Environment-friendly built-in sealant and preparation method thereof

A green and environmentally friendly sealant technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of long bonding and positioning time and slow curing speed of room temperature vulcanized silicone rubber, and improve the decoration work. Efficiency and quality assurance, the effect of improving adhesion and improving curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

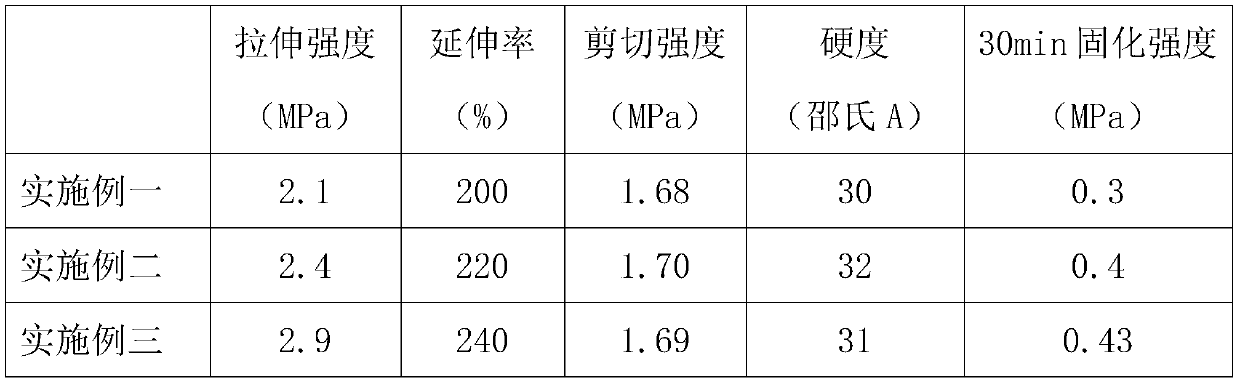

Embodiment 1

[0027] A green environment-friendly interior sealant, comprising the following components by weight: 100 parts by weight of hydroxyl-terminated polydimethylsiloxane, 80 parts by weight of hydrophobic silicon dioxide, 30 parts by weight of methyl silicone oil, 7 parts by weight of vinyl tri Ethoxysilane, 3 parts by weight of butyl titanate, 8 parts by weight of hydrophobic fumed silica, 1 to 2 parts by weight of γ-glycidyl etheroxypropyl triethoxy, 0.1 parts by weight of organic bismuth, wherein the hydrophobic two The ratio of silicon oxide to hydrophobic fumed silica is 10:1, and the ratio of butyl titanate to organic bismuth is 30:1.

Embodiment 2

[0029] A green environment-friendly interior sealant, comprising the following components by weight: 100 parts by weight of hydroxyl-terminated polydimethylsiloxane, 90 parts by weight of hydrophobic silicon dioxide, 30 parts by weight of methyl silicone oil, 7 parts by weight of vinyl tri Ethoxysilane, 3.6 parts by weight of butyl titanate, 9 parts by weight of hydrophobic fumed silica, 1 to 2 parts by weight of γ-glycidyl etheroxypropyl triethoxy, 0.12 parts by weight of organic bismuth, wherein the hydrophobic two The ratio of silicon oxide to hydrophobic fumed silica is 10:1, and the ratio of butyl titanate to organic bismuth is 30:1.

Embodiment 3

[0031] A green environment-friendly interior sealant, comprising the following components by weight: 100 parts by weight of hydroxyl-terminated polydimethylsiloxane, 100 parts by weight of hydrophobic silicon dioxide, 30 parts by weight of methyl silicone oil, 7 parts by weight of vinyl tri Ethoxysilane, 4.5 parts by weight of butyl titanate, 10 parts by weight of hydrophobic fumed silica, 1 to 2 parts by weight of γ-glycidyl etheroxypropyl triethoxy, 0.15 parts by weight of organic bismuth, wherein, hydrophobic two The ratio of silicon oxide to hydrophobic fumed silica is 10:1, and the ratio of butyl titanate to organic bismuth is 30:1.

[0032] A preparation method of a green environment-friendly interior sealant, comprising the following steps:

[0033] 1) Stir 100 parts by weight of hydroxyl-terminated polydimethylsiloxane and 80 to 100 parts by weight of hydrophobic silica at a vacuum of 0.085 to 0.1 MPa and a temperature of 120 to 140 degrees Celsius for 90 to 120 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com