Process for making hot melt adhesive net film

A preparation process, a technology for gluing omentum, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of omentum tearing, sticking mesh belt, and uniformity of omentum aperture, so as to reduce production failure and improve Effects on tensile strength, increased efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

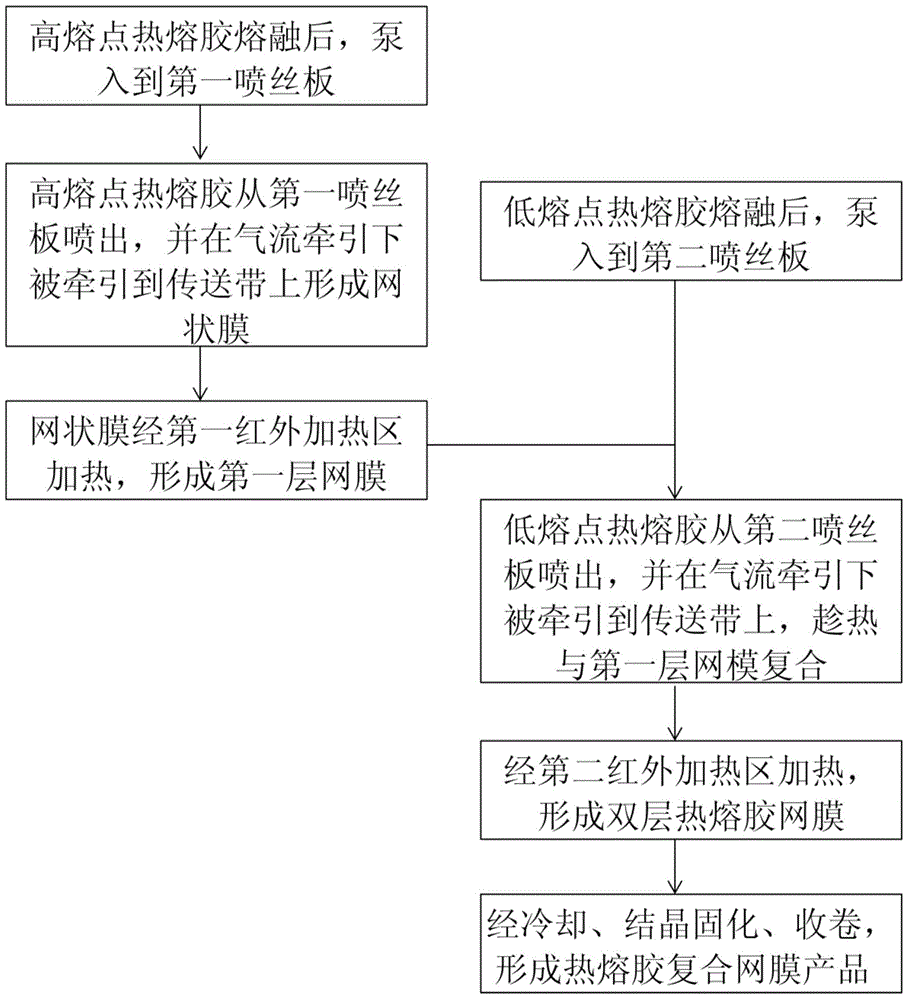

Embodiment 1

[0020] The high melting point (DSC final melting point 135°C) hot melt adhesive and the low melting point (DSC final melting point 105°C) hot melt adhesive are melted and pumped into the independent first spinneret and the second spinneret; the two spinneret The distance between the plates is 1m, the conveyor belt (steel belt) works, and its transmission speed is 13m / min; open the first spinneret, adjust its internal temperature to 210°C, spinneret speed to 10m / min, airflow (compressed air) speed The high melting point hot melt adhesive is spun from the first spinneret to the conveyor belt under the airflow traction to form a mesh film; the mesh film is heated by the first infrared heating zone with a temperature of 100°C to form the first Layer omentum; open the second spinneret, adjust its internal temperature to 180°C, spinneret speed to 8m / min, air velocity (nitrogen) to 100m / min, low melting point hot melt adhesive from the second spinneret and The filaments are spun onto...

Embodiment 2

[0022] The high melting point (DSC final melting point 147°C) hot melt adhesive and the low melting point (DSC final melting point 73°C) hot melt adhesive are melted and then pumped into the independent first spinneret and second spinneret; the two spinnerets The distance between the plates is 1m, the conveyor belt (steel belt) is working, and the transmission speed is adjusted to 13 m / min; the first spinneret is opened, and the internal temperature is adjusted to 220°C, the spinneret speed is 8m / min, and the air flow (nitrogen) The speed is 100m / min, and the high melting point hot melt adhesive is spun from the first spinneret to the conveyor belt under the airflow traction to form a mesh film; the mesh film is heated by the first infrared heating zone with a temperature of 110°C to form the second A layer of omentum; open the second spinneret, adjust its internal temperature to 200°C, spinneret speed to 8m / min, air velocity (nitrogen) to 100m / min, low melting point hot melt a...

Embodiment 3

[0024] The high melting point (DSC final melting point 180°C) hot melt adhesive and the low melting point (DSC final melting point 100°C) hot melt adhesive are melted and then pumped into the independent first spinneret and second spinneret; the two spinneret The distance between the plates is 2m, the conveyor belt (steel belt) is working, and the transmission speed is adjusted to 15 m / min; the first spinneret is opened, the internal temperature is adjusted to 240 °C, the spinneret speed is 12m / min, and the air flow (compressed air ) at a speed of 100m / min, the high-melting point hot melt adhesive is spun from the first spinneret to the conveyor belt under airflow traction to form a mesh film; the mesh film is heated by the first infrared heating zone with a temperature of 130°C to form The first layer of omentum; open the second spinneret, adjust the internal temperature to 190°C, the spinning speed to 10m / min, the air velocity (compressed air) to 120m / min, and the low-melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com