Parallel drum wheel for PASSIM cigarette making machine

A drum and unit technology, applied in the fields of application, tobacco, and cigarette manufacturing, can solve the problems affecting the normal operation of production, aggravating drums, and wear, so as to ensure long-term normal operation, prolong service life, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

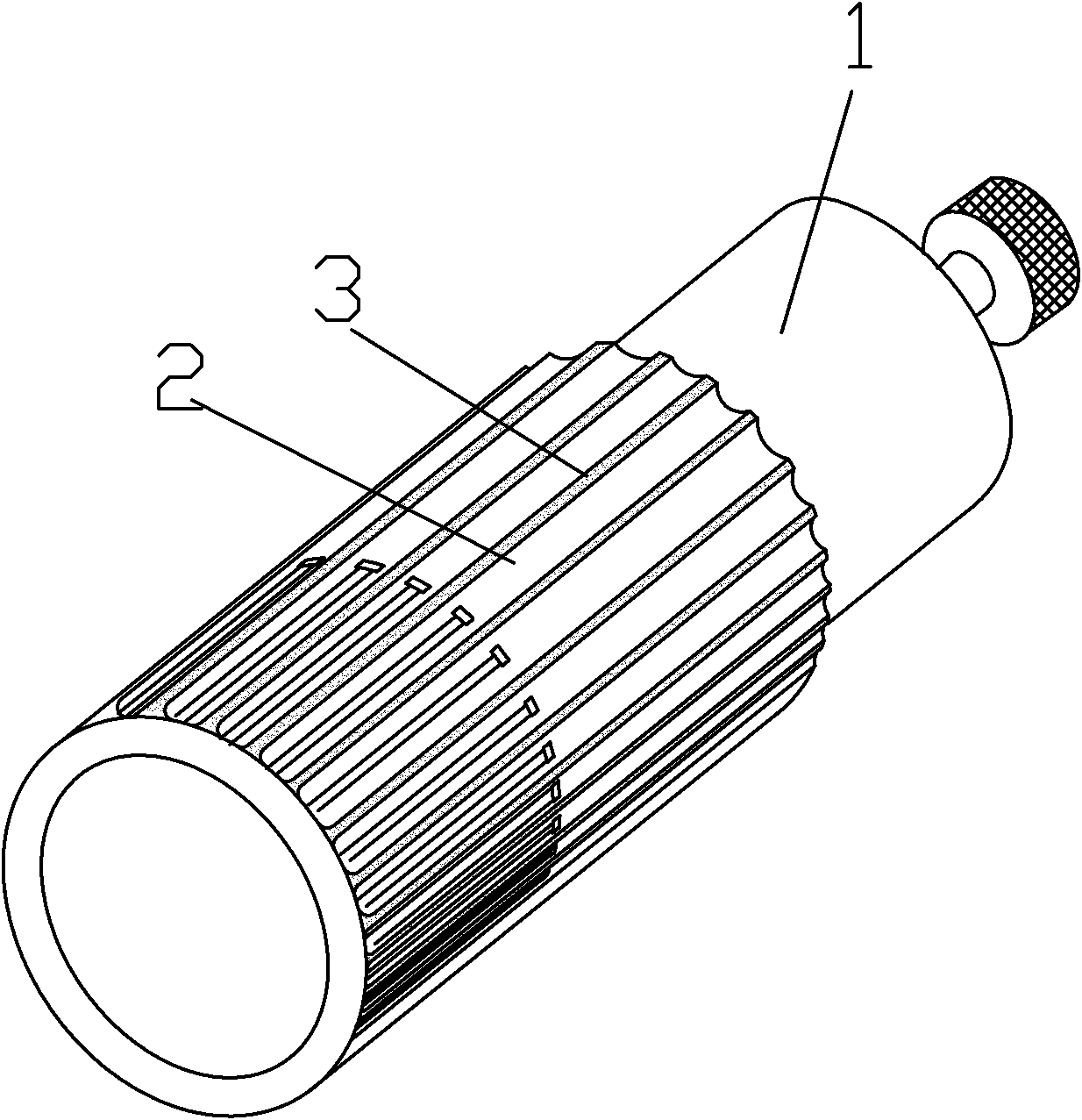

[0014] Such as figure 1 As shown, the parallel drum used for the PASSIM coiling unit includes a drum wheel body 1, and several air suction grooves 2 are evenly distributed on the outer peripheral surface of the drum wheel body 1, and the surface of the air suction groove 2 is smooth. A partition is formed between the two air suction slots, a protrusion is formed on the partition, and a wear-resistant material layer 3 is sprayed on the upper surface of the protrusion. The wear-resistant material layer 3 can be a copper ore sand material layer, a quartz sand material layer or a carborundum material layer, and the surface of the wear-resistant material layer 3 should be polished and smooth.

[0015] The wear-resistant material layer 3 is sprayed on the raised upper surface of the partition by a sandblasting process. The sandblasting uses compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com