Patents

Literature

33results about How to "Fast cross-linking reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based composite adhesive

InactiveCN102618193AHigh peel strengthGood high and low temperature resistanceEster polymer adhesivesCross-linkWater based

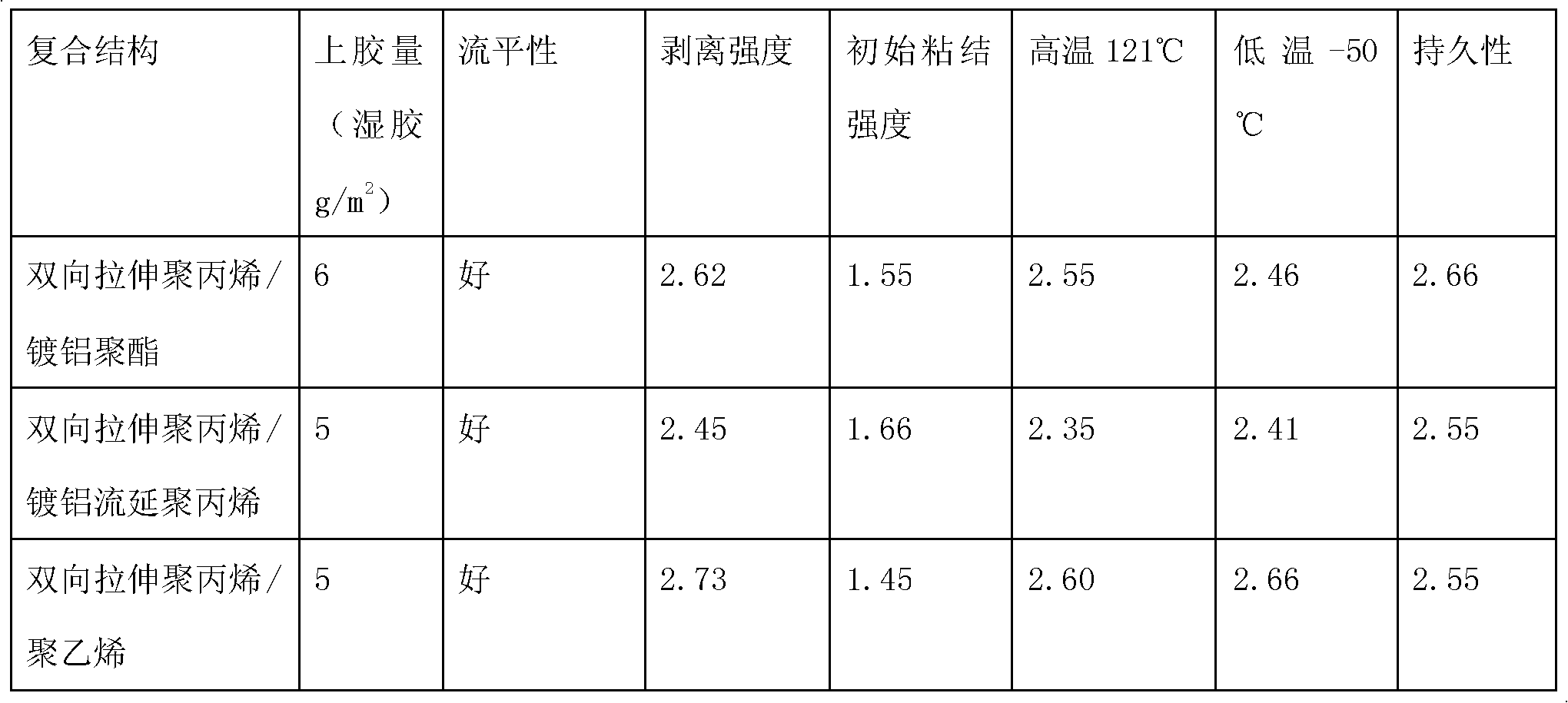

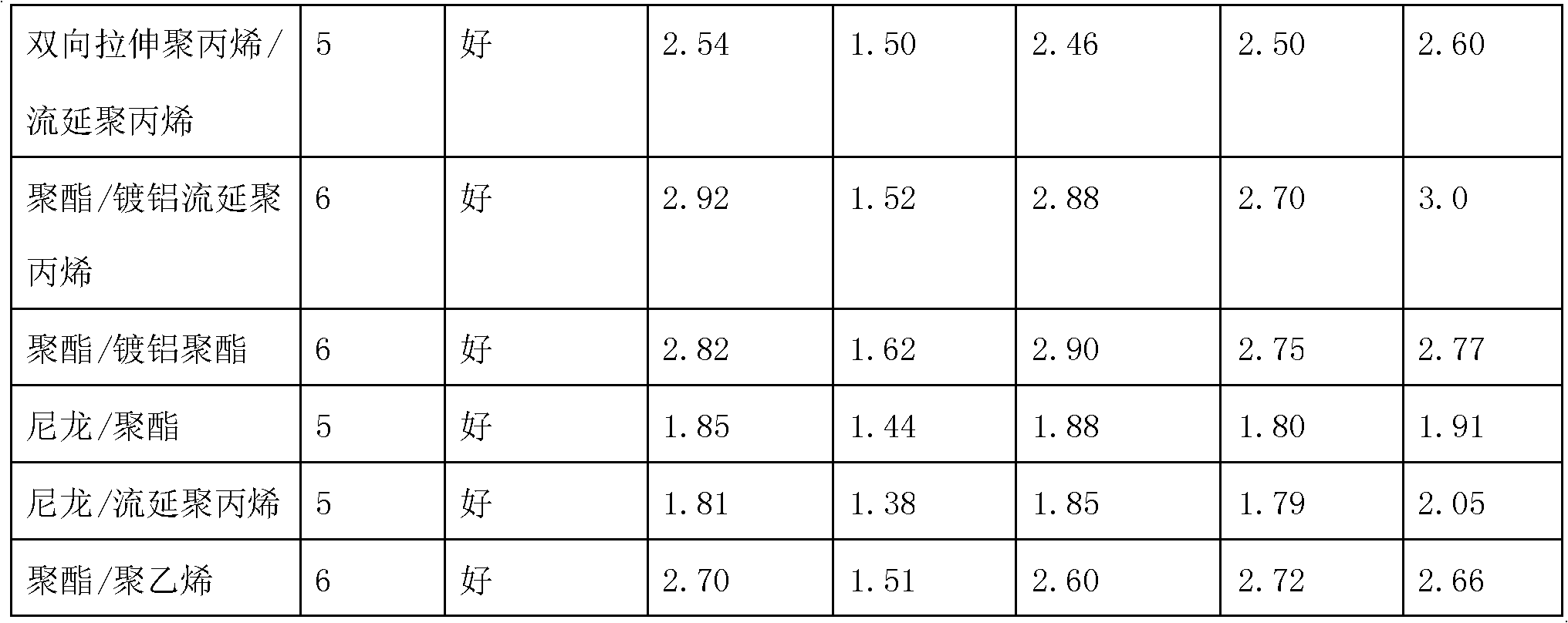

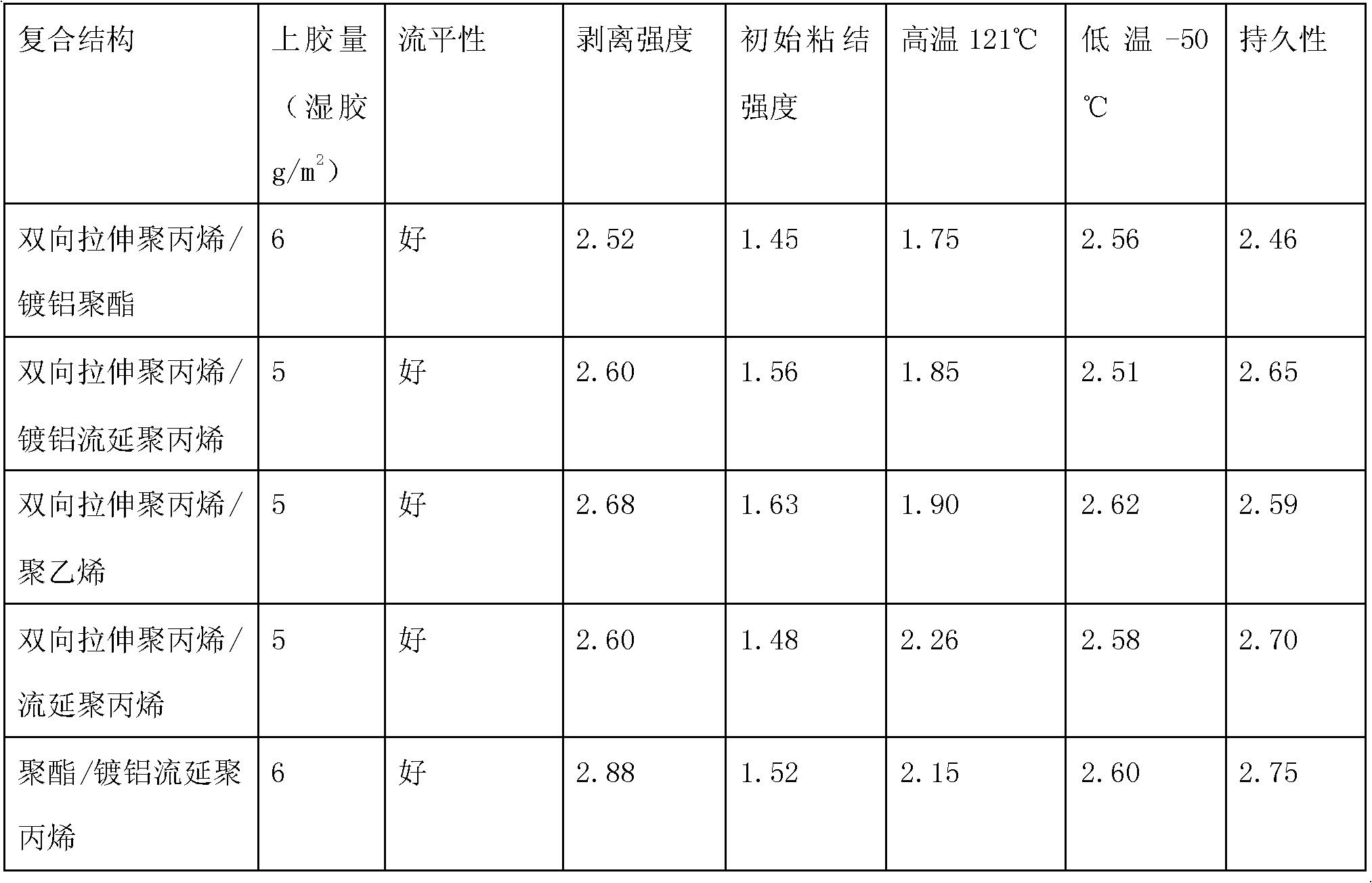

The invention discloses water-based composite adhesive, which contains acrylate emulsion and a cross-linking agent, wherein the weight of the cross-linking agent is 0.1-6 percent of the weight of the acrylate emulsion; the cross-linking agent is any one or a mixture of hexamethylenediamine and adipic acid dihydrazide; and the acrylate emulsion is formed by copolymerizing a terpenes hard monomer, a terpenes soft monomer, a terpenes carboxylic acid monomer, a terpenes functional monomer, a dual-vinyl monomer and a terpenes cross-linking monomer through nuclear shells under an emulsion system. The adhesive is particularly suitable for dry-type composite adhesion between flexible package composite base materials such as a plastic film and a vacuum aluminized film which are processed through corona; has good leveling, fast drying, high transparency, capability of curing at room temperature, high initial strength, excellent peel strength, difficulty in mesh clogging and skinning, wide adaptability and low cost; and can be applied to various machine types, does not contain any organic solvent, can replace solvent adhesive at present completely, and belongs to environment friendly adhesive.

Owner:GUANGDONG RONGYU INDAL

Method for preparing functional polymer material

ActiveCN106283275AIncrease profitImprove efficacyMelt spinning methodsCellulose/protein filament chemical after-treatmentFiberPolymer science

The invention discloses a method for preparing a functional polymer material, and belongs to the field of fiber material and plastic processing. The invention aims at solving the shortcomings of low efficiency and high cost of carrying out functionalization on traditional polymer materials by blending and surface chemical grafting. The method disclosed by the invention comprises the following steps: acting an alternating electric field on functional material particles to be physically embedded on the surface of an extruded base material of the polymer material, carrying out chemical crosslinking and physical blending on a crosslinking group and the surface of the base material of the polymer material, and blowing cold air to the base material of the polymer material for curing or blowing cold air to the base material of the polymer material for curing after stretching to obtain the functional polymer material. The selection range of functional substances in the method disclosed by the invention is very wide, the utilization rate is high, the effect is good, the dosage is small, the preparation procedure of the material is short, and the efficiency is high, so that the method can be widely used in the fields of the textile and garment industry, plastic industry, environmental management, drug extraction and the like.

Owner:WUYI UNIV +1

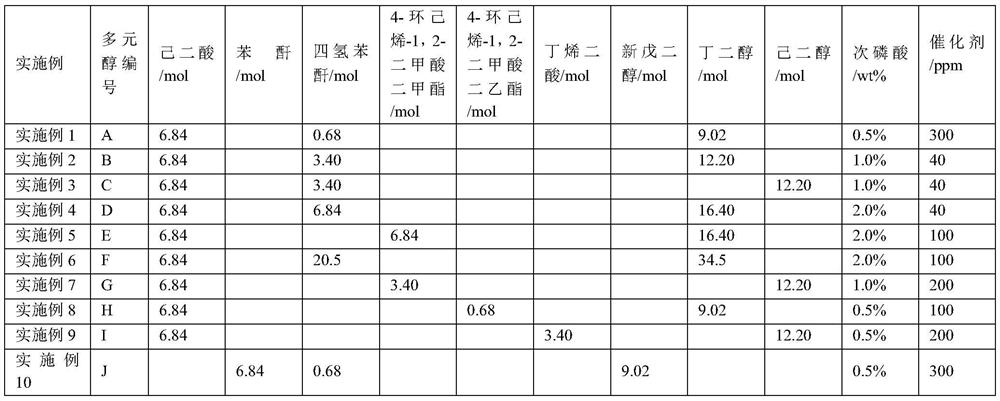

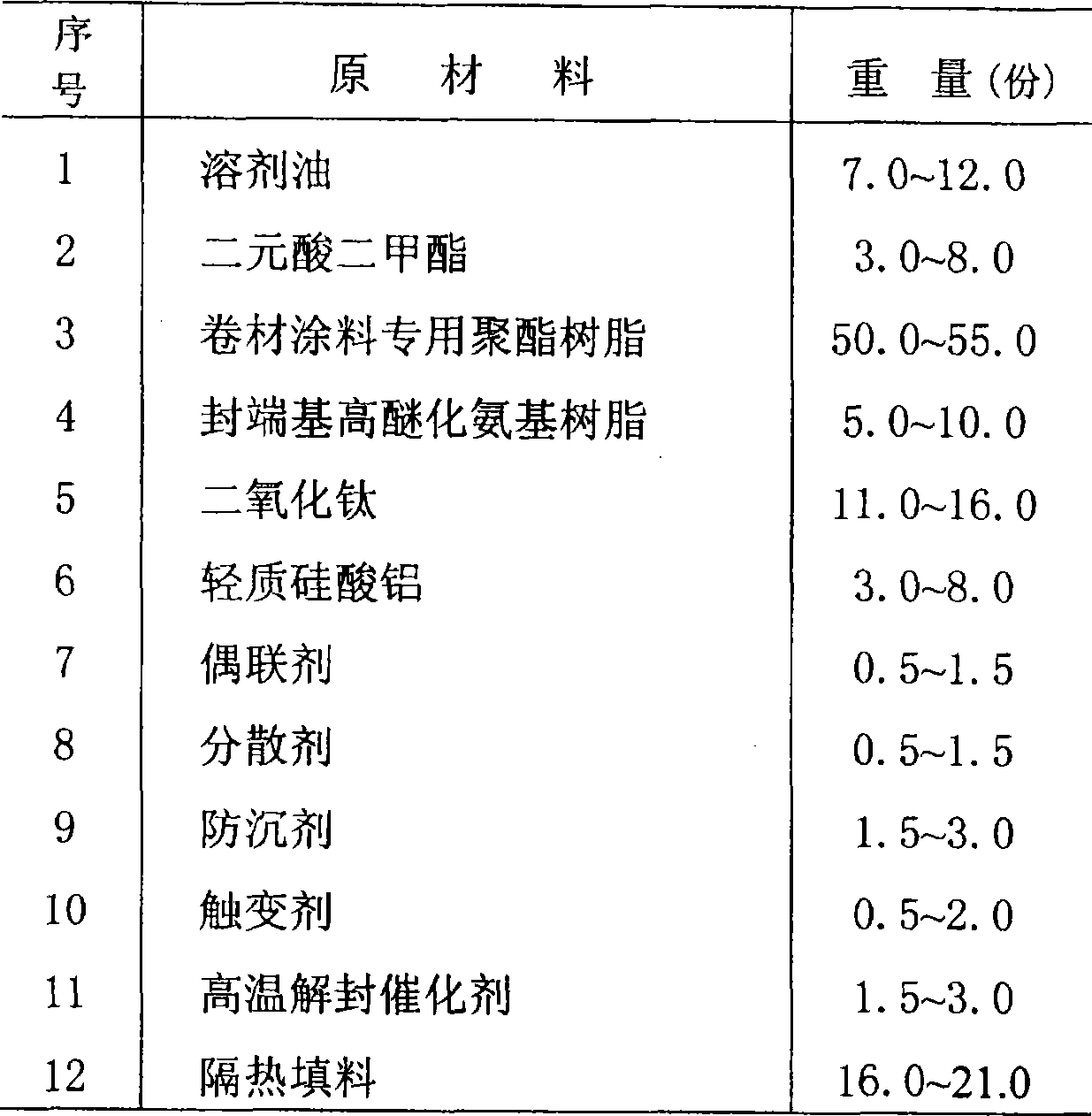

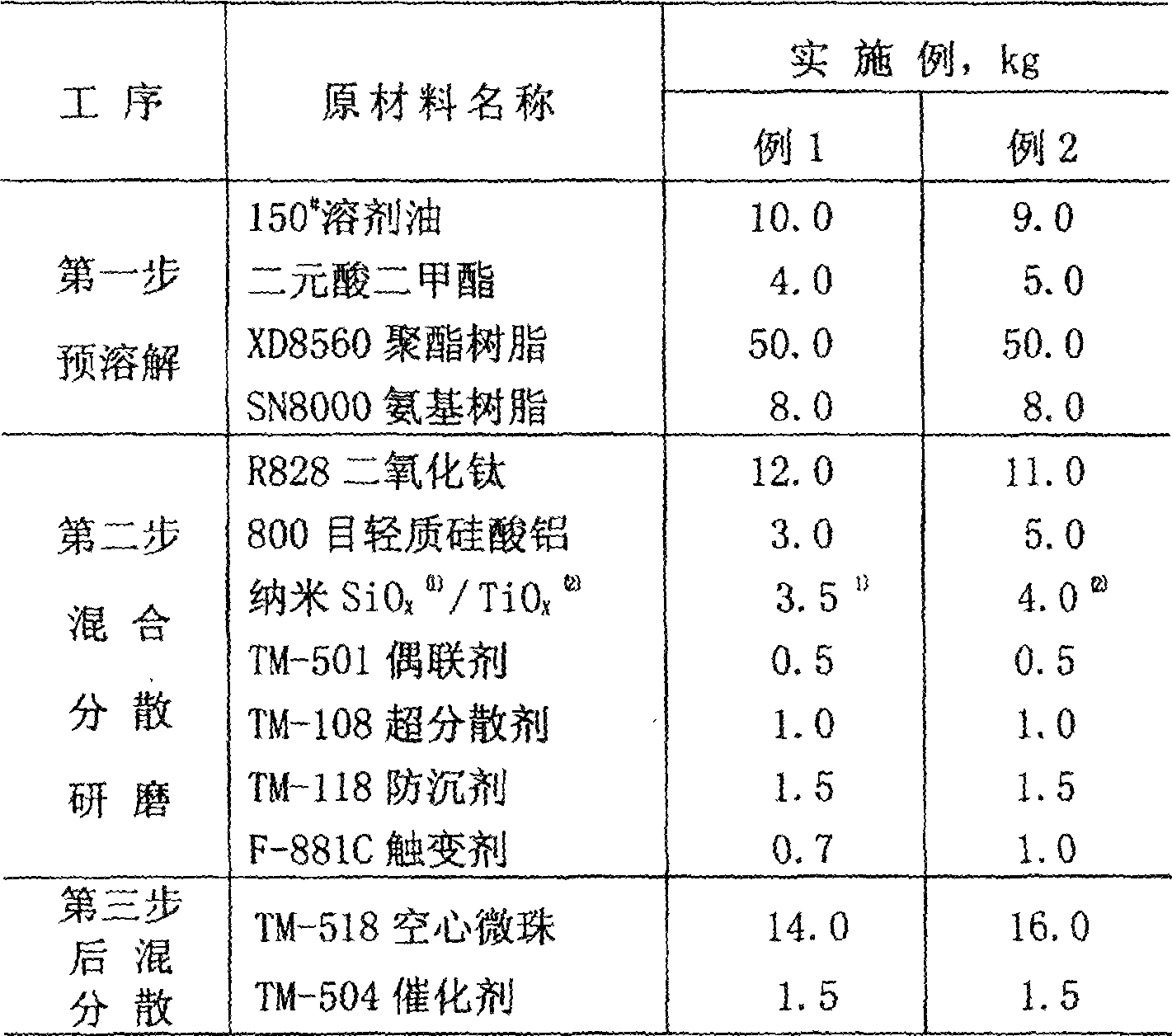

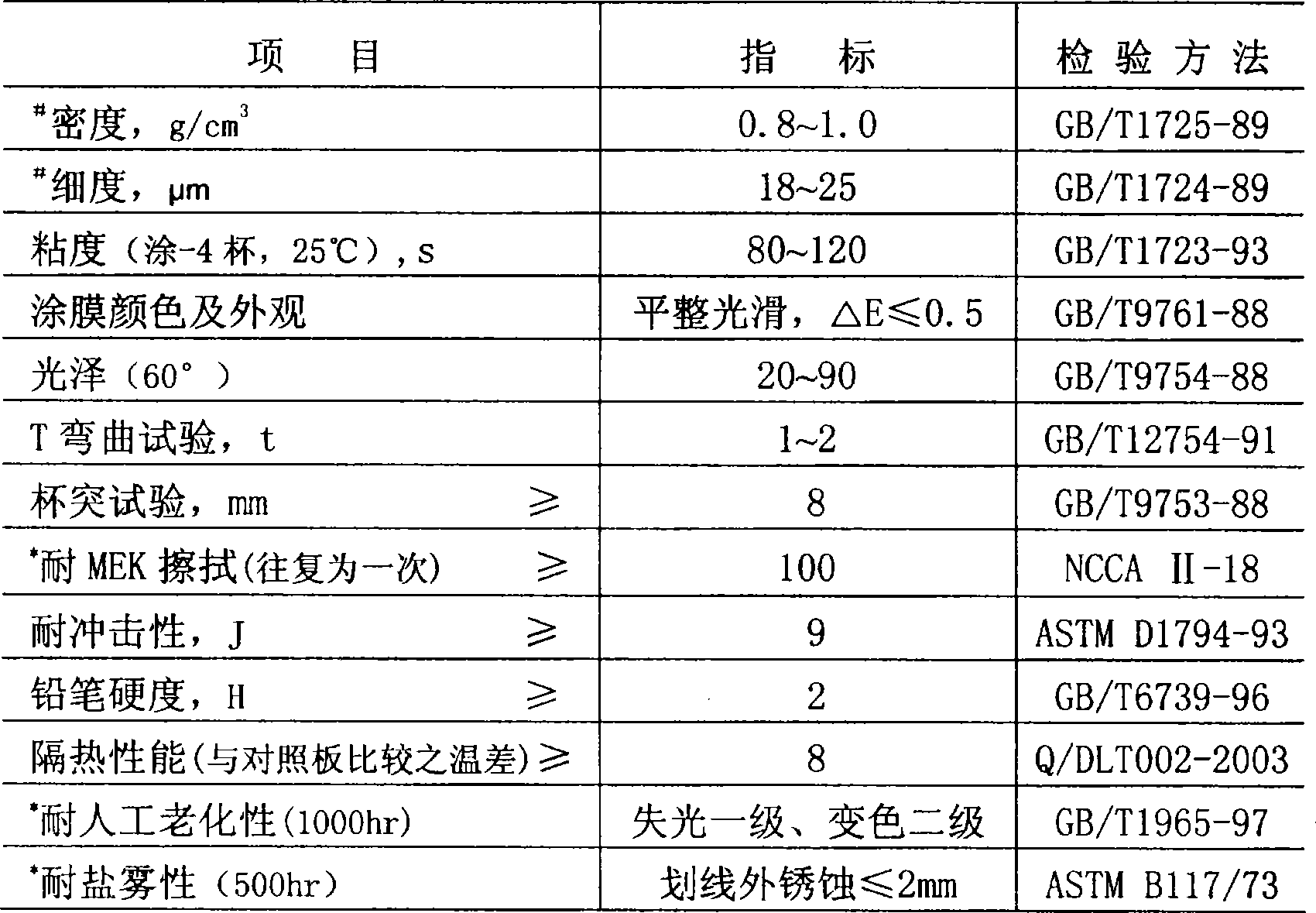

Heat insulated anticorrosive coating for coiled material, and fabricating method

InactiveCN1760292AGood heat insulationReduce indoor temperatureAnti-corrosive paintsPolyester coatingsCross-linkHigh resistance

A paint for the coiled insulating and anticorrosion material is prepared from special polyester resin, high etherified cross-linking resin and pigment, functional insulating filler, special chemical assistant and solvent through proportional mixing, dispersing, grinding, adding insulating filler, etc. Its advantages are no poison and pollution, high flame-retarding and insulating effect, and high resistance to ageing and corrosion.

Owner:广东创想现代产业科技有限公司

Waterborne UV-curable matt paint

InactiveCN106675275AHigh hardnessTo achieve the surface effectPolyurea/polyurethane coatingsWater basedSilicon dioxide

The invention discloses waterborne UV-curable matt paint for furniture. Raw materials of the paint are composed of the following ingredients (by weight): 30-50% of a polyurethane acrylate emulsion, 20-40% of a self-drying acrylate emulsion, 5-10% of purified water, 5-10% of water-based color paste, 1-5% of white carbon black fumed silica, 3-5% of a photoinitiator and 1-3% of an auxiliary agent. According to a common paint preparation method used by a technicist in the field, the above materials are made into a spraying waterborne UV-curable matt paint. The paint is automatically sprayed by equipment or manually onto a base material. Therefore, VOC emission can be greatly reduced and production efficiency can be enhanced. By infrared curing and then UV light curing, excellent leveling property can be obtained, and surface effect of PU paint and hardness and scratch resistance of UV can be achieved.

Owner:HUIZHOU CHANGRUNFA PAINT

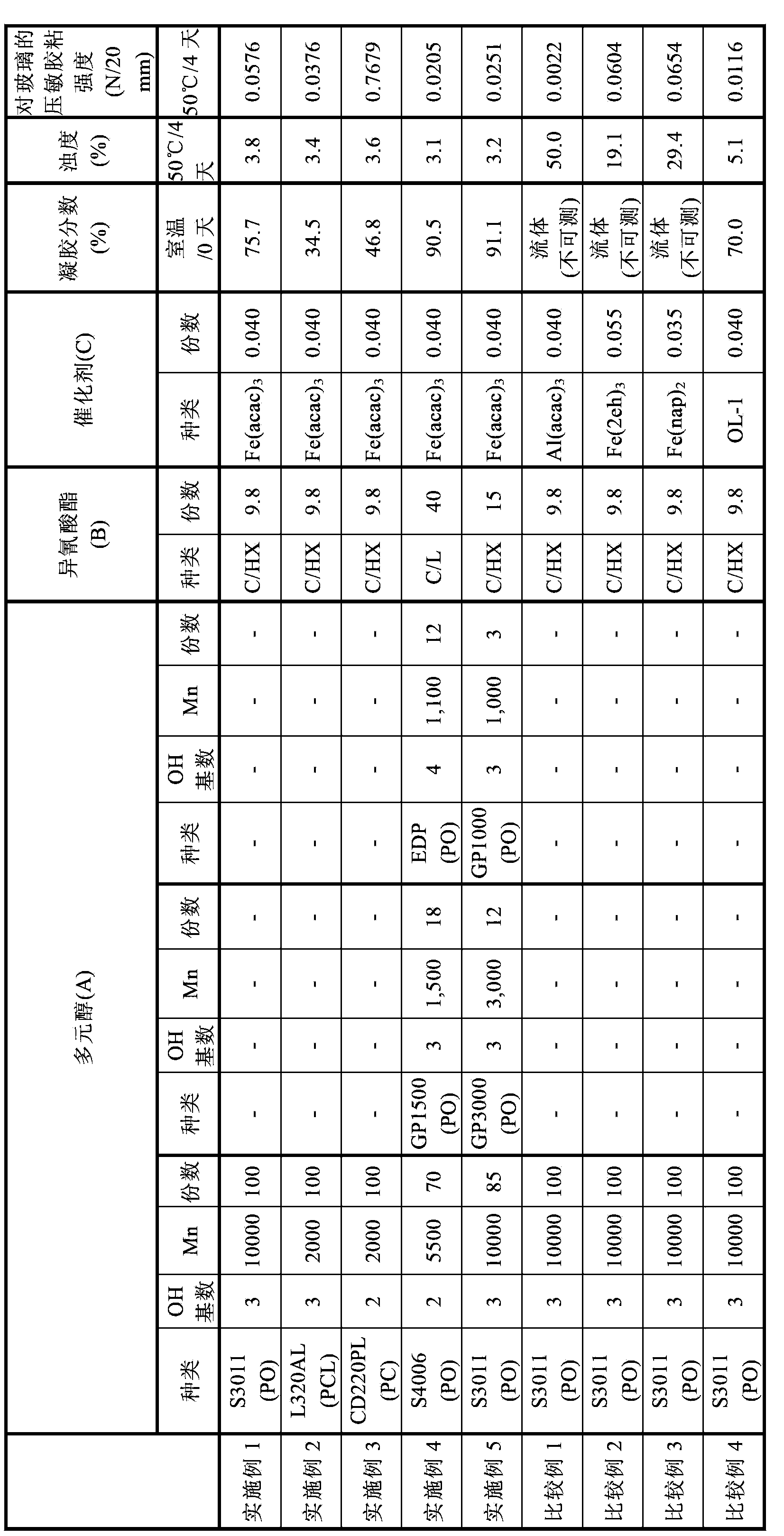

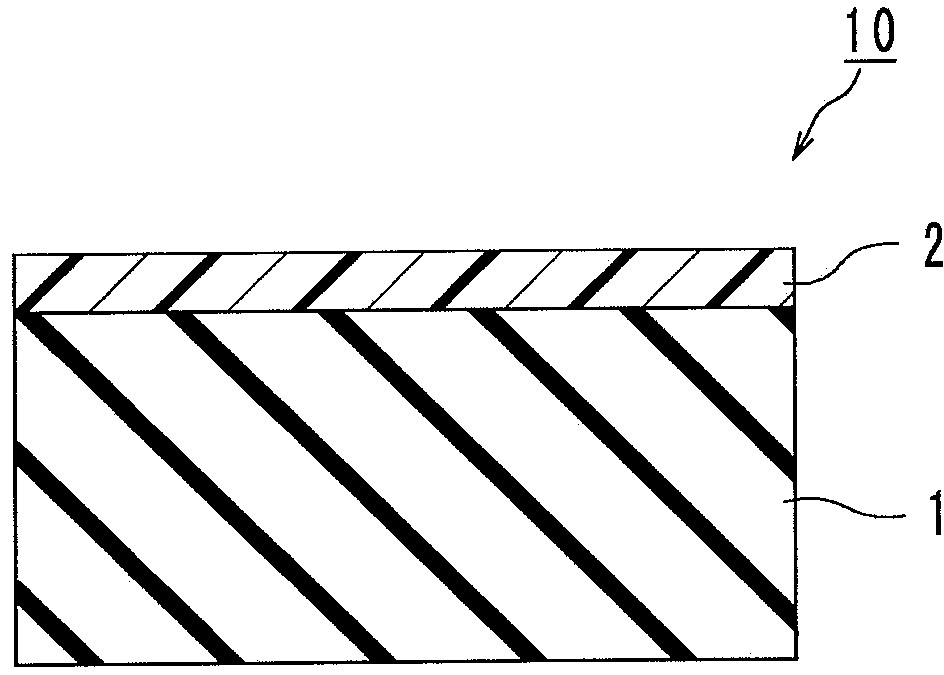

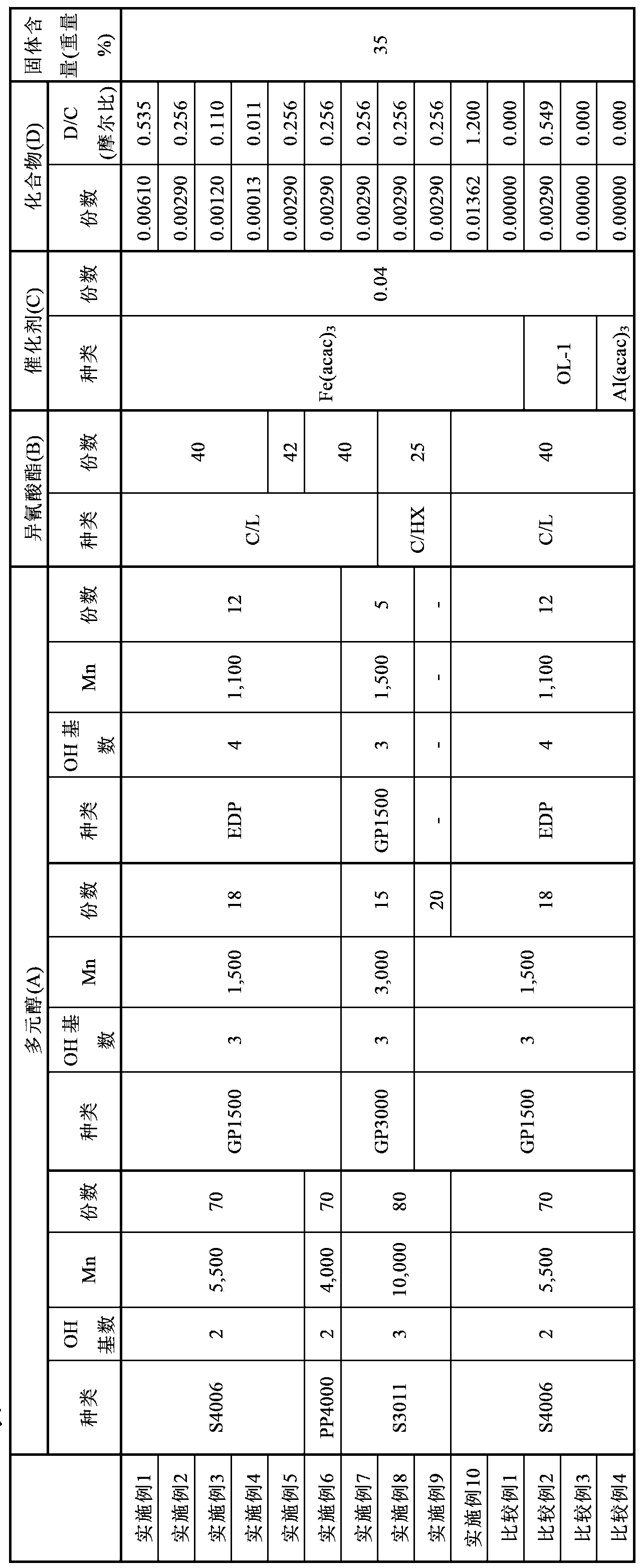

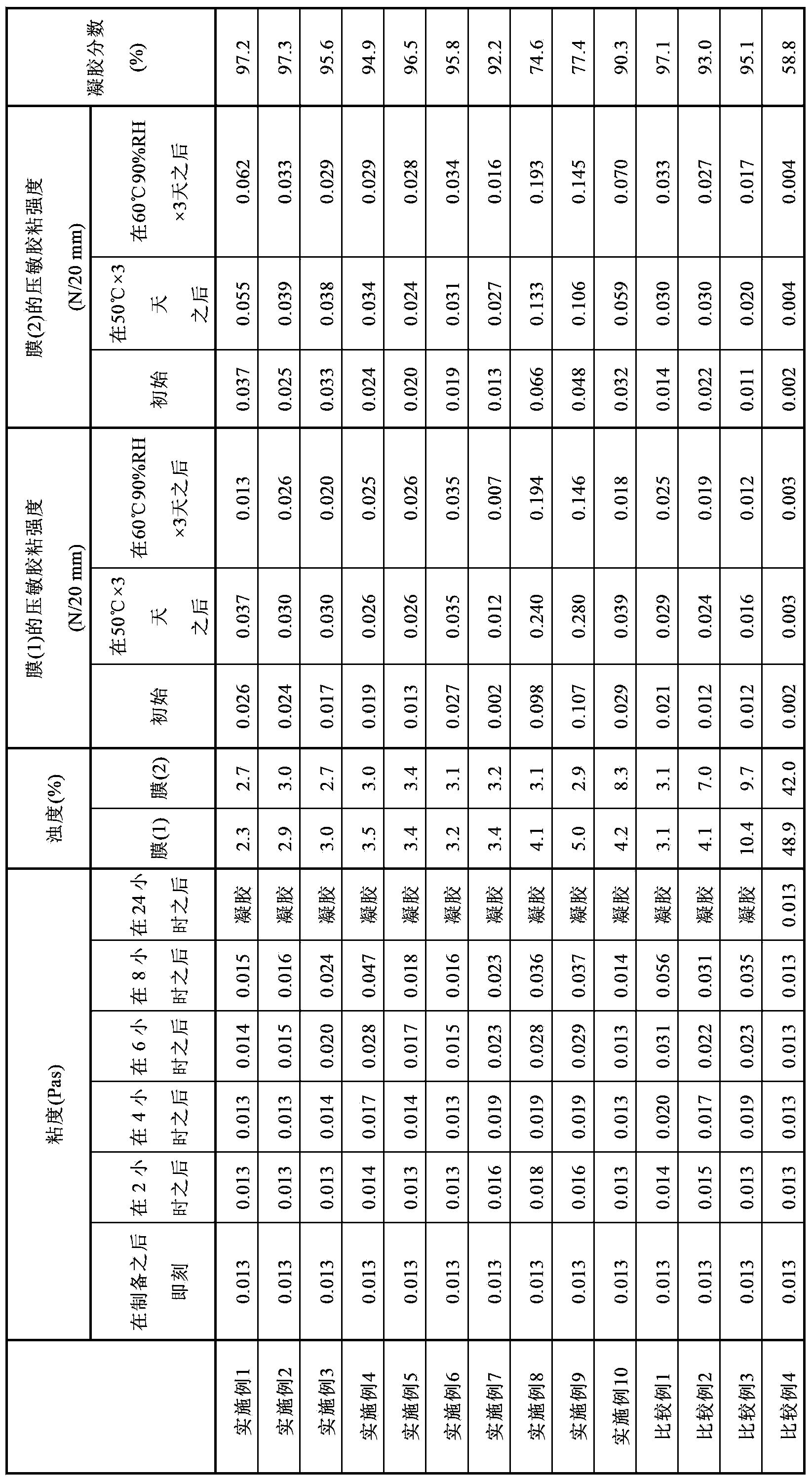

Resin composition, pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, pressure-sensitive adhesive sheet, and surface protective film

ActiveCN103570912AImprove responseHigh transparencyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPolyol

Provided is a resin composition that can serve as a pressure-sensitive adhesive composition that is a material for forming a pressure-sensitive adhesive layer containing a polyurethane-based resin, the resin composition showing extremely high reactivity without any use of a tin compound as a catalyst, allowing a cross-linking reaction between a polyol and a polyfunctional isocyanate compound to rapidly progress, and being capable of providing a pressure-sensitive adhesive layer having high transparency. Also provided is a pressure-sensitive adhesive composition formed of such resin composition. Also provided is a pressure-sensitive adhesive layer having high transparency formed through the use of such pressure-sensitive adhesive composition. Also provided are a pressure-sensitive adhesive sheet and a surface protective film each including such pressure-sensitive adhesive layer. The resin composition includes: a polyol (A) having two or more OH groups; a polyfunctional isocyanate compound (B); and a catalyst (C), in which: the content ratio of the polyfunctional isocyanate compound (B) with respect to 100 parts by weight of the polyol (A) is 1 part by weight to 100 parts by weight; and the catalyst (C) includes an iron complex compound.

Owner:NITTO DENKO CORP

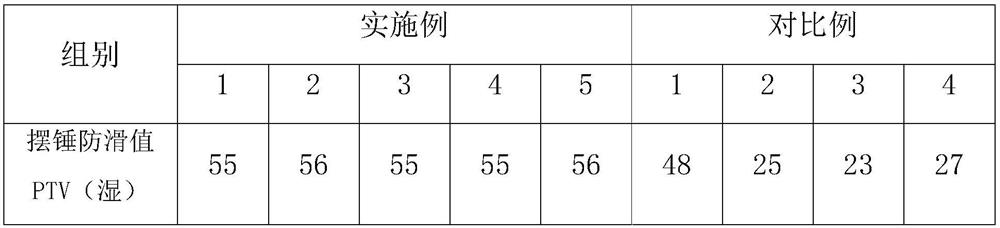

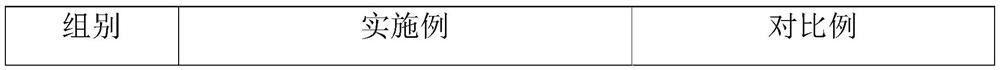

Anti-skid powder coating and preparation method thereof

ActiveCN112724805AGood weather resistanceImprove wear resistancePowdery paintsPolyester coatingsWeather resistanceFirming agent

The invention provides an anti-skid powder coating. The anti-skid powder coating is prepared from carboxyl-terminated polyester resin, a curing agent, filler, talcum powder, titanium dioxide, mica powder, an anti-skid additive, a wear-resistant additive, a curing accelerator, a three-dimensional sand streak agent, a conventional additive, a surface roughening agent, a dispersing agent and pigment. Through cross-linking reaction of two carboxyl-terminated polyester resins with different acid values and the curing agent, the weather resistance of the prepared anti-skid powder coating is improved, and the cross-linking reaction of the two carboxyl-terminated polyester resins with different acid values and the curing agent can be effectively accelerated by adding the curing accelerator, so that the coating is quickly cured, and the anti-skid performance of a coating film is improved; and the mica powder, the dispersing agent and the anti-skid additive are premixed and then added, and the mica powder, the dispersing agent, the anti-skid additive, the three-dimensional sand streak agent, the surface roughening agent and the wear-resistant additive have a synergistic effect, so that a concave-convex state is formed on the surface of a coating, a three-dimensional effect is achieved, and the anti-skid powder coating has remarkable anti-skid performance, wear resistance, weather resistance and scratch resistance.

Owner:广东华江粉末科技有限公司

Preparation method of low-pressure polymer decoloration nanofiltration membrane as well as product and application thereof

ActiveCN111437733ANot easy to fall offAdjust the degree of crosslinkingMembranesSemi-permeable membranesFoaming agentPolymer solution

The invention discloses a preparation method of a low-pressure polymer decolorization nanofiltration membrane as well as a product and application thereof, and the method comprises the following steps: S1, mixing a polymer, a copolymer, a pore-foaming agent and a solvent to obtain a polymer solution, coating the surface of a non-woven fabric with the polymer solution for forming, and washing to remove the solvent and the pore-foaming agent to obtain a blended polymer ultrafiltration membrane; S2, coating the surface of the blended polymer ultrafiltration membrane obtained in the step S1 with apolyamine solution to carry out a cross-linking reaction so as to form a nanofiltration separation layer; and S3, carrying out heat treatment on the ultrafiltration membrane obtained in the step S2 to obtain the product. Articles and uses thereof are also disclosed. The low-pressure polymer decoloration nanofiltration membrane is resistant to oxidation and small in thickness, the separation layerdoes not fall off in the using process, multivalent ions and colored soluble organic matters can be efficiently separated, and the hydrophilicity, pollution resistance and permeation flux of the membrane are good; besides, the preparation method of the nanofiltration membrane is simple in process, can be used for large-scale production, and has a good industrial application prospect.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

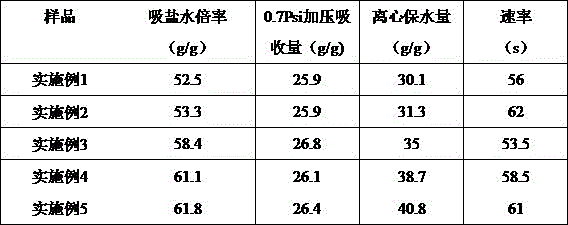

Preparation method of high-saline-absorbency high-water-absorptivity resin

The invention provides a preparation method of a high-saline-absorbency high-water-absorptivity resin, relating to the technical field of high-polymer material production. According to the method, high-purity acrylic acid is used as a monomer, N,N-methylene bis acrylamide is used as a crosslinking agent, and inorganic nanosheets are added in the preparation process; the nano sheets are introduced into the high-water-absorptivity resin, and the inorganic nanosheet surface has negative charges and large specific area, and thus, can adsorb and shield ions in the saline; and meanwhile, the nano sheets can be utilized to generate strong interactions with the adsorbed water, thereby enhancing the saline absorbency and water absorption retention rate of the high-water-absorptivity resin.

Owner:YANGZHOU UNIV

A kind of preparation method of functional polymer material

ActiveCN106283275BIncrease profitImprove efficacyMelt spinning methodsCellulose/protein filament chemical after-treatmentFiberCold air

Owner:WUYI UNIV +1

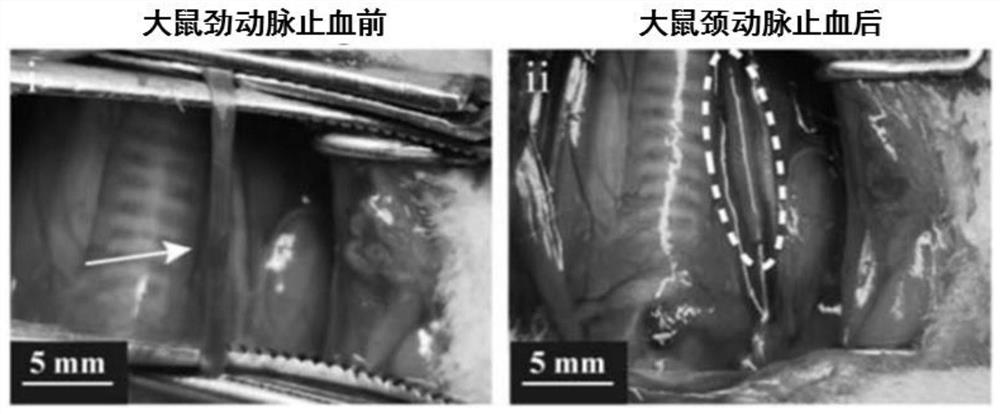

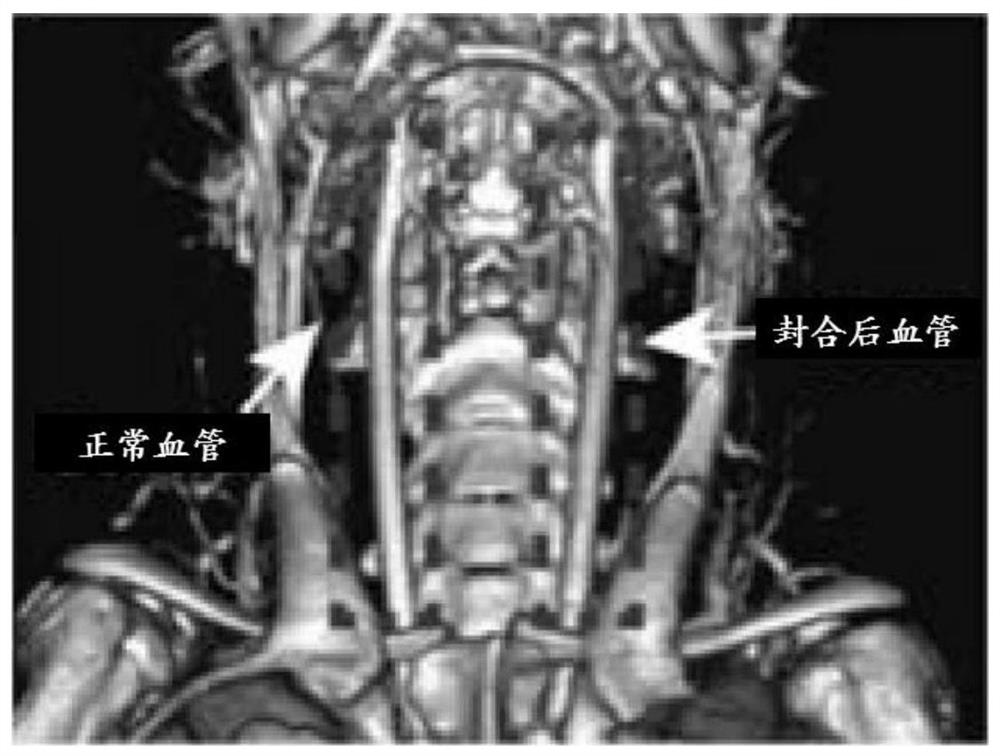

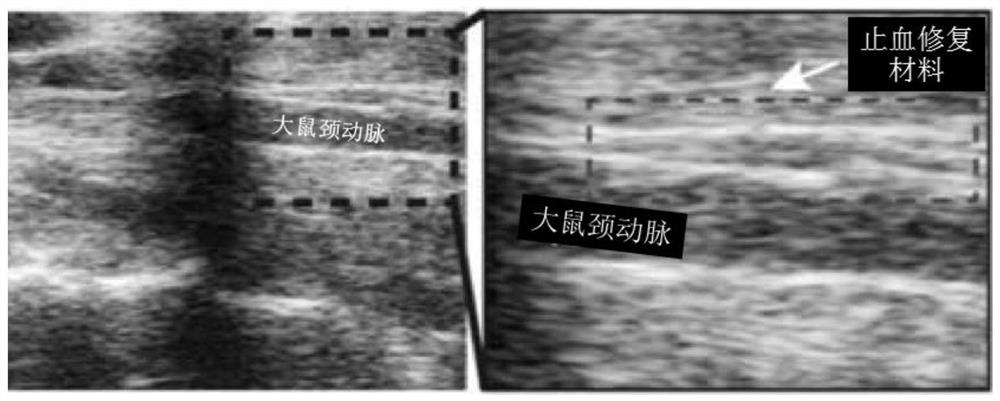

Hydrophobic polymer hemostatic repair material and preparation method and application thereof

ActiveCN113599566AShort curing timeStrong adhesionSurgical adhesivesPharmaceutical delivery mechanismTissue AdhesionBiomedical engineering

The invention relates to a hydrophobic polymer hemostatic repair material and a preparation method and application thereof. The repair material can be rapidly adhered to a moist tissue interface and comprises a component A and a component B. The component A comprises a catalytic unit and a tissue cross-linking agent, and the component B comprises flowable hydrophobic macromolecules and a coupling unit; and the catalytic unit and the coupling unit form a forming agent. According to the hydrophobic polymer hemostatic repair material disclosed by the invention, rapid adhesion to the moist tissue interface is realized by virtue of strong drainage capacity of hydrophobic macromolecules, rapid underwater gelling capacity of the forming agent and cross-linking reaction of the tissue cross-linking agent to the tissue interface. The hydrophobic polymer hemostatic repair material provided by the invention has the advantages of good tissue adhesion, strong plasticity and good biocompatibility, can effectively promote the repair and healing of wounds and wounds, and has good clinical application prospects in the aspects of hemostasis and repair of tissues and organs such as blood vessels, skin, heart, lung, bone and the like.

Owner:重庆市沙坪坝区中智医谷研究院

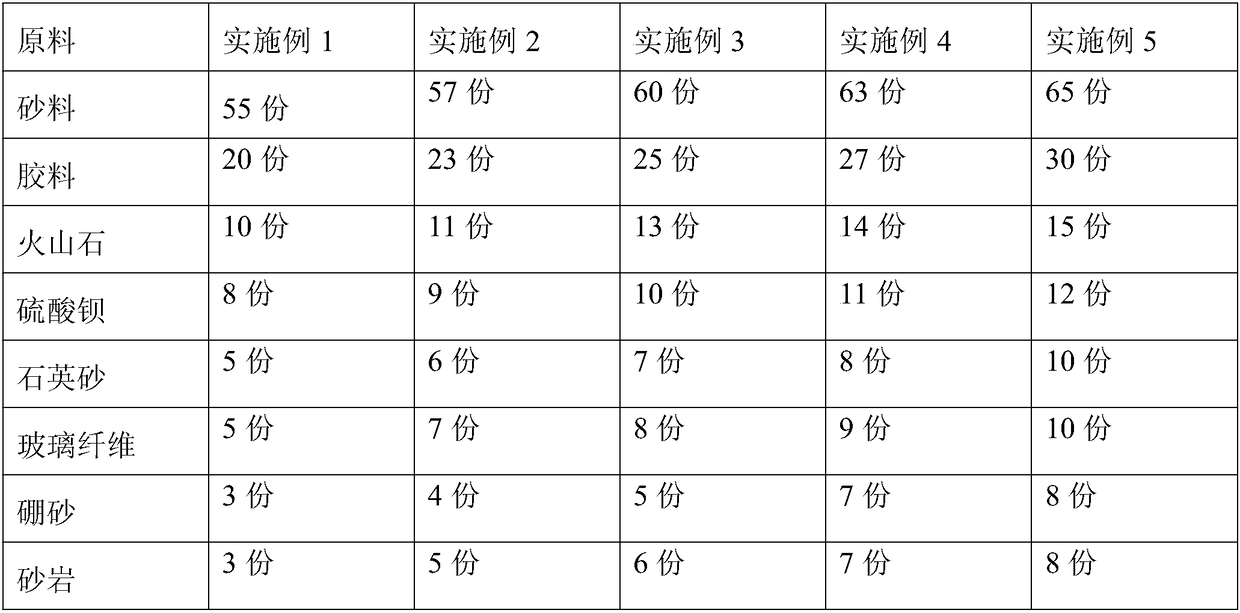

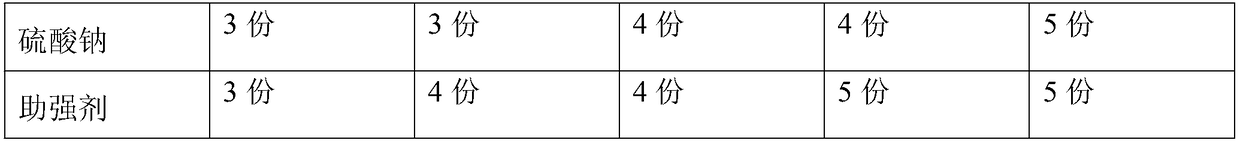

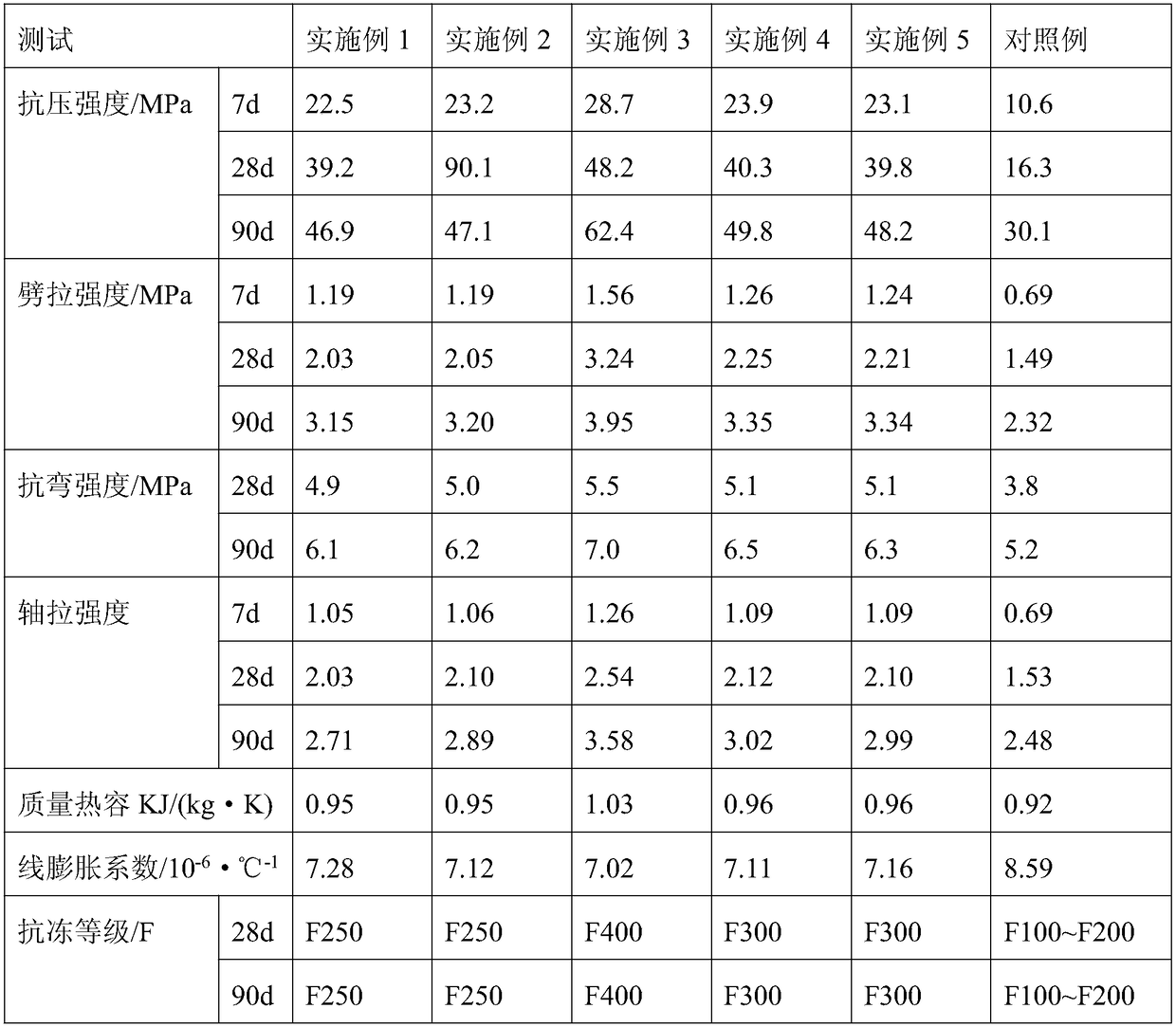

Dry reinforced concrete and preparation method thereof

The invention provides dry reinforced concrete. The concrete is prepared from, by weight, 55-65 parts of sand, 20-30 parts of rubber material, 10-15 parts of pelelith, 8-12 parts of barium sulfate, 5-10 parts of quartz sand, 5-10 parts of glass fibers, 3-8 parts of borax, 3-8 parts of sandstone, 3-5 parts of sodium sulfate and 3-5 parts of reinforcing agent. The rubber material is a mixture of cement powder, magnesia clay and rubber powder, wherein the weight ratio of the cement powder to the magnesia clay to the rubber powder is (5-8):(3-5):(1-3); the reinforcing agent is a mixture of siliconoxide, allophane and dry reinforcing agent, wherein the weight ratio of silicon oxide, allophane and the dry reinforcing agent is (7-13):(7-10):(3-10). The dry reinforced concrete obtained by adopting the raw materials and a method is high in strength, good in heat resistance and high in frost resistance.

Owner:南京御森建筑科技发展有限公司

Preparation method of high-strength open-hole SiOC ceramic material

The invention relates to a preparation method of a high-strength open-hole SiOC ceramic material. The preparation method comprises the following steps: taking an organic silicon polymer as a precursorto prepare a blank by molding through a reaction induced phase separation method, then carrying out cracking at an inert atmosphere to obtain the porous SiOC ceramic material, wherein the mass ratioof the organic silicon polymer to a reaction phase separating agent is 1:(0.2-5), the mass ratio of the organic silicon polymer to a catalyst is 1:(0.0001-0.1), and the mass of the addition amount ofa solvent accounts for 0-30% of the total mass of the organic silicon polymer and the reaction phase separating agent. The ceramic material provided by the invention has the characteristics of simpleprocess, low cost, high opening rate of the prepared material, good air permeability, high mechanical strength, thermal shock resistance and the like, can be widely used as a high-temperature filter material, and can also be used as a carrier material and high-temperature heat-insulation material for chemical reactions.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

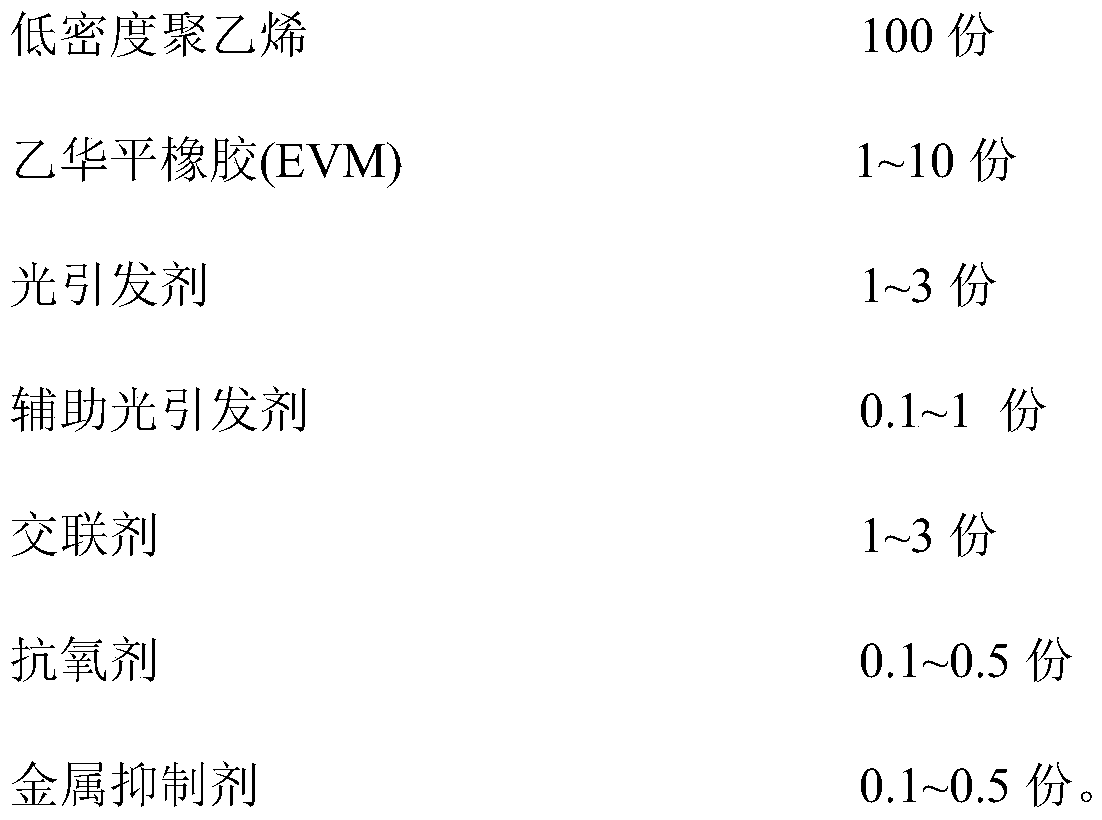

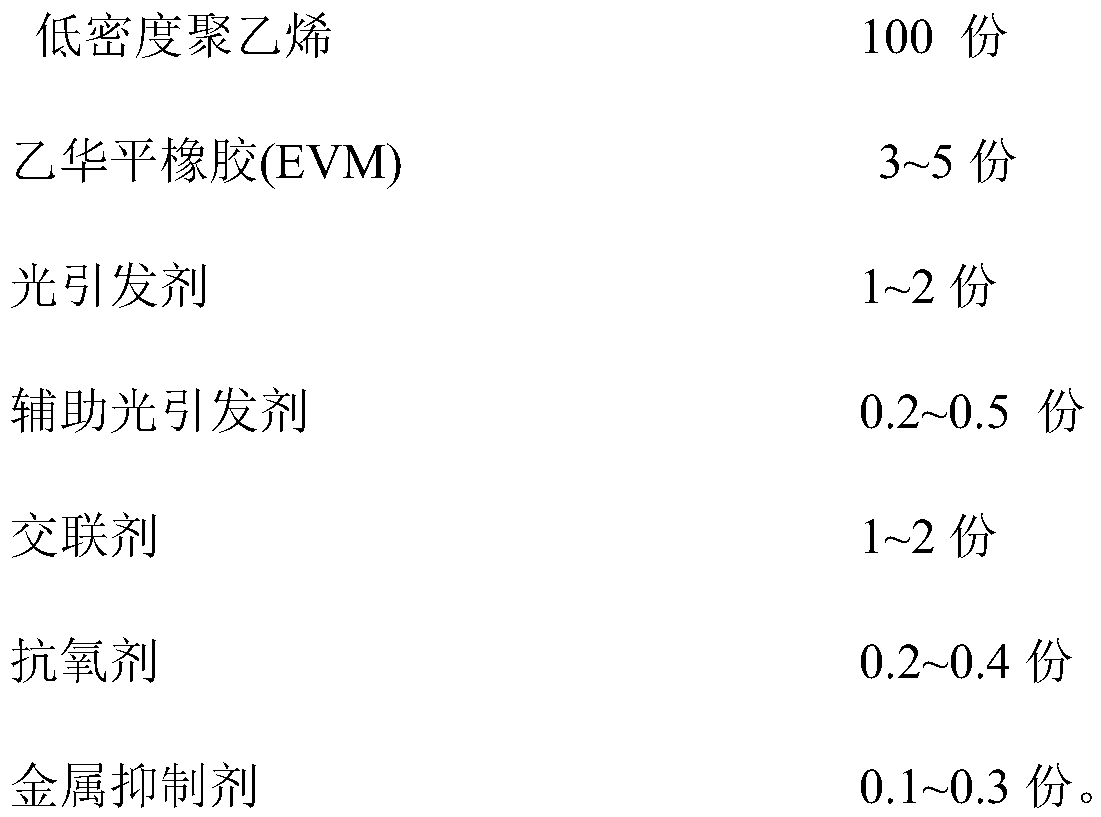

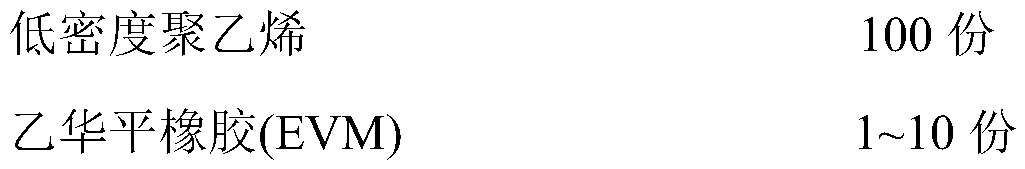

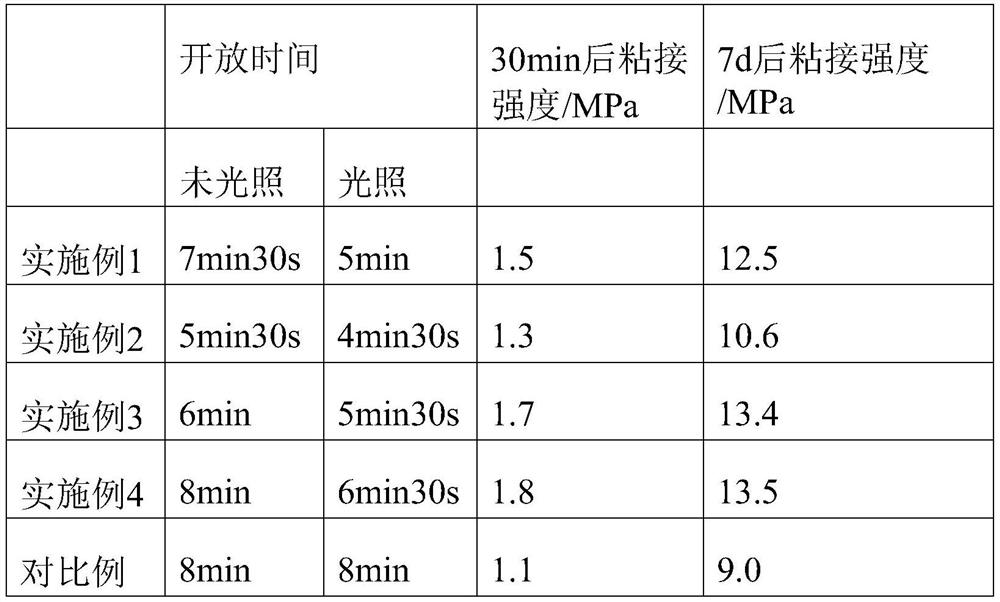

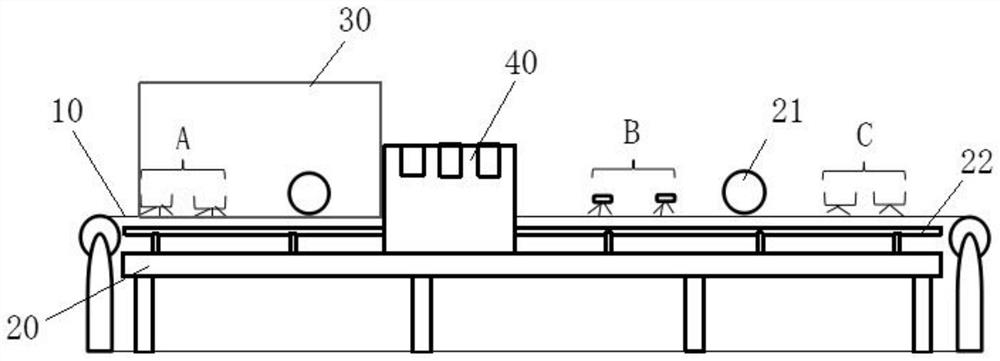

Low-odor fast UV-LED ultraviolet cross-linked polyethylene insulation material and preparation method thereof

The present invention provides a low-odor fast UV-LED ultraviolet cross-linked polyethylene insulation material, comprising following components shown in the specification by weight. The cross-linkedpolyethylene insulation material crosslinked by UV-LED ultraviolet radiation of a system of a novel photoinitiator and blended resin is provided. The material has characteristics of no flammable and explosive additives, low odor, low smoke, fast cross-linking, and the like, and is used for the insulation of low-voltage power cables and photoelectric composite cables.

Owner:上海新上化高分子材料有限公司

Light-moisture dual-curing polyurethane hot melt adhesive

PendingCN113717678AImprove initial tackTo avoidNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to a light-moisture dual-curing polyurethane hot melt adhesive comprising the components in parts by mass: 30 to 80 parts of a polyol polymer, 20 to 40 parts of a polyisocyanate compound, 0.5 to 10 parts of a photobase generator, 5 to 30 parts of thermoplastic resin, 3 to 12 parts of tackifying resin, 0.1 to 5 parts of a photosensitizer and 0.01 to 3 parts of a catalyst. The photobase generator capable of generating primary amine by illumination is introduced into a polyurethane system, a primary amine group generated by illumination quickly reacts with an isocyanate group, carbon dioxide gas is not generated, bubbles are avoided, and meanwhile, due to the delayed reaction characteristic of anions, the opening time has a certain adjustable space, the hot melt adhesive can be used for bonding non-light-transmitting materials; and due to the relatively fast cross-linking reaction, fast fixing can be achieved, and the initial adhesion of polyurethane is improved.

Owner:YANTAI DARBOND TECH

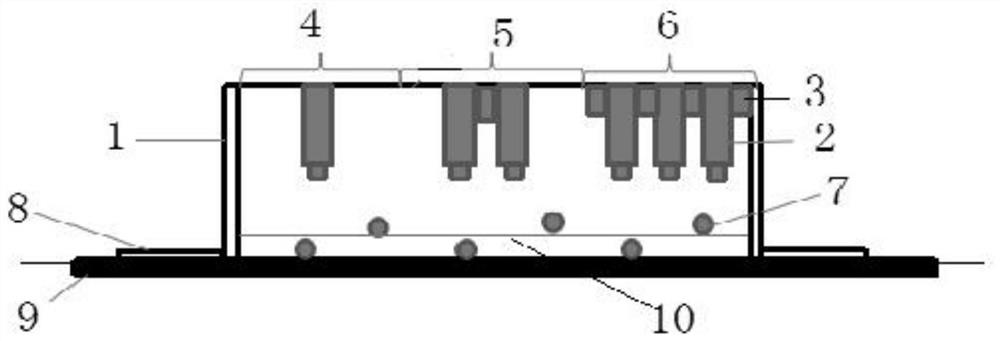

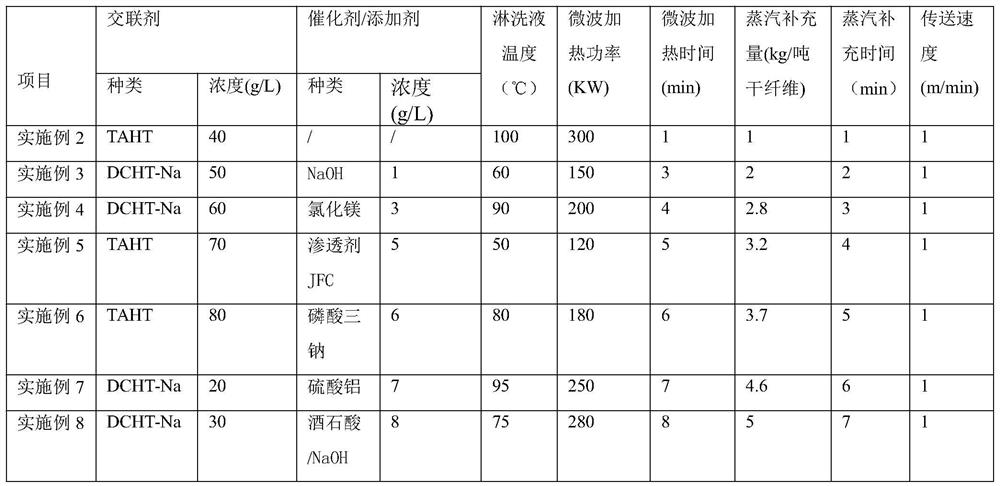

Rapid cross-linking method of cellulosic fiber and preparation method of antigen fibrillated cellulosic fiber

PendingCN112281483AStable and controllable temperatureStable temperature controlRadio/micro wave fibre treatmentVegetal fibresPolymer scienceCellulose fiber

The invention belongs to the field of cellulosic fiber, and particularly discloses a rapid cross-linking method of cellulosic fiber. The rapid crosslinking method comprises the following steps: sending the cellulosic fiber treated by a cross-linking agent into a microwave heating device for microwave heating, and supplementing steam in the microwave heating process. And in the microwave heating process, supplement of steam starts when the fiber temperature is more than or equal to 60 DEG C. According to the method, the fiber can be rapidly heated on a cellulose fiber production line to initiate a cross-linking reaction to prepare the functional cellulose fiber, the method is particularly suitable for achieving a Lyocell short fiber rapid cross-linking reaction on a Lyocell fiber productionline, the fibrillation tendency of Lyocell fiber is reduced, and compared with heating through pure steam and heating through pure microwave, the method is higher in temperature rising speed, carriesout the rapid cross-linking reaction in the heating process, and is better in heating uniformity, lower in energy consumption.

Owner:CHINESE TEXTILE ACAD

Preparation method of monocomponent polyurethane flocking adhesive

ActiveCN102516919BImprove wear resistanceImprove water resistancePolyureas/polyurethane adhesivesMacromolecular adhesive additivesEpoxyPolyester

The invention discloses a preparation method of a monocomponent polyurethane flocking adhesive. The preparation method comprises the following sequential steps of: a. reacting isocyanate or isocyanate mixture A, mixture B of polyester polyol and polyether polyol containing at least two hydroxy groups, epoxy resin C, organic tin and organic amine catalysts D and a solvent E at the temperature of 60-120 DEG C for 1-6 hours to obtain polyurethane prepolymer; b. cooling to 40-60 DEG C, adding an isocyanate sealant F, and reacting for 1-4 hours; and c. controlling the temperature at 20-40 DEG C, and adding a low-molecular-weight chain extender G and an adhesion accelerant H. The polyurethane sol prepared by the method has the advantages of good adhesion to a rubber base material, excellent wear resistance and water resistance, and good opened standing performance and rapid curing performance.

Owner:云南三恩汽车新材料有限公司

Novel bi-component dealcoholization type silicon rubber sealant and preparation method thereof

ActiveCN102408722BSolve the shortcomings of large temperature and humidity dependenceReduce sensitivityNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

Novel bi-component dealcoholization type silicon rubber sealant and preparation method thereof, wherein component A itself is single-component dealcoholization type silicon rubber and can offer a final strength value equal to the mixture of component A and component B, and has a good storage stability. The component B contains water, wherein the water can be directly added in free-state way and carried on the filler material; the component B also contains reactive polymer which can be activated by contacting with the catalyst of the component A, and perform quick cross-linking reaction with the cross-linking agent in the component A at the same time, the advantages of the invention are as follows: on one hand, the invention solves the shortcoming that the single-component silicon rubber has bigger reliance on the temperature and humidity of the environment; on the other hand, the invention accelerates the curing and reduces sensibility of the bi-component system to the mix error and measurement error at the same time. The ratios of the component A and component B in the bi-component system can vary in a large range without producing adverse effect to the final strength.

Owner:TONSAN ADHESIVES INC

Resin composition, pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, pressure-sensitive adhesive sheet, and surface protective film

ActiveCN103570914ALong application periodFast cross-linking reactionPolyureas/polyurethane adhesivesThin material handlingCross-linkPolyol

Provided is a resin composition that can serve as a pressure-sensitive adhesive composition that is a material for forming a pressure-sensitive adhesive layer containing a polyurethane-based resin, the resin composition having a sufficiently long pot life in a stage where the resin composition is stored as it is, while allowing a cross-linking reaction between a polyol and a polyfunctional isocyanate compound to rapidly progress upon formation of a pressure-sensitive adhesive layer through the use of a pressure-sensitive adhesive composition containing the resin composition. Also provided is a pressure-sensitive adhesive composition formed of such resin composition. Also provided is a pressure-sensitive adhesive layer formed through the use of such pressure-sensitive adhesive composition. Also provided are a pressure-sensitive adhesive sheet and a surface protective film each including such pressure-sensitive adhesive layer. The resin composition includes: a polyol (A) having at least two OH groups; a polyfunctional isocyanate compound (B); a catalyst (C); and a compound (D) that undergoes keto-enol tautomerization, in which: a content ratio of the polyfunctional isocyanate compound (B) with respect to 100 parts by weight of the polyol (A) is 1 part by weight to 100 parts by weight; and the catalyst (C) includes an iron-based compound containing iron as an active center thereof.

Owner:NITTO DENKO CORP

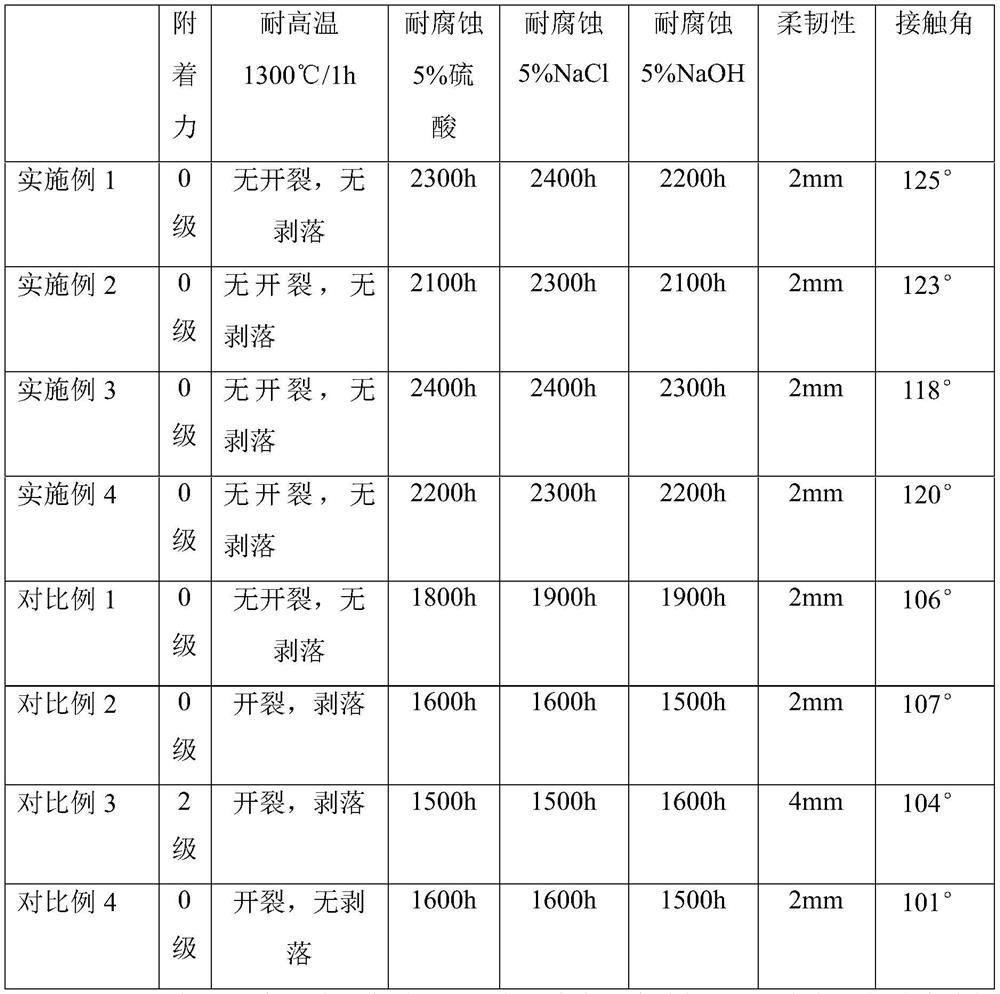

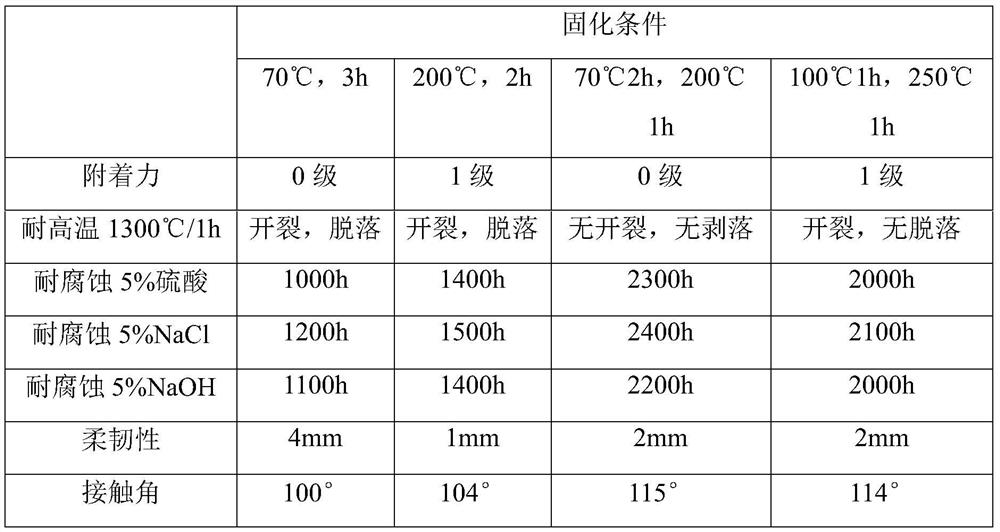

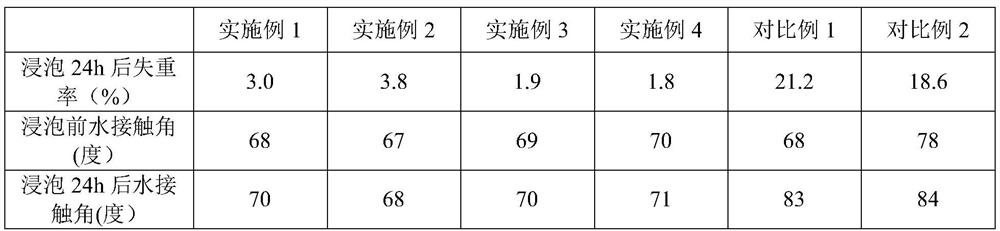

Anti-corrosion and anti-sticking coating for fire grate segment of garbage incinerator as well as preparation method and application of anti-corrosion and anti-sticking coating

ActiveCN114644843ASimple construction methodDry fastFireproof paintsPretreated surfacesDoped grapheneNanoceramic

The invention relates to an anti-corrosion and anti-sticking coating for a fire grate segment of a garbage incinerator as well as a preparation method and application of the anti-corrosion and anti-sticking coating. The paint of the anti-corrosion and anti-sticking coating is prepared from the following components: 40 to 60 parts of metal oxide sol, 2 to 4 parts of fluorine-doped graphene, 8 to 12 parts of nano ceramic powder, 6 to 8 parts of anti-corrosion filler, 3 to 6 parts of compatilizer, 1 to 3 parts of silane coupling agent, 4 to 7 parts of auxiliary agent and 40 to 60 parts of solvent, and the sum of all the components is 100 parts.

Owner:深圳优易材料科技有限公司

Microporous membrane containing cross-linked hydrophilic polymer and preparation method thereof

PendingCN114588786AImprove water resistanceGood solvent resistanceMembranesGeneral water supply conservationNon solventPolymer science

The invention relates to the field of microporous separation membranes, and discloses a microporous membrane containing a cross-linked hydrophilic polymer and a preparation method of the microporous membrane, raw materials comprise a microporous membrane main body material and the cross-linked hydrophilic polymer, and the cross-linked hydrophilic polymer is cross-linked polyvinyl acetal; the preparation method comprises the following steps: (1) preparing a membrane preparation solution: adding a microporous membrane main body material, polyvinyl acetal and a non-solvent for membrane preparation into a solvent, and dissolving to obtain the membrane preparation solution; (2) preparing a membrane: preparing the obtained membrane preparation solution into a polymer microporous membrane through a phase inversion process; and (3) cross-linking: soaking the polymer microporous membrane in an aqueous solution of a cross-linking agent, and treating to obtain the microporous membrane containing the cross-linked hydrophilic polymer. The polyvinyl acetal polymer is blended in the polymer membrane material body, and hydroxyl in polyvinyl acetal molecules is crosslinked, so that the hydrophilic stability of the membrane material can be ensured.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD

Environment-friendly built-in sealant and preparation method thereof

InactiveCN110317568AFast preparationWith tensile strengthNon-macromolecular adhesive additivesPolymer scienceVinyltriethoxysilane

The invention discloses an environment-friendly built-in sealant which is prepared from hydroxyl-terminated polydimethylsiloxane, hydrophobic silicon dioxide, vinyltriethoxysilane, butyl titanate, organic bismuth and the like. The invention also relates to a preparation method of the environment-friendly built-in sealant. According to the preparation method of the environment-friendly built-in sealant, the components are put into a reaction kettle in sequence and are fully stirred under the corresponding conditions. According to the method, the cured dealcoholized silicone sealant can be quickly prepared by adding the vinyltriethoxysilane and has a certain tensile strength in a short time, so that the decoration working efficiency and the quality guarantee can be effectively improved in the indoor decoration industry; by creatively adding butyl titanate and a supplemented organic ruthenium catalyst, the butyl titanate serves as a tackifier for improving polymer adhesion, not only provided rapid cross-linking reaction can be, but also the adhesion of a polymer system is improved, and the curing efficiency and the initial tensile strength in a short time can be further improved.

Owner:江苏华硅新材料科技有限公司

Antifouling light fireproof door

InactiveCN107603024AImprove high temperature resistanceImprove adhesionAntifouling/underwater paintsFireproof doorsSodium silicateDichloromethane

The invention relates to the technical field of researching and manufacturing of a fireproof door and discloses an antifouling light fireproof door. A fireproof door core veneer is the core part. Theantifouling light fireproof door is prepared from the following components in parts by weight: 40-45 parts of perlite, 20-25 parts of silicon carbide, 15-20 parts of kieselguhr, 14-16 parts of butyl titanate, 10-15 parts of glass enamel powder, 10-12 parts of polypropylene resin, 13-16 parts of dichloromethane, 5-8 parts of methyl acrylate, 4-6 parts of N-hydroxymethyl acrylamide, 2-4 parts of OPseries emulsifiers, 4-6 parts of copper iodide compound salt, 1-2 parts of sodium silicate and 25-30 parts of water. Compact silicon carbide powder is acquired in the manner of static sintering; on the basis of the characteristics of high melting point, high hardness, abrasion resistance, corrosion resistance and oxidation resistance of the silicon carbide powder, the silicon carbide powder is used as a filling material of the fireproof door; the fireproof door is capable of resisting against the high temperature of 1550 DEG C; the fireproof door has high mechanical, thermal and chemical stabilities, excellent properties and multiple safety.

Owner:阜南县民安人防工程设备有限公司

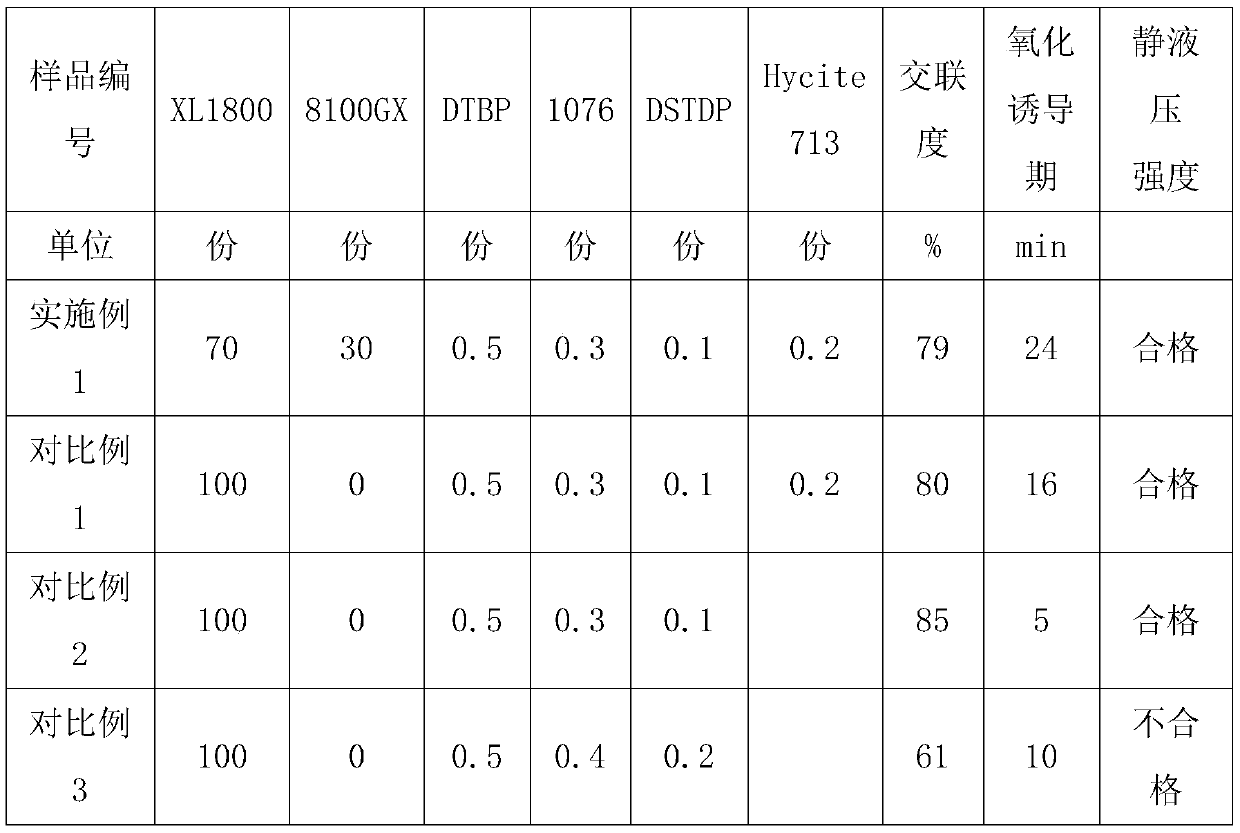

A kind of chlorine peroxide-resistant cross-linked polyethylene pipe and its preparation method

The invention discloses a chlorine-resistant peroxide crosslinked polyethylene tubular product and a preparation method thereof. By adding an acid remover, chlorine ions in water can be fully removed, so that a strong oxidation action on the plastic tubular product by chlorine ions in water is avoided, and the service life of the tubular product is prolonged; and by mixing two types of high density polyethylene resin, the two types of high polyethylene resin are complemented in performance and fully exert the excellent characteristics of the raw materials, so that the degree of crosslinking and the oxidation induction time of the tubular product can be taken into consideration at the same time. According to the preparation method, consumption of free radicals captured by an antioxidant is accelerated through high-temperature and high-speed production, so that the purposes of high degree of crosslinking and high chlorine-resistant performance are achieved. The peroxide crosslinked polyethylene tubular product disclosed by the invention can meet the demands on national standards GB / T 18992.2-2003 and Australian standards AS / NZS 2492:2007 at the same time, and has wide application prospects.

Owner:WUHAN KINGBULL ECONOMIC DEV

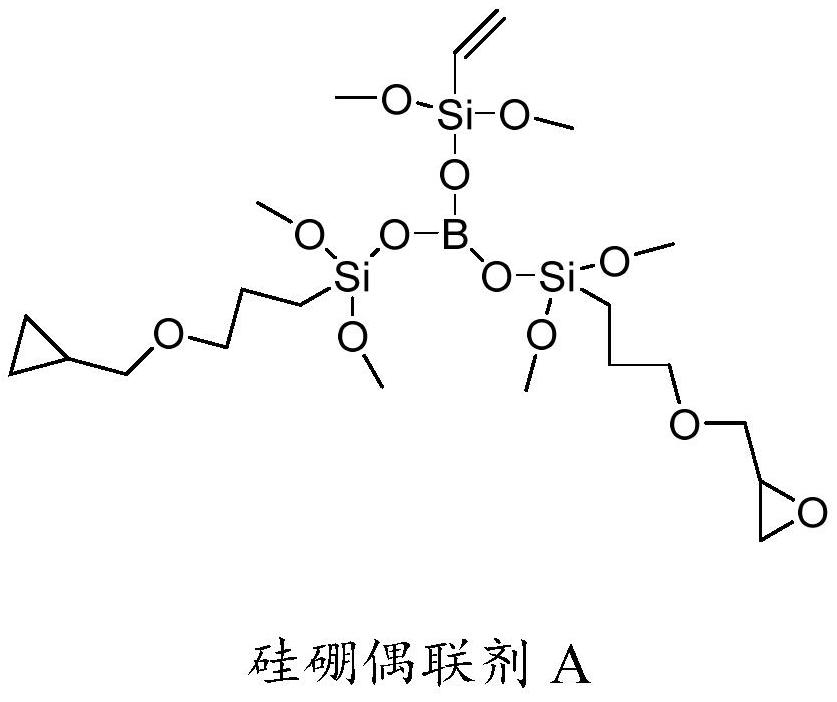

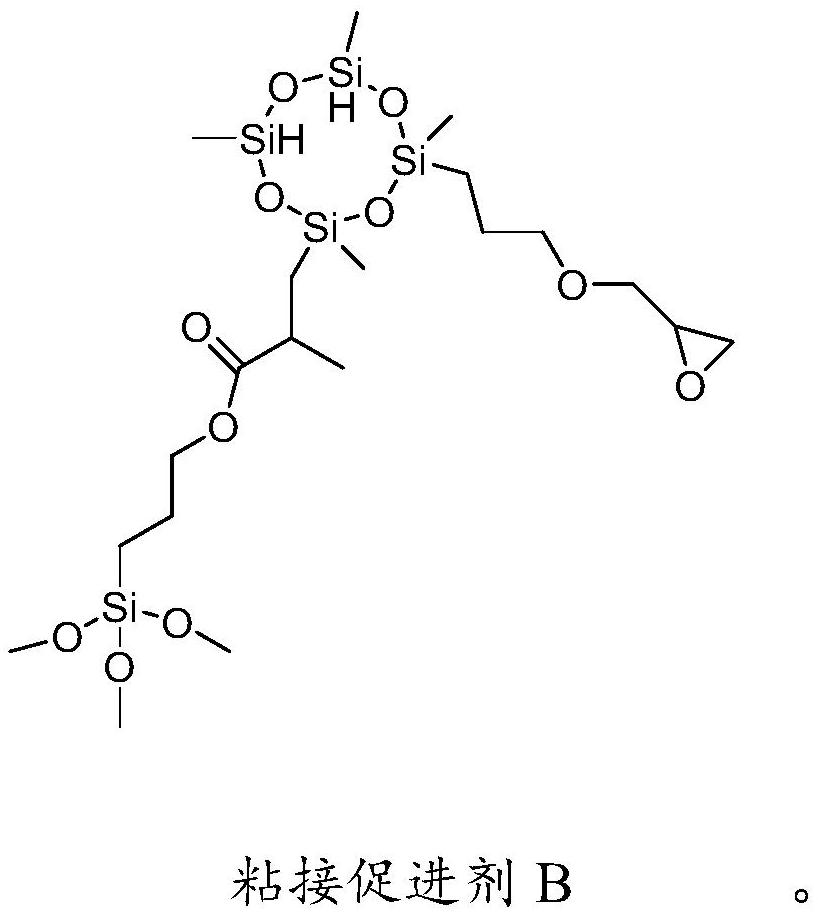

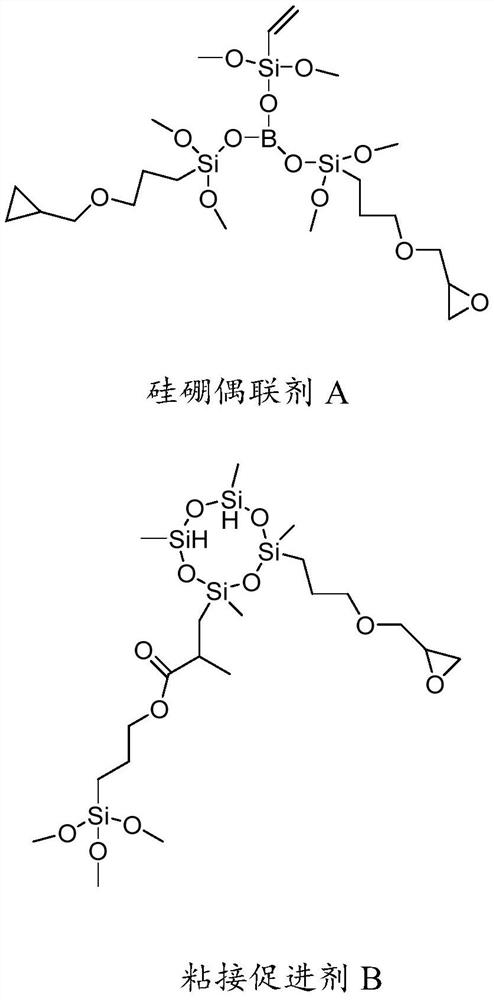

Organopolysiloxane composition with excellent adhesion and reliability and preparation method thereof

PendingCN114058326AImprove reinforcementHigh reactivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPhysicsComposite material

The invention aims to provide an organopolysiloxane composition with excellent adhesion and reliability and a preparation method thereof, in particular to an organopolysiloxane composition suitable for positioning and adhesion of a semiconductor chip heat dissipation cover plate and a preparation method of the organopolysiloxane composition. According to the invention, the branched hydrogen-containing polysiloxane is used as a cross-linking agent, so that the reaction activity is improved while reinforcement is realized; meanwhile, a self-made capsule type platinum catalyst is adopted, reaction is well inhibited at low temperature, rapid dissociation and release are achieved at high temperature, and rapid cross-linking reaction can be conducted; in addition, by means of an effective pre-reaction treatment mode of the adhesion promoter and organopolysiloxane containing Si-H bonds, excellent adhesion performance and adhesion reliability are provided. Moreover, an effective method for avoiding generation of H2 in the long-term storage process is provided, and the adhesion failure risk in the long-term use process is reduced.

Owner:YANTAI DARBOND TECH

A kind of preparation method of low pressure polymer decolorization nanofiltration membrane and its product and application

ActiveCN111437733BEasy to prepareDensity can be adjustedMembranesSemi-permeable membranesPolymer sciencePolymer solution

The invention discloses a preparation method of a low-pressure polymer decolorization nanofiltration membrane, which comprises the following steps: S1, taking a polymer, a copolymer, a porogen and a solvent, mixing it with a solvent to form a polymer solution, coating it on the surface of a nonwoven fabric, and forming a polymer solution. Washing to remove the solvent and porogen to obtain the blended polymer ultrafiltration membrane; S2, coating the surface of the blended polymer ultrafiltration membrane obtained in S1 with a polyamine solution for cross-linking reaction to form a nanofiltration separation layer; S3, applying S2 The obtained ultrafiltration membrane is obtained by heat treatment; the product and application thereof are also disclosed. The low-pressure polymer decolorization nanofiltration membrane of the present invention is resistant to oxidation, thin in thickness, does not fall off during use, and can efficiently separate multivalent ions and colored soluble organic substances. The membrane has good hydrophilicity, pollution resistance and permeation flux; In addition, the preparation method of the nanofiltration membrane has a simple process, can be produced in a large scale, and has good industrial application prospects.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

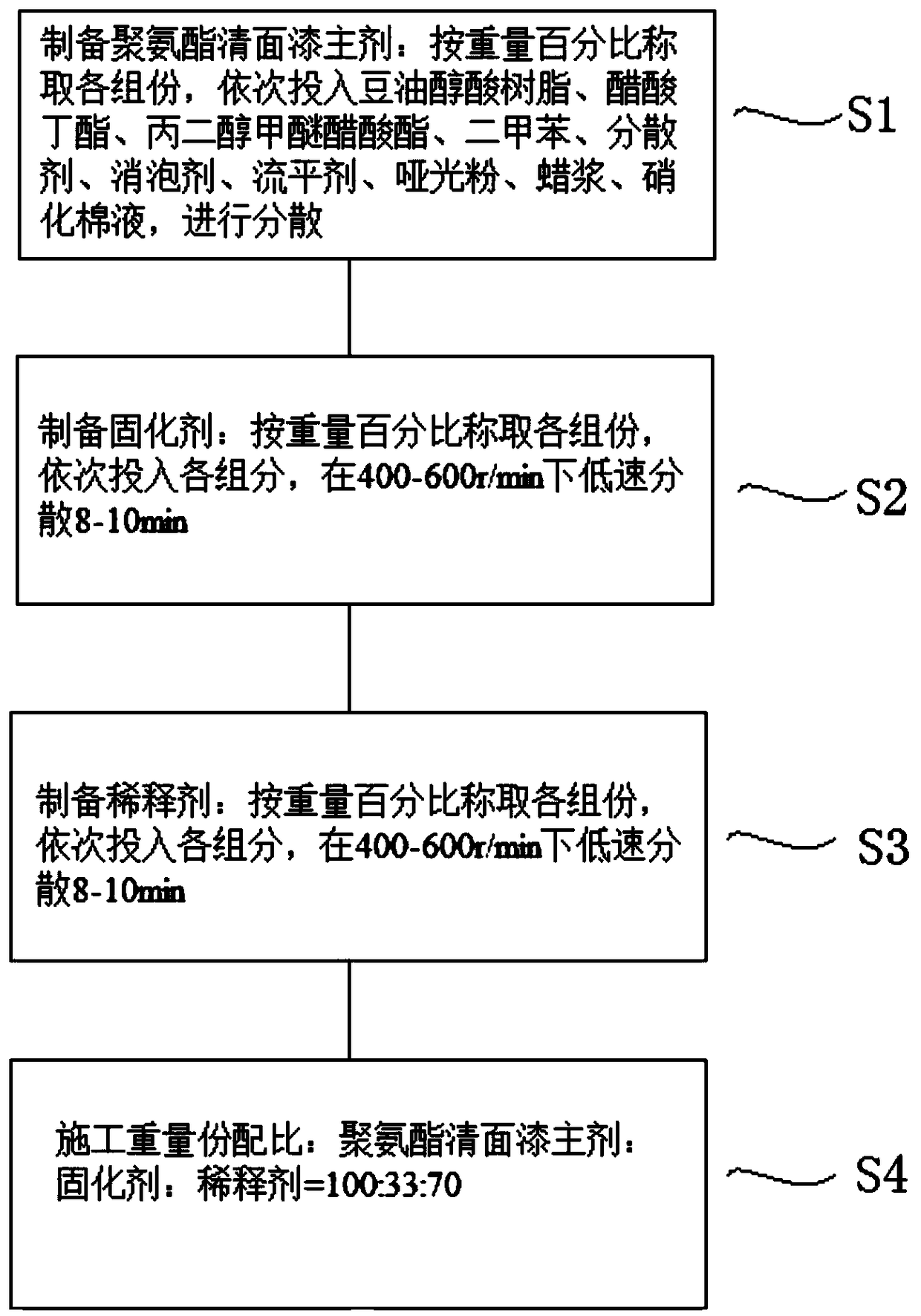

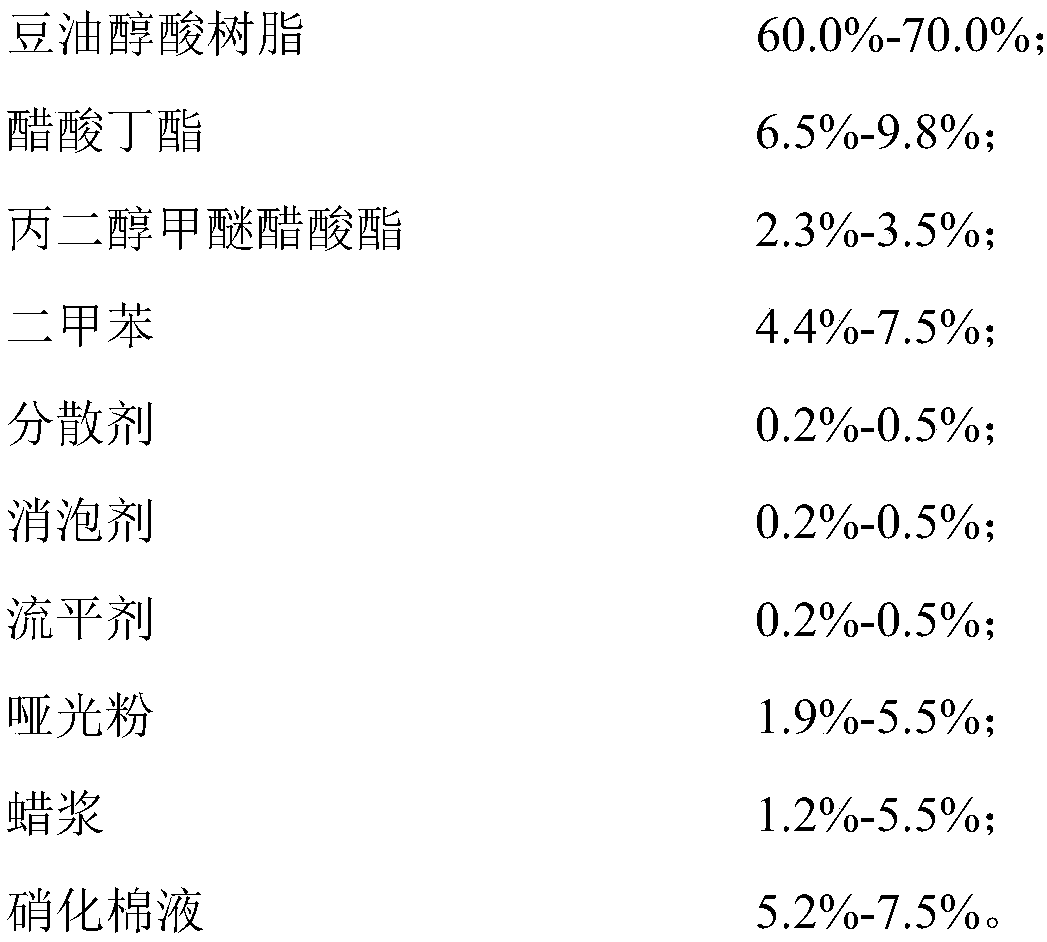

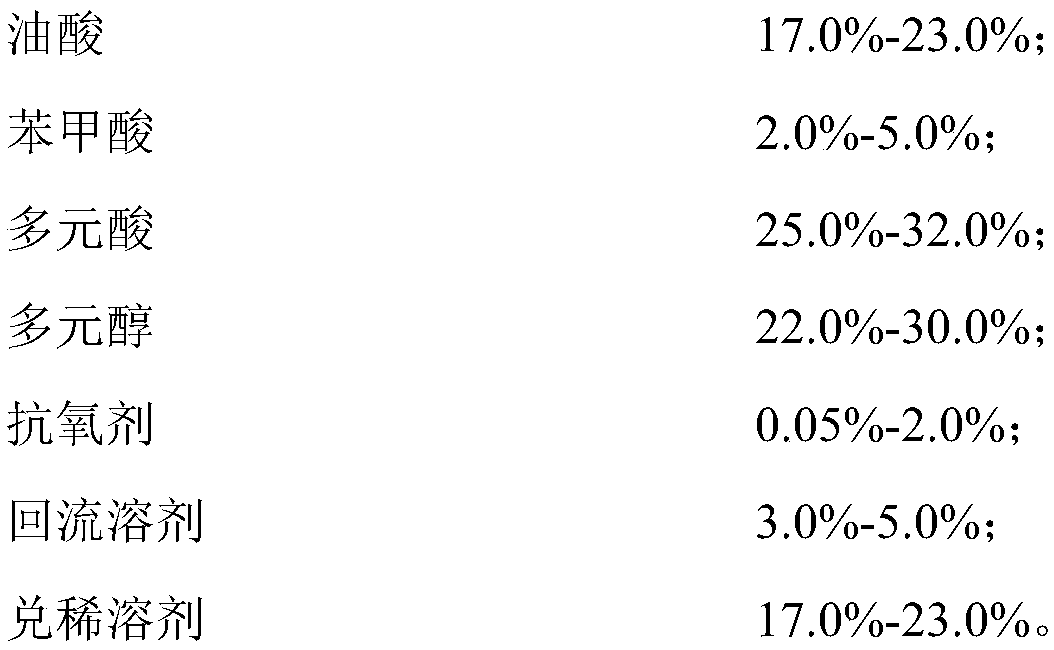

Matte top-varnish with low ratio and low VOC and preparation method of matte top-coat paint

InactiveCN108774457ALow VOC contentFast cross-linking reactionPolyurea/polyurethane coatingsWaxSlurry

The invention discloses matte top-varnish with a low ratio and low VOC. The matte top-varnish is prepared from a polyurethane top-varnish main agent, a curing agent and a diluting agent according to aconstruction weight ratio of 100:33:70, wherein the polyurethane top-varnish main agent is prepared from the following components in percentage by weight: 60.0 to 70.0 percent of soya oil alkyd resin, 6.5 to 9.8 percent of n-butyl acetate, 2.3 to 3.5 percent of propylene glycol methyl ether acetate, 4.4 to 7.5 percent of xylene, 0.2 to 0.5 percent of dispersing agent, 0.2 to 0.5 percent of defoaming agent, 0.2 to 0.5 percent of flatting agent, 1.9 to 5.5 percent of matte powder, 1.2 to 5.5 percent of wax slurry, and 5.2 to 7.5 percent of nitrocotton solution. The invention also discloses a preparation method of the matte top-varnish with the low ratio and low VOC. The product is used for coating the surface of woodware in a spraying manner, and has the characteristics of low ratio, low VOC, low odor, high pressure resistance, high transparency, high flexibility, good fullness, good flatting performance and good hand feeling and the like.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

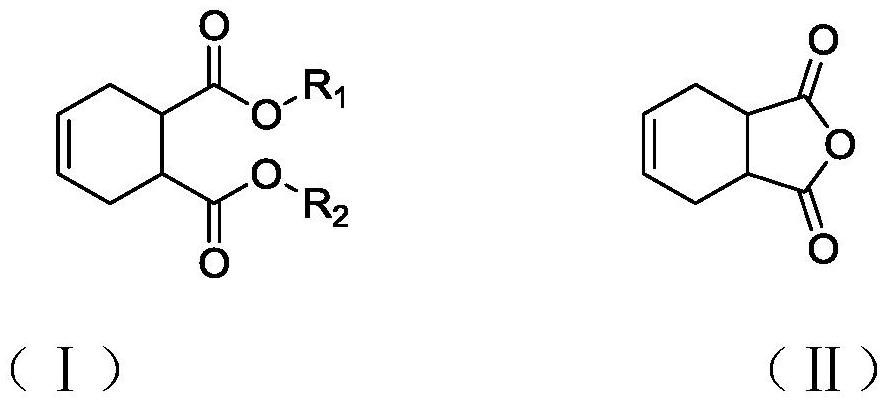

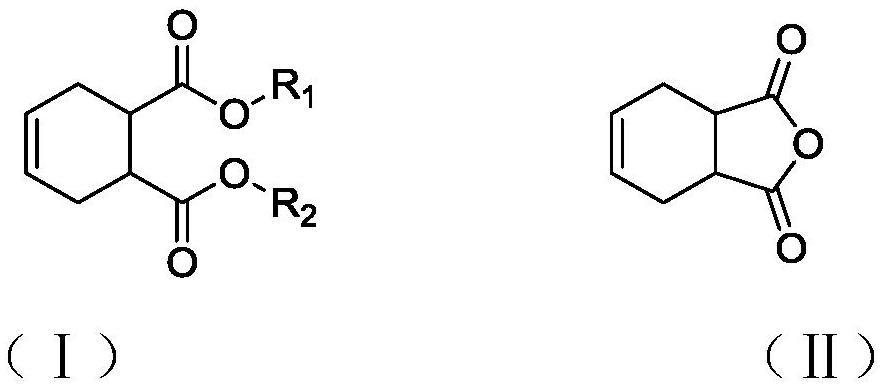

Polyester polyol for polyurethane hot melt adhesive as well as preparation method and application of polyester polyol

ActiveCN112745492ALow free spinImprove cohesionPolyureas/polyurethane adhesivesPhotovoltaic energy generationPolyesterPolymer science

The invention provides polyester polyol for a polyurethane hot melt adhesive as well as a preparation method and application of the polyester polyol. The polyol is prepared from the following three components: dicarboxylic acid or anhydride containing unsaturated bonds without polymerization reaction activity, dicarboxylic acid or anhydride containing unsaturated double bonds or triple bonds with polymerization reaction activity, and dihydric alcohol. The carboxylic acid monomer with a rigid cyclic structure is introduced into the raw materials, so that the initial adhesion strength of the hot melt adhesive can be remarkably improved, and the positioning time of the hot melt adhesive is shortened.

Owner:WANHUA CHEM GRP CO LTD

Heat insulated anticorrosive coating for coiled material

InactiveCN100497505CGood heat insulationReduce indoor temperatureAnti-corrosive paintsPolyester coatingsCross-linkHigh resistance

A paint for the coiled insulating and anticorrosion material is prepared from special polyester resin, high etherified cross-linking resin and pigment, functional insulating filler, special chemical assistant and solvent through proportional mixing, dispersing, grinding, adding insulating filler, etc. Its advantages are no poison and pollution, high flame-retarding and insulating effect, and high resistance to ageing and corrosion.

Owner:广东创想现代产业科技有限公司

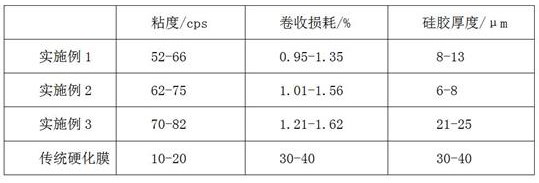

PET film production line mother roll single-layer direct winding and coating technology

PendingCN112756236AReduce labor costsFast cross-linking reactionPretreated surfacesCoatingsWinding machineProduction line

The invention relates to the technical field of protective films, in particular to a PET film production line mother roll single-layer direct winding and coating technology. The technology specifically comprises the following steps that a PET film is unwound through unwinding equipment, a PET film base material is evenly coated with silica gel coating liquid, and the PET film base material is put into a rotary press to be subjected to UV curing; and the cured PET film is wound through a four-roller winding machine. The PET film is coated with the silica gel, and the PET film coated with the silica gel coating liquid is put into the rotary press for UV curing, so that when the PET film is exposed to focused ultraviolet light, the catalyzed vinyl organic silicon resin coating can be quickly subjected to cross-linking reaction, and the generation speed is increased; winding is very stable and uniform through the four-wheel winding machine, no bubbles or wrinkles exist, products of long meters can be rolled, the production qualification rate is up to 98%, the production loss can be controlled within 2%, and the produced product has a silica gel single layer; and the appearance winding effect is good, the loss rate can be reduced, and the rewinding equipment and labor cost can be reduced.

Owner:揭西鑫昌顺电子科技有限公司

A nanofiber/mofs-based pervaporation membrane with alcohol-preferential permeation and its preparation method

The invention relates to and discloses a preparation method of a nanofiber / MOFs-based alcohol-preferential pervaporation membrane, and belongs to the technical field of membrane separation. Load MOFs on the nanofiber hydrogel film skeleton in situ to obtain a nanofiber / MOFs composite hydrogel film with uniformly dispersed MOFs particles, and then vacuum freeze-dry to obtain a nanofiber / MOFs hybrid airgel film; (3 ) Backfill the polymer matrix into the above gel membrane network and cross-link and solidify to obtain a nanofiber / MOFs-based pervaporation membrane with a high-loaded MOFs uniform distribution and alcohol-preferential pervaporation. For the first time, the strategy of pre-uniformly loading MOFs particles on the porous fiber gel skeleton as a "composite network filler" for pervaporation membranes, and then backfilling the polymer matrix and curing can effectively achieve high-load MOFs particles in the polymer matrix. The resulting mixed matrix membrane has excellent mechanical properties and efficient pervaporation performance, and has a good application prospect in the separation of ethanol / butanol and other bioalcohol mixed systems.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com