Abrasion-proof false pipe component, detachable assembly component and smoke heat exchanger

A technology for flue gas heat exchangers and anti-friction fake tubes, which is applied to heat exchanger shells, installations, safety devices for heat exchange equipment, etc., and can solve problems such as indirect damage to heat exchange tube rows, inconvenient cutting and welding, and small operating space , to achieve the effect of convenient replacement, improved utilization rate and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

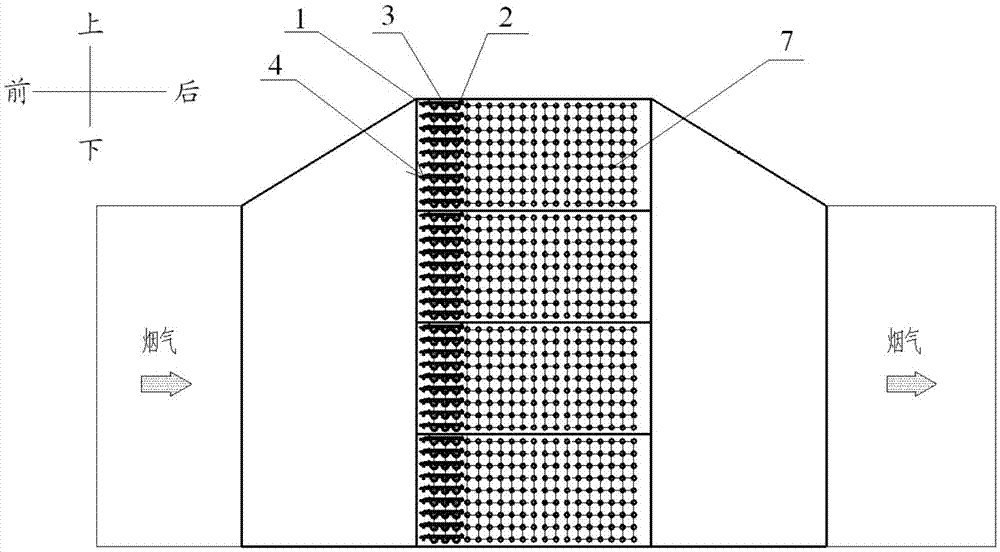

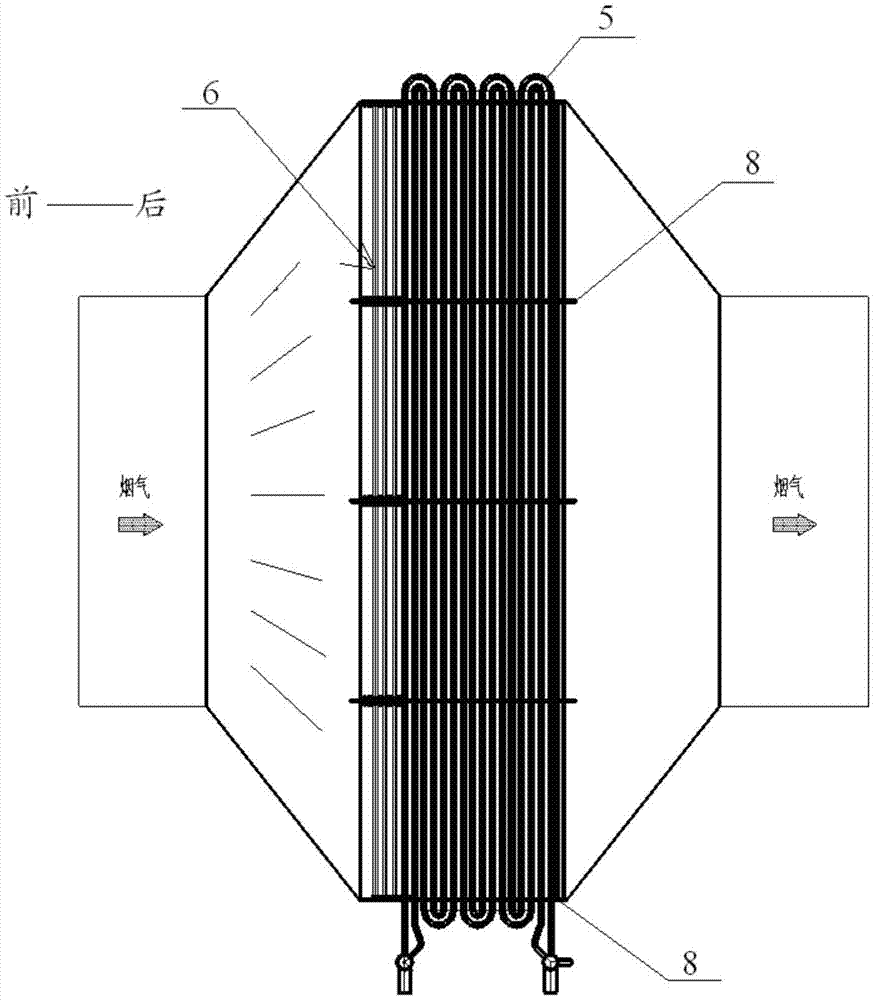

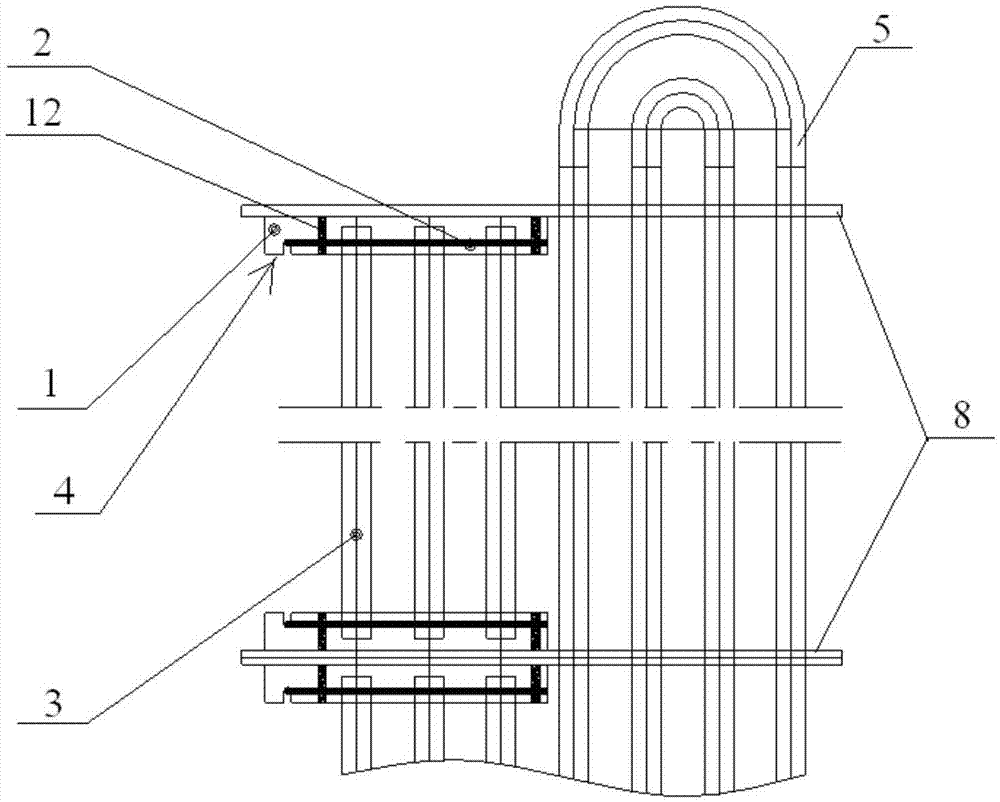

[0030] The core of the present invention is to provide a flue gas heat exchanger and its wear-resistant dummy tube assembly, as well as the detachable mounting parts of the wear-resistant dummy tube, which can realize the detachable installation of the wear-resistant dummy tube, so that after the wear-resistant dummy tube is worn The replacement is more convenient, and at the same time, it avoids the performance of the flue gas heat exchanger being affected by the replacement.

[0031] The flue gas heat exchanger and its wear-resistant dummy tube assembly of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

[0032] In the absence of special instructions, the directions of inside and outside, up and down, and horizontal directions described in this article are all based on the flue gas heat exchanger, and the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com