Quality control expert system and method for FPC manufacturing process

A manufacturing process and expert system technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., to achieve the effect of improving automation and informatization, reducing production failures, and solving quality control and defect analysis problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

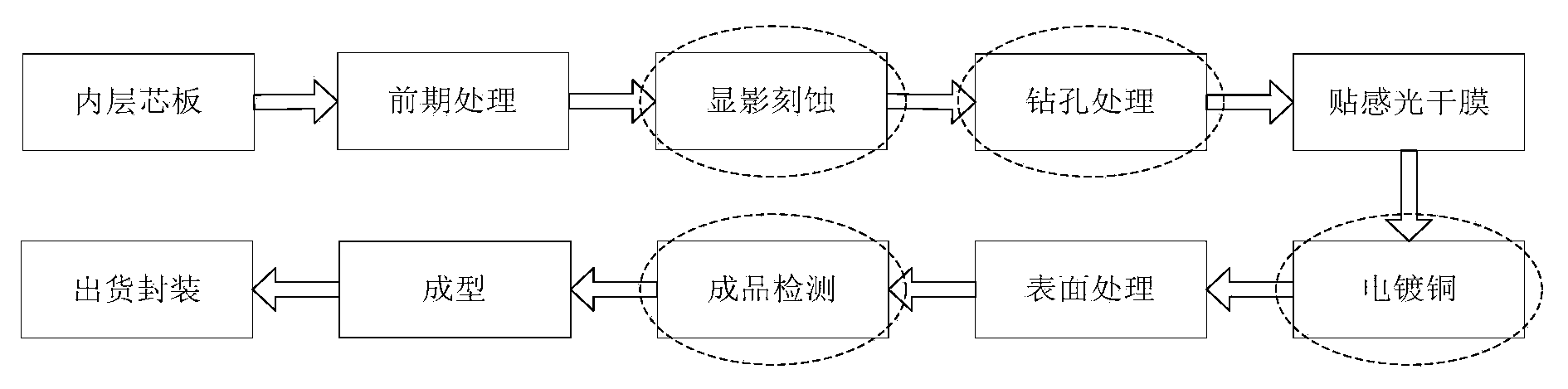

[0047] Such as figure 1 As shown, the FPC manufacturing process includes pre-lamination treatment, development and etching, drilling treatment, photosensitive dry film, copper electroplating, surface treatment, finished product inspection, etc. The processing and manufacturing process is relatively complicated, such as figure 1 The etching, drilling, copper plating and finished product inspection processes shown in the dotted line box are the key processes in the FPC manufacturing process.

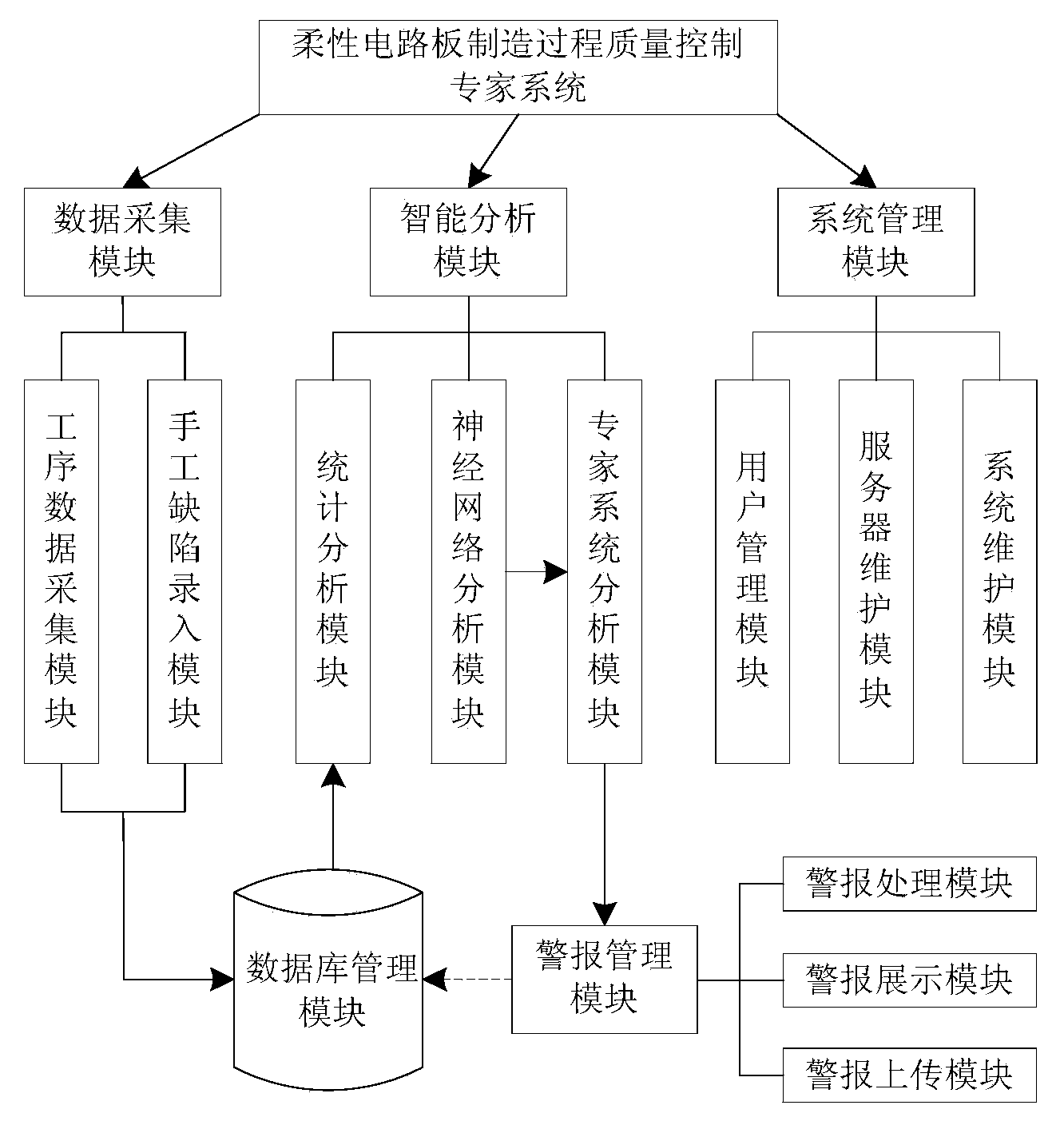

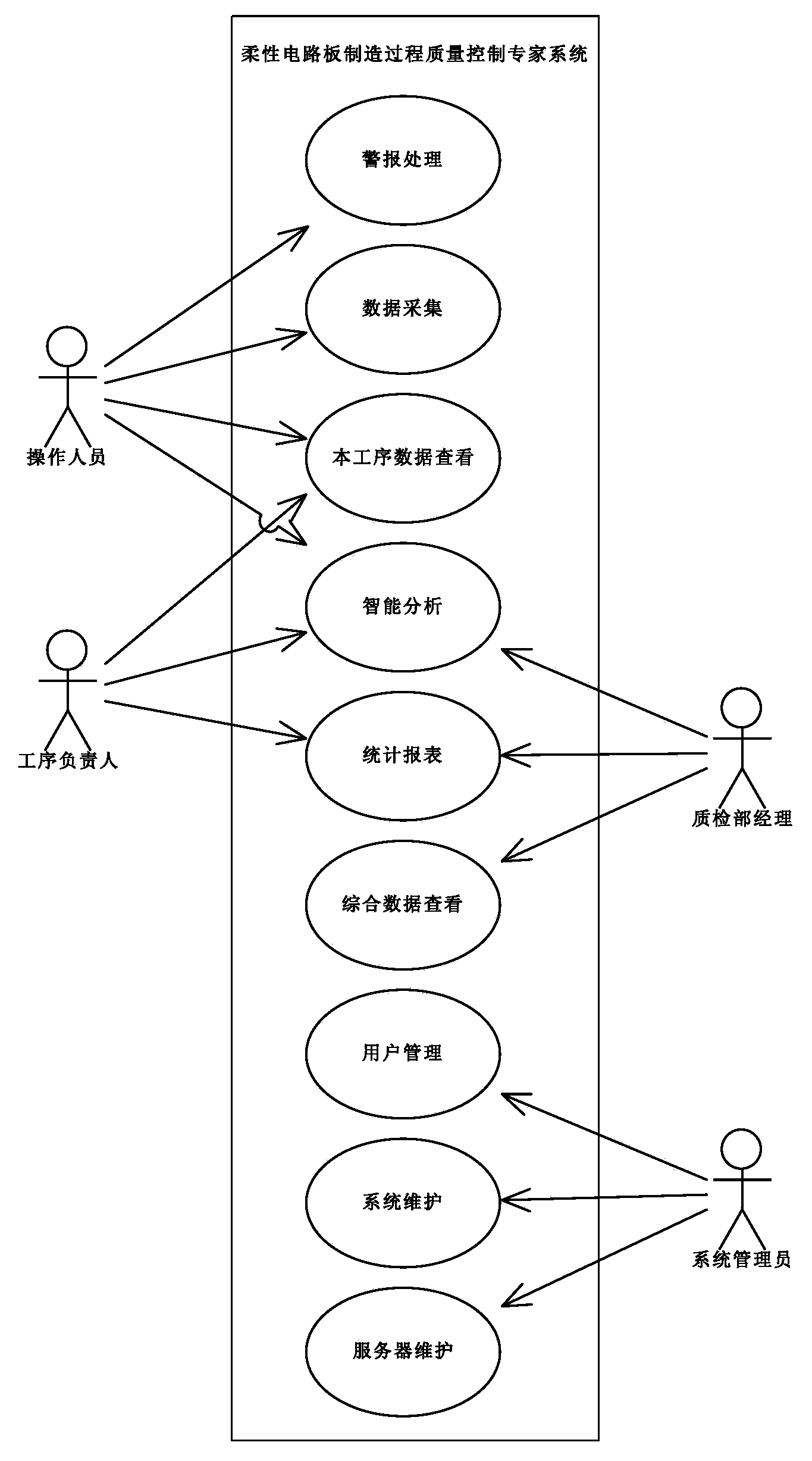

[0048] Such as figure 2 As shown, this embodiment discloses a quality control expert system for FPC manufacturing process. The system of this embodiment is mainly aimed at the key processes of etching, drilling, copper plating and finished product inspection in the FPC manufacturing process for automatic monitoring and related defect diagnosis. Analysis, the system of this embodiment includes a data acquisition module, an intelligent analysis module, an alarm management module, a system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com