Inserted connection type aluminum alloy ceiling mounting structure

An installation structure, aluminum alloy technology, applied in the direction of ceiling, building components, building structure, etc., can solve the problems of troublesome replacement, low work efficiency, etc., and achieve the effect of improved work efficiency, strong corrosion resistance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the invention will be further elaborated below in conjunction with specific illustrations.

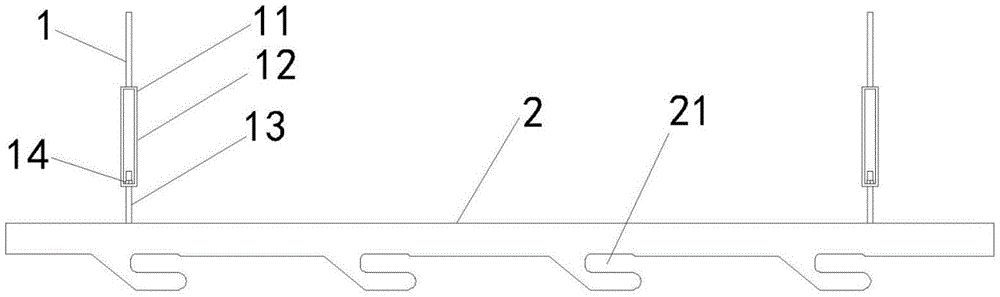

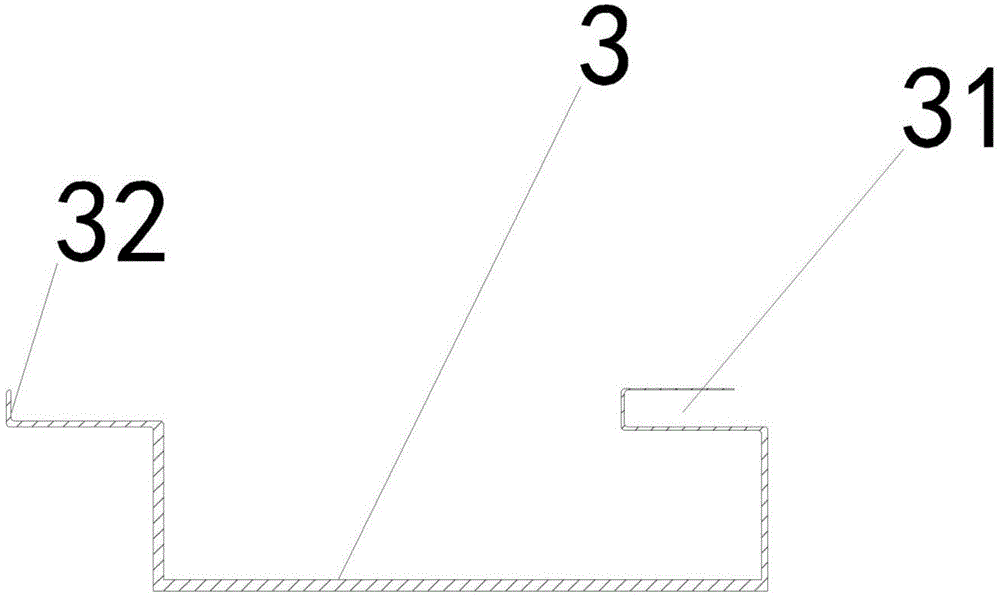

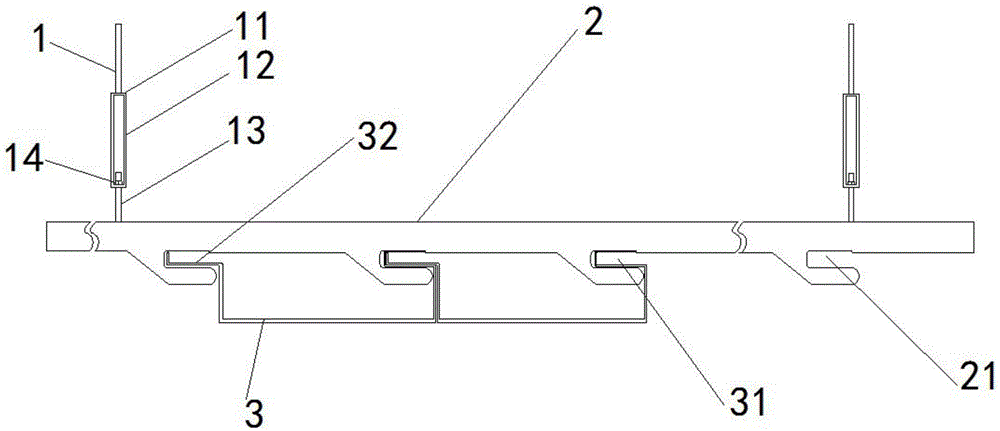

[0018] see figure 1 , figure 2 , image 3 , a plug-in aluminum alloy ceiling installation structure, which is composed of a suspender 1, a load-bearing main keel 2 and an aluminum alloy ceiling panel 3, wherein one end of the suspender 1 is fixed to the top of the wall, and the other end is fixed with a connector connected to the load-bearing main keel 2 11. The load-bearing main keel 2 has a "C"-shaped cross-section. One side of the "C"-shaped opening is provided with a mounting hole, and the other side of the "C"-shaped opening is provided with an insertion slot for fixing the aluminum alloy ceiling board 3 21. The aluminum alloy ceiling board 3 is formed with buckle structures matching the insertion slots 21 on both sides, and the aluminum alloy ceil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com