supporting the abrasion-proof false pipes; and the insertion rod is inserted and connected with the top surface of the support plate so as to press and block the abrasion-proof false pipes. The abrasion-proof false pipe component comprises the plurality of abrasion-proof false pipes which are arranged at intervals in the same direction, and the two ends of each abrasion-proof false pipe separately extend into the corresponding assembly position of the corresponding detachable assembly component. The smoke heat exchanger comprises a plurality of heat exchange pipe rows and the above abrasion-proof false pipe components which are arranged at the front-most end and in front of the heat exchange pipe rows.

Owner:FUJIAN LONGKING

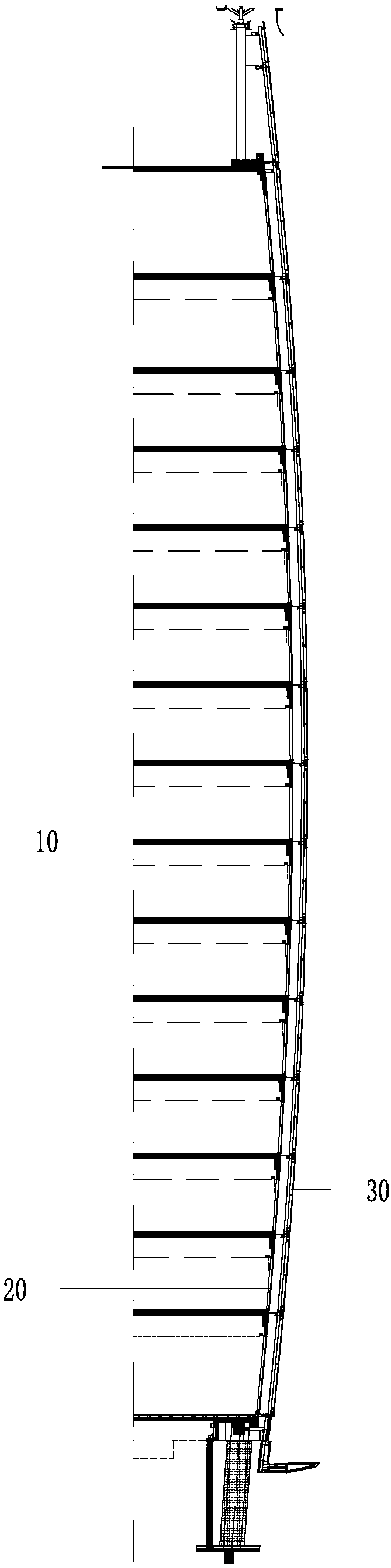

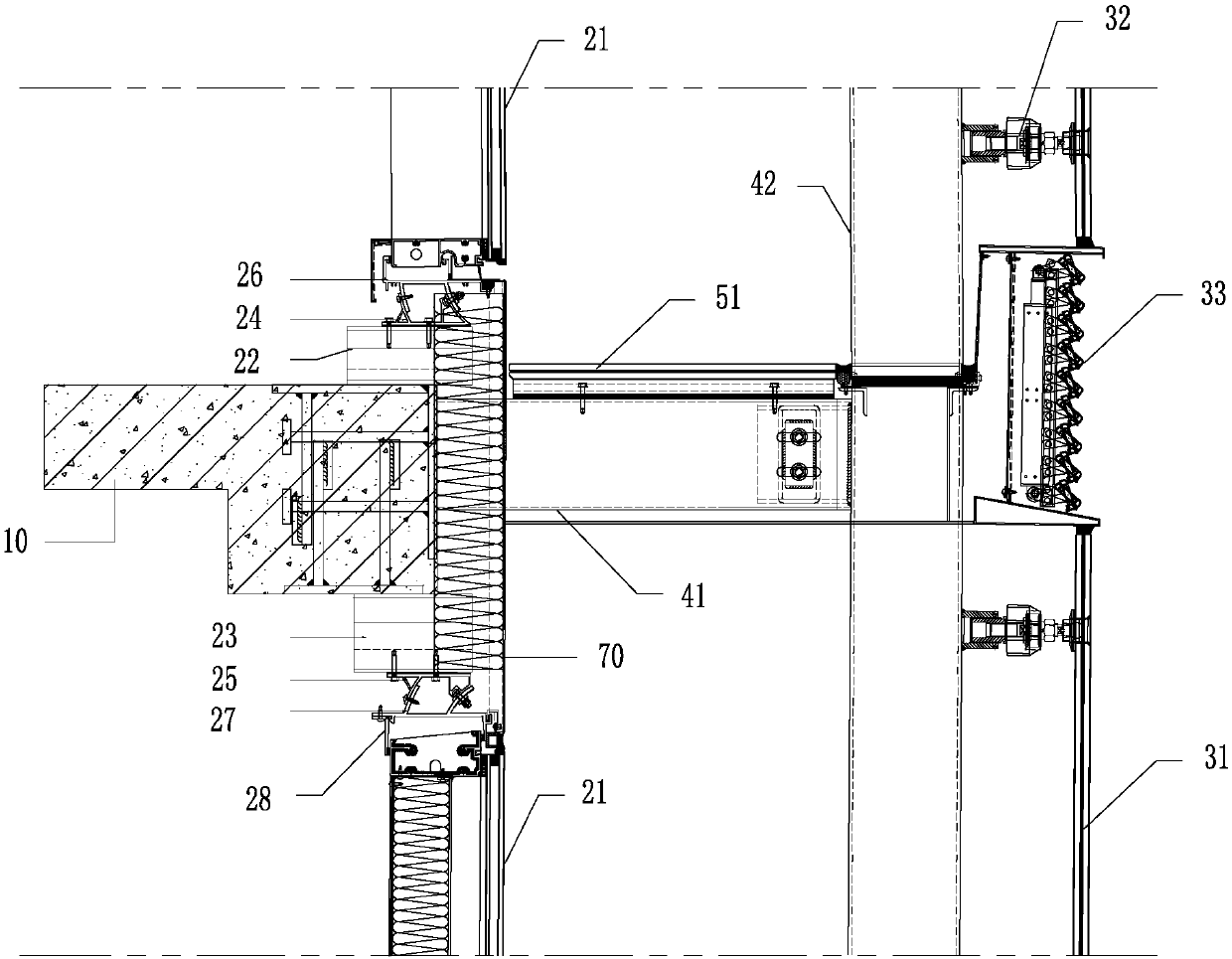

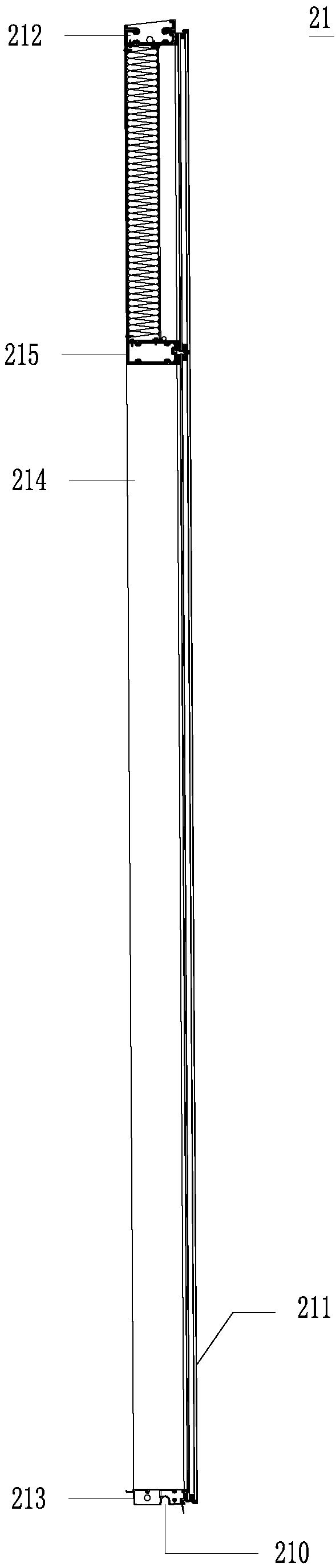

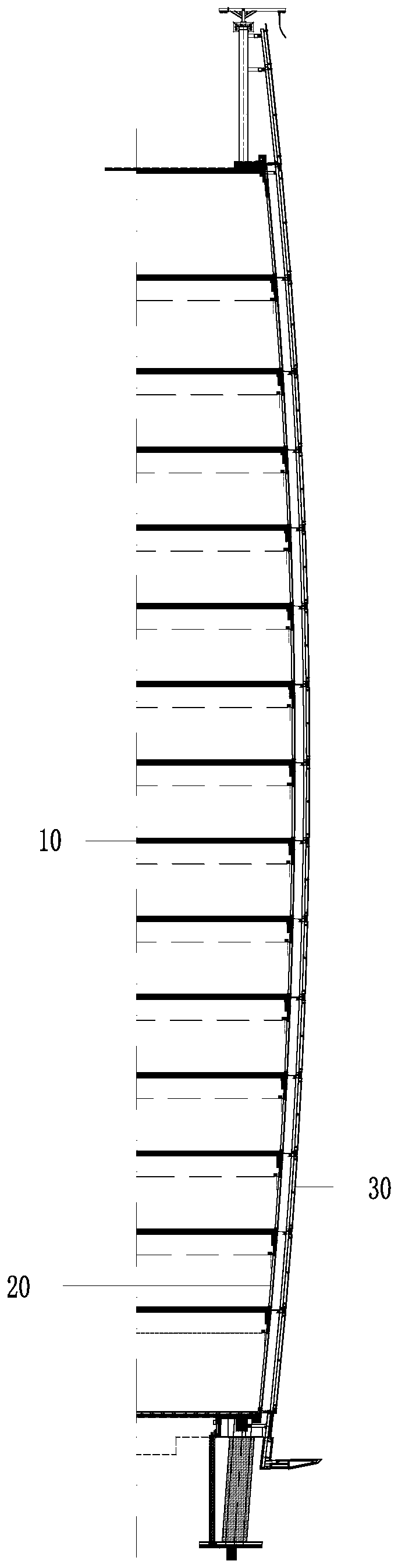

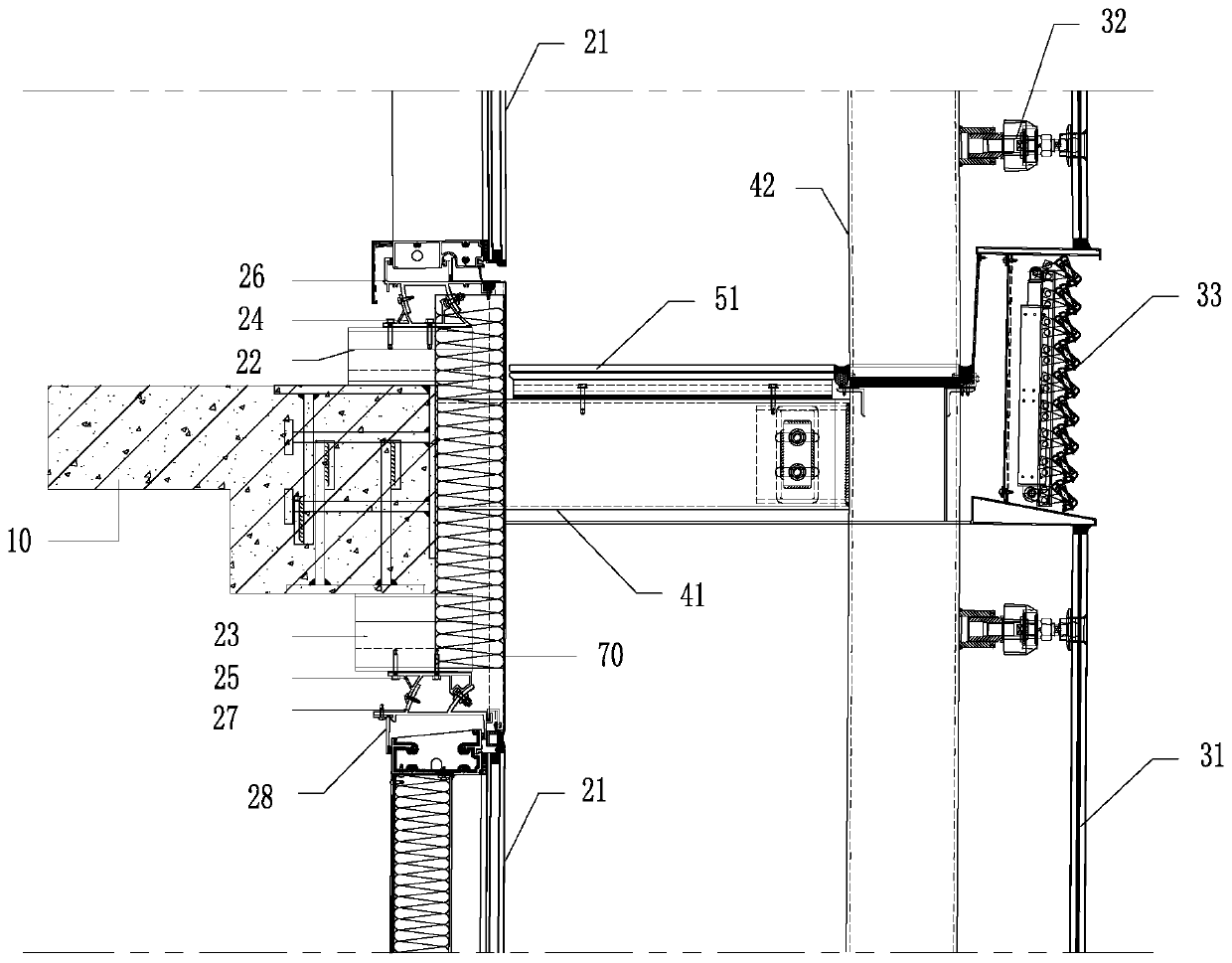

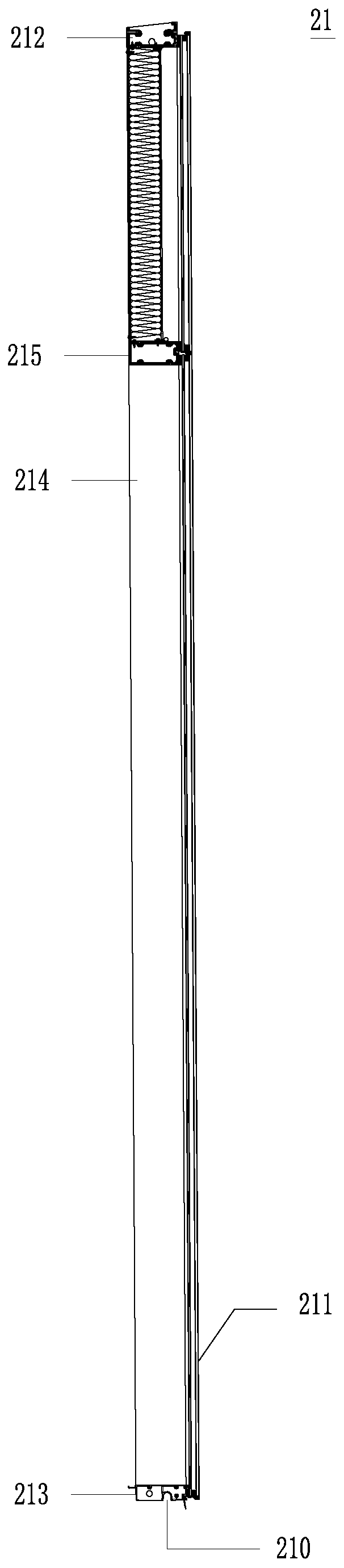

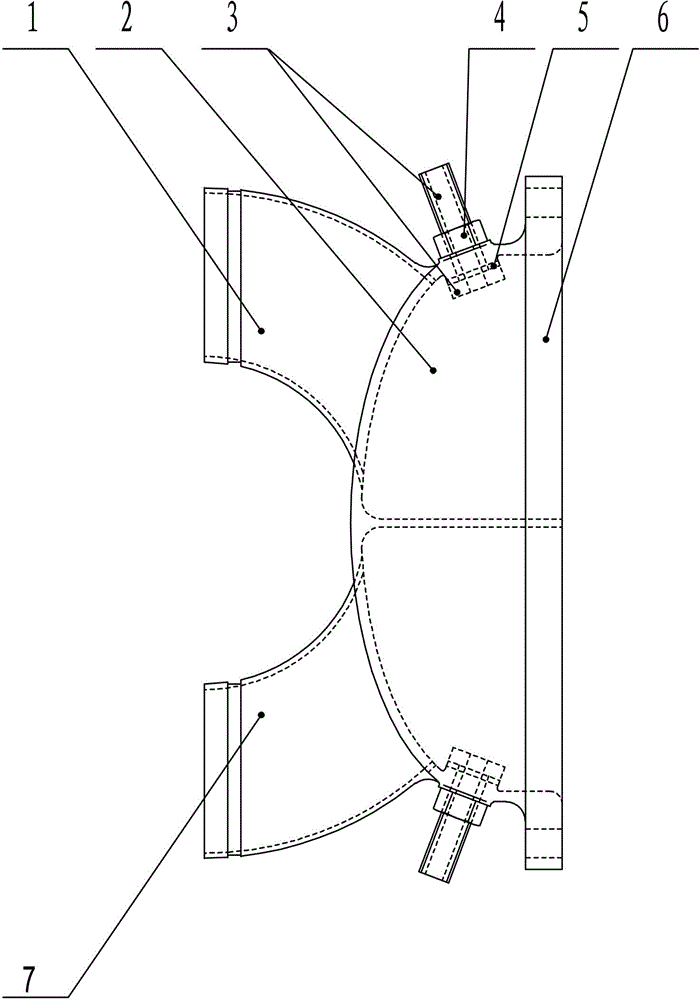

Ground type external-circulation double-layer curved-face curtain wall and installation technology thereof

ActiveCN107654005AMeet the appearance and visual needsImprove structural safetyWallsSupporting systemUpper floor

The invention discloses a ground type external-circulation double-layer curved-face curtain wall and an installation technology thereof. The ground type external-circulation double-layer curved-face curtain wall comprises a curved-face inner curtain wall body and a curved-face outer curtain wall body, wherein the curved-face inner curtain wall body is installed on a main body structure, and the curved-face outer curtain wall body is located on the outer side of the inner curtain wall body and fixed to the main body structure through an outer supporting system penetrating through the inner curtain wall body. An inner curtain wall unit body is installed between the upper and lower adjacent floors of the main body structure, the bottom of the inner curtain wall unit body is supported on a concentric rotary bottom adjusting assembly installed at the top of the lower floor, the top of the inner curtain wall unit body is fixed to a concentric rotary top adjusting assembly installed at the bottom of the upper floor, and the concentric rotary bottom adjusting assembly and the concentric rotary top adjusting assembly adjust the inclination and upward-facing angle, towards the indoor space,of the inner curtain wall unit body through a concentric rotary mode. According to the ground type external-circulation double-layer curved-face curtain wall and the installation technology thereof, the curtain wall structure is simple, the energy-saving effect of double-layer curtain-wall external circulation is achieved, the appearance visual demand of a smooth curved face is further met, the structural safety performance is good, the installation technology is easy to implement and not tedious, and the construction efficiency is high.

Owner:JANGHO GRP

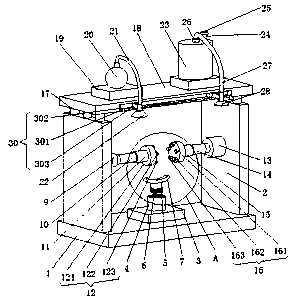

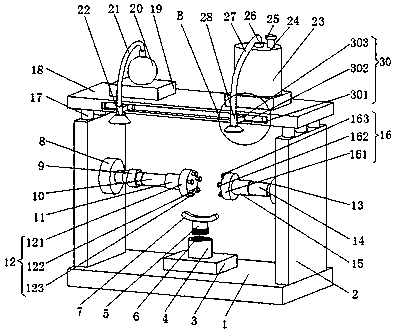

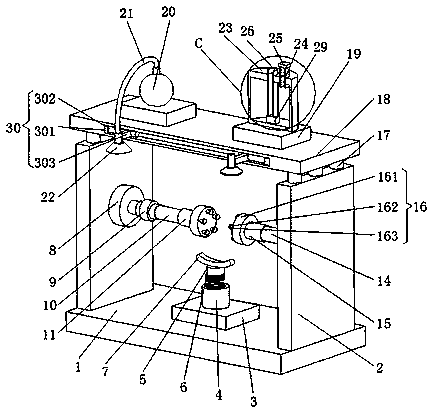

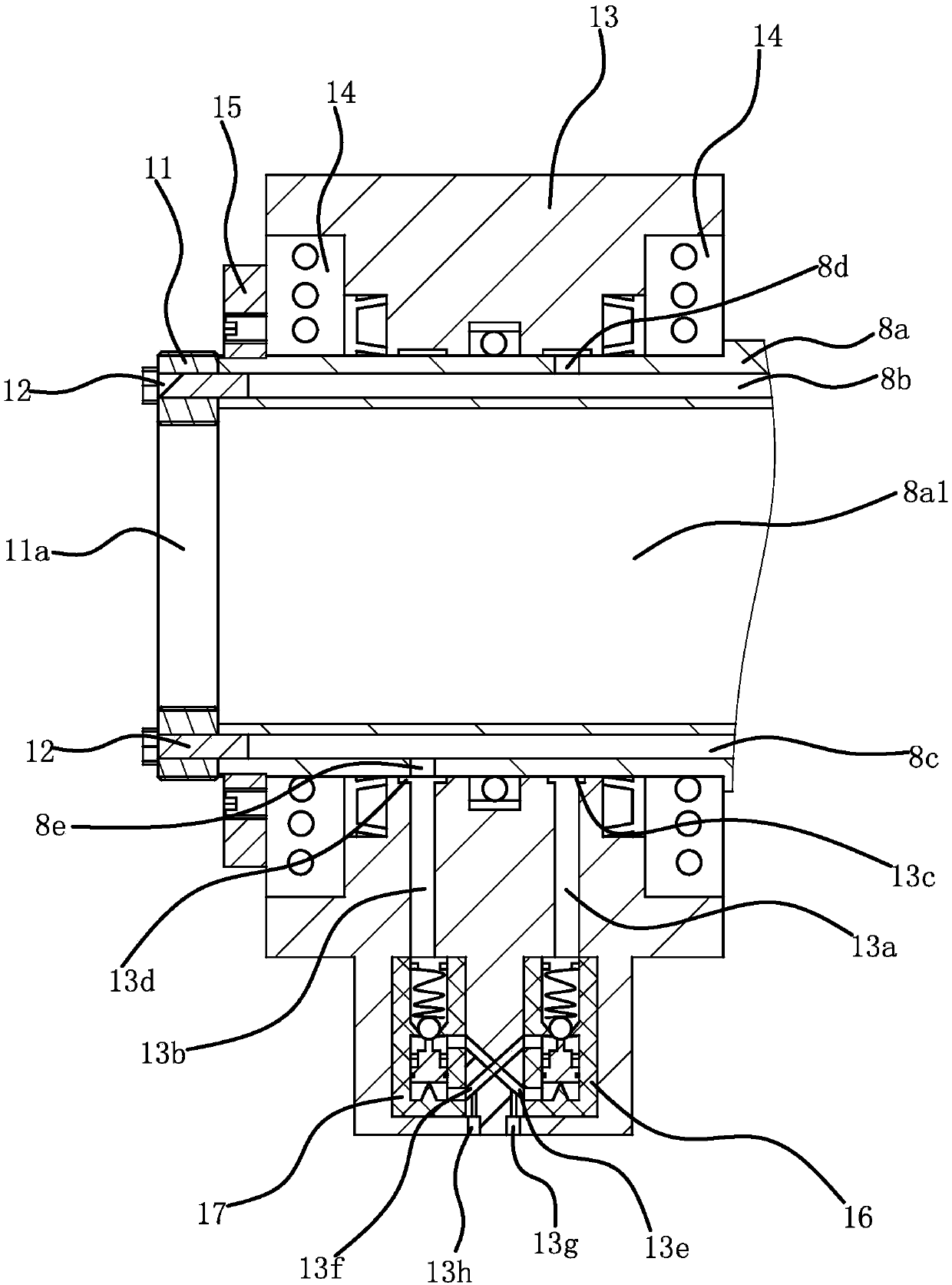

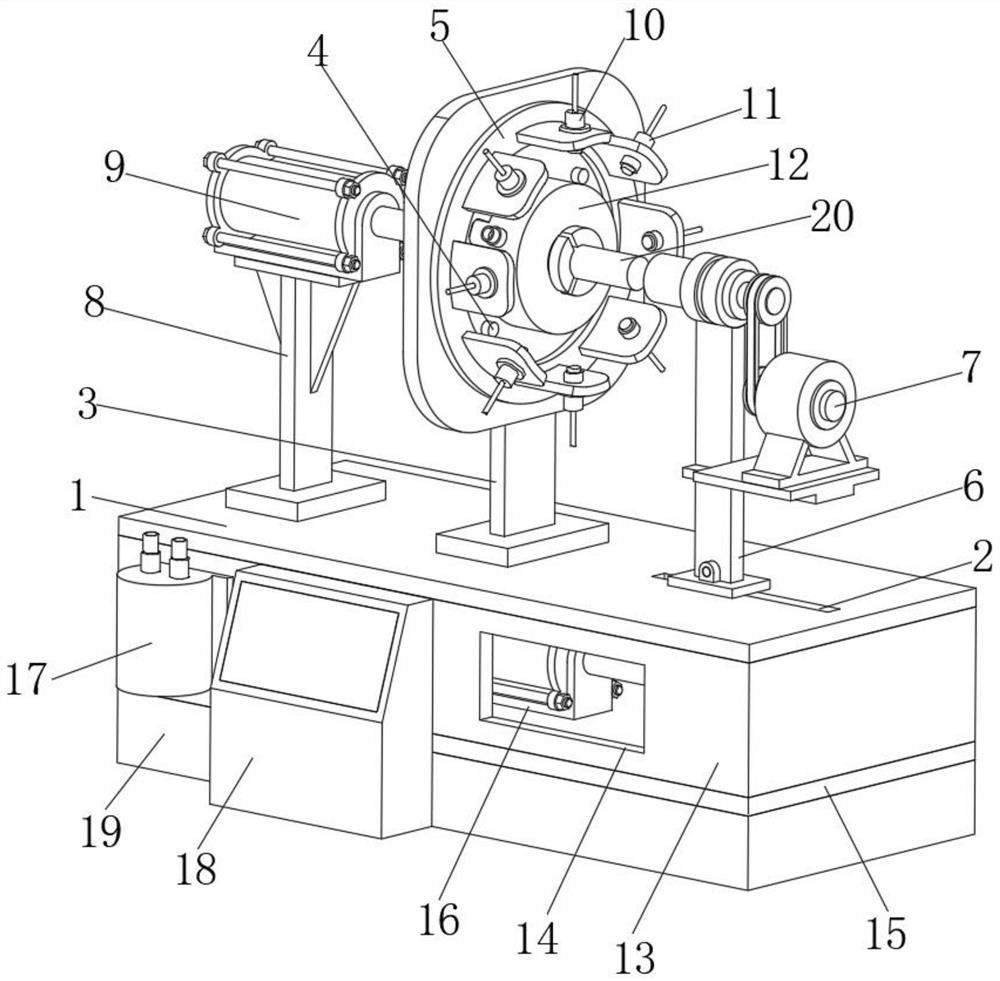

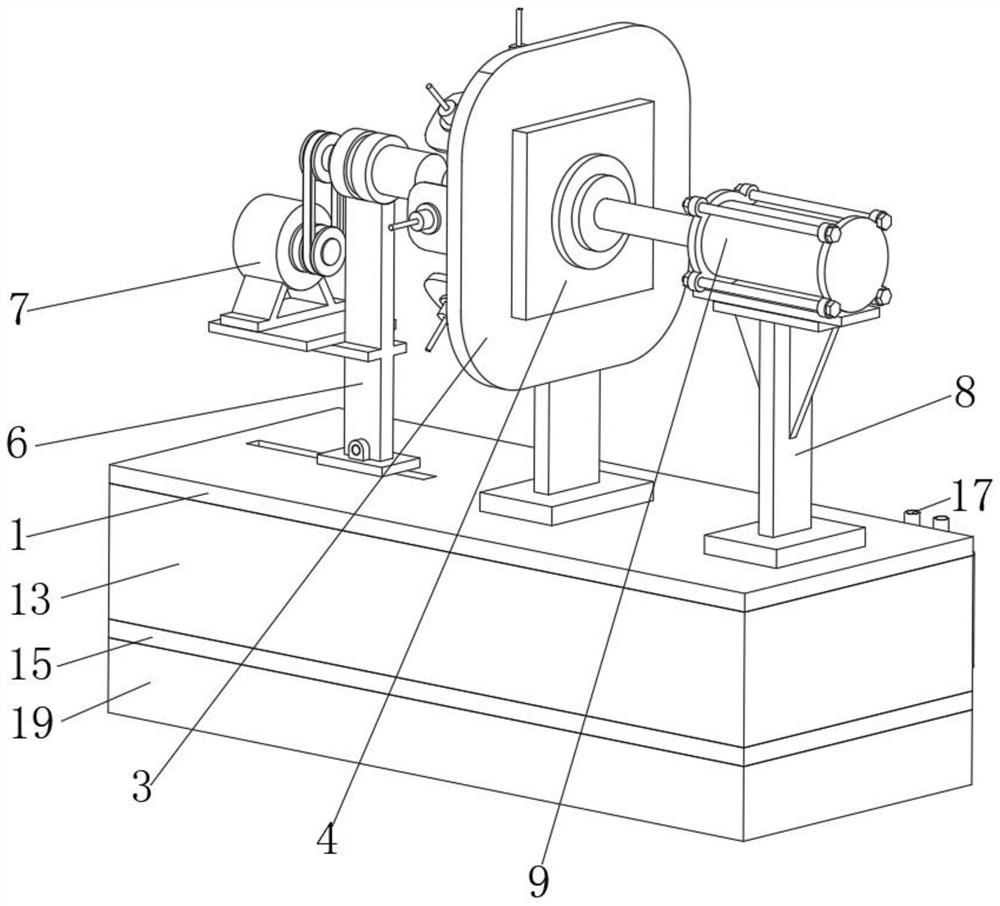

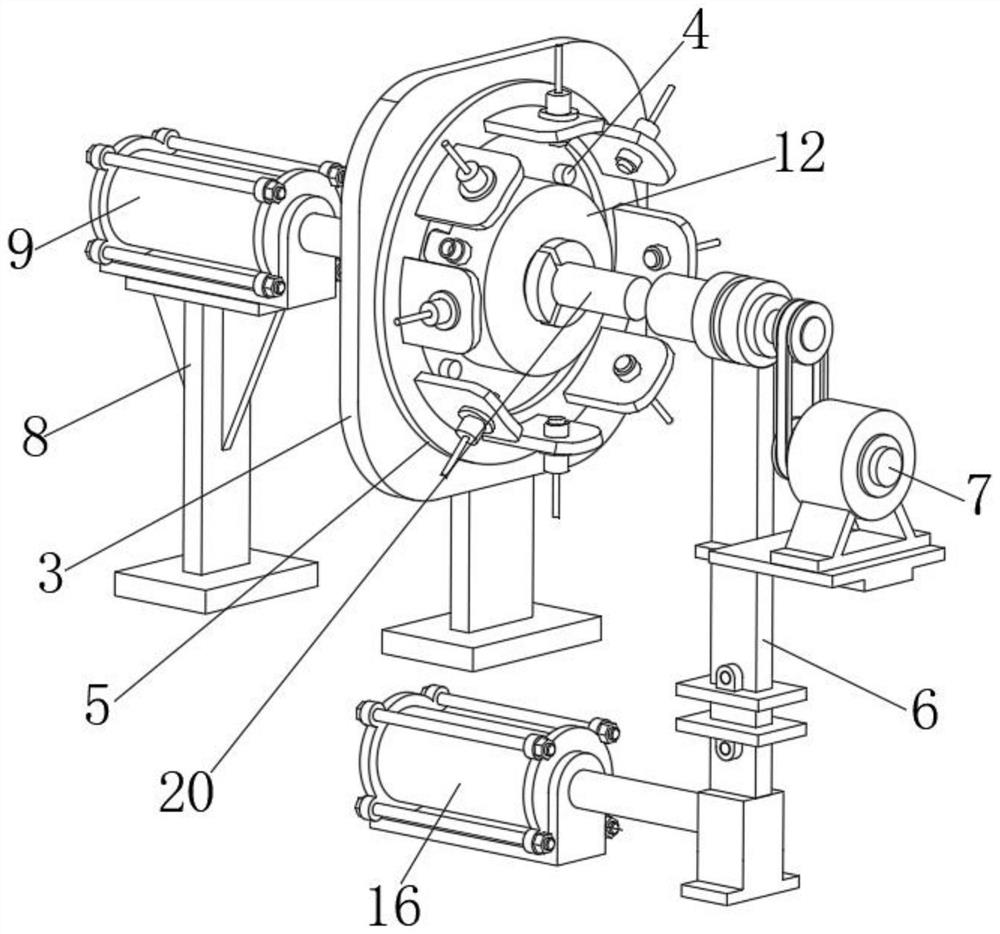

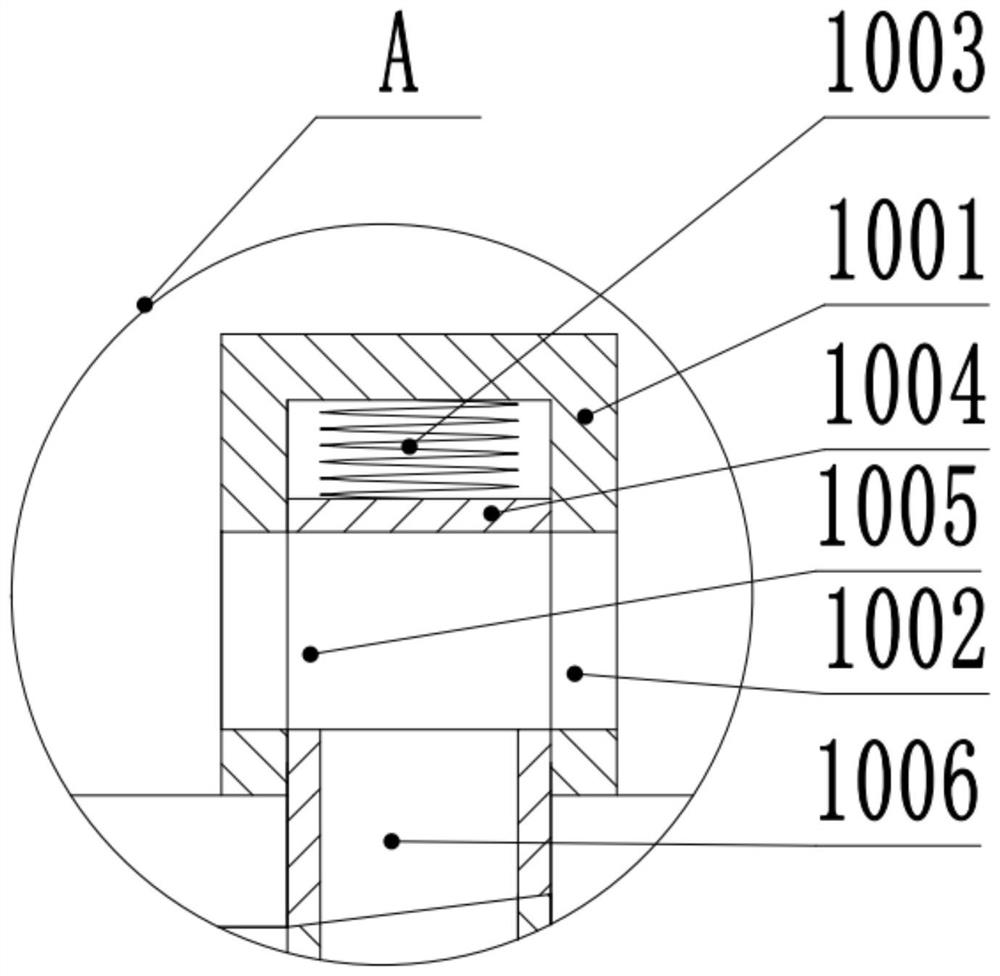

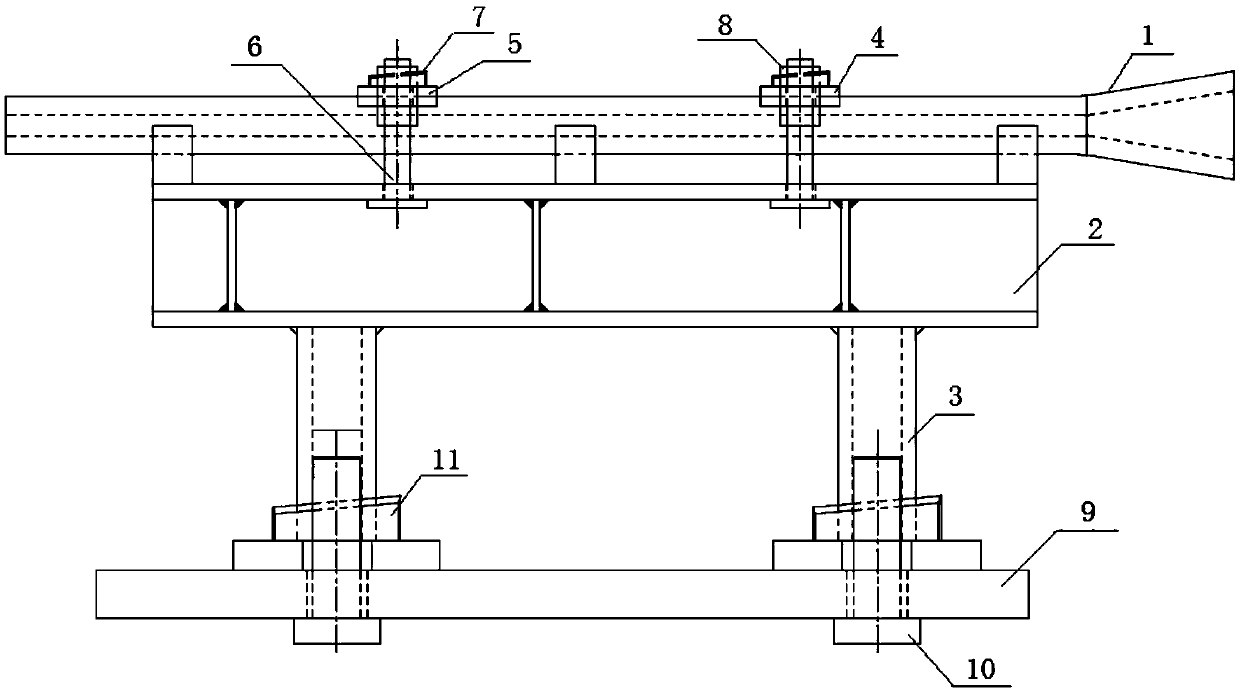

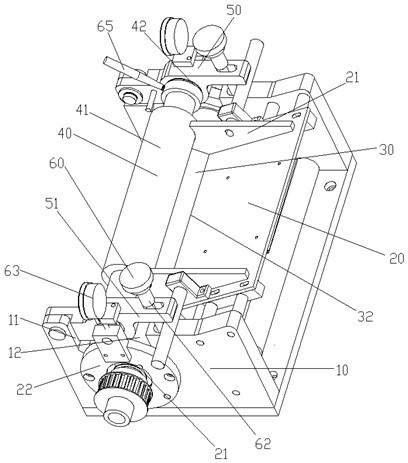

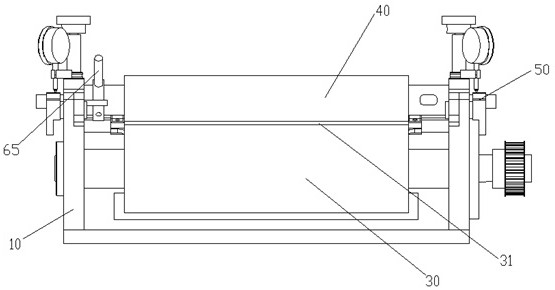

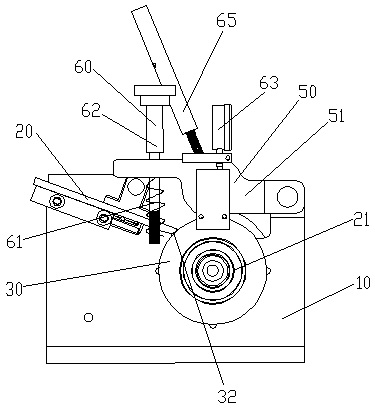

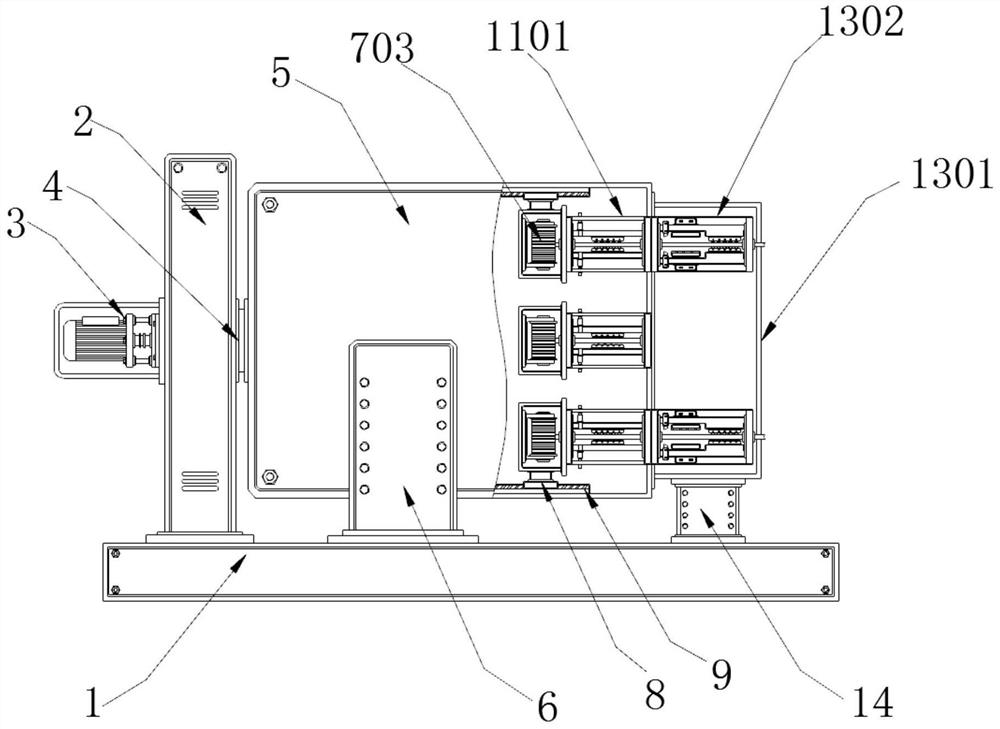

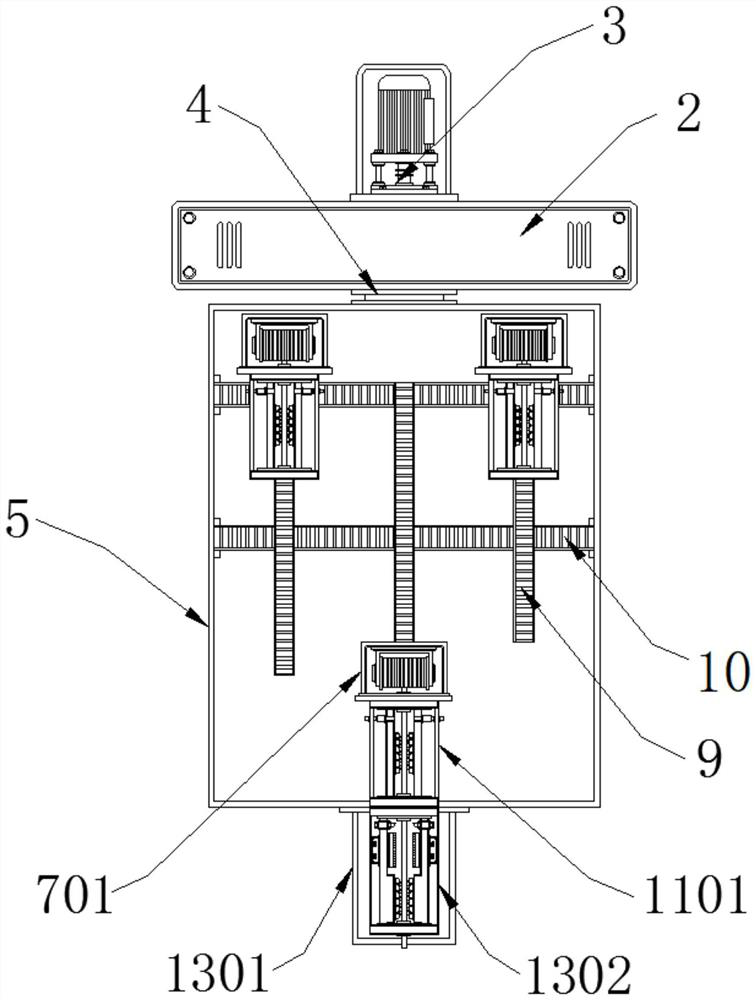

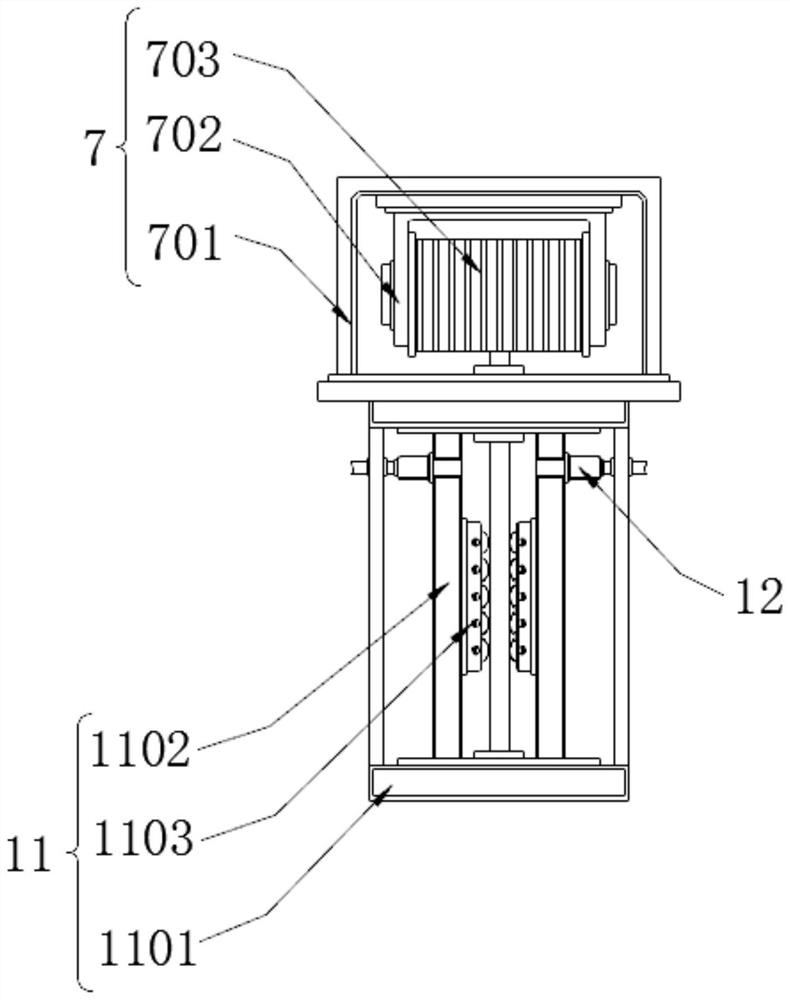

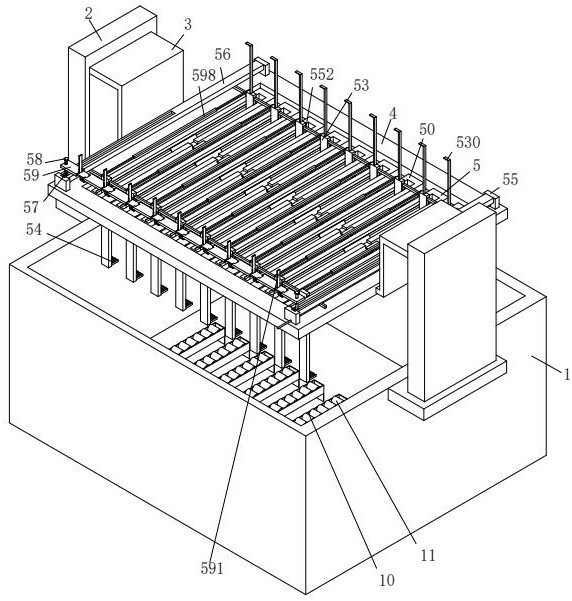

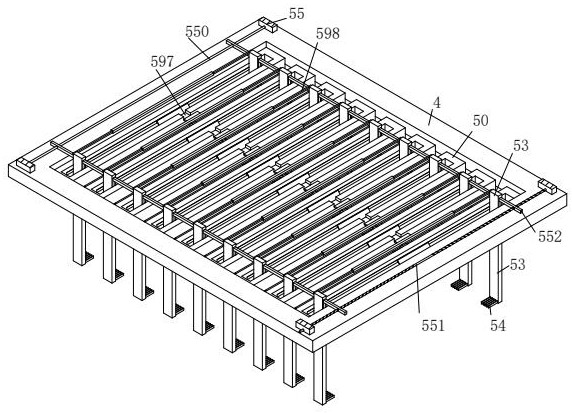

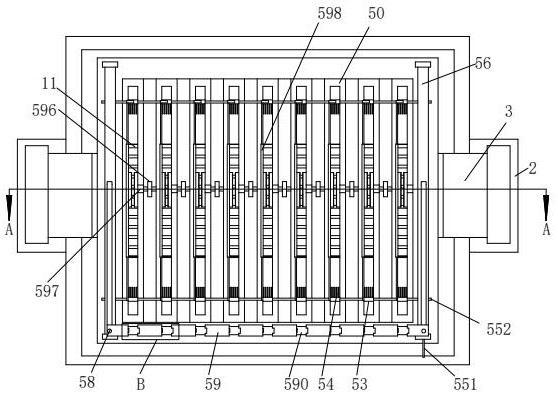

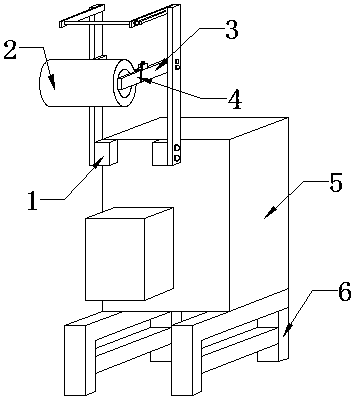

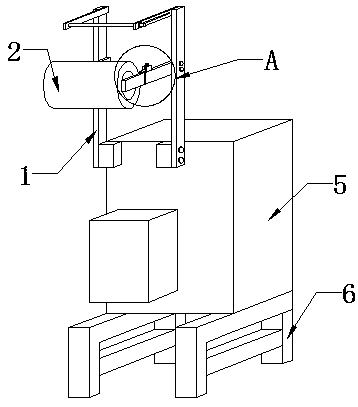

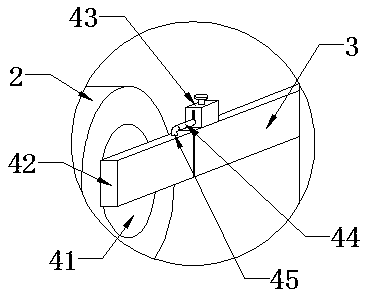

Reliability test device for elastic chuck of numerical control machine tool

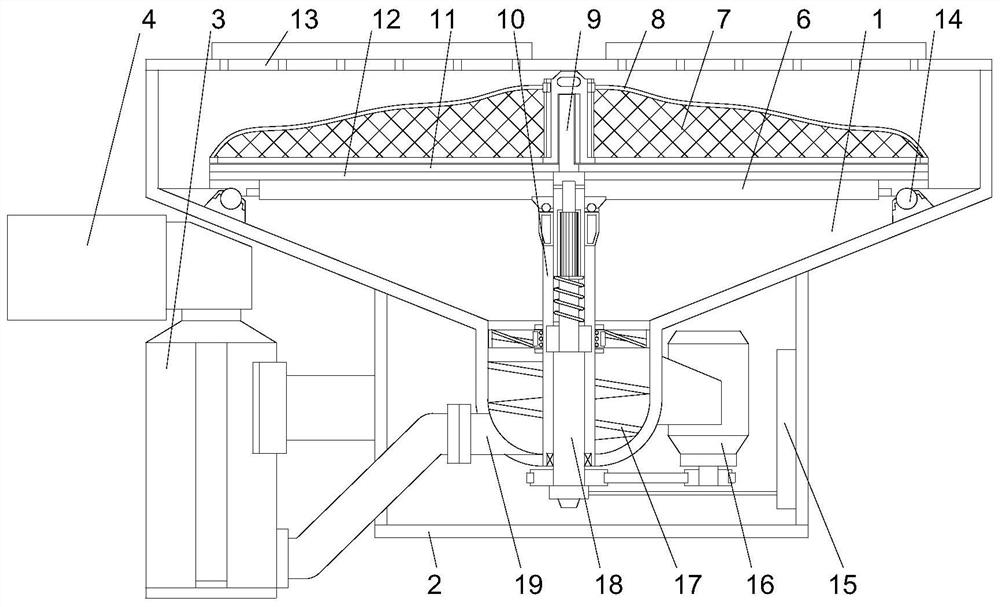

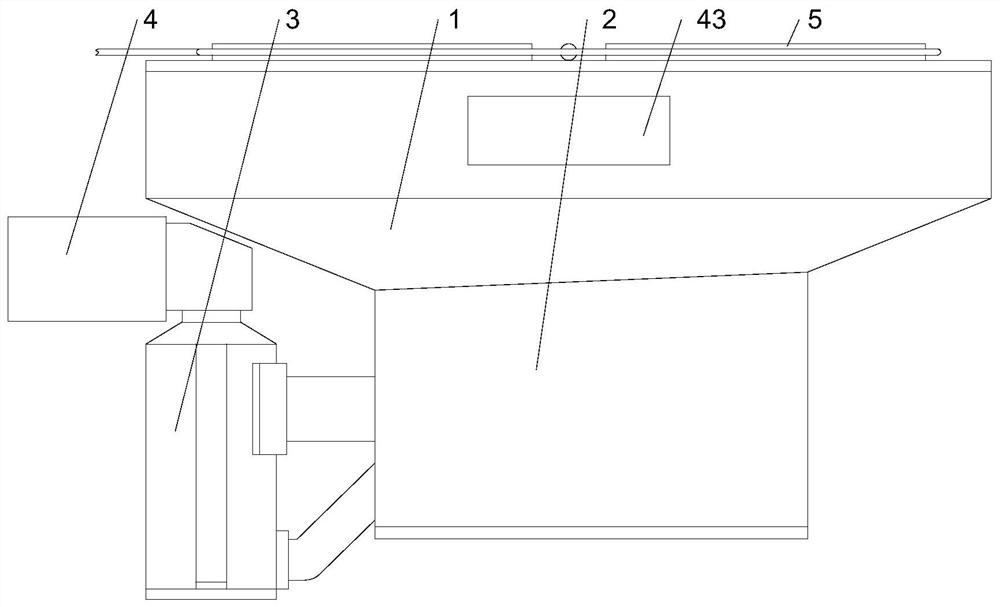

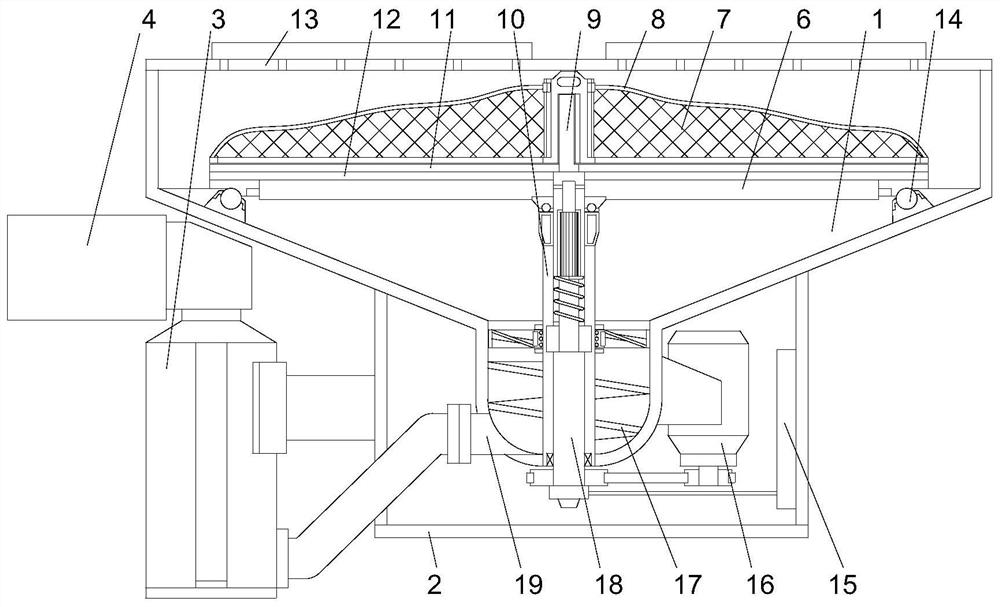

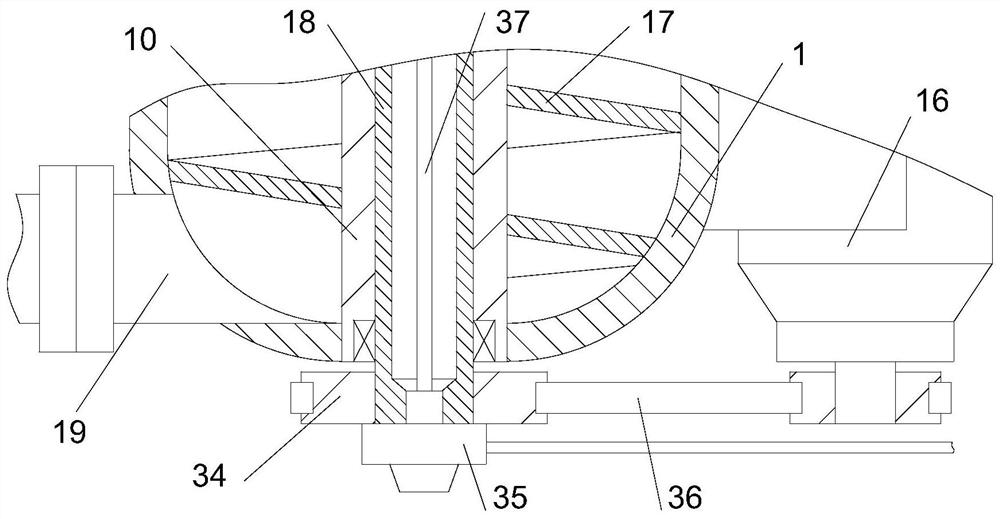

ActiveCN112461531AEasy to fixImprove the convenience of replacementMachine part testingNumerical controlHydraulic cylinder

The invention discloses a reliability test device for an elastic chuck of a numerical control machine tool, and the device comprises a bedplate, a connecting mechanism is fixedly connected to the middle part of the upper end of the bedplate, a supporting frame is fixedly connected to the left part of the upper end of the bedplate, and a clamping hydraulic cylinder is fixedly connected to the upperend of the supporting frame. A clamping mechanism is fixedly connected to the output end of the clamping hydraulic cylinder, a detector mounting mechanism is fixedly connected to the upper portion ofthe right end of the connecting mechanism, a displacement sensor and a temperature sensor are fixedly connected to the detector mounting mechanism in a penetrating mode, and a sliding supporting mechanism is arranged on the right portion of the upper end of the table plate. A loading mechanism is arranged on the upper portion of the sliding supporting mechanism, and a console is fixedly connectedto the middle of the front end of the supporting surrounding shell. According to the reliability test device for an elastic chuck of the numerical control machine tool, the reliability test of the elastic chuck body has reproducible conditions, so that the test can be repeated, the test period is short, the test effect is better, and data obtained by the test is more valuable.

Owner:JILIN UNIV

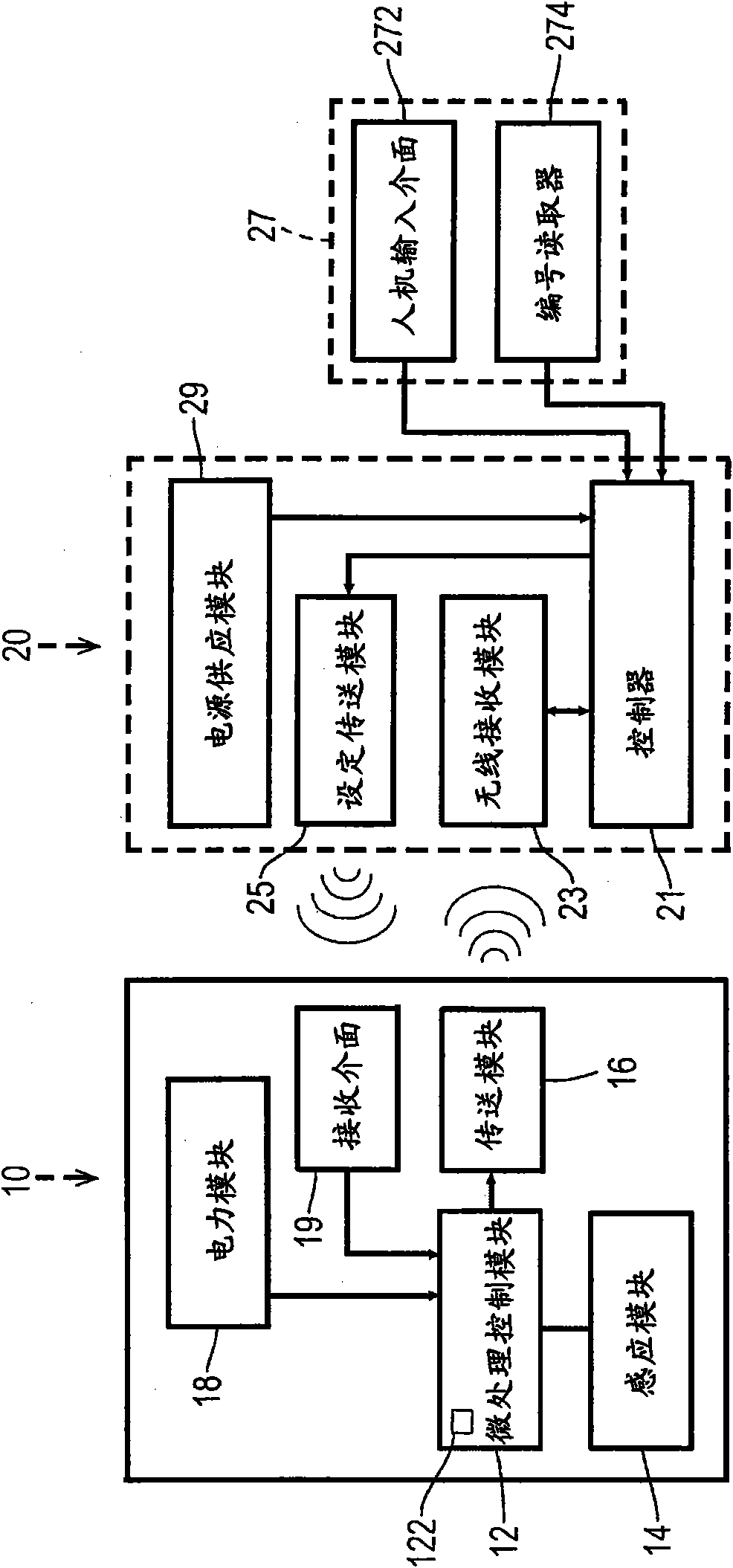

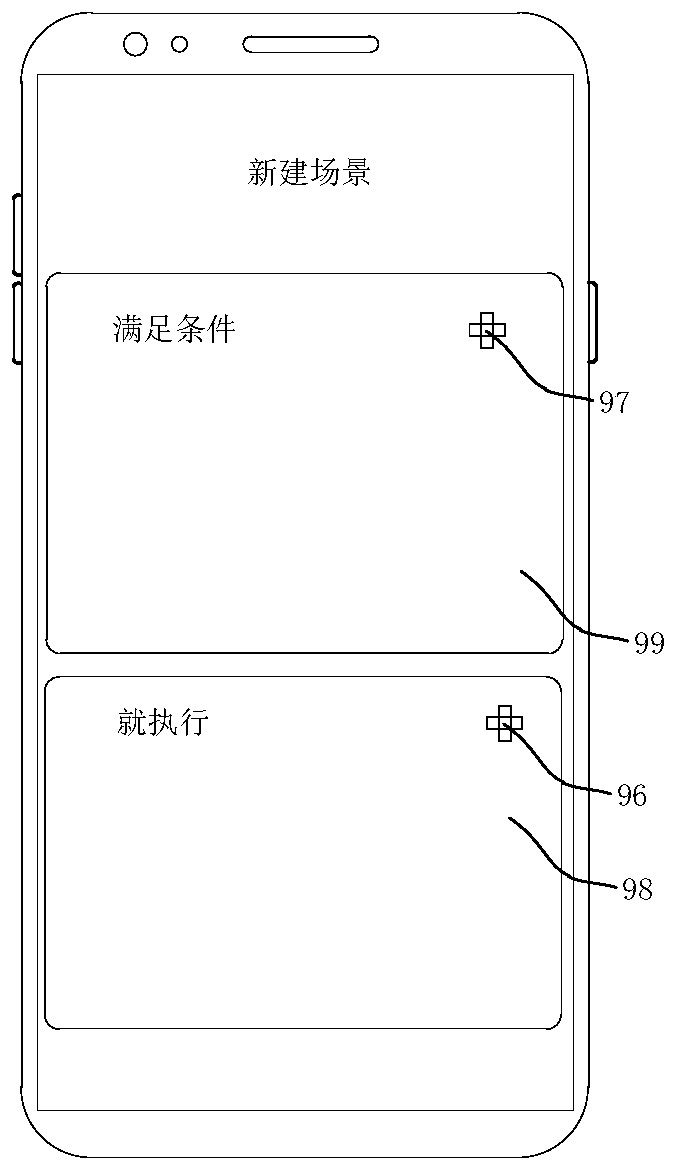

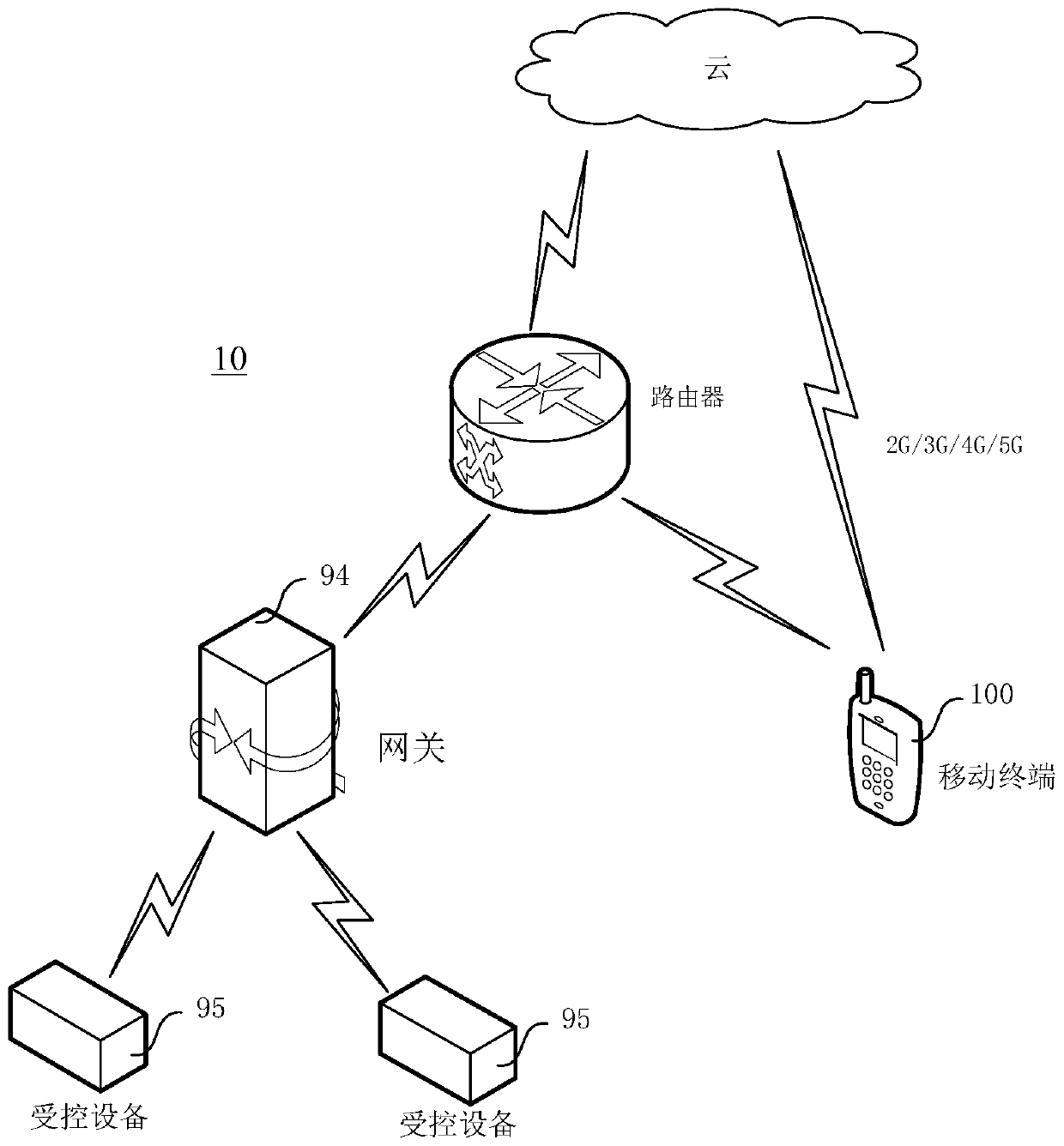

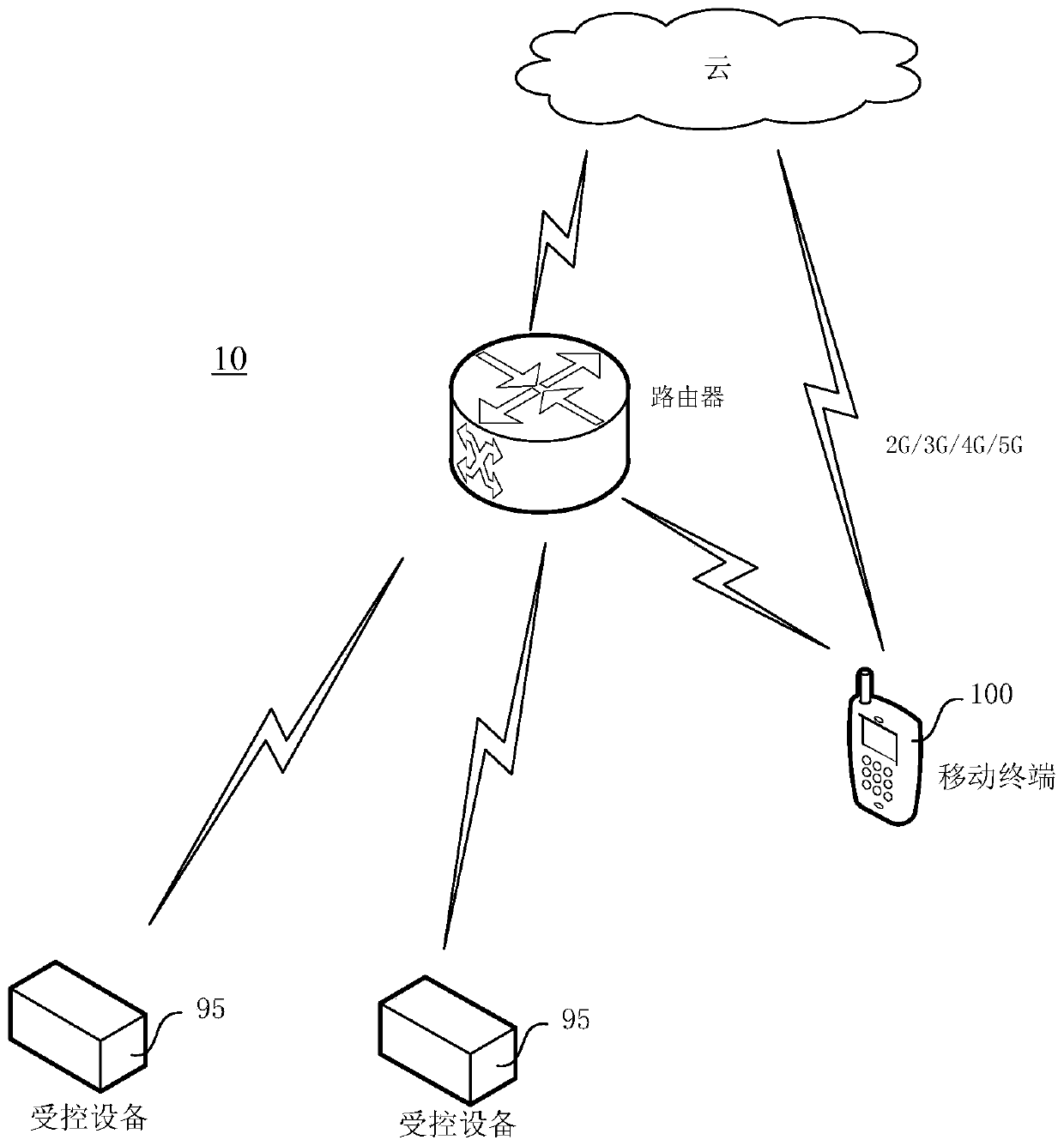

Equipment control method and device, electronic equipment and Internet of Things system

ActiveCN109714195AImprove experienceImprove the convenience of replacementData switching networksWeb data retrieval using information identifiersElectric equipmentEmbedded system

The embodiment of the invention discloses an equipment control method and device, electronic equipment and an Internet of Things system. The method comprises the steps of obtaining an identifier of afirst device and an identifier of a second device; Obtaining a replacement guide resource corresponding to the identifier of the first device; Finding a control resource associated with the identifierof the first device in the replacement guide resources; And modifying the control resource to be associated with the identifier of the second device. According to the method, the control resource ofthe first equipment can be automatically configured to the second equipment in the replacement process of the equipment, and then replacement of the equipment is completed, so that a user does not need to manually configure the control resource of the second equipment any more, the replacement convenience of the equipment is improved, and meanwhile, the user experience is also improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

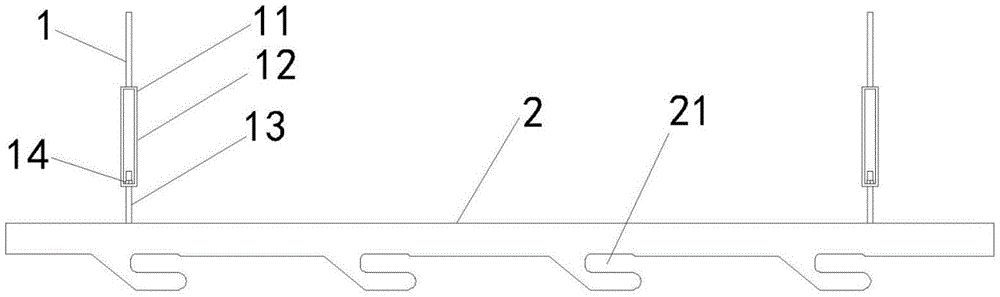

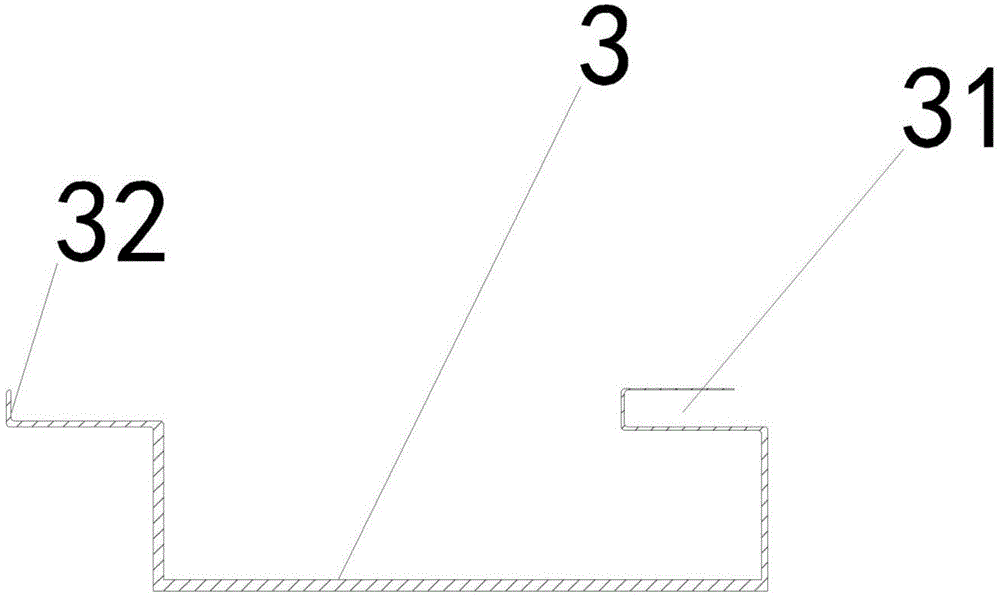

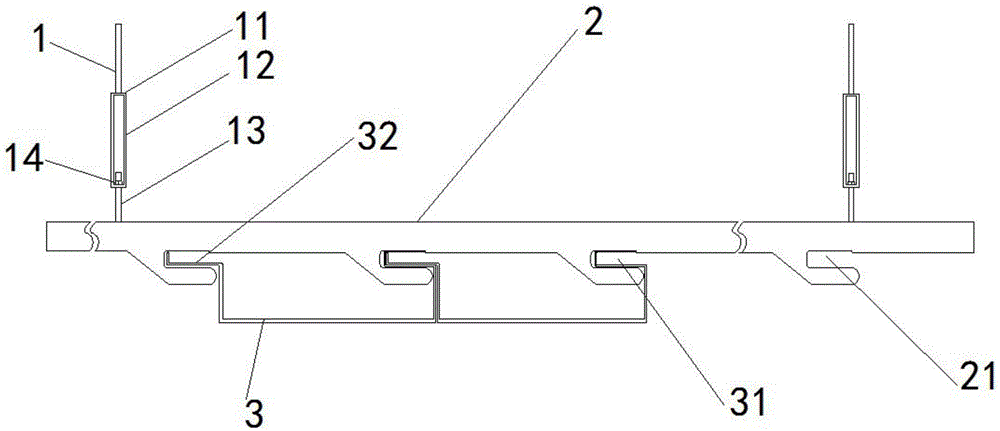

Inserted connection type aluminum alloy ceiling mounting structure

The invention discloses an inserted connection type aluminum alloy ceiling mounting structure which is formed by hanging rods, a bearing main runner and aluminum alloy ceiling boards. One end of each hanging rod is fixed to the top of a wall, and a connector connected with the bearing main runner is fixed to the other end of each hanging rod. The section of the bearing main runner is in a 'C' shape, one side of an opening of the 'C' shape is provided with mounting holes, and the other side of the opening of the 'C' shape is provided with insert slots used for fixing the aluminum alloy ceiling boards. Insert fastening structures matched with the insert slots are formed on two sides of each aluminum alloy ceiling board, and the aluminum alloy ceiling boards are fixed to the bearing main runner through the insert fastening structures. The inserted connection type aluminum alloy ceiling mounting structure has the advantages that high stability, high corrosion resistance, excellent fireproof performance and the like are achieved since an aluminum alloy material serves as a main material of the ceiling structure; by fixation of the aluminum alloy ceiling boards and the bearing main runner through the insert fastening structures, mounting efficiency is further improved.

Owner:上海西蒙铝业有限公司

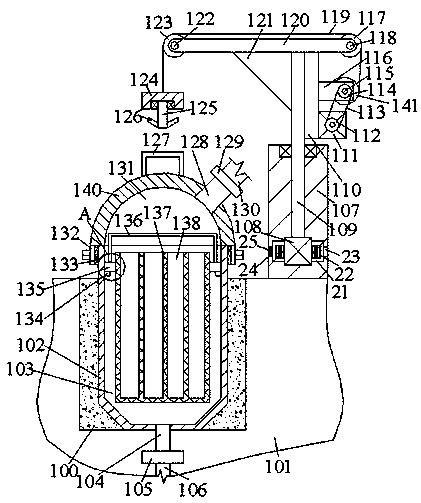

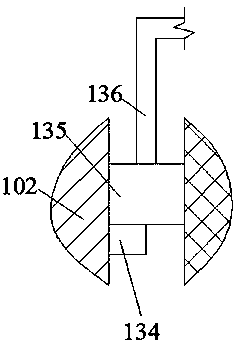

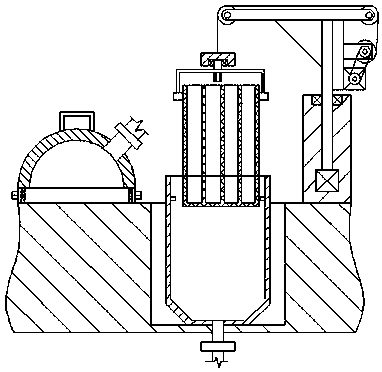

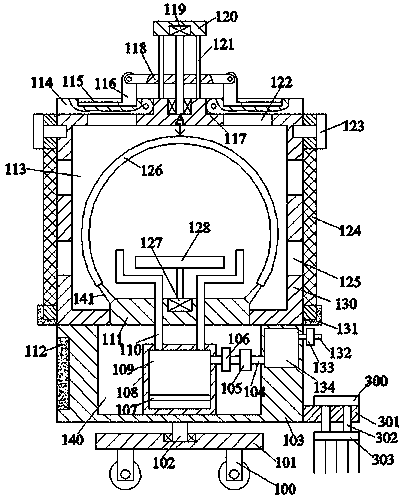

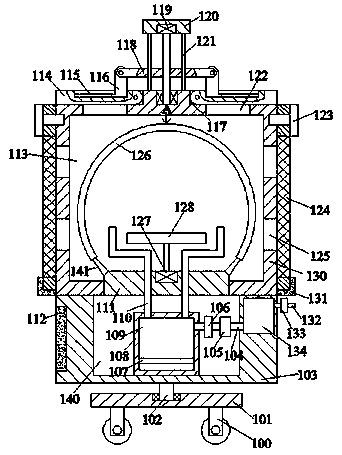

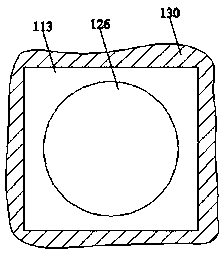

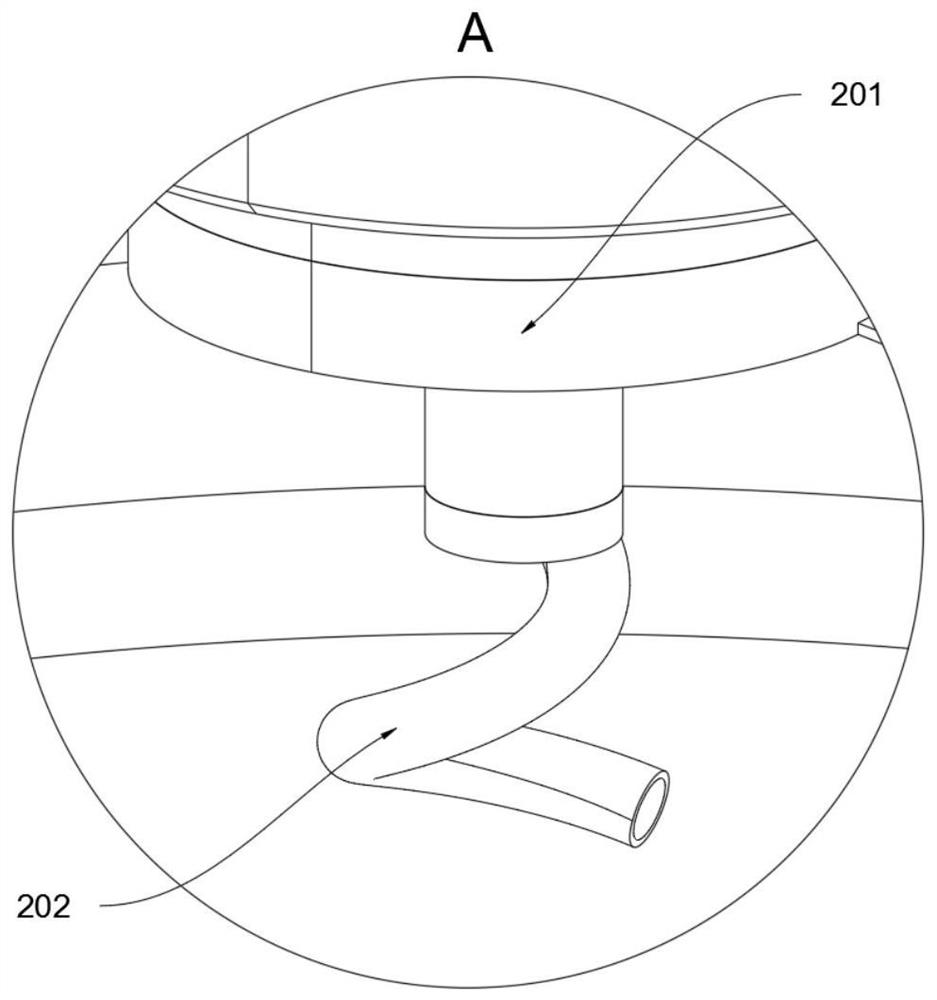

Efficient anaerobic fermentation device

InactiveCN108130264AImprove reliabilityEasy maintenanceBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBilateral symmetry

The invention discloses an efficient anaerobic fermentation device. The efficient anaerobic fermentation device comprises a concrete block fixedly arranged on the ground, wherein a holding cavity withan upward opening is formed in the concrete block; a box body A fixed on the lower end wall of the holding cavity is arranged in the holding cavity; a fermentation cavity with an upward opening is arranged in the concrete block; a guide pipe A which extends downwards and is communicated with the fermentation cavity is fixedly arranged in the lower end wall of the fermentation cavity; a valve A located in the concrete block is arranged at the lower part of the guide pipe A in a communicating manner; a guide pipe B communicated with a waste disposal device is arranged at the lower part of the valve A in a communicating manner; bulges in bilateral symmetry are fixedly arranged on the inner walls of the left side and the right side of the fermentation cavity; and cushion blocks are fixedly arranged on the upper end surfaces of the bulges. The efficient anaerobic fermentation device is simple in structure and convenient to use, and realizes efficient anaerobic fermentation by different structures through quick replacement of a reactant.

Owner:PUJIANG ZHIYIN TECH CO LTD

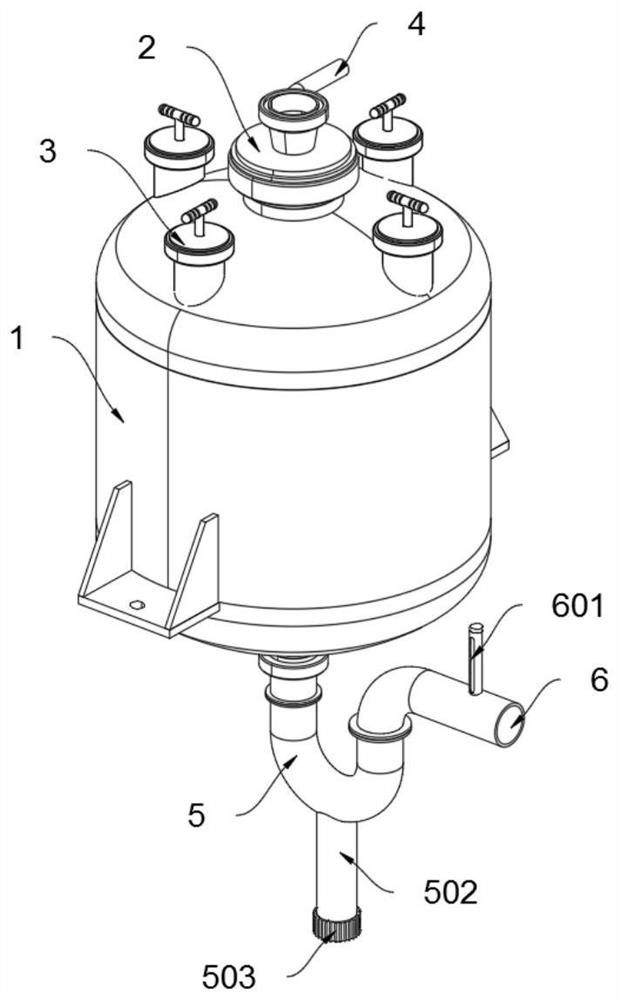

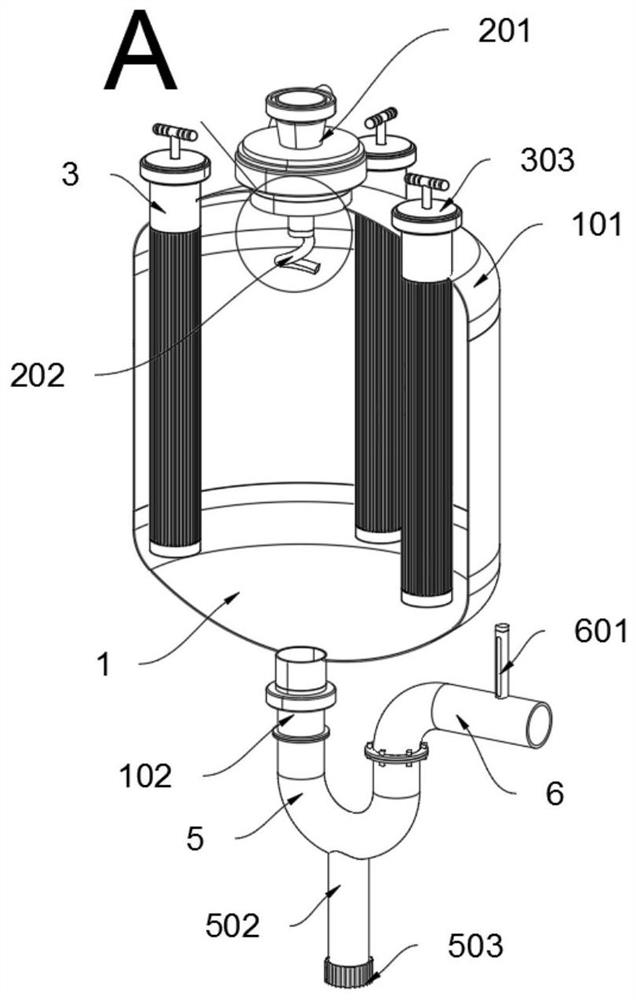

Water purifier convenient to replace filter element

InactiveCN111974219AImprove the efficiency of filter replacementRealize automatic replacementSpecific water treatment objectivesUltrafiltrationEnvironmental engineeringMechanical engineering

The invention discloses a water purifier convenient to replace a filter element, and relates to the field of water purifiers. The water purifier comprises a box body, the bottom of the box body is fixedly connected with a supporting leg adjusting mechanism, the upper part of the box body is fixedly connected with a water inlet, the right side of the box body is fixedly connected with a water outlet, and the inner wall of the box body is fixedly connected with a first partition and a second partition; the right side of the box body is fixedly connected with a locking door mechanism, a water inlet mechanism is fixedly connected onto the first partition, a water outlet mechanism is fixedly connected onto the second partition, a filter element replacing mechanism is fixedly connected to the inner wall of the box body, and a filter element is arranged on the filter element replacing mechanism; and a filter element water inlet part is fixedly connected to the upper part of the filter element, and a filter element water outlet part is fixedly connected to the lower part of the filter element. The filter element can be automatically replaced by arranging the filter element replacing mechanism, the water purifier can be isolated from dust by arranging the locking door mechanism, the water in the water tank can be prevented from being polluted by arranging the water inlet mechanism and the water outlet mechanism when the filter element is replaced, the filter element replacing efficiency of the water purifier is improved, and the labor cost is reduced.

Owner:陈朱灵

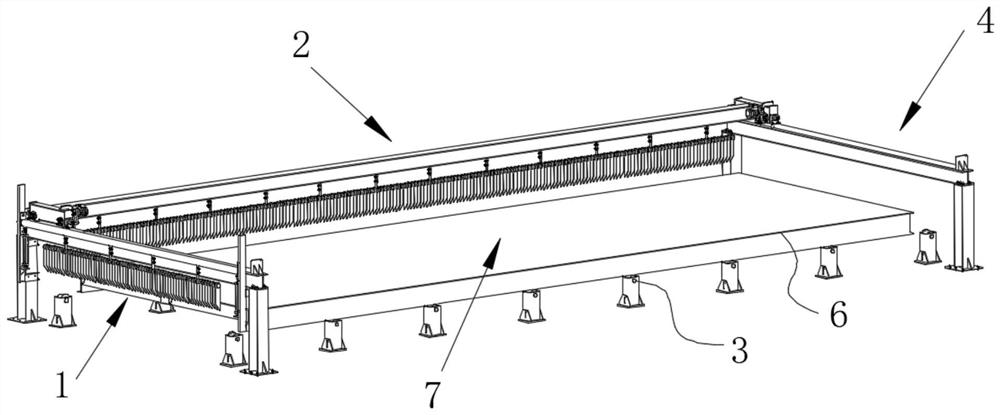

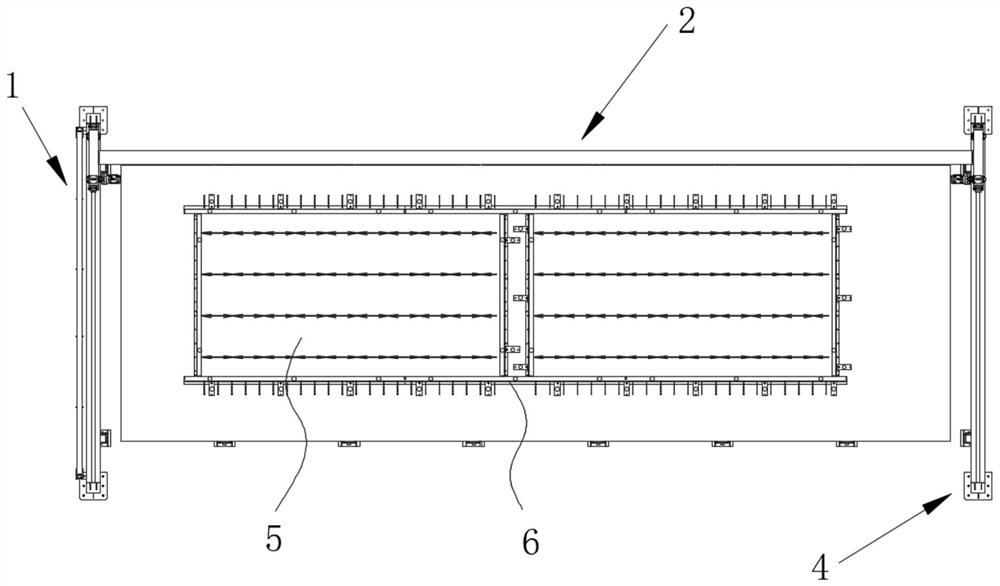

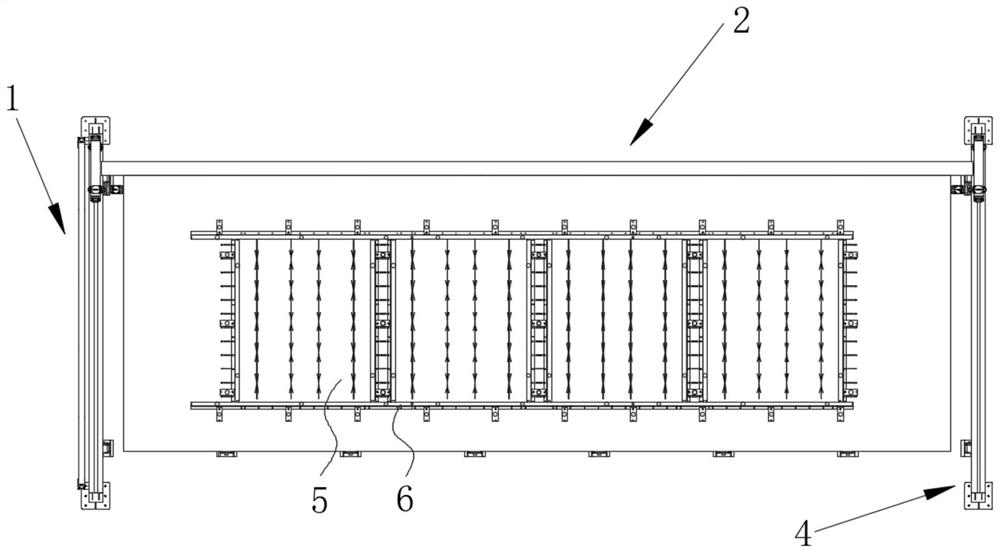

Galling device

InactiveCN112405800ASatisfy the needs of nappingImprove versatilityAuxillary shaping apparatusGallingRebar

The invention belongs to the technical field of building equipment, and discloses a galling device. The galling device comprises a feeding channel, a transverse galling mechanism and a longitudinal galling mechanism, wherein the feeding channel is used for allowing a prefabricated part to pass through in the conveying direction; the transverse galling mechanism is transversely arranged at least one end of the feeding channel in the conveying direction, the prefabricated part can penetrate through the transverse galling mechanism in the conveying direction, and when the steel bar extending direction of the prefabricated part is the same as the conveying direction, the transverse galling mechanism sweeps and scrapes the to-be-treated surface of the prefabricated part in the conveying direction; and the longitudinal galling mechanism is horizontally and movably arranged relative to the feeding channel, the horizontal moving direction of the longitudinal galling mechanism is perpendicularto the conveying direction, and when the steel bar extending direction of the prefabricated part is perpendicular to the conveying direction, the longitudinal galling mechanism sweeps and scrapes theto-be-treated surface in the direction perpendicular to the conveying direction. According to the galling device, the galling requirements of the prefabricated parts with different orientations can bemet, the universality of the galling device is improved, the rapid switching of the galling device can be improved, and the overall operation efficiency is further improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

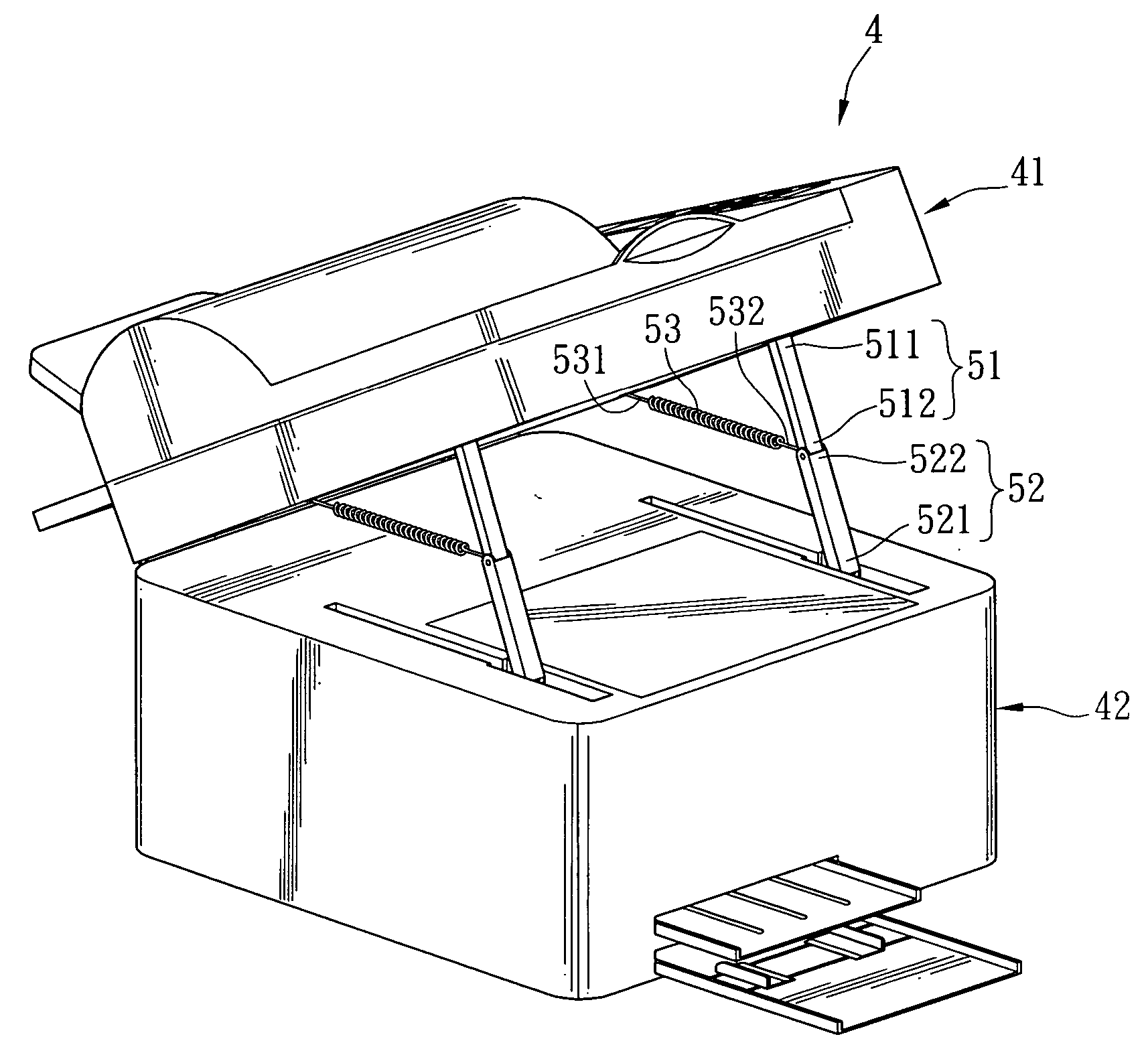

Bracing apparatus

InactiveUS20050152105A1Improve the convenience of replacementAvoid problemsDigital data processing detailsRecord information storageEngineeringElectronic equipment

Owner:LITE ON TECH CORP

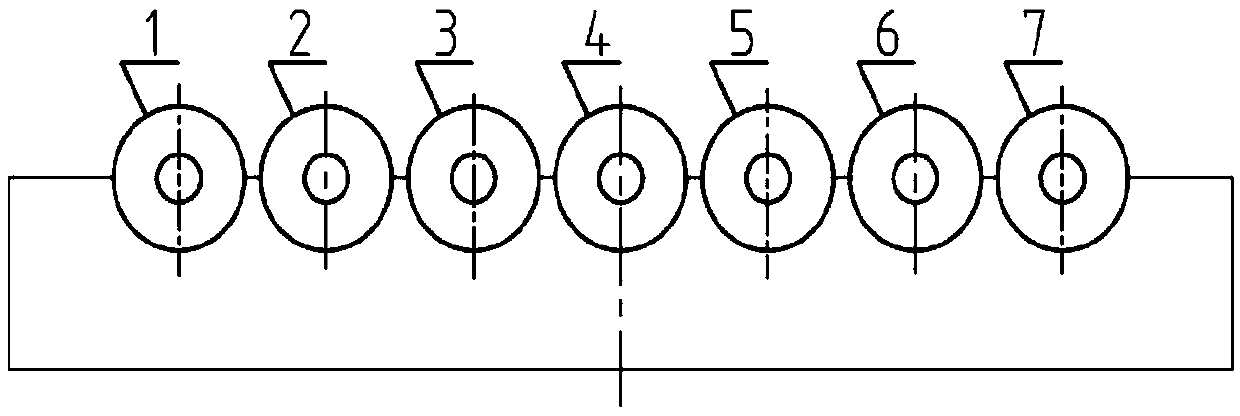

Universal three-cut and four-cut hollow guide pipe device

PendingCN109550785AReduce weightImprove the convenience of replacementMetal rolling arrangementsCompression deviceEngineering

The invention relates to a universal three-cut and four-cut hollow guide pipe device, which includes a hollow guide pipe, three three-cut guide grooves, four four-cut guide grooves, an installation base, a base supporting frame and a compression device, the three-cut guide grooves and the four-cut guide grooves are formed in the installation base, the compression device is fixedly installed on theinstallation base, the hollow guide pipe is fixedly clamped in the three-cut guide grooves and the four-cut guide grooves through the compression device, the installation base is connected with the base supporting frame by welding, the base supporting frame is fixedly installed on the ground, and each three-cut guide groove is arranged between every two adjacent four-cut guide grooves. Accordingto the universal three-cut and four-cut hollow guide pipe device, the structure is simple, the manufacturing cost is low, the requirements of three-cut and four-cut rolling can be met at the same time, and quick replacement of the hollow guide pipe can be realized.

Owner:张家港联峰钢铁研究所有限公司

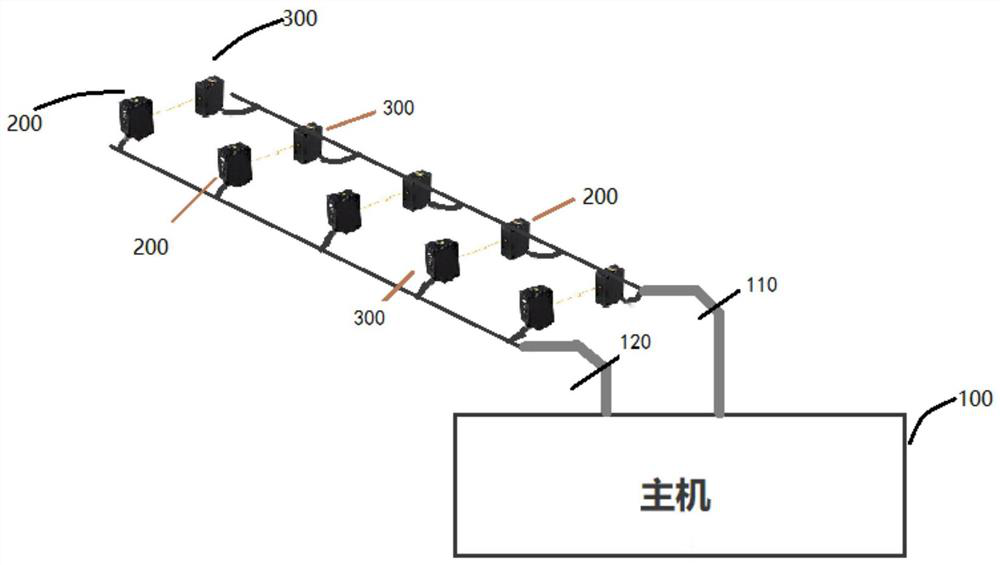

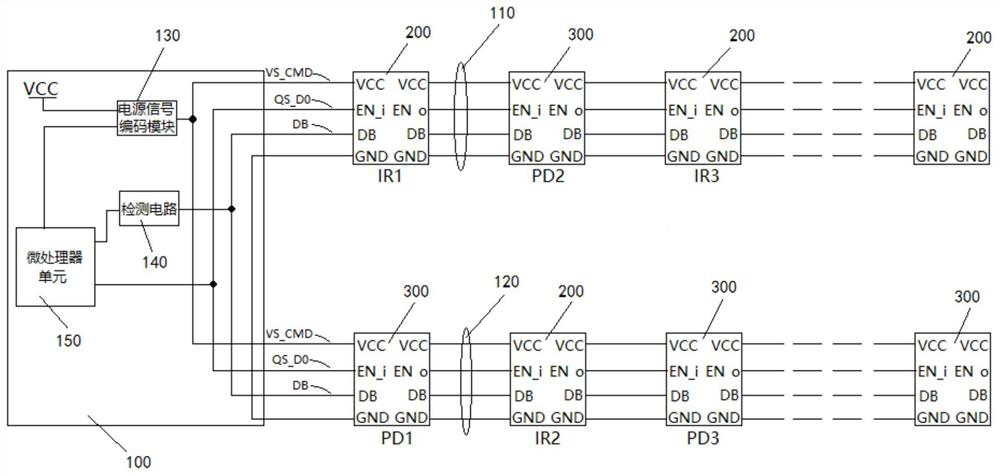

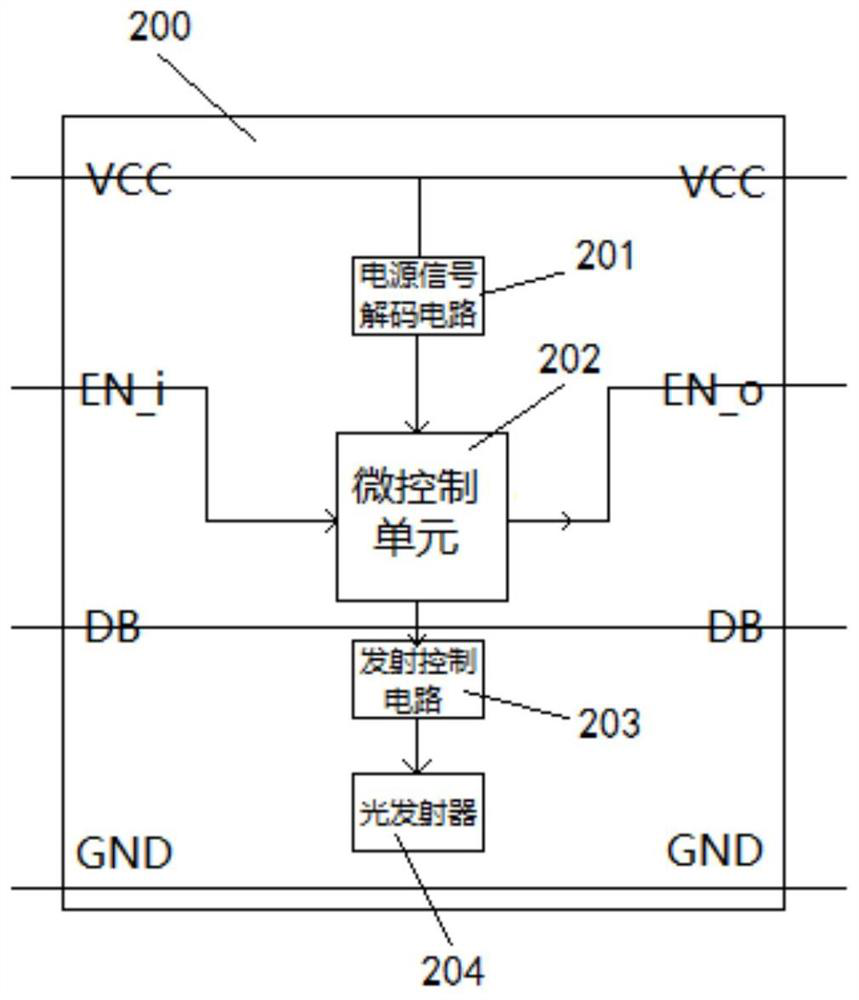

Photoelectric detection system based on power coding, control method and coding method

PendingCN112946772AImprove the convenience of replacementImprove efficiencyOptical detectionTelecommunicationsElectrical and Electronics engineering

The invention relates to a photoelectric detection system based on power coding, a control method and a coding method. The system comprises a host and at least two groups of photoelectric emission and reception pairs, for any photoelectric emission and reception pair, a photoelectric emission unit in the photoelectric emission and reception pair is adaptively connected with one photoelectric detection connection line group, and a photoelectric reception unit in the photoelectric emission and reception pair is adaptively connected with the other photoelectric detection connection line group; for any photoelectric detection connecting line group, the power supply signal bus in the photoelectric detection connecting line group can be used for supplying power to the photoelectric emission unit or the photoelectric emission unit and the photoelectric receiving unit which are connected to the photoelectric detection connecting line group; the photoelectric emission unit or the photoelectric emission unit and the photoelectric receiving unit which are connected to the photoelectric detection connecting line group are connected in series step by step according to a required sequence; according to the invention, the detection system can be simplified, the anti-interference capability can be improved, the time sequence error accumulation caused by multi-point cascading of the system can be reduced, flexible installation can be achieved, and the cost can be reduced.

Owner:WUXI DECHIP MICROELECTRONICS CO LTD

Home Internet small indoor humidifier device

InactiveCN108534277AImprove work coordinationLow densityLighting and heating apparatusSpace heating and ventilation detailsWater storageWater vapor

The invention discloses a home Internet small indoor humidifier device which comprises an evaporation box. A base plate is arranged below the evaporation box, universal wheels symmetrical left and right are fixedly arranged on the lower end face of the base plate, a rotating shaft is rotationally arranged in the upper end face of the base plate, the rotating shaft and the evaporation box are fixed, an opening cavity with an upward opening is fixedly arranged in the evaporation box, a water storage cavity located in the evaporation box is arranged in the right side of the evaporation box, an input pipe rightwards extending out of an external space is arranged in the right end wall of the water storage cavity in a communicating manner, an input valve is arranged in the input pipe in a communicating manner, a heat box is fixedly arranged on the lower end wall of the opening cavity, an evaporation cavity is fixedly arranged in the evaporation box, an electric heating bar is fixedly arranged in the evaporation cavity, and a connecting pipe is arranged in the right end wall of the evaporation cavity in a communicating manner. The home Internet small indoor humidifier device is simple instructure and convenient to use; a water vapor manner is adopted by the device, and therefore the bacterium density is effectively reduced; and the permeation manner is used, and therefore the indoorenvironment humidity is effectively improved.

Owner:ZHUJI CITY JIMAILUO IMPORT & EXPORT CO LTD

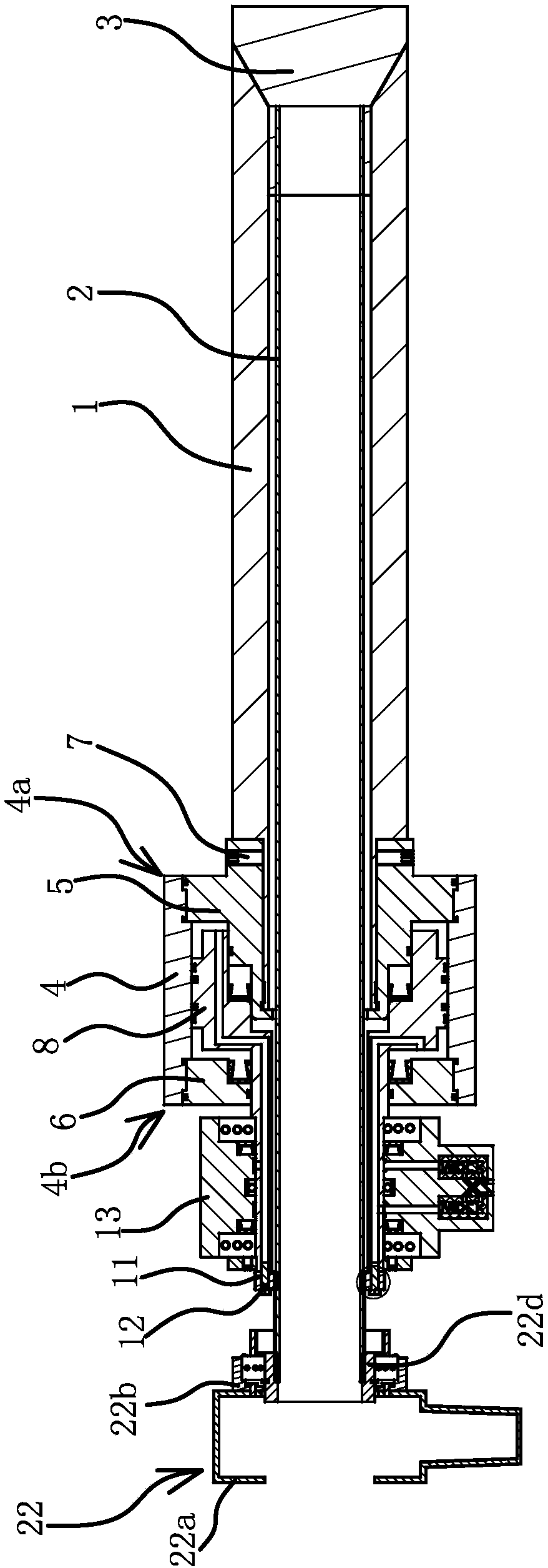

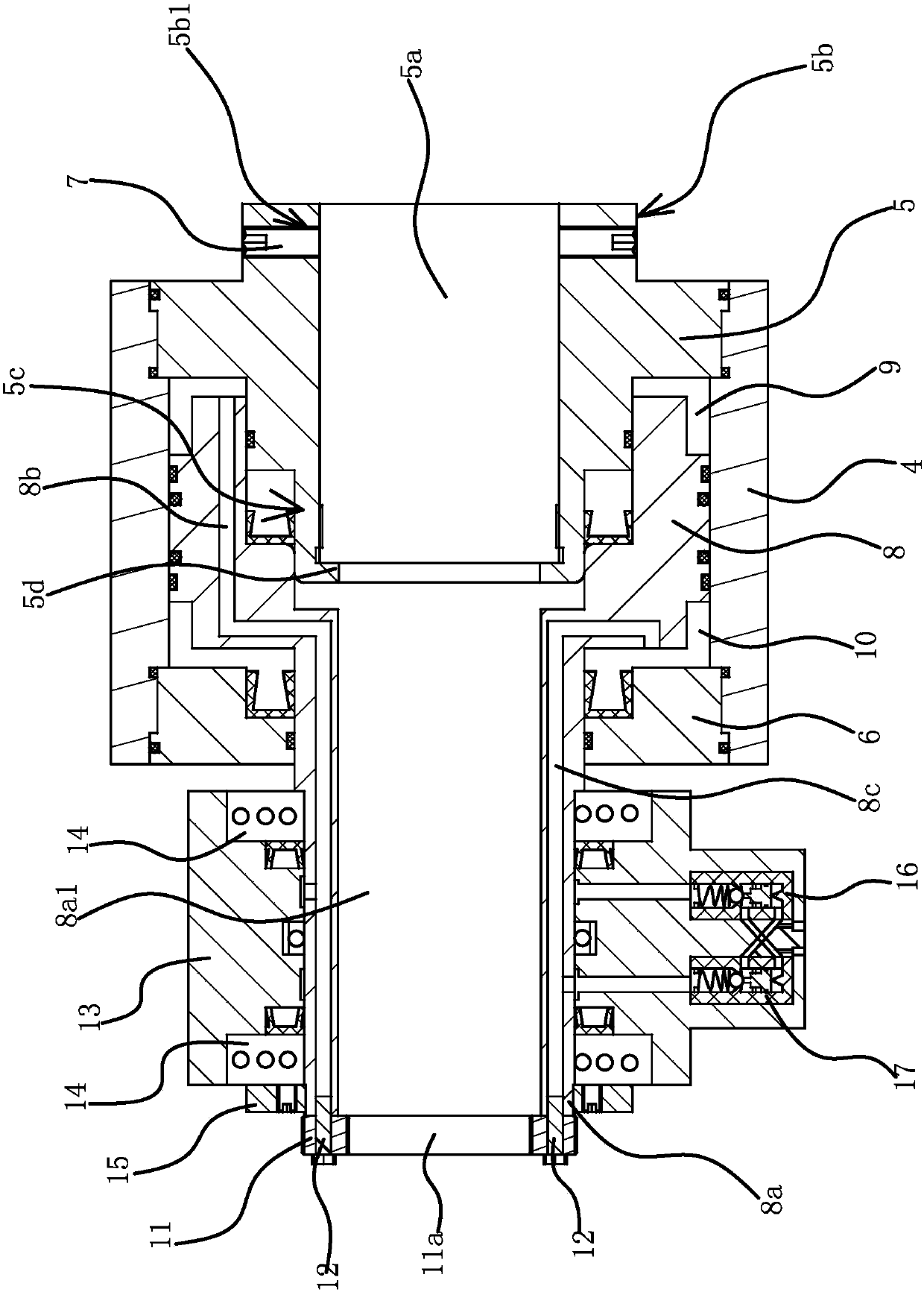

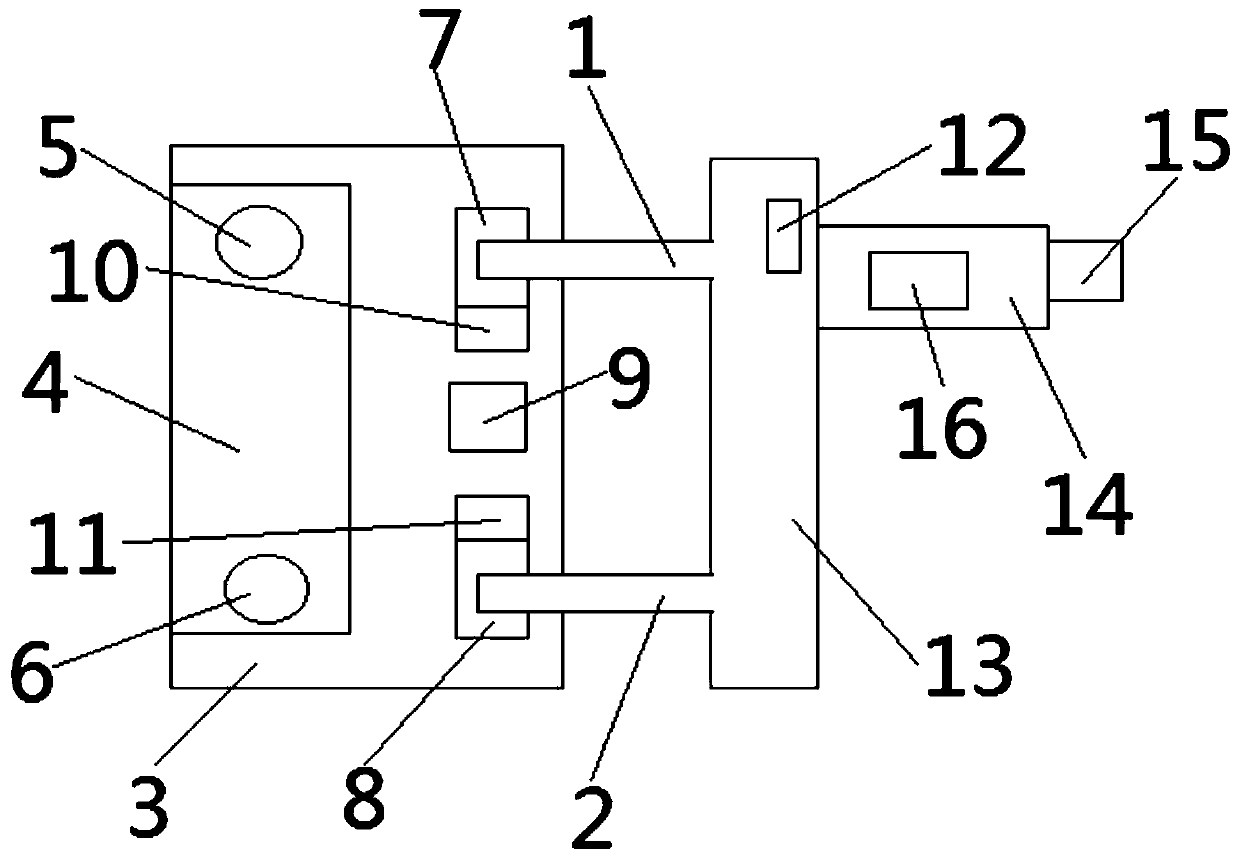

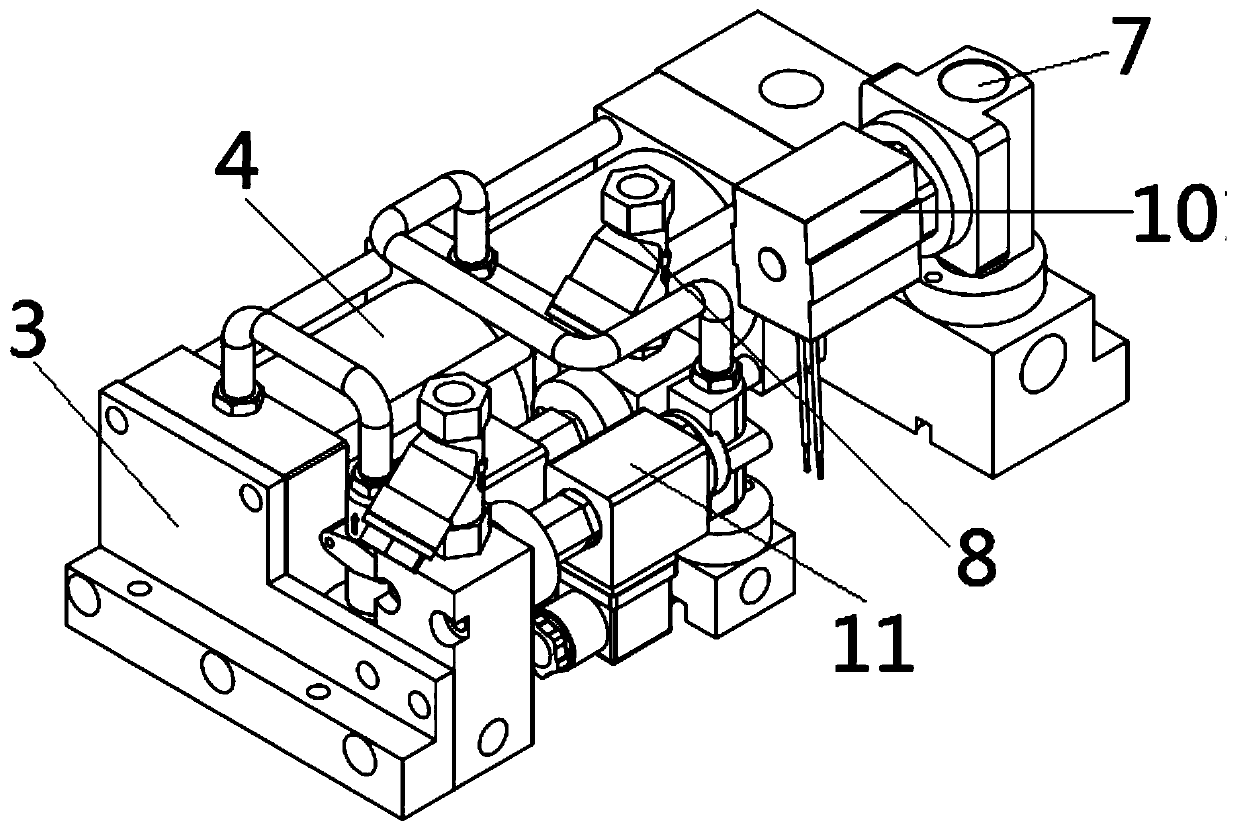

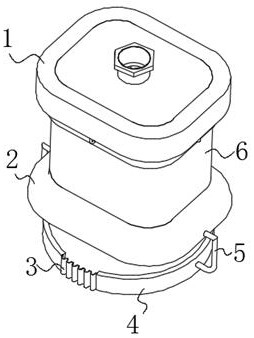

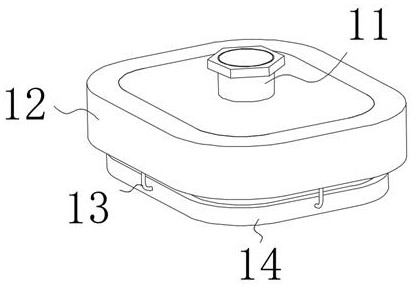

A robot electrode cap replacement auxiliary device

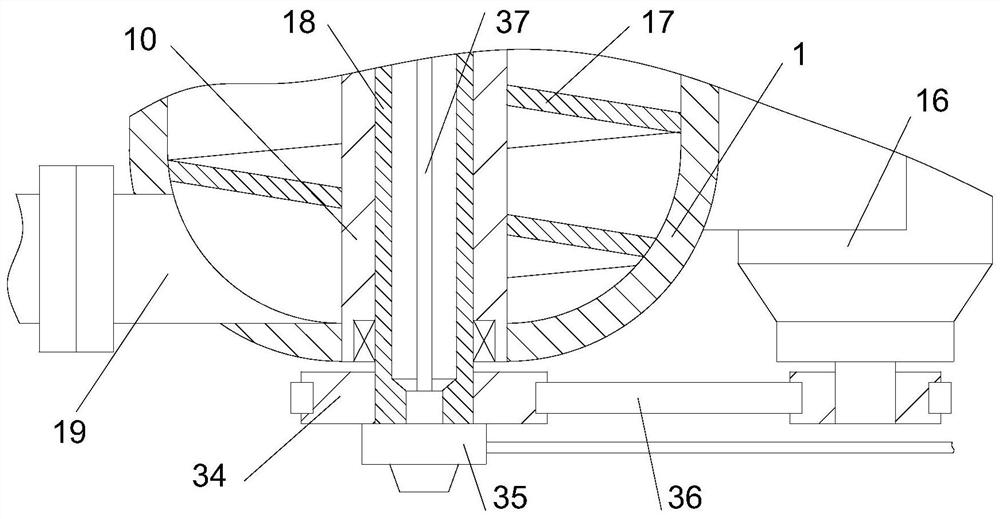

ActiveCN107877044BReduce the amount of waterReduce water pressureWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides a robot electrode cap replacement auxiliary device applied to the technical field of robot parts in an automobile welding production line. A cooling water outlet (1) and a cooling water inlet (2) are formed in a cooling water channel of a robot; a water pumping pump (5) and a water feeding pump (6) are arranged in a water storage cavity (4) inside a residual water treatmentpart (3) of the robot electrode cap replacement auxiliary device; a treatment part water inlet (7) and a treatment part water outlet (8) communicate with the water storage cavity (4); the cooling water outlet (1) communicates with the treatment part water inlet (7); and the cooling water inlet (2) communicates with the treatment part water outlet (8). According to the robot electrode cap replacement auxiliary device, when the robot needs to replace an electrode cap, cooling water control can be achieved, cooling water in the cooling water channel is prevented from being sprayed outwards when the electrode cap is replaced, and thus the convenience and safety of electrode cap replacement are improved.

Owner:ANHUI RUIXIANG IND

Small indoor humidifier device

InactiveCN108758932AImprove work coordinationLow densityMechanical apparatusLighting and heating apparatusWater storageWater vapor

The invention discloses a small indoor humidifier device. The small indoor humidifier device comprises an evaporation tank. A bottom plate is arranged on the lower portion of the evaporation tank. Universal wheels which are in bilateral symmetry are fixedly arranged on the lower end face of the bottom plate. A rotary shaft is rotationally arranged in the upper end face of the bottom plate and fixed to the evaporation tank. A cavity with an opening facing upwards is fixedly arranged in the evaporation tank. A water storage cavity located in the evaporation tank is arranged in the right side ofthe evaporation tank. An input pipe extending rightwards to the outer space is arranged in the right end wall of the water storage cavity in a communicating mode. An input valve is arranged in the input pipe in a communicating mode. A heat box is fixedly arranged on the lower end wall of the cavity. An evaporation cavity is fixedly arranged in the heat box. An electric heating rod is fixedly arranged in the evaporation cavity. A connecting pipe is arranged in the right end wall of the evaporation cavity in a communicating mode. The small indoor humidifier device is simple in structure and convenient to use, the bacterial density is effectively lowered through the vapor form, and the humidity of the indoor environment is effectively improved through a permeation mode.

Owner:ZHUJI CITY JIMAILUO IMPORT & EXPORT CO LTD

Plaster gluing equipment

ActiveCN114011650AAvoid wrinklesAvoid contactLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention provides plaster gluing equipment. The equipment comprises a machine base, a conveying platform with a heating function, a conveying roller and a glue scraping mechanism, the conveying roller is rotatably arranged on the machine base, the glue scraping mechanism is arranged above the conveying roller, a first gap is reserved between the glue scraping mechanism and the conveying roller, the conveying platform is obliquely arranged on one side of the conveying roller, a second gap is reserved between the conveying platform and the conveying roller, and the end, close to the conveying roller, of the conveying platform is lower than the end, far away from the conveying roller, of the conveying platform. The glue scraping mechanism is connected with a height adjusting device, and the glue scraping mechanism adjusts the first gap between the glue scraping mechanism and the conveying roller through the height adjusting device. According to the plaster gluing equipment, plaster backing paper can be prevented from being in contact with the conveying platform, the contact time of high-temperature plaster colloid and the plaster backing paper is greatly shortened, the plaster backing paper can be effectively prevented from being wrinkled, the plaster colloid is uniformly scraped and coated, the quality of plaster products is greatly improved, the conveying roller and a scraper are convenient and rapid to clean and replace, and plaster colloid thickness adjustment is accurate and rapid.

Owner:HEBEI HUASHENG PLASTIC & RUBBER MACHINERY

Floor-standing double-layer curved curtain wall with external circulation and its installation process

ActiveCN107654005BMeet the appearance and visual needsImprove structural safetyWallsSupporting systemEngineering

The invention discloses a ground type external-circulation double-layer curved-face curtain wall and an installation technology thereof. The ground type external-circulation double-layer curved-face curtain wall comprises a curved-face inner curtain wall body and a curved-face outer curtain wall body, wherein the curved-face inner curtain wall body is installed on a main body structure, and the curved-face outer curtain wall body is located on the outer side of the inner curtain wall body and fixed to the main body structure through an outer supporting system penetrating through the inner curtain wall body. An inner curtain wall unit body is installed between the upper and lower adjacent floors of the main body structure, the bottom of the inner curtain wall unit body is supported on a concentric rotary bottom adjusting assembly installed at the top of the lower floor, the top of the inner curtain wall unit body is fixed to a concentric rotary top adjusting assembly installed at the bottom of the upper floor, and the concentric rotary bottom adjusting assembly and the concentric rotary top adjusting assembly adjust the inclination and upward-facing angle, towards the indoor space,of the inner curtain wall unit body through a concentric rotary mode. According to the ground type external-circulation double-layer curved-face curtain wall and the installation technology thereof, the curtain wall structure is simple, the energy-saving effect of double-layer curtain-wall external circulation is achieved, the appearance visual demand of a smooth curved face is further met, the structural safety performance is good, the installation technology is easy to implement and not tedious, and the construction efficiency is high.

Owner:JANGHO GRP

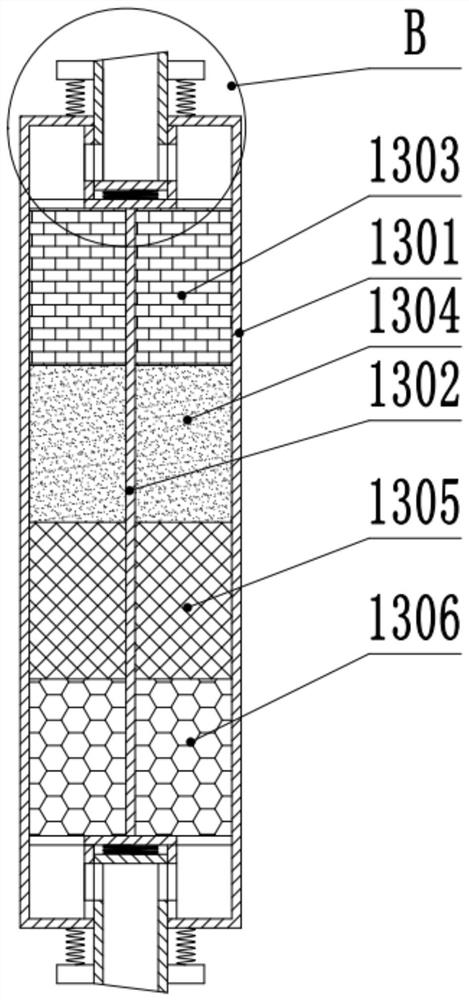

Flue gas purification device for environmental protection

ActiveCN114288772AEase of use guaranteedEnsure connection tightnessHuman health protectionDispersed particle filtrationRubber ringFlue gas

The invention belongs to the field of environmental protection, and particularly relates to a flue gas purification device for environmental protection, which comprises a closing device, an outer cylinder is arranged at the bottom of the closing device, the bottom of the closing device is movably connected with the top of the outer cylinder, a fitting frame is arranged at the bottom of the outer cylinder, and the bottom of the outer cylinder is fixedly connected with the top of the fitting frame. Supporting rods are symmetrically arranged on the outer surface of the attaching frame, the outer surface of the attaching frame is fixedly connected with the tops of the supporting rods, fastening rings are arranged at the bottoms of the supporting rods, the bottoms of the supporting rods are fixedly connected with the outer surfaces of the fastening rings, and rubber rings are symmetrically arranged at the two ends of the fastening rings. In order to overcome the defects in the prior art, the flue gas purification device for environmental protection is provided, and the problems that filtering equipment in a traditional flue gas purification device needs to be dismounted and cleaned, and dismounting is difficult are solved.

Owner:房卫东

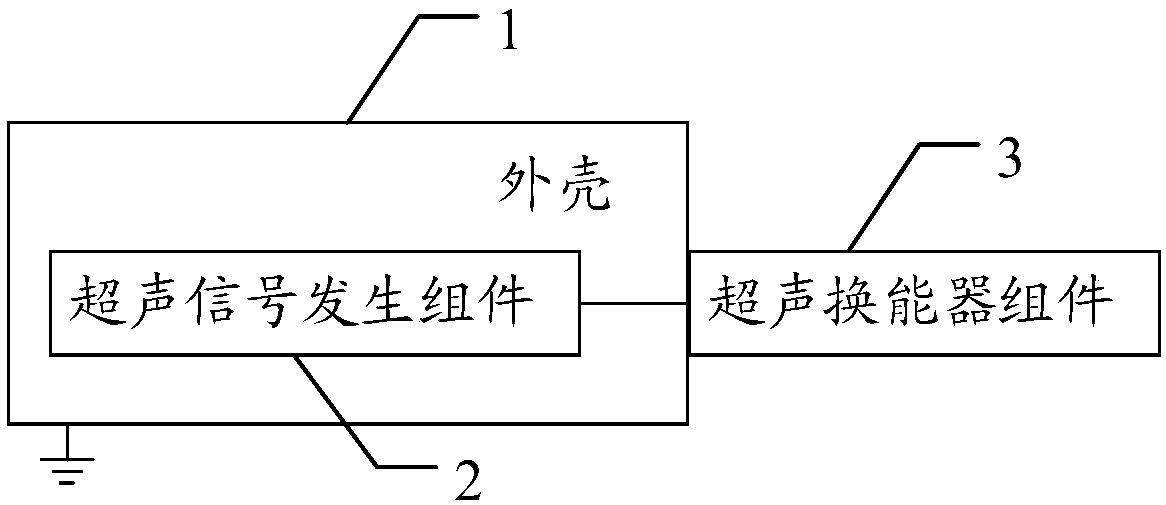

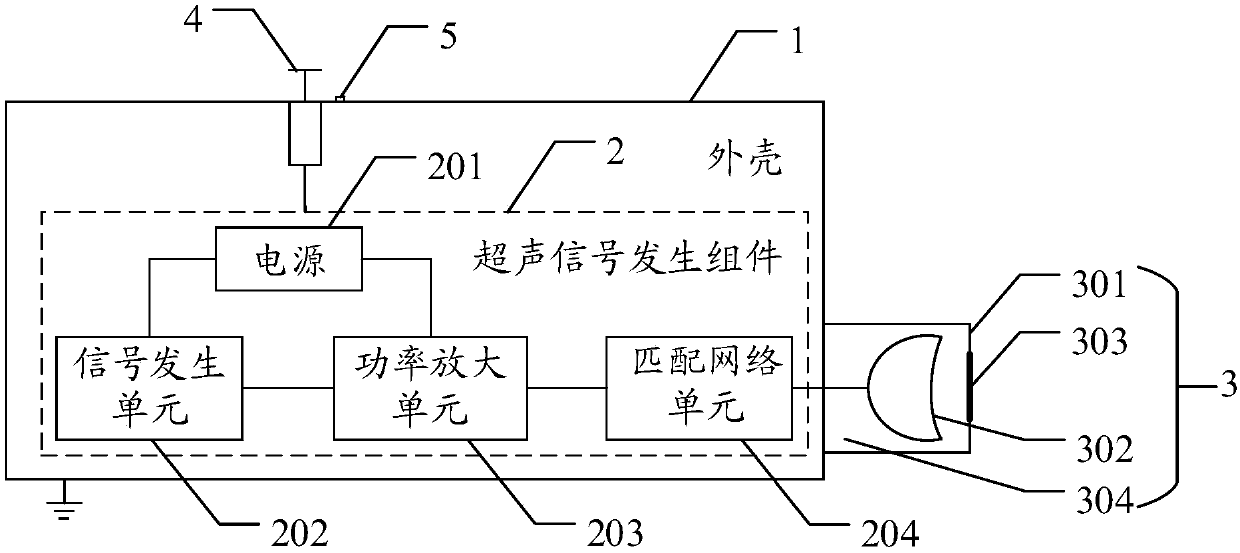

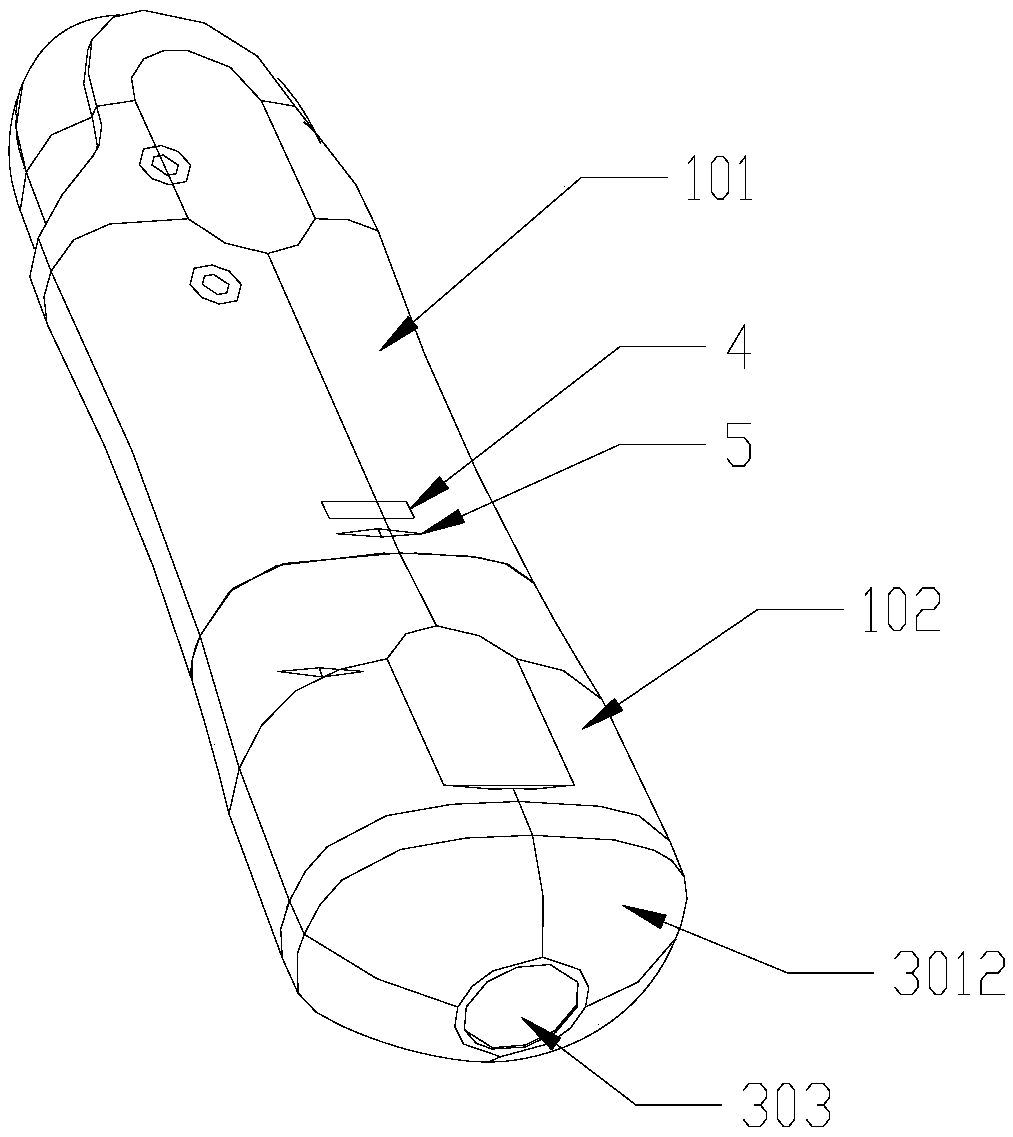

Ultrasonic treatment device

InactiveCN111375146AImprove the convenience of replacementUltrasound therapyUltrasonic sensorTransducer

The invention discloses an ultrasonic treatment device and is applied to the technical field of medical instruments. The device comprises a shell, an ultrasonic signal generation assembly and an ultrasonic transducer assembly, wherein the ultrasonic signal generation assembly is arranged in the shell; the ultrasonic transducer assembly is detachably arranged at one end of the shell. The ultrasonicsignal generation assembly and the ultrasonic transducer assembly are detachably electrically connected. By adopting the device, convenience in change can be improved.

Owner:SHENZHEN INST OF ADVANCED TECH

Composite end enclosure and processing process

ActiveCN102967036BImprove the convenience of replacementSave materialLighting and heating apparatusSpace heating and ventilation detailsMetallic materialsEngineering

A composite end enclosure belongs to the technical field of central air conditioners. An end enclosure body is arranged on a vessel flange of the end enclosure, valve seats and rubber gaskets are arranged on the end enclosure body, a water inlet connector and a water outlet connector are arranged on the end enclosure body, and thereby the integrated composite end enclosure is formed. A processing process for the composite end enclosure includes the following steps: mold preparation, reinforcing material laying, vacuumization and closing of an upper mould and a lower mould, vacuumization, glue preparation, resin impregnation, curing, demoulding, trimming, post-trimming processing, inspection and warehousing. The invention has the advantages that: firstly, since the water inlet connector, the water outlet connector, the end enclosure and the vessel flange are formed in one step, the production efficiency is increased, metal material is saved, and the production cost is reduced; secondly, after connector flanges are removed from the product and locknuts and the gaskets are added on the product, the production cost is reduced, and the corrosion resistance, the tightness and the part replacement convenience are enhanced; thirdly, the processing process is simplified, the production period is shortened, and the working efficiency is increased.

Owner:SHANDONG GRAD GROUP

Line position-adjustable yarn conveying equipment for large-scale spinning

PendingCN114368649AAvoid equipment jamsEasy to replaceFilament handlingElectric machineryTextile yarn

The invention discloses a large-scale textile yarn-position-adjustable yarn conveying device, and relates to the technical field of textile processing, the large-scale textile yarn-position-adjustable yarn conveying device comprises a base, a position adjusting assembly and a yarn outlet assembly, a fixing seat is arranged on the outer side of the top of the base, the outer end of the fixing seat is connected with a motor, and the motor is connected with a rotating box through a rotating shaft. When equipment needs to replace spinning threads, a cut-off tool works, the currently conveyed spinning threads can be cut off, at the moment, a motor on the outer side of a fixing base works, a rotating shaft can drive a rotating box to rotate, and the spinning threads can be replaced through rotation of the rotating box; the wire placing assembly and the position adjusting assembly at the current position can be moved away from the vertical center line of the wire outlet assembly, and the wire placing assembly and the position adjusting assembly with different types of wires are replaced and moved to the vertical center line of the wire outlet assembly, so that the equipment can replace the output wires quickly and conveniently; and meanwhile, the wire placing assembly and the position adjusting assembly are integrated, so that equipment blockage caused by wire winding in the wire changing process can be avoided.

Owner:JIHUA 3509 TEXTILE

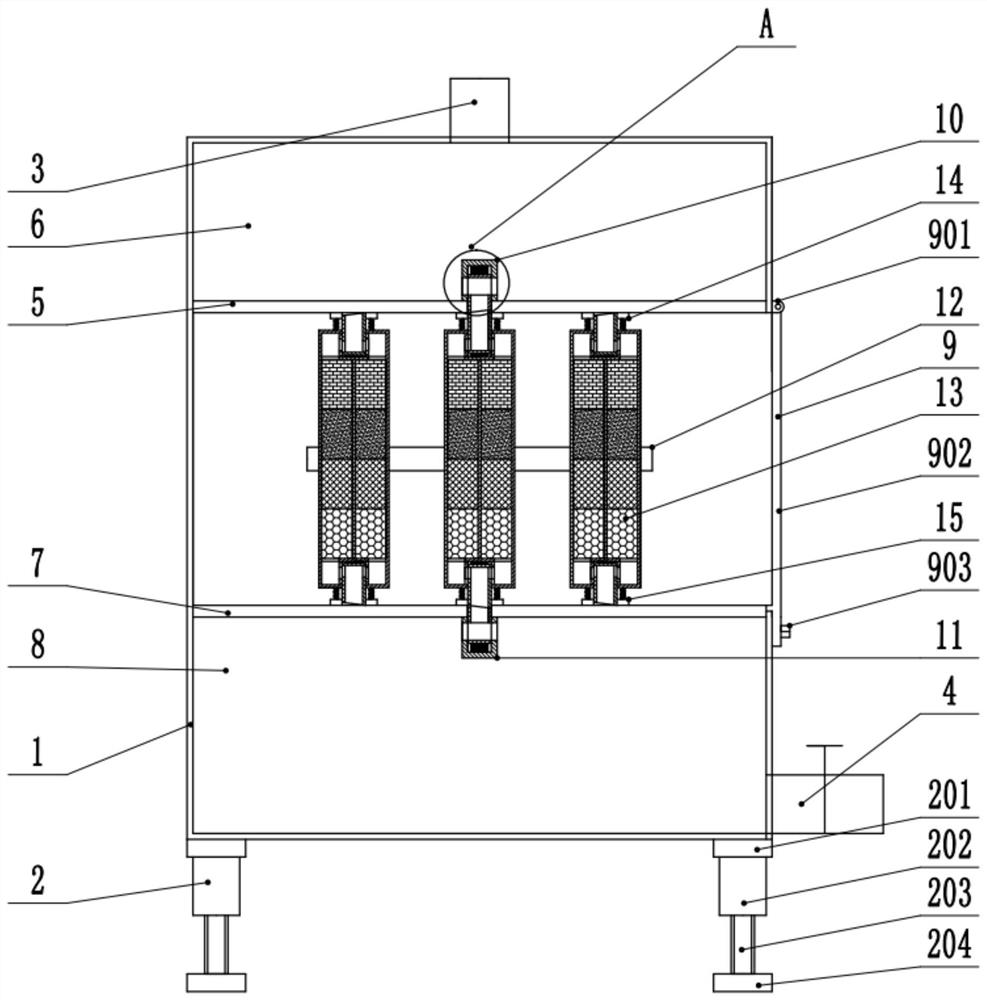

Formation equipment and method for battery plate formation

ActiveCN114512639BFull chemical treatmentAvoid becoming inadequate problemsFinal product manufactureLead-acid accumulator electrodesChemical reactionClassical mechanics

The invention relates to the technical field of formation of battery pole plates, in particular to a formation equipment and method for battery pole plates, including a formation pool, a connecting seat, a Z-shaped frame plate, a fixing frame and a fixing mechanism. When the present invention fixes the polar plate entering the chemical formation pool, the upper and lower sides of the polar plate are fixed by means of line contact and point contact through the supporting roller and the pressing ball on the pressing block, so that the polar plate can be fully The formation treatment avoids the problem of insufficient formation when the pole plate is fixed, and at the same time, the pole plate in the present invention is always located in the middle of the card placement frame under the guidance of the left and right inclined guide plates, thereby improving the accuracy of the pole plate placement position , when the pressing block and the pole plate continue to move downward, the push plate pushes the inclined guide plates on the left and right sides to move to both sides respectively, so that the inclined guide plate and the pole plate are separated, preventing the inclined guide plate from contacting the pole plate and affecting the pole. The plate undergoes a chemical conversion reaction.

Owner:深圳市熊利达科技有限公司

Ultrasonic cleaning device for ophthalmic instruments

ActiveCN113182263AGuaranteed cleaning efficiencyEnsure stabilityCleaning using liquidsMedicineElectric machinery

The invention discloses an ultrasonic cleaning device for ophthalmic instruments, and belongs to the field of medical instruments. The ultrasonic cleaning device comprises a shell, a bottom shell, a filter, a drainage pump, a water spraying frame, a motor, a storage rack, an adsorption disc, a transmission shaft and a pushing frame, wherein a top plate is arranged at the top end of the shell, the water spraying frame is fixedly installed at the top end of the top plate in a penetrating mode, the water spraying frame fixedly communicates with external water supply equipment, and the shell is in a funnel shape. The parts which are not involved in the device are the same as those in the prior art or can be realized by adopting the prior art. The cleaning use efficiency of the device is high, high-adaptability pressing is carried out on different tools, the stability during cleaning is guaranteed, the device is flexible, magnetic coupling pushing can be carried out through the pushing frame, the smooth water changing inside is guaranteed, and impurity deposition can be avoided.

Owner:永州爱尔眼科医院有限公司

Wastewater drainage and purification device in the process of shampoo processing

ActiveCN110981035BIncrease the degree of mixingImprove contact efficiencyTreatment involving filtrationMultistage water/sewage treatmentProcess engineeringSewage treatment

The invention provides a wastewater drainage and purification device in the process of shampoo processing, which relates to the field of sewage treatment and solves the problem that the use period is short, and the purification box needs to be removed after a short period of use to clean the sundries on the surface of the purification box ; Furthermore, it is impossible to realize the problem of rotating and mixing by improving the structure without using electrical components. A device for draining and purifying waste water during shampoo processing, comprising a barrel body; a feed structure is installed at the top of the barrel body at the position of the feed inlet. The feeding structure is improved, because the feeding pipe on the feeding structure of the device is changed to a spiral structure, and the spiral feeding pipe can push the liquid to rotate during feeding, thereby improving the mixing degree of the liquid and the purified liquid, and It can also improve the contact efficiency between the liquid and the column-shaped purification box. Compared with the existing device, the spiral feeding pipe can push the liquid in the barrel to rotate to speed up the mixing with the purification liquid, and can also speed up the contact between the liquid and the column-shaped purification box. contact efficiency.

Owner:温州圆拓机械科技有限公司

Ultrasonic cleaning equipment for ophthalmic instruments

ActiveCN113182263BGuaranteed cleaning efficiencyEnsure stabilityCleaning using liquidsMedicineElectric machinery

The invention discloses an ultrasonic cleaning device for ophthalmic instruments, which belongs to the field of medical instruments. It includes a casing, a bottom casing, a filter, a drainage pump, a water spray rack, a motor, a storage rack, an adsorption plate, a transmission shaft and a push frame. The frame is fixedly connected with the external water supply equipment, and the shell is shaped like a funnel. The parts not involved in the device are the same as the prior art or can be realized by using the prior art. The cleaning efficiency of the device of the present invention is high, and the compression of different tools is performed with high adaptability to ensure the stability during cleaning. It is flexible and can be driven by magnetic coupling through the push frame to ensure smooth internal water exchange and avoid the deposition of impurities.

Owner:永州爱尔眼科医院有限公司

Automatic packaging machine equipment

InactiveCN111252293AImprove the convenience of replacementReasonable structureWrapping material feeding apparatusWebs handlingSlide plateMechanical equipment

The invention provides automatic packaging machine equipment. Fixing blocks, a packaging roll bag, an installing frame, a packaging machine body, a supporting frame, a rolling roller, a movable plate,a fixing frame, a connecting rod, a holding handle, a threaded rod, a sliding plate and a spring are included. The packaging machine body is arranged on the upper end face of the supporting frame. The fixing blocks are fixed to the front end face of the packaging machine body. The installing frame is arranged on the upper sides of the fixing blocks. The packaging roll bag is assembled to the inner side of the installing frame. The movable plate is connected to the front end face of the installing frame. The rolling roller is arranged on the left end face of the movable plate. The fixing frameis fixed to the upper end face of the installing frame. The threaded rod is arranged in the fixing frame. The holding handle is fixed to the upper end face of the threaded rod. The sliding plate is arranged on the lower end face of the threaded rod. The spring is assembled to the lower side of the sliding plate. The connecting rod is fixed to the front end face of the sliding plate. The design solves the problem that original automatic packaging machine equipment cannot conveniently replace a packaging roll bag; and the automatic packaging machine equipment is reasonable in structure, convenient to combine and install and good in usage effect.

Owner:山东省青东智能科技有限公司

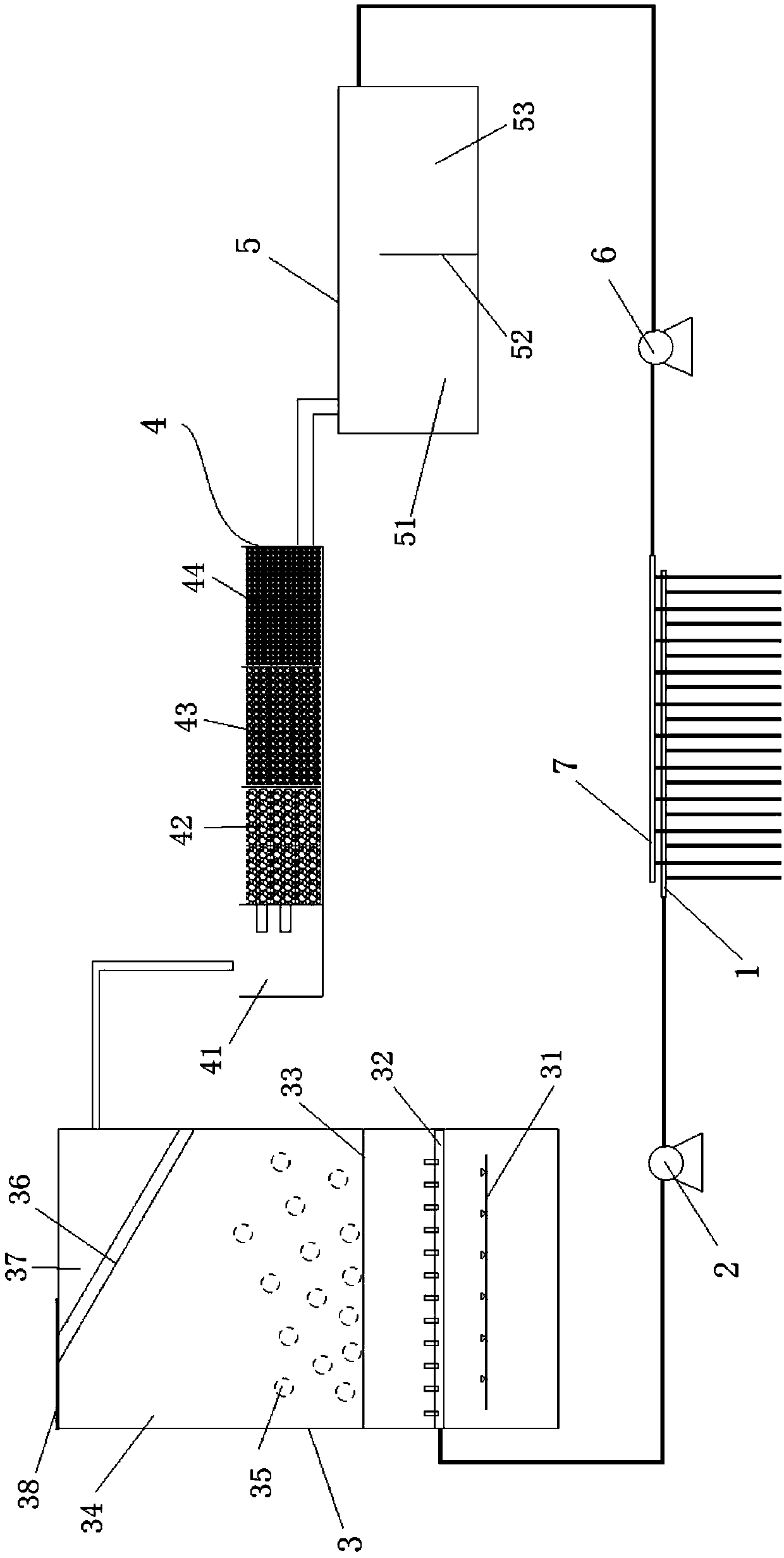

Ecological restoration device for underground water polluted by heavy metals and organic matters

InactiveCN110963633AEasy to handleImprove responseWater contaminantsWater/sewage treatment by ion-exchangeElectrolysisSewage

The invention relates to an ecological restoration device for underground water polluted by heavy metals and organic matters. The ecological restoration device comprises an underground water pumping pipeline, an internal electrolysis section, a biochemical treatment section, a clarified water outlet section and an underground water drainage pipeline which are sequentially arranged in a sewage treatment direction, wherein the internal electrolysis section comprises an internal electrolysis box body, and further comprises an internal electrolysis water outlet area, an internal electrolysis treatment area and a water inlet and gas distribution area which are sequentially arranged in the internal electrolysis box body from top to bottom; the internal electrolysis water outlet area and the internal electrolysis treatment area are separated by a heavy metal filtering assembly equipped with cation exchange resin; a plurality of internal electrolysis filler balls are added into the internal electrolysis treatment area; each internal electrolysis filler ball comprises a hollow spherical shell internally provided with an internal electrolysis filler; and micropores enabling to-be-treated sewage to be in full contact with the internal electrolysis filler are further hermetically formed in the hollow spherical shells. Compared with the prior art, the underground water body polluted by heavy metals and organic matters can be effectively restored; the whole device does not need to adopt chemical reagents; and the device is good in ecological environmental protection property and treatment effect.

Owner:上海景域园林建设发展有限公司

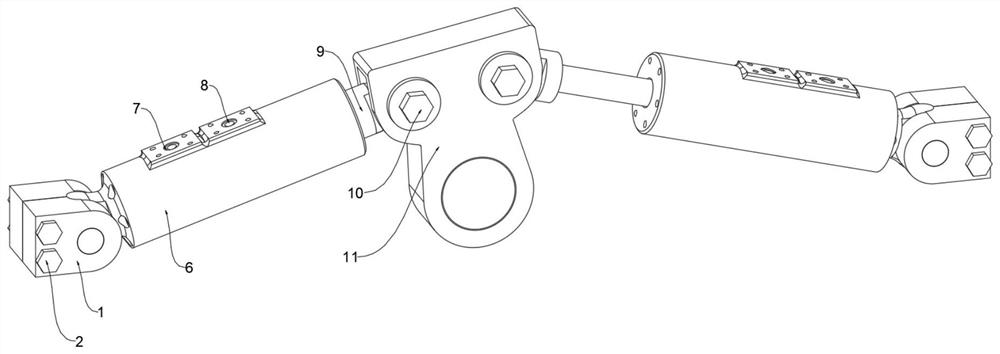

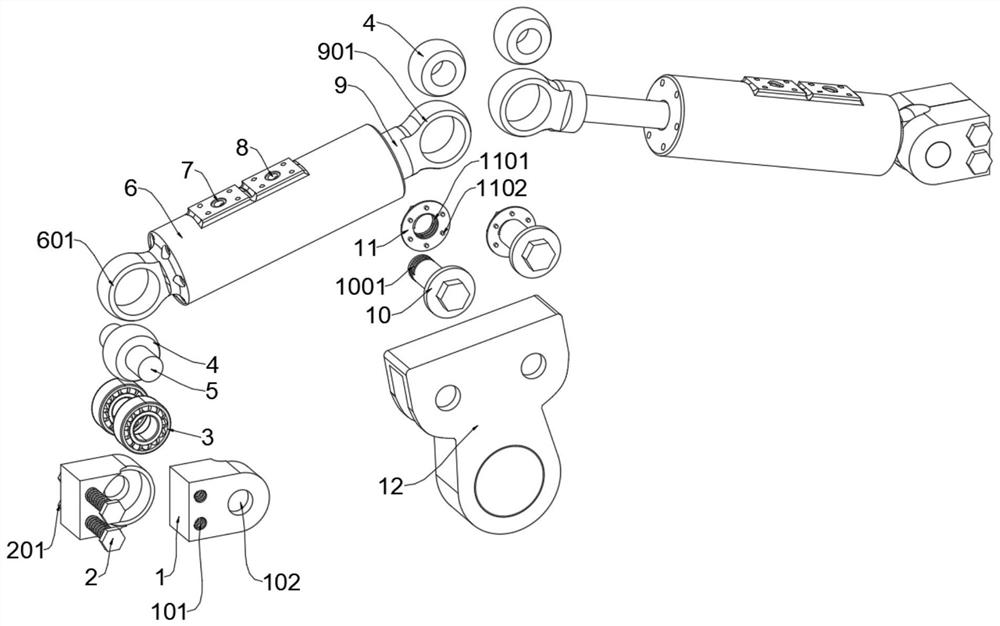

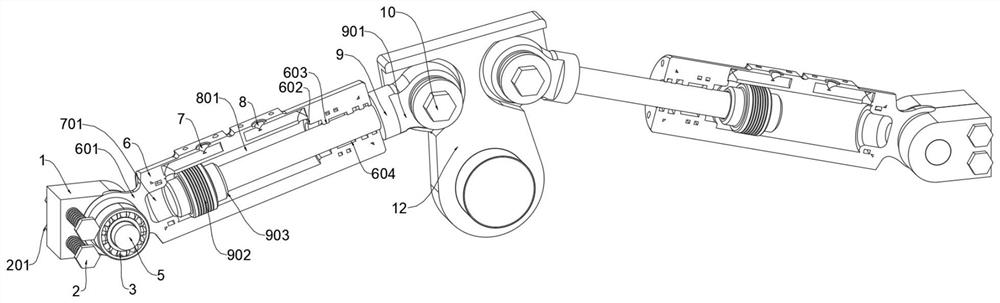

Mechanical tilt cylinder for concrete mechanical pumping

InactiveCN112555221AEasy to fixImprove the convenience of replacementFluid-pressure actuatorsClassical mechanicsHydraulic ram

The invention provides a mechanical tilt cylinder for concrete mechanical pumping. The mechanical tilt cylinder comprises fixed mounting seats, wherein fixing bolts are arranged at the outer side of each fixed mounting seat, and a bearing is arranged at the inner side of a connecting rotating hole of each fixed mounting seat; a tilt cylinder hydraulic oil cylinder barrel is rotationally connectedto the inner side of each fixed mounting seat, and a connecting ball head is connected into the bottom of each tilt cylinder hydraulic oil cylinder barrel; a first oil inlet and a second oil inlet arearranged in the top of the outer wall of each tilt cylinder hydraulic oil cylinder barrel; and a hydraulic ejector rod is slidably connected to the interior of each tilt cylinder hydraulic oil cylinder barrel, each hydraulic ejector rod is connected to a connecting pin connected to a tilt cylinder base, and an anti-skid nut is connected to the rear end of each connecting pin. According to the mechanical tilt cylinder, the fixing bolts are screwed into threaded holes of the fixed mounting seats, the two fixing mounting seats are combined and connected, and then the rear ends of the fixing bolts are locked through locking nuts, so that the fixed mounting seats are fixed conveniently, firmness and reliability of the fixed mounting seats are guaranteed, and meanwhile, convenience in replacement of the tilt cylinder hydraulic oil cylinder barrel is improved.

Owner:陈林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com